Patents

Literature

38results about How to "Reduce demoulding resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

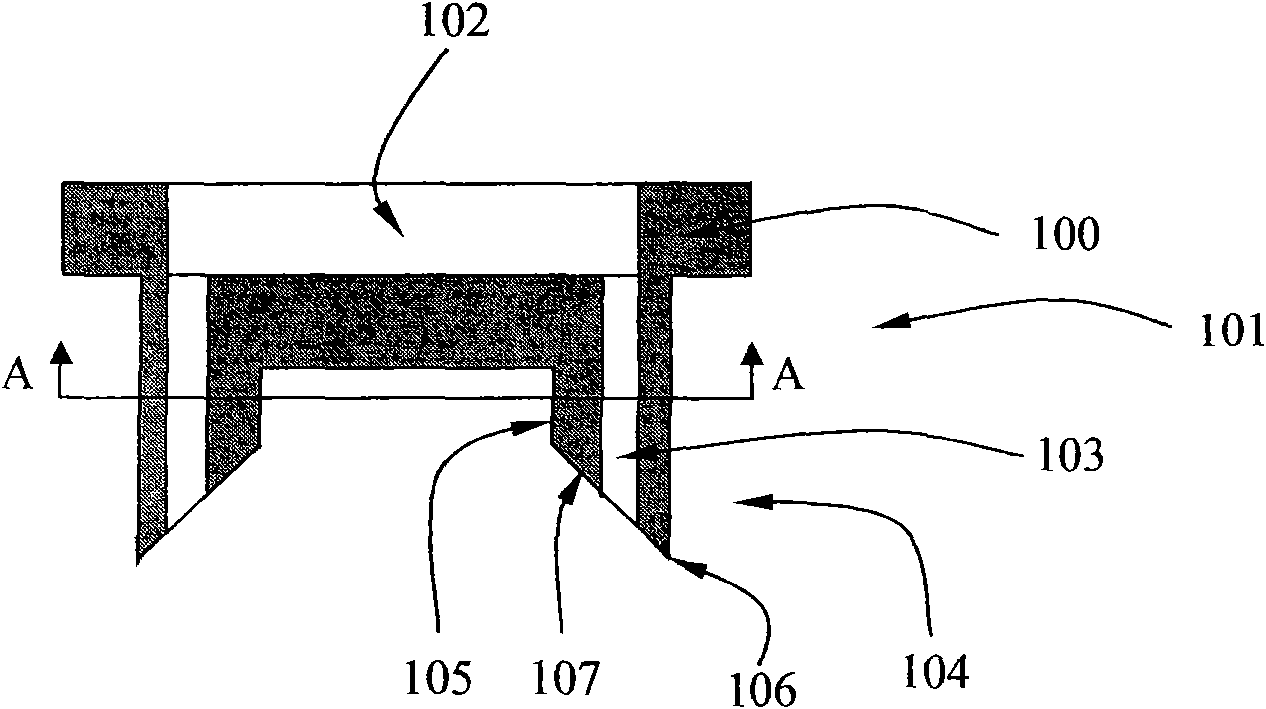

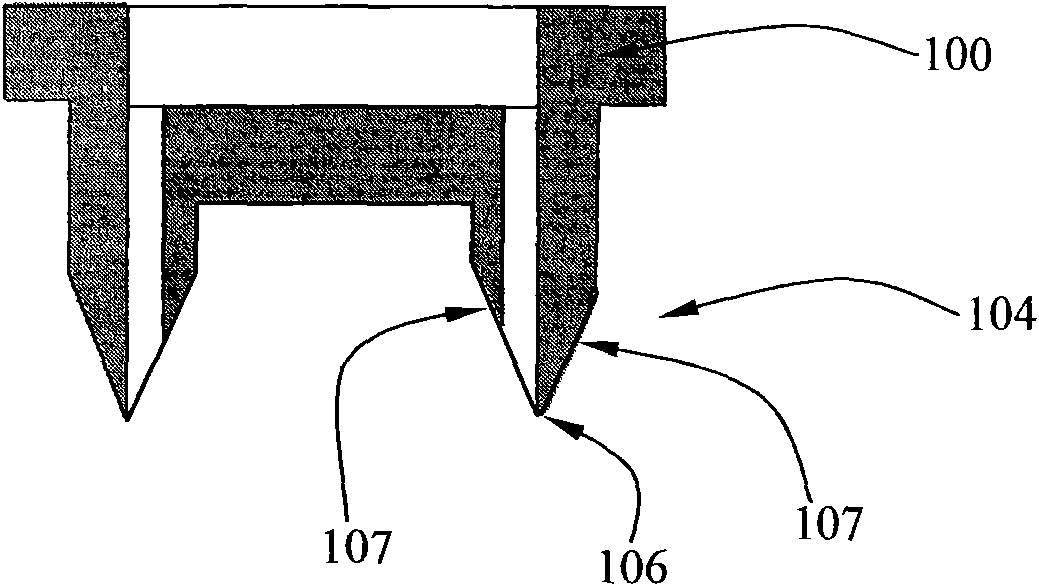

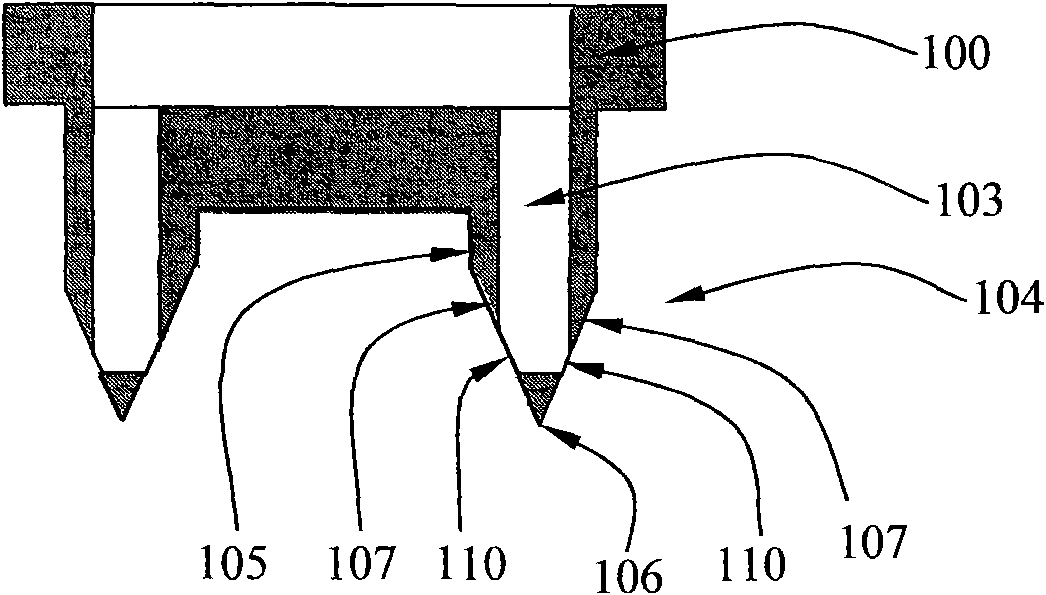

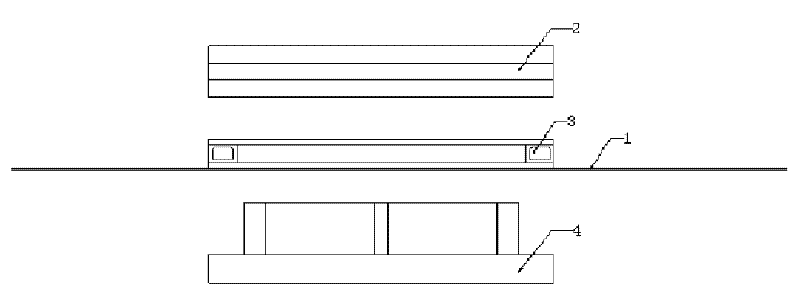

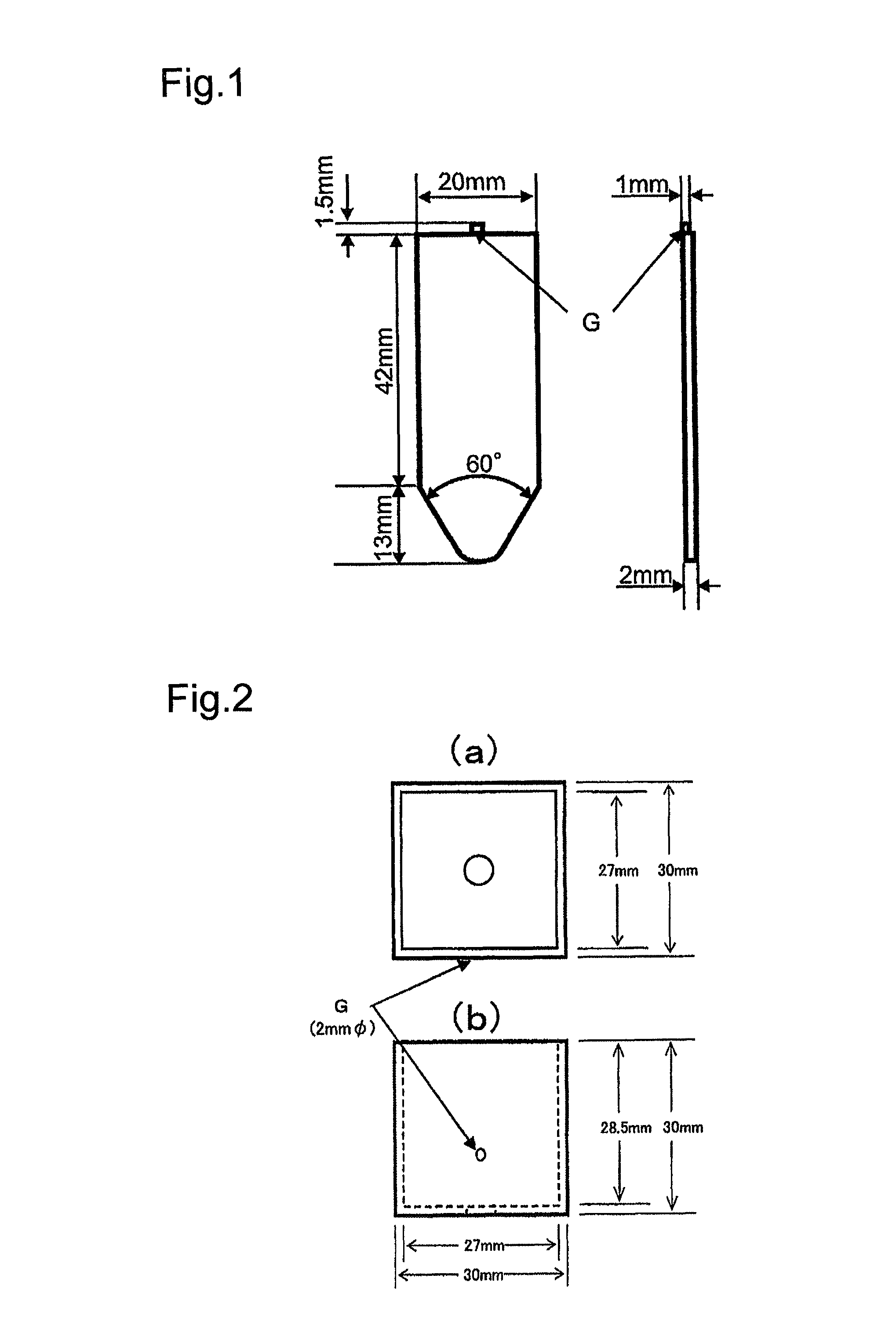

