Vacuum assisted molding system of composite and molding method of composite

A composite material and vacuum-assisted technology, applied in the field of forming systems, can solve the problems of low mold versatility and high process cost, and achieve the effects of less internal defects, good mechanical properties, and reduced equipment costs and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

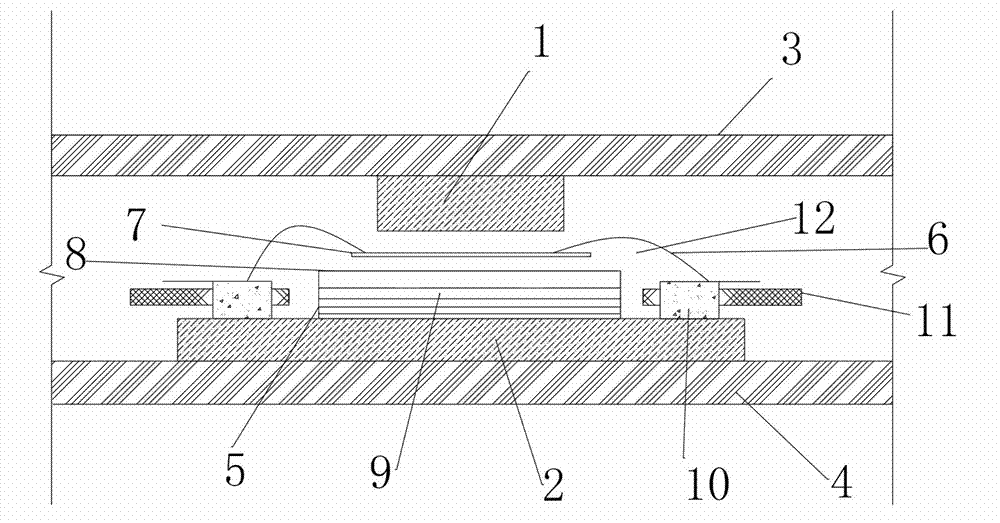

[0024] a kind of like figure 1 The vacuum-assisted compression molding system for composite materials shown, the system includes an open molding mold, the open molding mold includes an upper mold 1 and a lower mold 2 arranged oppositely, and a prepreg 5 to be formed is sealed and connected above the lower mold 2 A vacuum bag pressure system that implements vacuum bag pressure; the outer side of the open forming mold is connected with a mold pressing heating system (including hydraulic press upper 3 and hydraulic press lower 4). In this embodiment, the upper mold 1 and the lower mold 2 are single-sided molds, and the length and width of the upper mold 1 are the same as the length and width of the product to be formed; the edges of the lower mold 2 exceed the edges of the prepreg 5 placed on it The distance is more than 30mm. After the upper mold 1 and the lower mold 2 are closed, they do not touch or close.

[0025] The vacuum bagging system of the present embodiment includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com