Transferring device for hot and protruding gold stamping

A transfer device and embossing technology, applied in transfer printing, rotary printing press, printing and other directions, can solve the problems of disconnection, low production efficiency, inability to realize the embossing process of fine lines, etc., to achieve good gloss and save hot stamping. The effect of printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

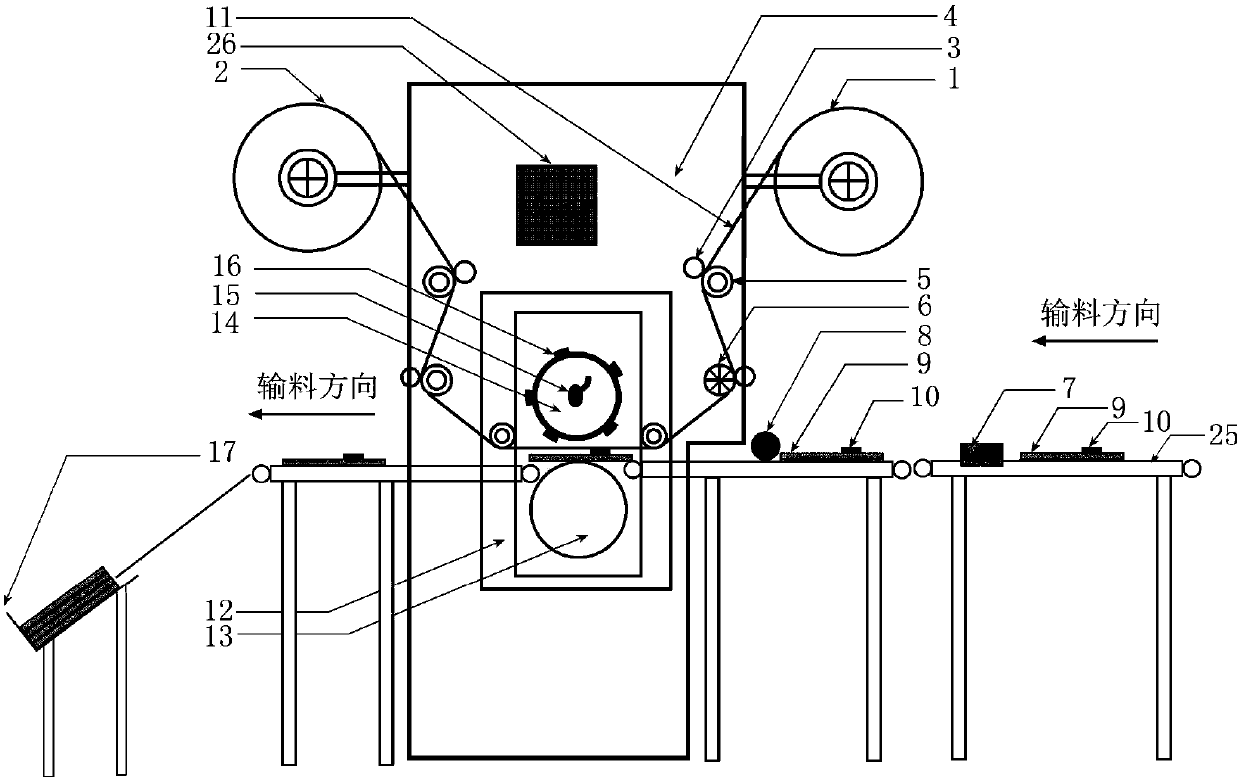

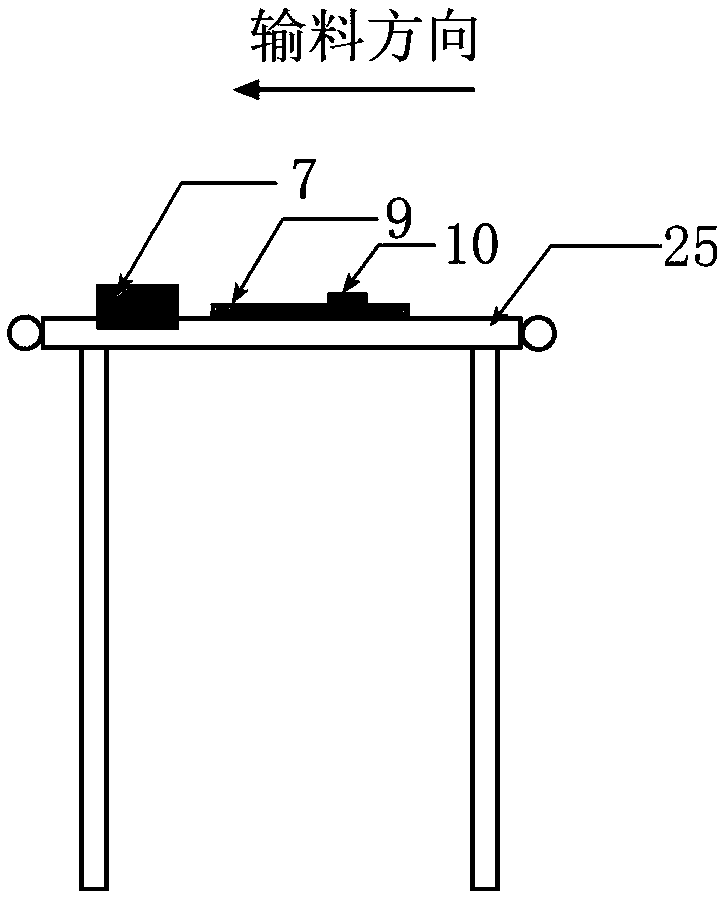

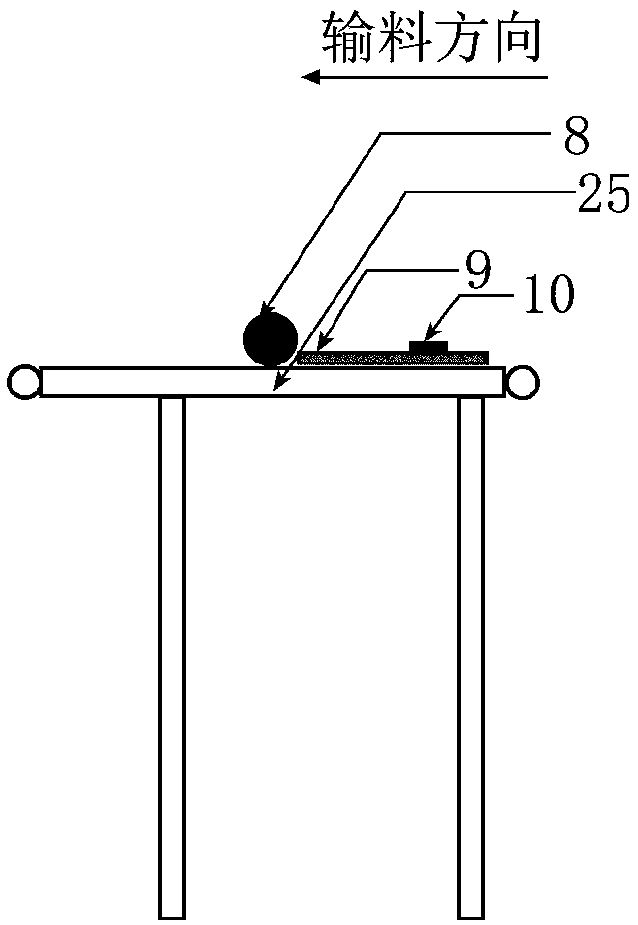

[0037] Figure 1-6 The hot embossing hot stamping transfer device shown is used for hot stamping of a single substrate; it includes a substrate side positioning mechanism 7, a substrate front positioning mechanism 8, a hot emboss transfer embossing mechanism, a material discharging mechanism and a material receiving mechanism 17; The substrate side positioning mechanism, the substrate front positioning mechanism, the thermal embossing transfer embossing mechanism, the discharging mechanism and the receiving mechanism are sequentially connected.

[0038] The emboss transfer embossing mechanism includes a hot emboss stamping transfer main frame 4, a control system 26, a foil belt conveying mechanism arranged on the hot emboss bronzing transfer main frame, and a hot emboss transfer mechanism 12; the hot emboss transfer mechanism includes Rotate the heating roller 14 that is arranged on the heat embossing bronzing transfer main frame, the oil circulation heating system 15 that is ...

Embodiment 2

[0050] Figure 8-12 The shown hot embossing hot stamping transfer device is used for hot stamping of coil substrates; it includes an unwinding mechanism 18, a storage material correction box 24, a hot embossing transfer embossing mechanism and a winding mechanism 20; the unwinding mechanism, the storage material The deviation correction box, the hot embossing transfer embossing mechanism and the winding mechanism are connected in sequence.

