Polymer/foam aluminum integrated composite sandwich board

A foamed aluminum plate and polymer technology, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of poor performance, low bonding strength, and easy corrosion, etc., to achieve superior energy absorption performance, Low yield strength, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

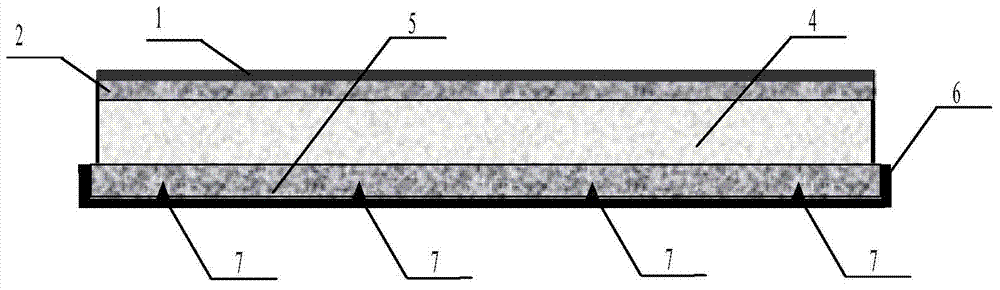

[0022] Prepare polyurethane / aluminum foam integrated composite sandwich panel, the design thickness of polyurethane surface layer is 2mm, and the design thickness of polyurethane / aluminum foam composite layer is 3mm:

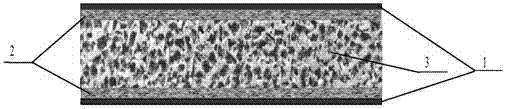

[0023] (1) Choose a spherical open-cell foam aluminum plate with a porosity of 85%, a through-porosity of 90%, and a pore size of 4mm. The plate size is (2000×1000×30) mm. Use low-concentration HCl acid solution to clean, then clean in low-concentration NaoH alkali solution, then rinse with clean water, dry and use silane coupling agent alcohol solution for treatment, and dry for use.

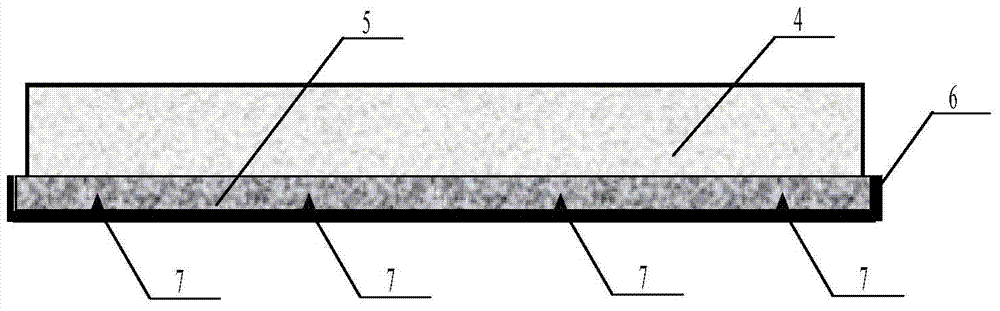

[0024] (2) if figure 2 As described above, a mold 6 with a height of 5 mm is prepared, and the bottom of the mold is provided with 8 thimbles for controlling the thickness of the pure polymer layer, and the height of the thimbles is 2 mm. After mixing the two raw materials of polyurethane, white material polyether triol N303 and black material toluene diisocyanate PM200 1:1, st...

Embodiment 2

[0027] Prepare epoxy resin / foam aluminum integrated composite sandwich panel, the design thickness of epoxy resin surface layer is 3mm, and the design thickness of epoxy resin / foam aluminum composite layer is 2mm:

[0028] (1) Choose a mesh-shaped open-cell foam aluminum plate with a porosity of 80%, a through-porosity of 90%, and a pore size of 3mm. The plate size is (2000×1000×30) mm. Use low-concentration HCl acid solution to clean, then clean in low-concentration NaoH lye, rinse with clean water, dry and use silane coupling agent alcohol solution for treatment, and dry for use.

[0029] (2) Prepare a mold with a height of 5mm, and set 8 thimbles at the bottom of the mold to control the thickness of the pure polymer surface layer, and the height of the thimbles is 3mm. The type of epoxy resin is selected as (E-44), and the curing agent is polyamide active curing agent (650#). Heat it in a water bath at 80°C until it is clear and free of bubbles. Mix the epoxy resin and curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com