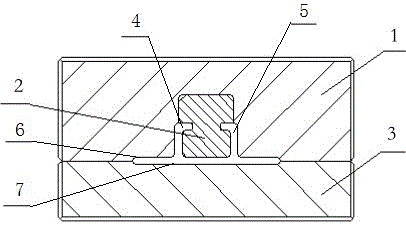

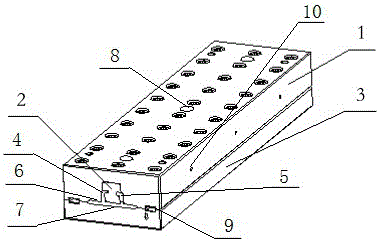

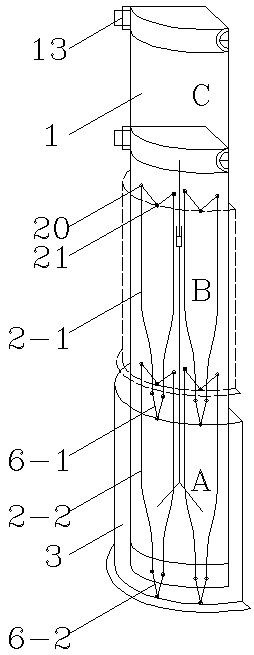

Microneedles array, die casting method for manufacturing microneedle array and die for manufacturing microneedle array

ActiveCN101856538AReduce manufacturing costLow priceMicroneedlesMedical devicesMetallic materialsDie casting

