Baseboard plywood of high-intensity composite container

A technology for container floor and plywood, applied in the field of plywood, can solve the problems of complex process, high cost, poor appearance quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

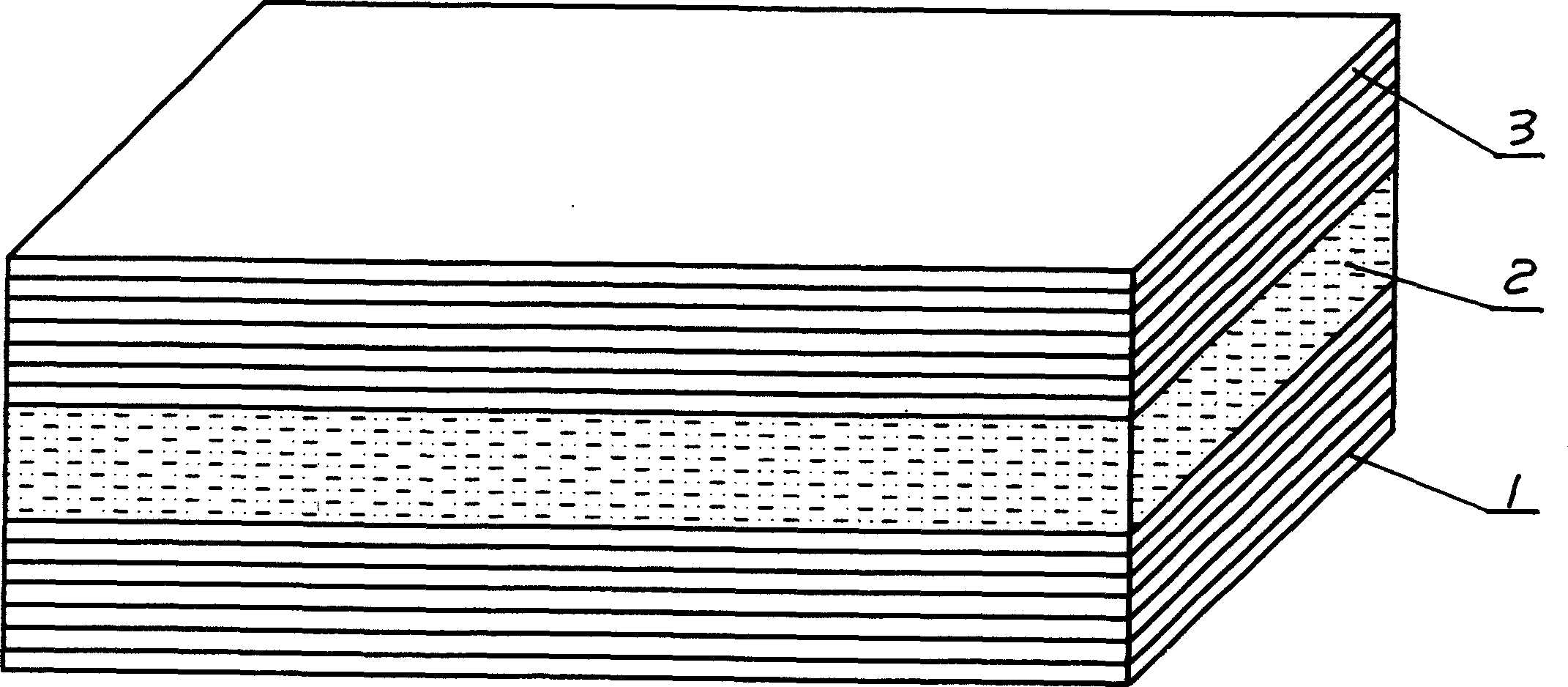

Embodiment 1

[0007] The upper and lower surface boards 1 and 3 are cologne wood, and the middle is medium density fiberboard 2 with a thickness of 8mm. There are 6 layers of veneer between the MDF and the upper and lower surface boards. The adjacent 2nd and 3rd layers of veneers are the long and medium boards, the 4th and 6th layers of veneers are the core boards, and the 5th and 7th layers of veneers are the long and medium boards. The configuration of the 6-layer veneer between the lower surface board and the MDF is symmetrical to the configuration of the veneer between the upper surface board and the MDF. Long medium board, the inner veneer whose wood grain direction is parallel to the wood grain direction of the surface board, core board, the inner layer veneer whose wood grain direction is perpendicular to the wood grain direction of the surface board. The long middle board and core board are made of domestic hardwood, the thickness of the upper and lower surface boards is 1.6mm, and ...

Embodiment 2

[0009] The veneer in the middle is particle board or oriented strand board, its thickness is 9mm, and there are 6 layers of veneer on each side, and the 2nd, 4th, and 6th veneer between the upper surface board and MDF are long medium boards , the 3rd and 5th veneers are core boards. The configuration of the 6-layer veneer between the lower surface board and the MDF is symmetrical to the configuration of the above-mentioned 6-layer veneer between the upper surface board and the MDF. Among them, the upper and lower surface boards are tropical broad-leaved hardwoods, and the other long middle boards and core boards are domestic hardwoods. The thickness of the upper and lower surfaces is 1.6mm, and the thickness of the long middle plate and core plate is 2mm. The above-mentioned veneers are formed by gluing and pressing, and the thickness is 28mm.

Embodiment 3

[0011] The thickness of the MDF in the middle is 7mm, and there are 8 layers of veneers on each side of it. The 2nd, 3rd, 5th, 7th, and 8th layers between the upper surface board and the MDF are long medium boards. The 6th layer is the core board. The arrangement of the 8-layer veneer between the lower surface plate and the MDF is symmetrical to the arrangement of the above-mentioned 8-layer veneer between the upper surface plate and the MDF. Among them, the upper and lower surface boards are tropical broad-leaved hardwoods, and the other long middle boards and core boards are domestic hardwoods. The thickness of the upper and lower surfaces is 1.6mm, and the thickness of the long middle plate and the core plate is 1.6mm. The above-mentioned veneers are formed by gluing and pressing, and the thickness is 28mm. The adhesive is a waterproof and anti-corrosion adhesive commonly used in container bottom plates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com