Waste concrete lightweight building block and preparation method thereof

A waste concrete, lightweight technology, used in the preparation of civil and building materials, the field of civil and building materials, can solve the problems of manpower and material resources, less utilization, waste of resources and the environment, and achieves environmental protection and recycling. , to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

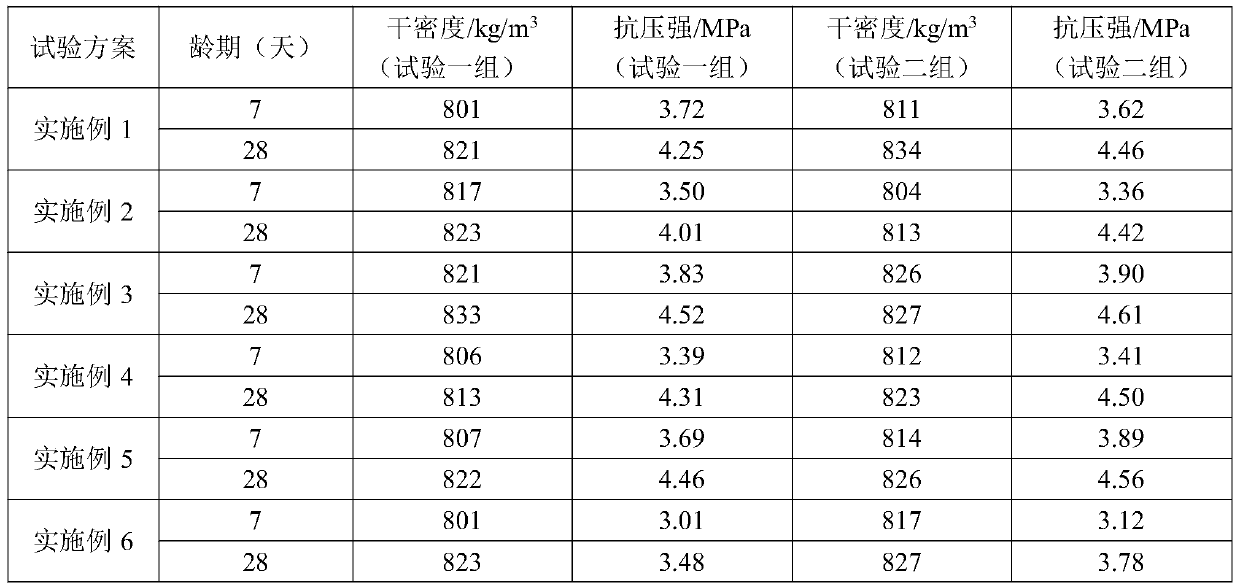

Embodiment 1

[0029] Weigh 4.0kg of waste concrete powder, 1.6kg of brick powder, 1.6kg of cement, 0.8kg of clay, 2600g of water required, and 11.4L of polystyrene particles, put them in a stirrer and stir at room temperature (25°C) for 3min to obtain a mixed The material is then vibrated and formed to make a lightweight block of 100mmⅹ100mmⅹ100mm, and the experimental component H1 is obtained. The curing system is standard curing.

Embodiment 2

[0031] Weigh 4.0kg of waste concrete powder, 0.8kg of brick powder, 1.6kg of cement, 1.6kg of clay, 2500g of water required, and 11.4L of polystyrene particles, put them in a stirrer and stir for 3min at room temperature (25°C) to obtain a mixed The material is then vibrated and formed to make a lightweight block of 100mmⅹ100mmⅹ100mm, and the experimental component H2 is obtained. The curing system is standard curing.

Embodiment 3

[0033] Weigh 4.0kg of waste concrete powder, 1.2kg of brick powder, 1.6kg of cement, 1.2kg of clay, 2550g of water required, and 11.4L of polystyrene particles, put them in a stirrer and stir for 3min at room temperature (25°C) to obtain a mixed The material is then vibrated and formed to make a lightweight block of 100mmⅹ100mmⅹ100mm, and the experimental component H3 is obtained. The curing system is standard curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com