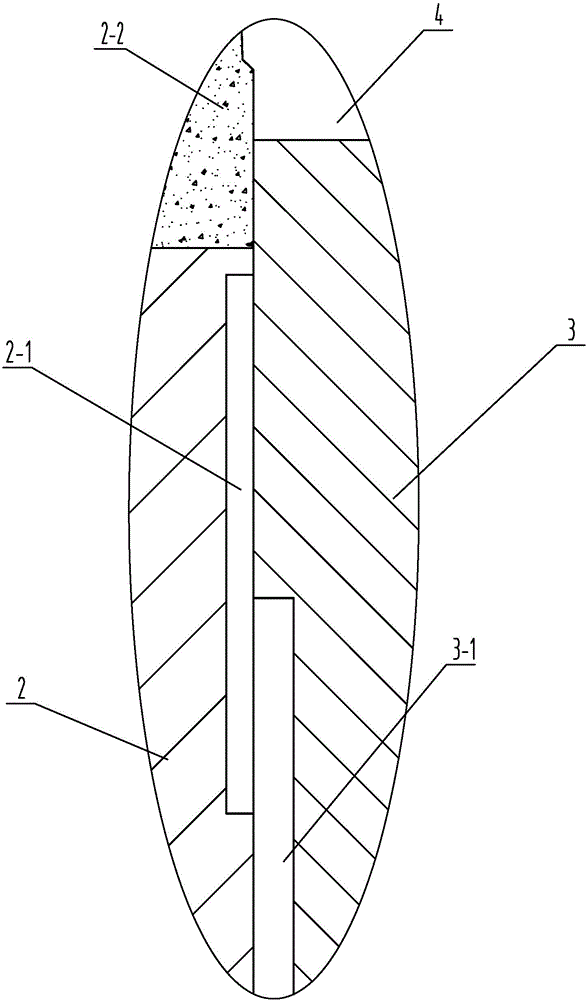

The invention provides a microneedles array, a method for manufacturing the microneedles array and a die for manufacturing the microneedles array. The microneedles array comprises a base and a plurality of microneedles which are integrated with the base, wherein a liquid storage cavity is arranged in the base, and each microneedle are provided with micro-pinholes which are communicated with the liquid storage cavity; the microneedles array is made of plastics, composite materials, and ceramics or metal materials by injection molding; and each microneedle has at least one inclined surface which is inclined towards the central line of the microneedle, and the outlet of each micro-pinhole is positioned on at least one inclined surface, so that the end of the outlet of the microneedle forms a pinnacle part. The die specialized for the invention comprises an upper die, a middle die and a lower die, wherein the middle die and the lower die are provided with cavities for forming the microneedles; and the upper die and the middle die are provided with grooves for forming the base. The three-plate die of the invention can be used for conveniently manufacturing the microneedles array with the pinnacles. Since the stripping process in the injection molding method is carried out step by step, the method has the advantages of small die drawing resistance and low manufacturing cost.