[0051] The hot embossing transfer embossing mechanism comprises a hot embossing hot stamping transfer main frame 4, a control system 26, and a foil belt conveying mechanism arranged on the hot embossing hot stamping transfer main frame, which is arranged on the hot embossing hot stamping transfer main frame and conveyed with the foil belt The substrate conveying mechanism that the mechanism cooperates, and the heat emboss transfer mechanism 12; The heat emboss transfer mechanism includes the heating roller 14 that is rotatably arranged on ...

Embodiment 3

[0063] Figure 13 The transfer device for hot embossing hot stamping shown, wherein the said hot embossing transfer embossing mechanism is at most two sets, and the substrate inlet end of the hot embossing transfer embossing mechanism is provided with a printing and curing mechanism 30, and the rest are basically the same as the first embodiment . The transfer device includes a feeding mechanism 27 , a side positioning mechanism 28 , a front positioning mechanism 29 , a printing and curing mechanism 30 , a thermal embossing transfer embossing mechanism 31 and a receiving mechanism 32 .

[0064] This embodiment is a single metal or non-metal foil film multi-station conveying material, the principle of hot embossing and bronzing is basically the same as the specific implementation of the single-single single-station conveying material in the first embodiment, the only difference is the single conveying The material multi-station metal or non-metal foil hot embossing transfer de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com