Application of starch octenyl succinate, building mortar, putty and tile glue

A technology of octenyl succinic acid and starch ester, applied in the field of putty, tile adhesive and building mortar, can solve problems such as high maintenance cost, shortened wall renovation period and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

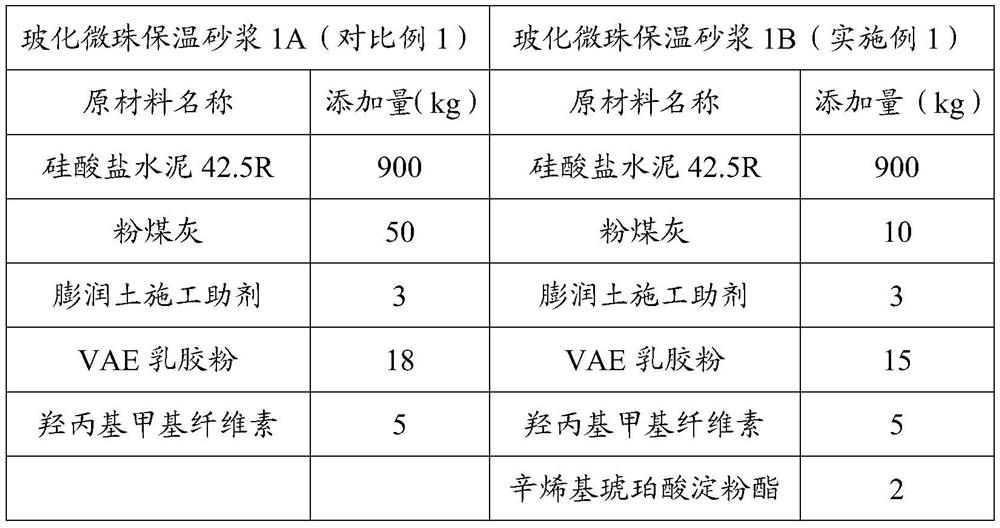

[0062] Vitrified microbead insulation mortar

[0063] Composition: Portland cement 42.5R 900kg, coal ash 10kg, construction aid 3kg, VAE latex powder 15kg, hydroxypropyl methylcellulose 5kg and octenyl succinic acid starch ester 2kg.

Embodiment 2

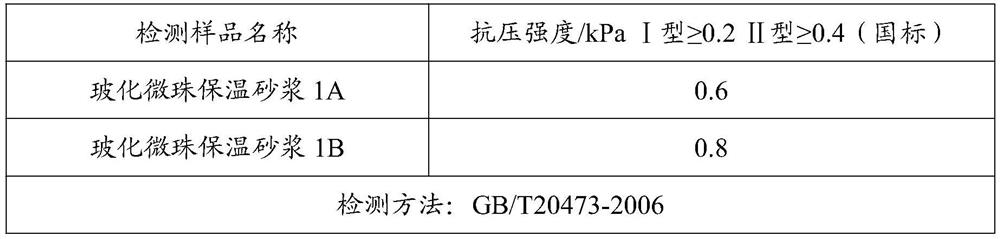

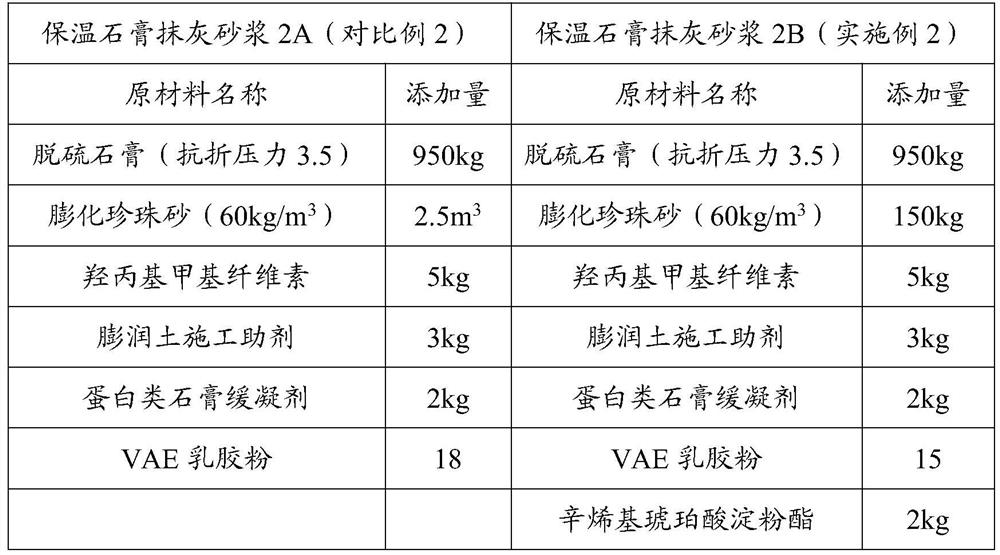

[0072] Example 2 and Comparative Example 2 are thermal insulation gypsum plastering mortars, the composition of which is shown in Table 3, and the results of compressive strength tests are shown in Table 4.

[0073] Table 3 Composition of thermal insulation gypsum plastering mortar

[0074]

[0075] Table 4 Test results of compressive strength of thermal insulation gypsum plaster mortar

[0076]

Embodiment 3

[0078] Example 3 and Comparative Example 3 are adhesive mortars, the composition of which is shown in Table 5, and the test results of tensile bond strength are shown in Table 6.

[0079] Table 5 Composition of bonding mortar

[0080]

[0081]

[0082] Table 6 Bonding Mortar Tensile Bond Strength Test Results

[0083]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com