Owner:THE HONG KONG POLYTECHNIC UNIV

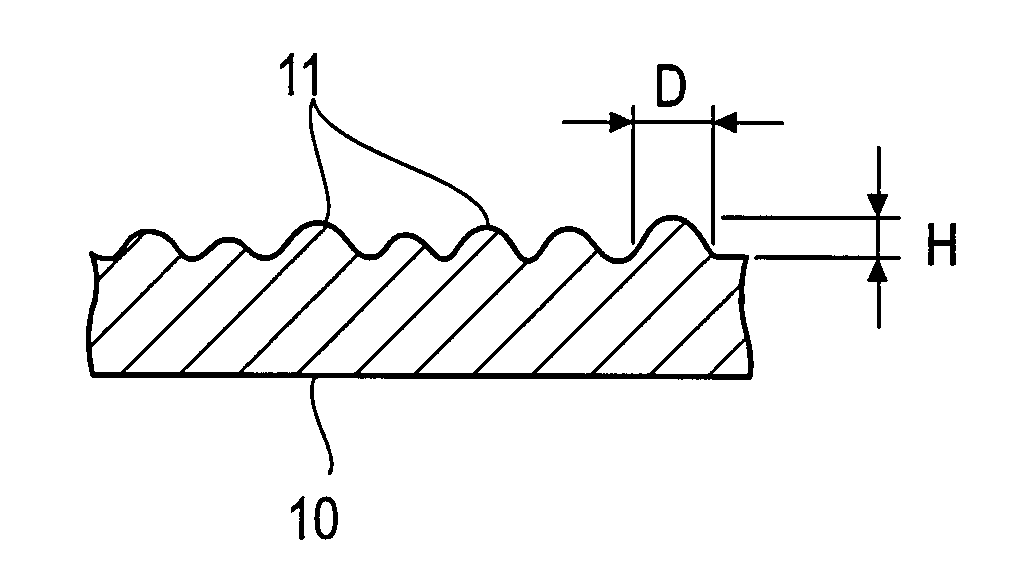

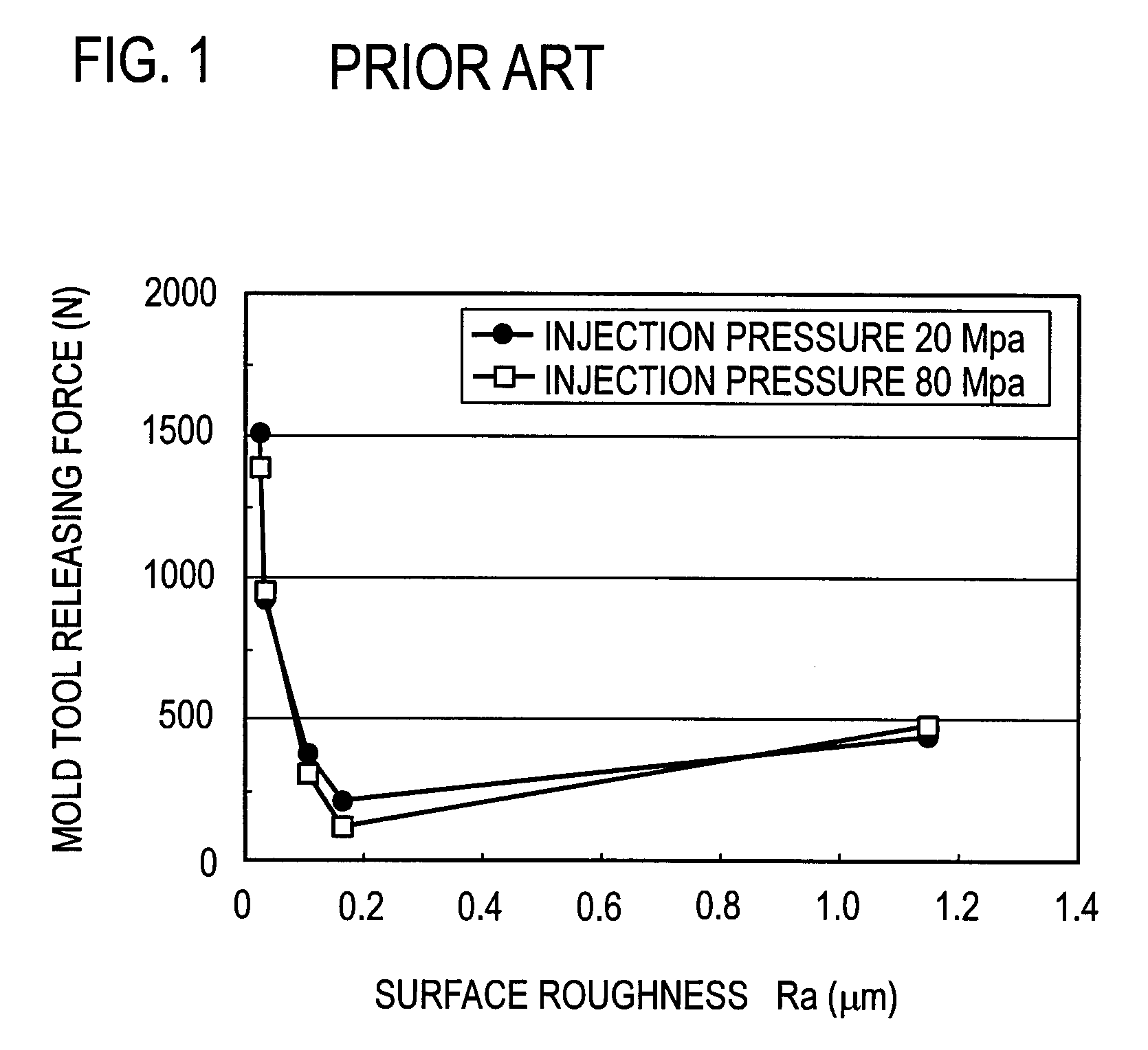

