Transferring method and device for positioning and non-positioning heat protruding gold stamping

A transfer method and non-positioning technology, applied in the field of hot stamping, can solve the problems of disconnection, low production efficiency, waste of cold stamping foil, etc., and achieve the effect of good gloss, saving process cost and saving hot stamping cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

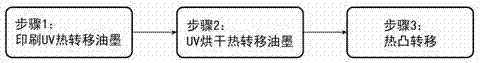

[0023] Such as figure 1 As shown, the transfer method of positioning and non-positioning heat embossing bronzing of the present invention is divided into three steps and carries out:

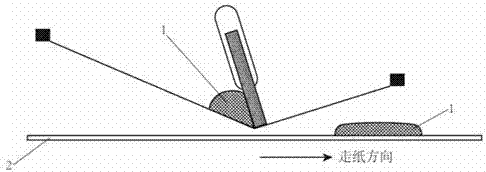

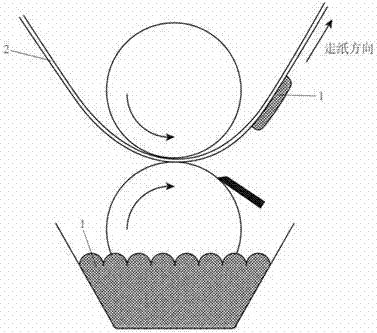

[0024] 1) Print the UV transfer hot-melt ink 1 on the paper 2 at the position where the paper needs to be bronzed by gravure printing, silk screen printing or offset printing, such as figure 2 , image 3 shown

[0025] 2) Drying of UV transfer hot-melt ink; UV curing light source 3 is used to cure the printed UV thermal convex transfer ink 1 to form cured UV thermal convex transfer ink 4, such as Figure 4 shown.

[0026] 3) The cured UV thermal embossing transfer ink 4 is pressed together by the high-temperature-resistant rubber soft roller 6 and the pressure roller 5, and the heating roller 9 provides a certain temperature for the pressed material to transfer the metal material on the metal transfer foil 7 to the The surface of the cured UV heat embossing transfer ink 4 is finally made in...

Embodiment 2

[0032] The UV transfer hot-melt ink is prepared from the following raw materials in parts by weight: acrylic resin 35, acrylate copolymer 15, 1,6 hexanediol diacrylate 16, tripropylene glycol diacrylate 21, trihydroxy Methyl propane triacrylate 10, photoinitiator 4, auxiliary agent 2.

[0033] Other methods are the same as in Example 1.

Embodiment 3

[0035] The UV transfer hot-melt ink is prepared from the following raw materials in parts by weight: acrylic resin 33, acrylate copolymer 14, 1,6 hexanediol diacrylate 14, tripropylene glycol diacrylate 20, trihydroxy Methyl propane triacrylate 9, photoinitiator 4, auxiliary agent 2.

[0036] Other methods are the same as in Example 1.

[0037] The metal material on the anodized aluminum metal foil is transferred to the surface of the cured UV heat embossing ink by thermal transfer, forming a raised effect similar to bronzing. This process can carry out heat embossing bronzing transfer of large areas of fine patterns , can avoid the disconnection problem caused by hot stamping large-area pattern, compared with cold stamping, the metallic luster is stronger, and the pattern has a raised feel. The whole process does not need to make a hot stamping plate, and the same printing volume can save 78.5% of the hot stamping cost, which greatly saves the process cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com