Air guide device and manufacturing and assembling method thereof

A technology of air guiding device and segment, which is applied to bridge parts, bridges, buildings, etc., which can solve the problems of difficulty in repairing and maintaining bridge air guiding devices, the inaccessibility of maintenance personnel, and easy deformation of welding, so as to save maintenance and repair costs , to avoid paint peeling, the effect of less connection nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

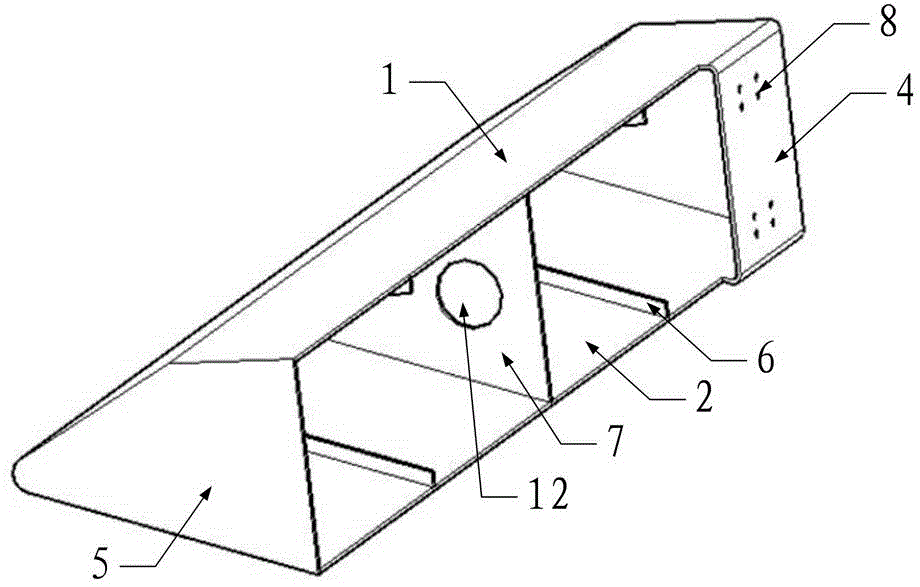

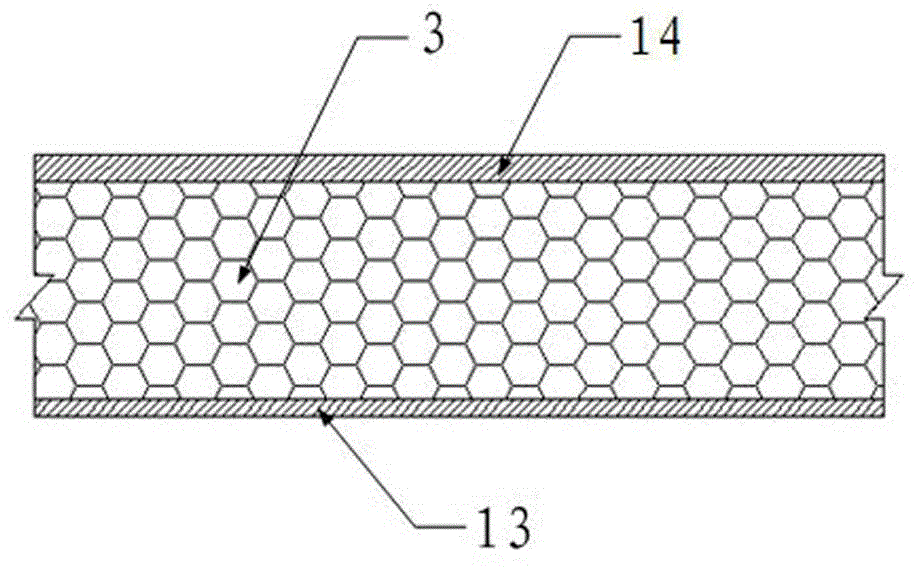

[0036] Figure 1 to Figure 3 The first embodiment of the air guiding device of the present invention is shown, which includes at least one section of the air guiding section. The air guiding section includes a body composed of a top plate 1 and a bottom plate 2. An opening is provided at one end of the body, and a cavity is formed inside the body. There are reinforcing ribs in the cavity, which can enhance the overall rigidity of the body. The top plate 1 , the bottom plate 2 and the reinforcement ribs are all composed of an inner layer 13 of fiber reinforced composite material and an outer layer 14 of fiber reinforced composite material. The air guiding device of the present invention adopts the structure of the inner layer 13 of fiber reinforced composite material and the outer layer 14 of fiber reinforced composite material, which has the characteristics of light weight, high strength, corrosion resistance, environmental protection, and high rigidity, and can not only meet ...

Embodiment 2