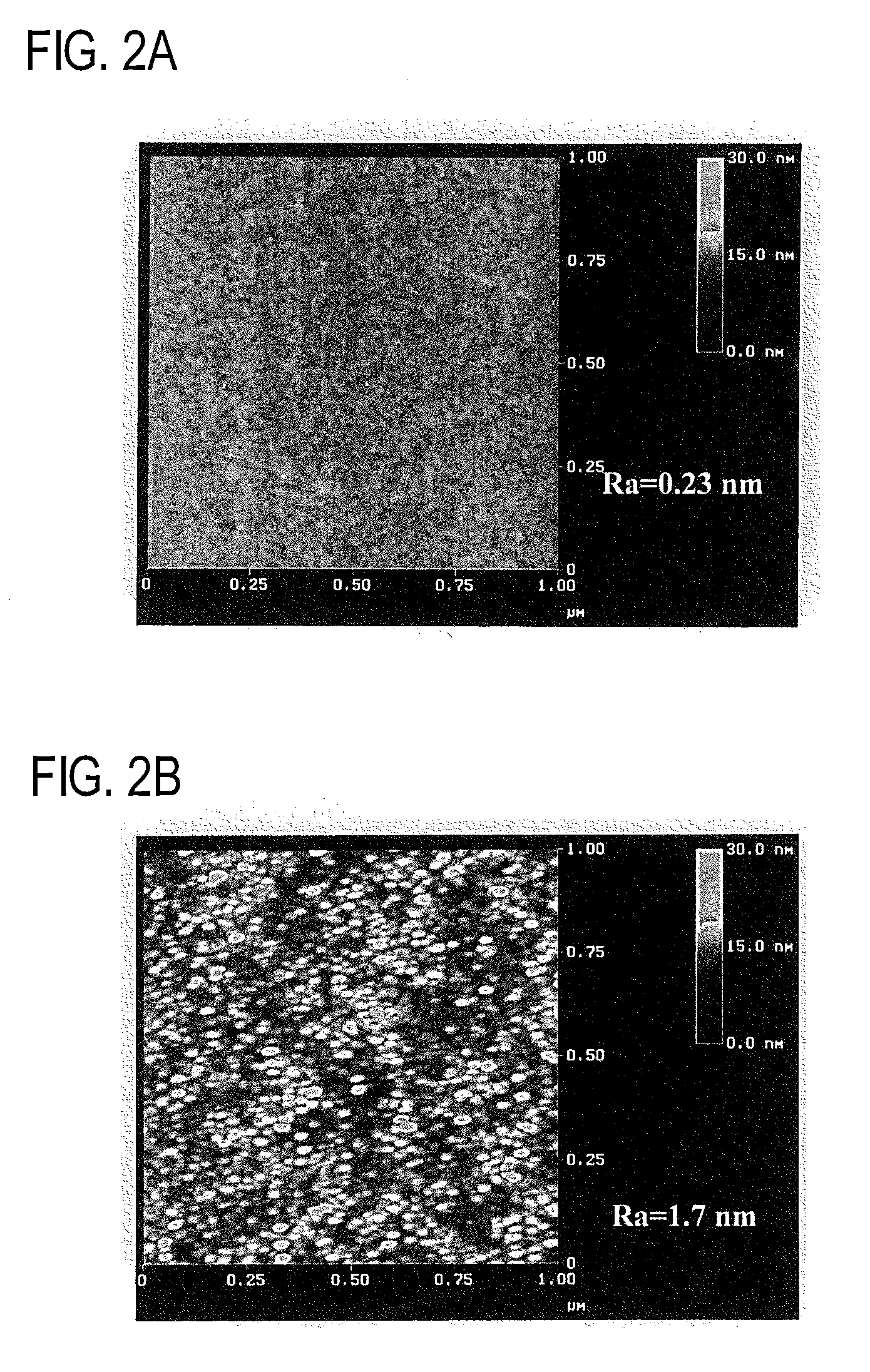

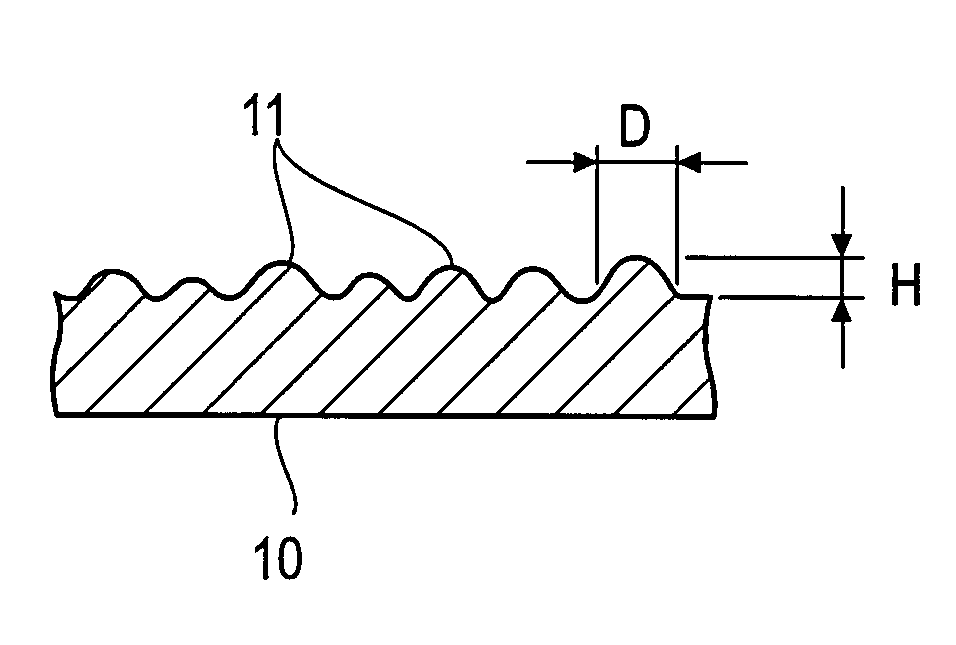

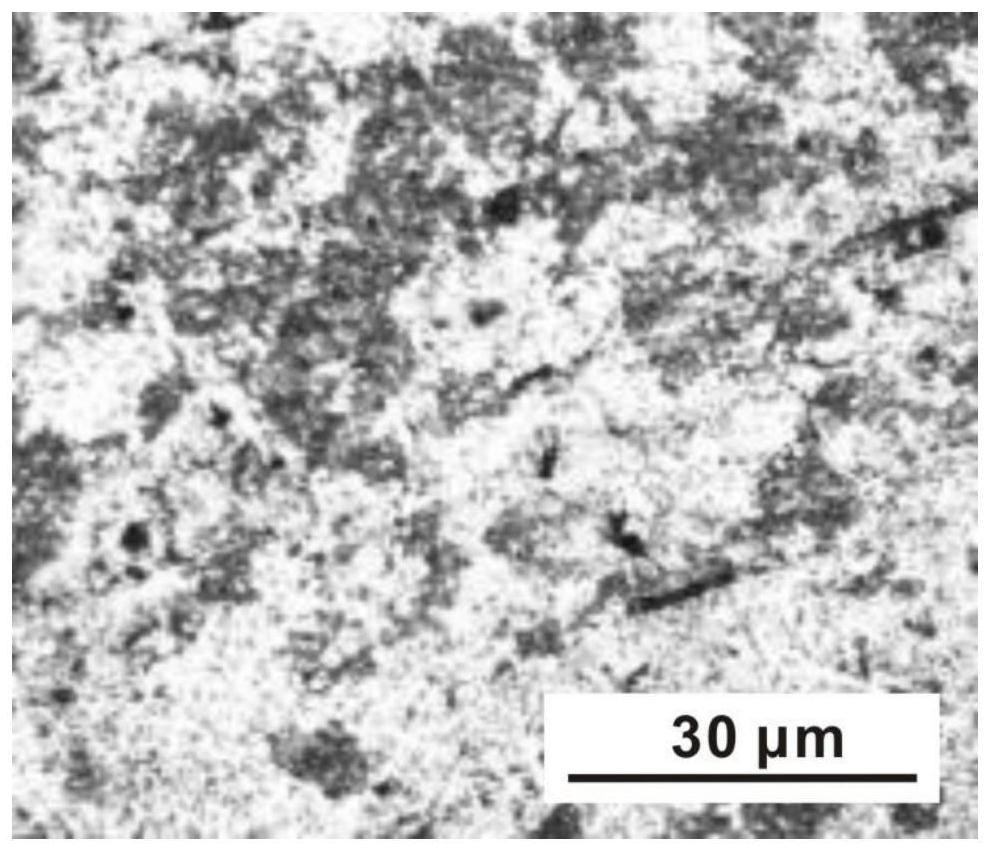

