Fibre reinforcement pyramid shape dot matrix sandwich board and preparation thereof

A pyramid-shaped, fiber-reinforced technology, applied in the direction of layered products, can solve the problems of difficulty in forming lattice sandwich panels, and achieve the effects of less product defects, strong designability, and high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

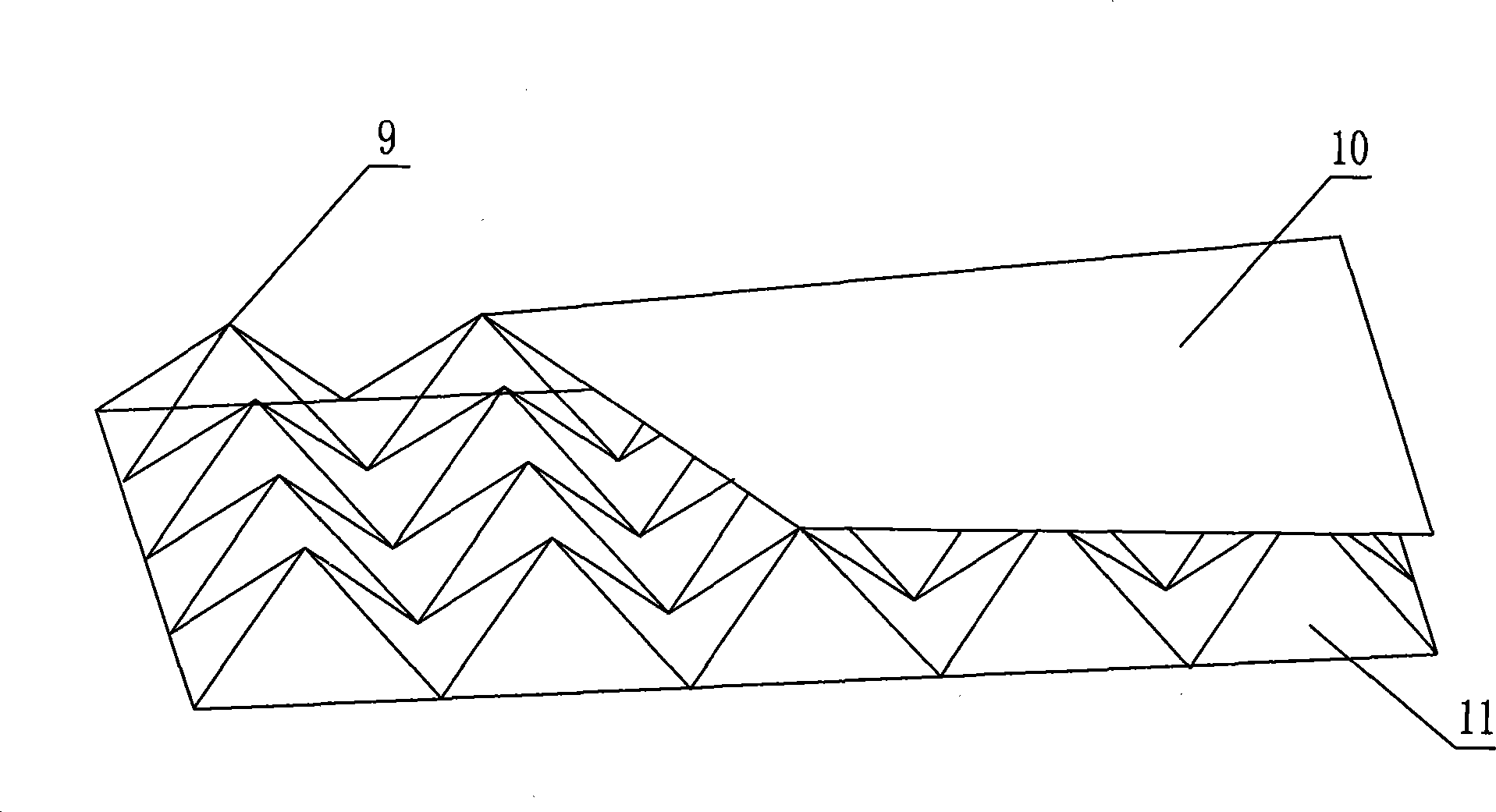

[0013] Specific implementation mode one: combine figure 1 The present embodiment will be described. Present embodiment is made of upper panel 10, lower panel 11 and pyramid-shaped lattice column 9, and pyramid-shaped lattice column 9 longitudinally has an inclination angle and is arranged between upper panel 10 and lower panel 11, and pyramid-shaped lattice column 9 is Several, the upper surface of the pyramid-shaped lattice column 9 is affixed to the lower plane of the upper panel 10, and the lower surface of the pyramid-shaped lattice column 9 is affixed to the upper surface of the lower panel 11.