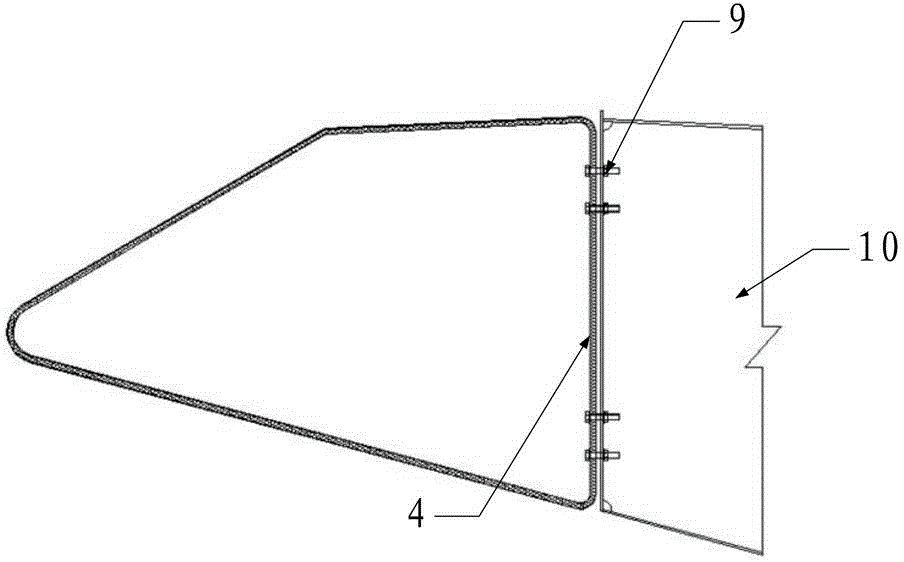

[0047] Figure 4 The second embodiment of the air guide device of the present invention is shown. The structure of the air guide device of this embodiment is basically the same as that of Embodiment 1, the only difference is that the upper and lower ends of the side plate 4 and the main beam 10 are provided with ears. The plate 11 connects the side plate 4 and the corresponding ear plate 11 on the main girder 10 through bolts 9 to fix the wind guide segment and the main girder 10 .

[0048] The parameters in this embodiment are as follows: the length of a wind guide segment is 12m, the fiber reinforced composite material layer 13 of the top plate 1 and the bottom plate 2, the fiber reinforced composite material outer layer 14 plus the lightweight interlayer 3 have an average thickness of 25mm, wherein the fiber reinforced composite material The inner layer 13 of the material (forming the inner cavity) is 2mm thick, the outer layer 14 of fiber reinforced composite material is 3...

Embodiment 4

[0055] Figure 6 The fourth embodiment of the air guide device of the present invention is shown. The structure of the air guide device of this embodiment is basically the same as that of Embodiment 3, the only difference is that the ear plate 11 is arranged on the top plate 1 and the bottom plate 2, and the top plate 1 The lugs 11 are directly fixedly connected to the main beam 10 , and the lugs 11 of the bottom plate 2 are connected to the corresponding lugs 11 of the main beam 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com