High density polyethylene pipe

A technology of high-density polyethylene and polyvinyl chloride, which is applied in the field of tubular materials containing high-density polyethylene, can solve the problems of low impact resistance, poor flame retardancy, and high static electricity, and achieve the effect of excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

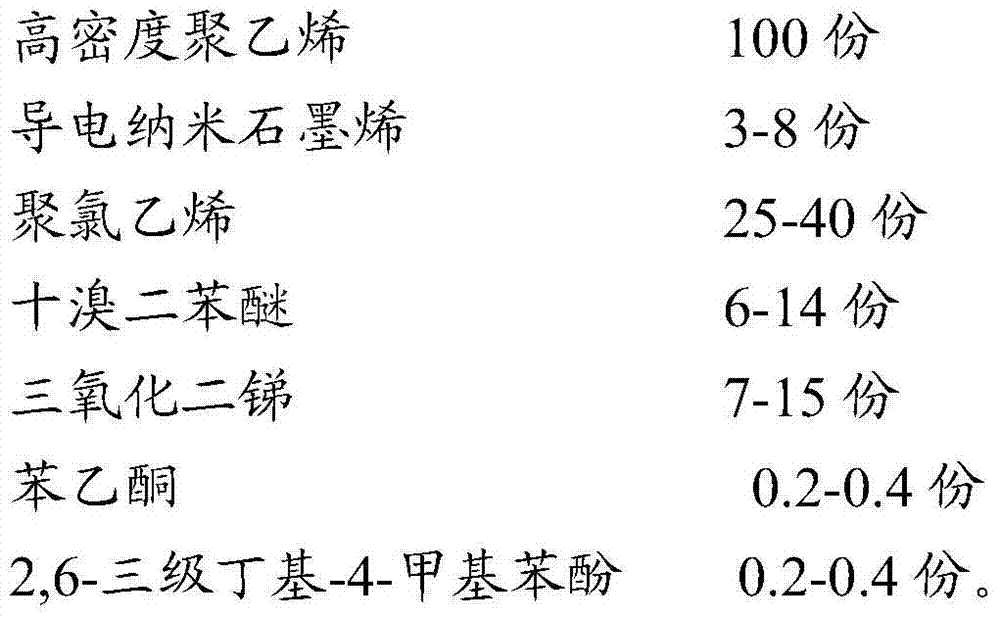

Method used

Image

Examples

Embodiment 1

[0013] 50 parts of high-density polyethylene, 6 parts of conductive nano-graphene, 25 parts of polyvinyl chloride, 5 parts of decabromodiphenyl ether, 5 parts of antimony trioxide, 0.5 parts of acetophenone, 2,6-tertiary butyl - 0.5 part of 4-methylphenol was put into a high mixer, and stirred at a temperature of 110° C. for 15 minutes. Put the mixed material into the extruder, the temperature of each section of the extruder screw is 150-200 ℃, the extruded material is pelletized, dried, and cooled to become an antistatic high toughness masterbatch.

[0014] Mix the masterbatch and the remaining portion of high-density polyethylene into the extruder. The length-to-diameter ratio of the extruder is 30. The temperature of each section of the extruder screw is 160-240°C. The mixture is heated at high temperature and the screw rotates. Fully mixed and extruded, the extruded material is shaped through a die, cooled, drawn, and cut to make a pipe that meets the requirements for use....

Embodiment 2

[0016] 50 parts of high-density polyethylene, 6 parts of conductive nano graphene, 28 parts of polyvinyl chloride, 18 parts of decabromodiphenyl ether, 10 parts of antimony trioxide, 2 parts of acetophenone, 2,6-tertiary butyl - Put 2 parts of 4-methylphenol into a high mixer, and stir for 15 minutes at a temperature of 110°C. Put the mixed material into the extruder, the temperature of each section of the extruder screw is 150-220 ℃, the extruded material is pelletized, dried, and cooled to become an antistatic high toughness masterbatch.

[0017] Mix the masterbatch and the remaining portion of high-density polyethylene into the extruder. The length-to-diameter ratio of the extruder is 30. The temperature of each section of the extruder screw is 160-200°C. The mixture is heated at high temperature and the screw rotates. Fully mixed and extruded, the extruded material is shaped through a die, cooled, drawn, and cut to make a pipe that meets the requirements for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com