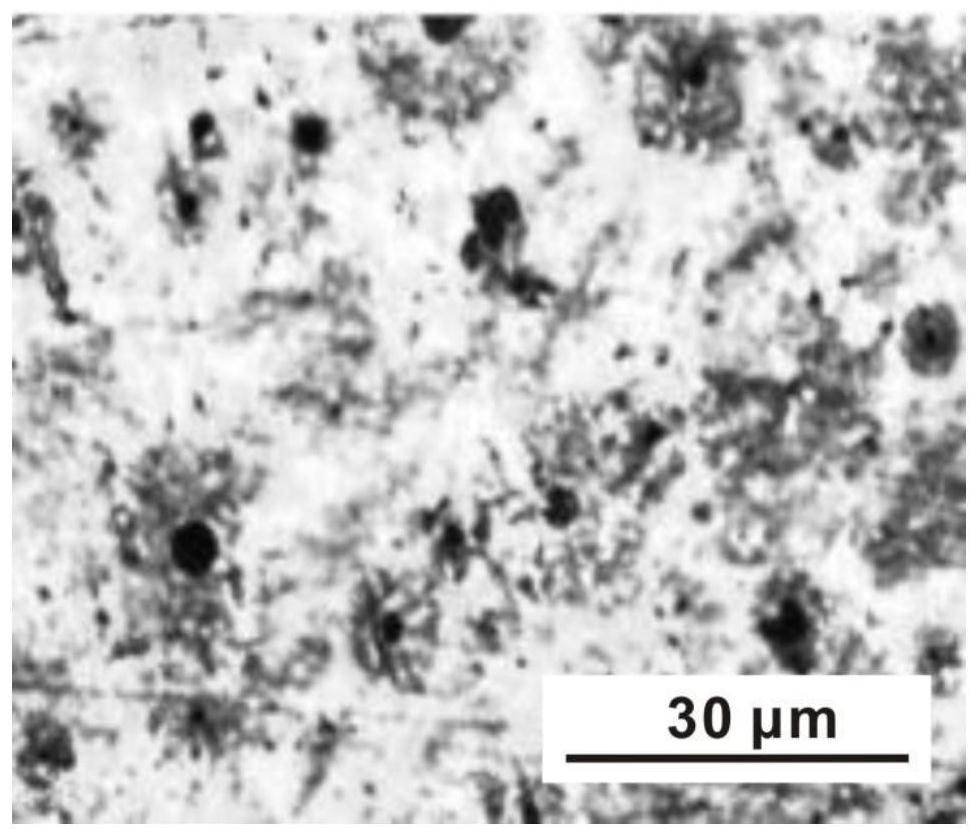

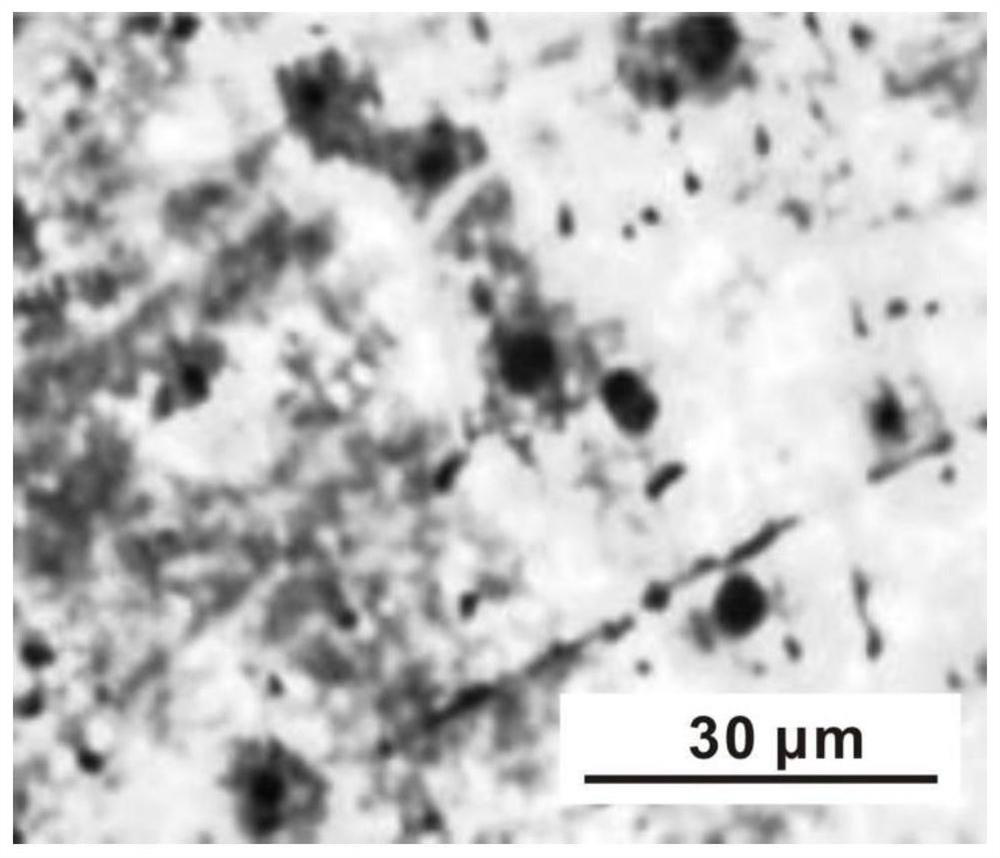

