Method for prducing and connecting ventilation pipe

A technology of ventilation pipes and connection methods, applied in the field of building materials, can solve the problems of low field operation efficiency and high cost, and achieve the effects of eliminating metal fasteners, large bonding strength and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

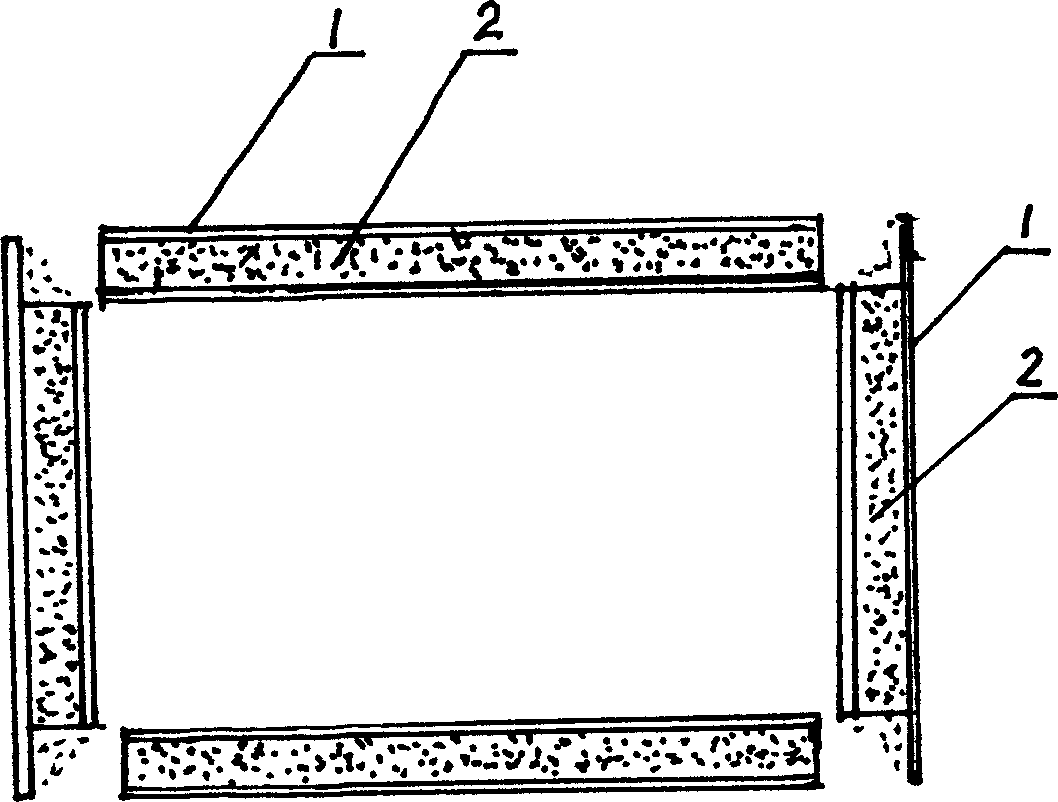

[0010] Assembling and making of ventilation ducts

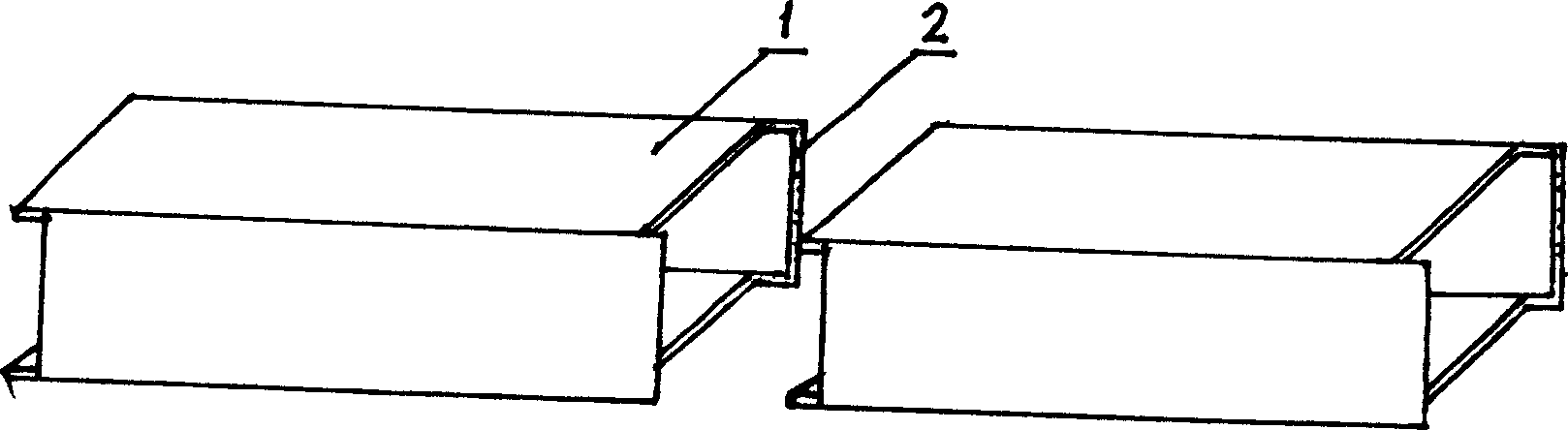

[0011] Cut the foam sandwich non-combustible panels according to the specifications and sizes of the ventilation ducts, respectively cut the upper and lower panels and the left and right panels of the ventilation ducts; It is designed as a right-angle stepped panel, and the assembled part of the other panel assembled with it is a right-angled flat mouth shape; then, apply adhesive on the assembled part of the