Microneedles array, die casting method for manufacturing microneedle array and die for manufacturing microneedle array

A microneedle array and microneedle technology, applied in the field of microneedle arrays, can solve the problems of non-reusable, poor practicability of microneedle arrays, and high cost of microneedle arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Specific embodiments of the present invention will be described in detail below. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

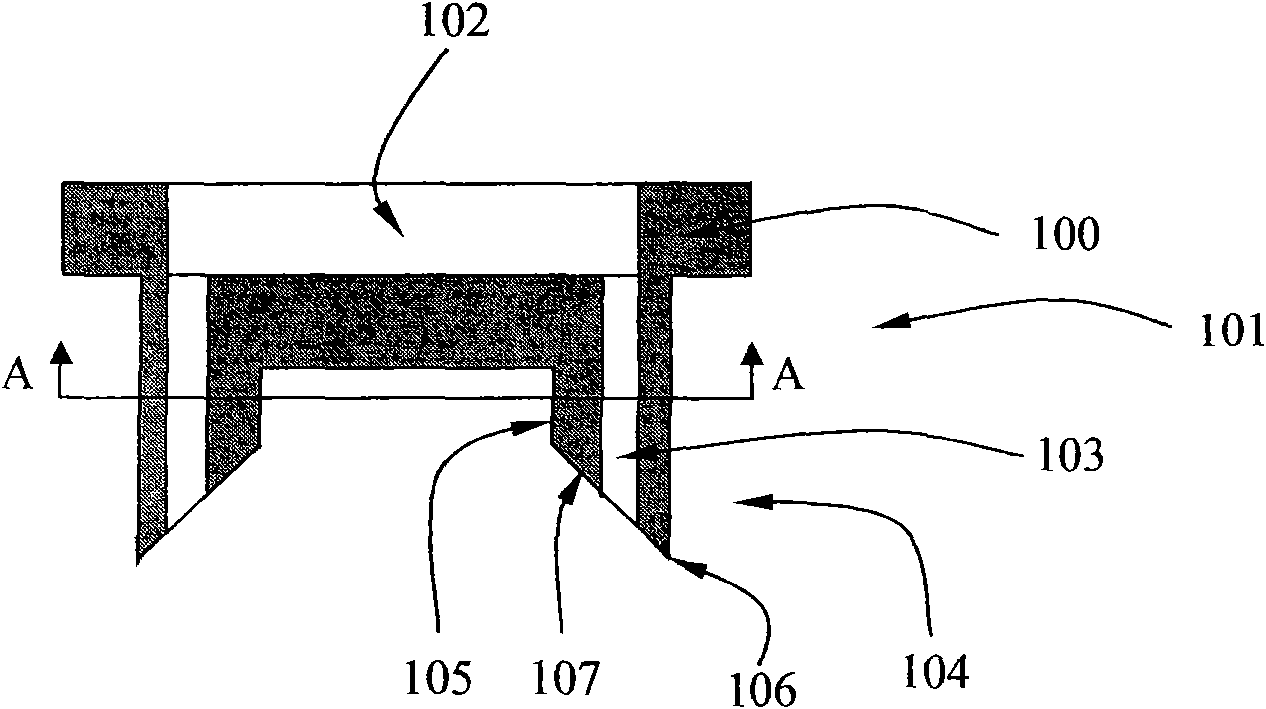

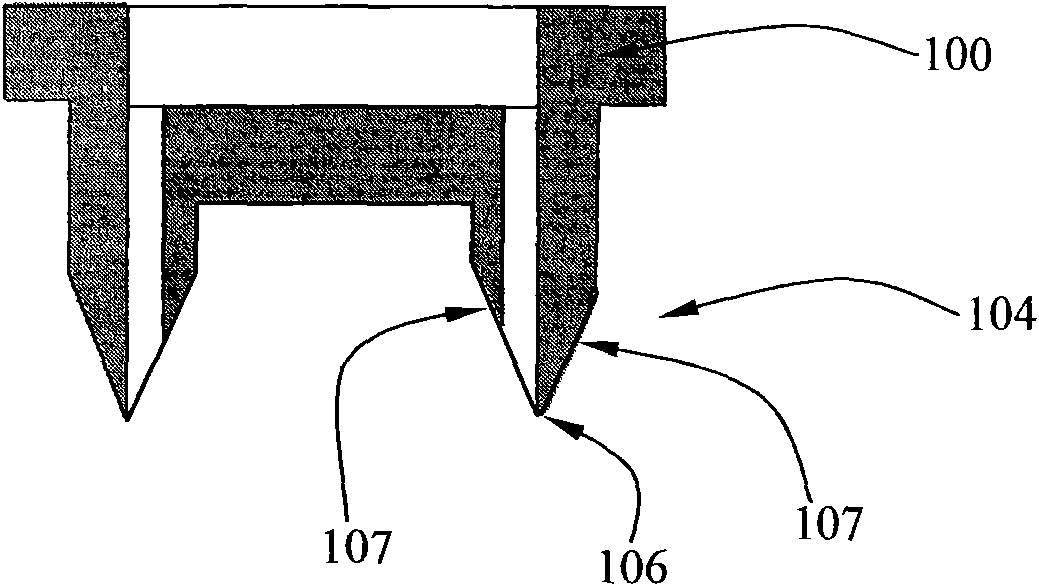

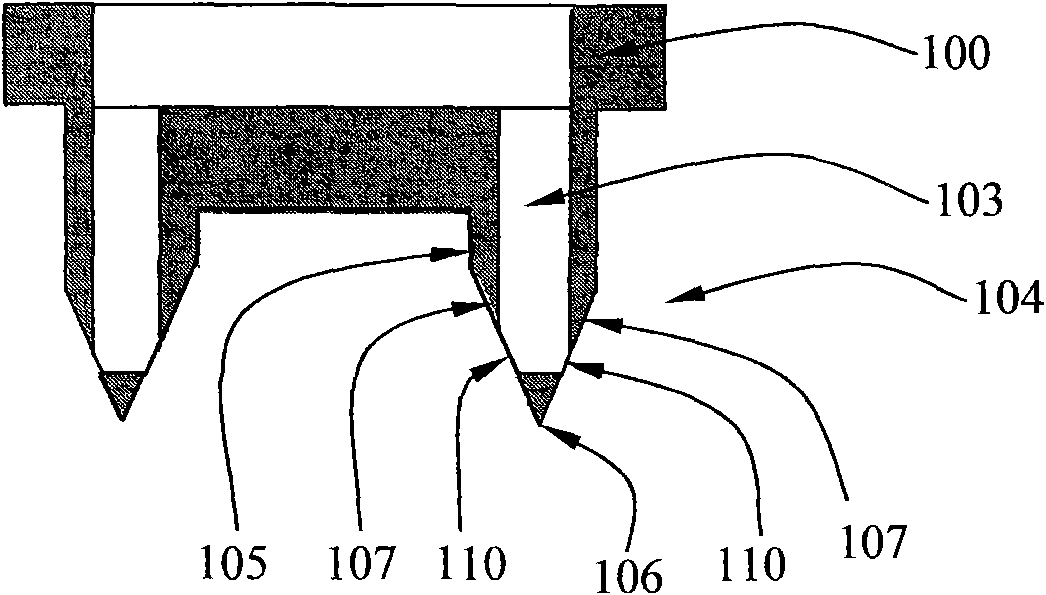

[0078] Such as figure 1 , Figure 1A , Figure 1B , Figure 1C and Figure 1D As shown, the microneedle array of the first embodiment of the present invention includes a relatively small number of microneedles, and its structure includes a base 100 and several microneedles 101 arranged centrally or axisymmetrically formed integrally with the base 100 . Wherein the base 100 has a liquid storage cavity 102 for storing medical liquid or interstitial fluid. The microneedle 101 has a microneedle hole 103 communicating with the liquid storage cavity 102 . The microneedle 101 includes a needle body part 105 and a peak part 104 integrally formed with the base 100 . The end surface of the peak portion 104 is a slope 107 forming an acute angle with the center...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com