specific Embodiment approach 2

[0014] Specific embodiment two: the steps of this embodiment method are as follows:

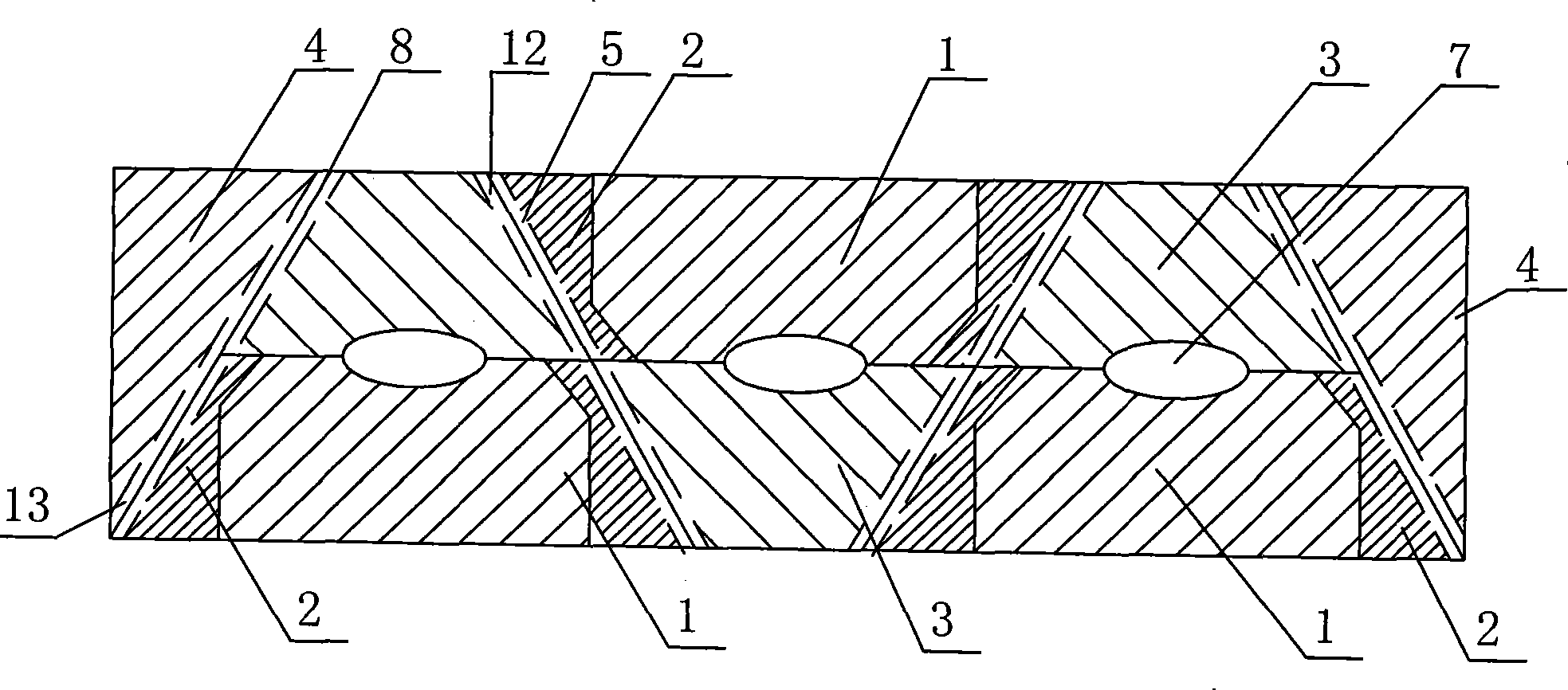

[0015] Step 1. The mold is composed of a polygonal module 1, a special-shaped module 2, a trapezoidal module 3 and two large triangular modules 4. A plurality of semicircular grooves 5 are provided on the long hypotenuse of each special-shaped module 2. A plurality of semicircular grooves 12 are provided on the hypotenuse of each trapezoidal module 3, and semicircular grooves 13 are provided on the hypotenuse of each large triangular module 4, and each polygonal module 1 and each The center of the matching surface of the trapezoidal module 3 has a semi-elliptical hole 7 respectively, and two semi-elliptical holes 7 form an elliptical hole. The groove 12 communicates with the semicircular groove 5 on the long hypotenuse of the special-shaped module 2, and the semicircular groove 13 on the hypotenuse of each large triangular module 4 matches the long hypotenuse of the special-shaped module 2. ...

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the curing temperature in step 5 is 165° C., the temperature is maintained for 3 hours, the curing pressure is 1.5 MPa, and the pressure is maintained for 3 hours. Its steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com