Treatment method for mold tool surface

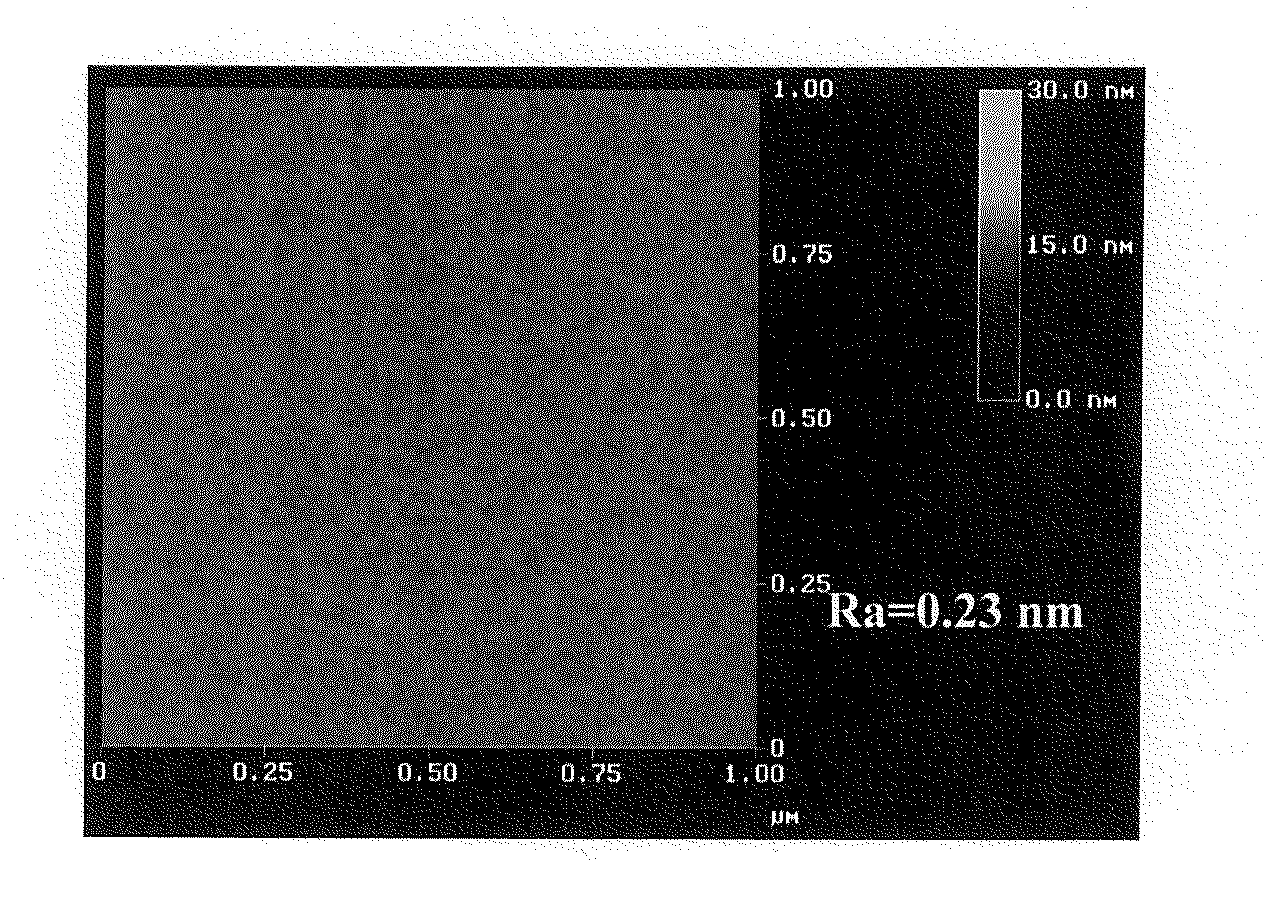

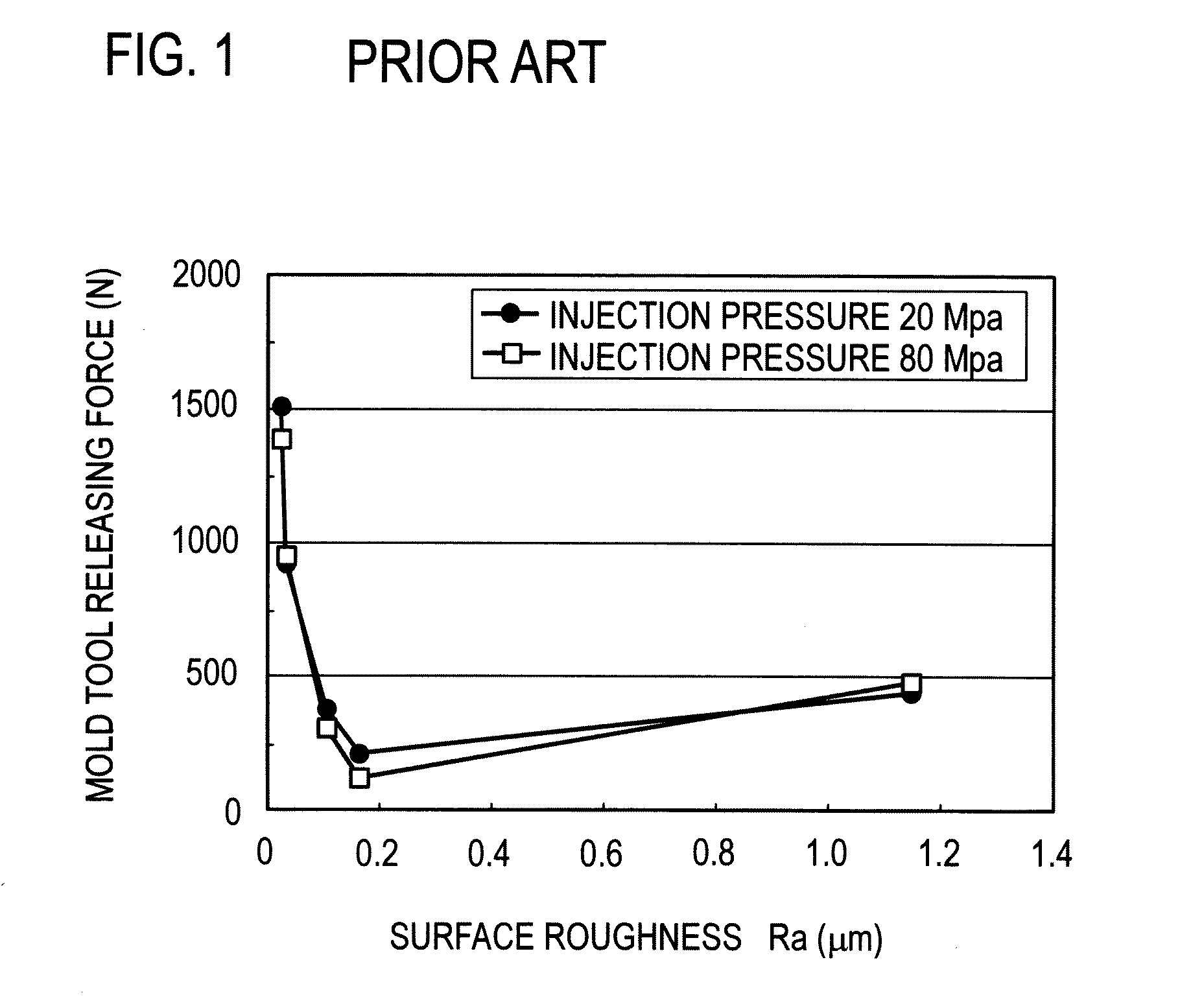