two panels in the shape of a right-angled stepped panel, and assemble with it When the other two right-angle flat-shaped panels are bonded to them, the upper and lower panels and the left and right panels are misaligned to set the distance in the length direction (attached figure 2 ), assembled into ventilation ducts.

Embodiment 2

[0013] The connection of the assembled ventilation duct

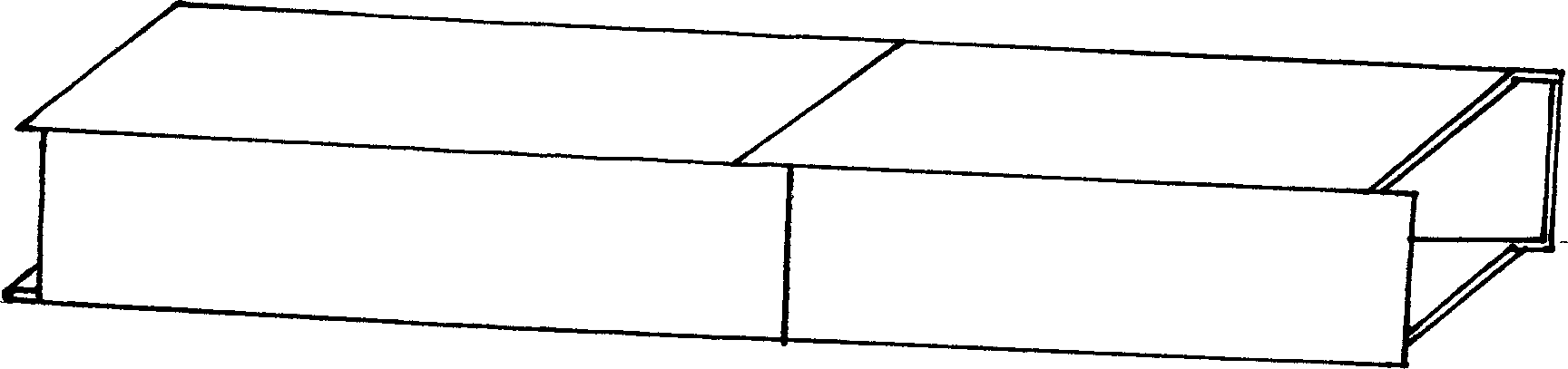

[0014] Apply adhesive to the misplaced joints of the assembled ventilation ducts (attached figure 2 ), insert the two connected ventilation pipes into the misplaced part, and then tighten them, so that the connection of the ventilation pipes is completed.

[0015] The connection process has the advantages of simple construction, high bonding strength, low cost, good sealing performance, no flange, and convenient installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com