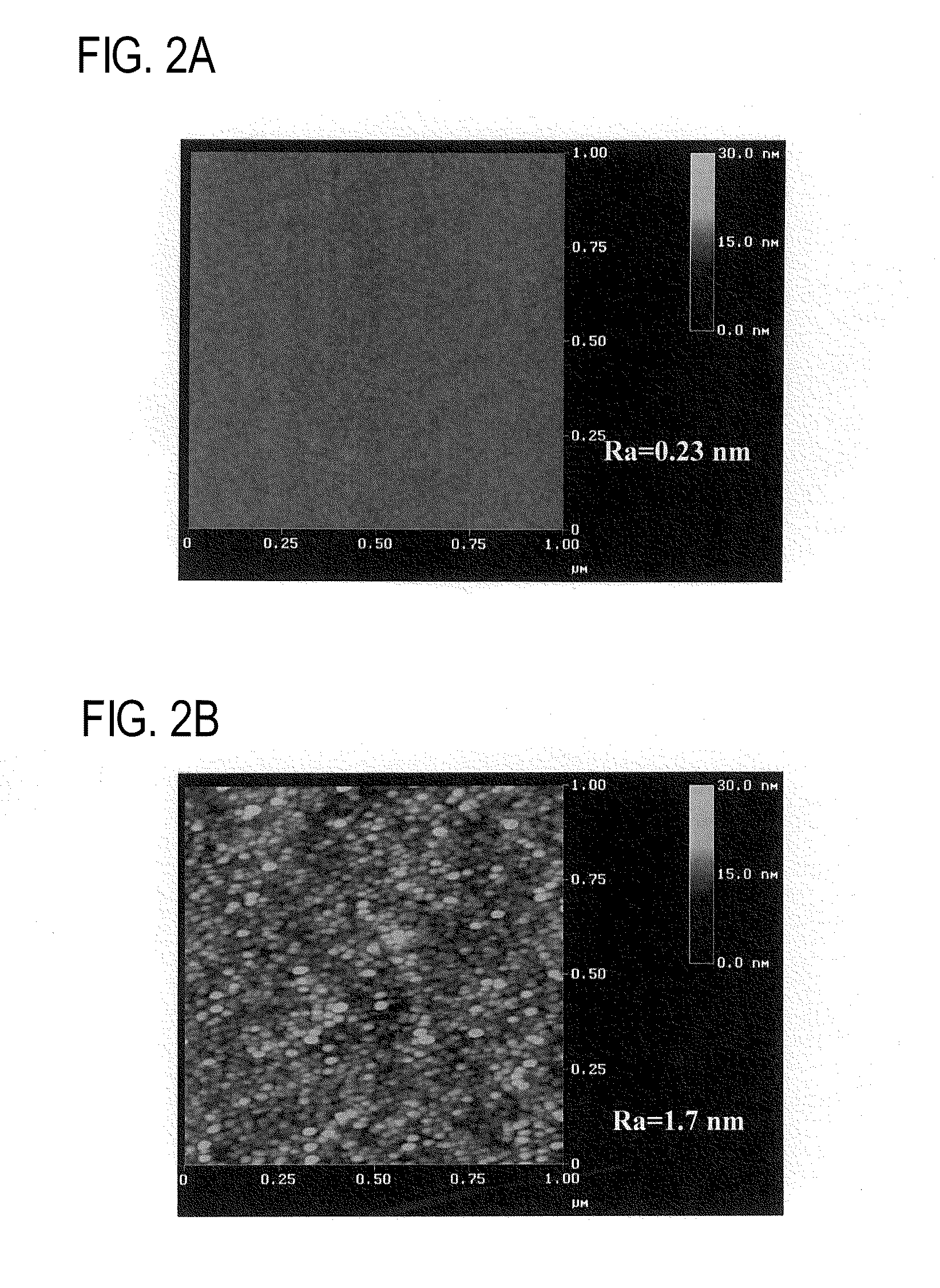

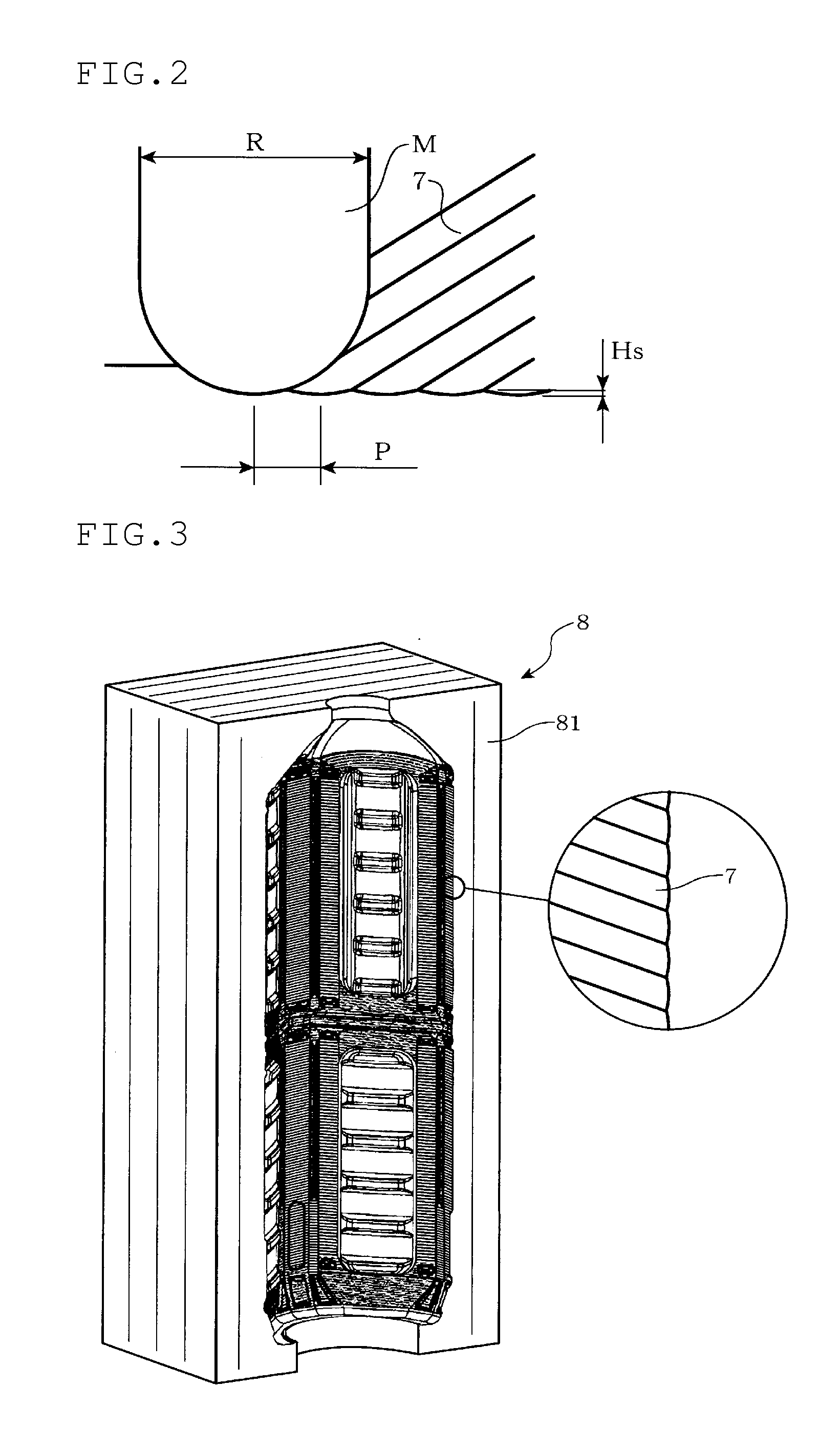

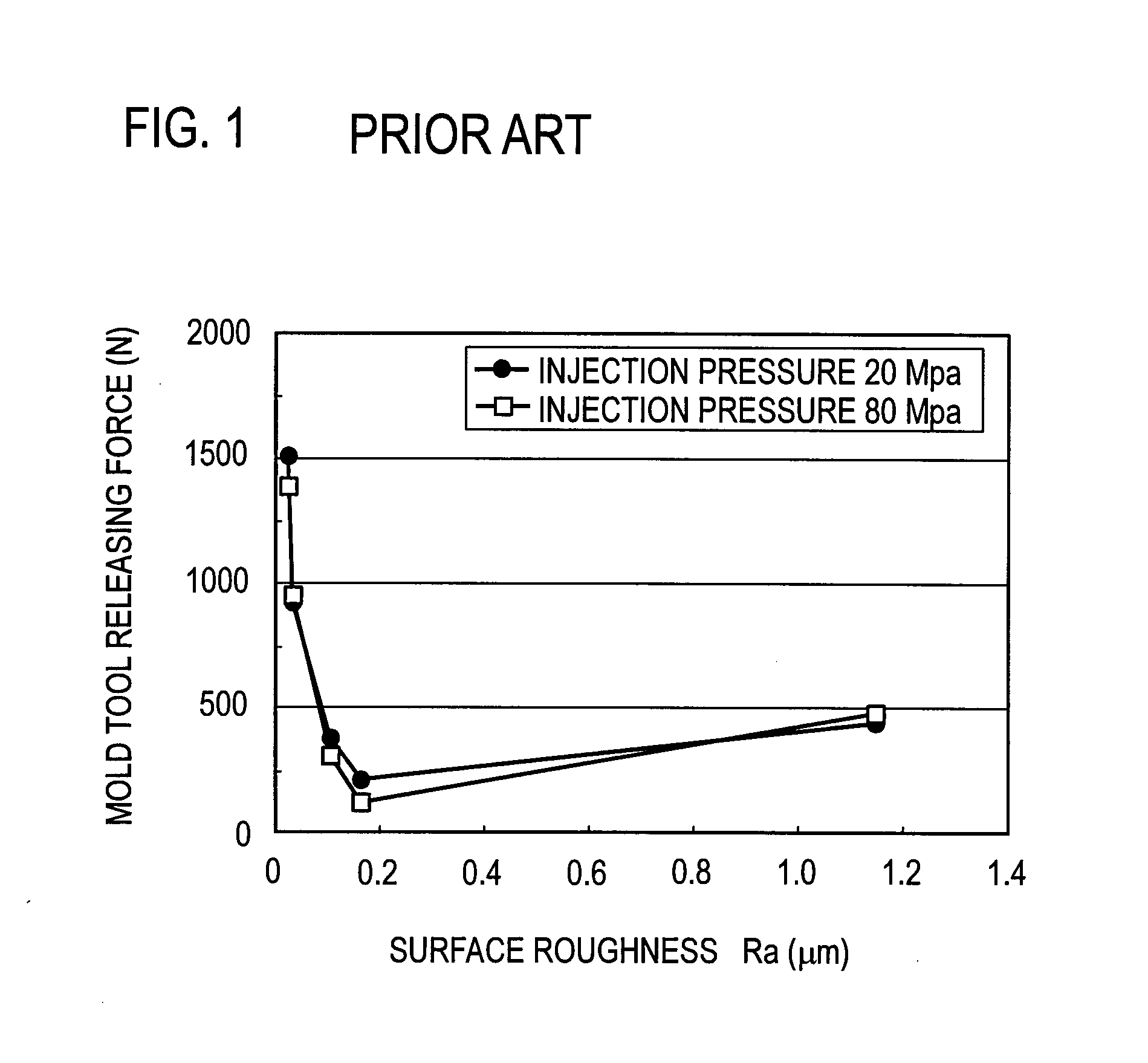

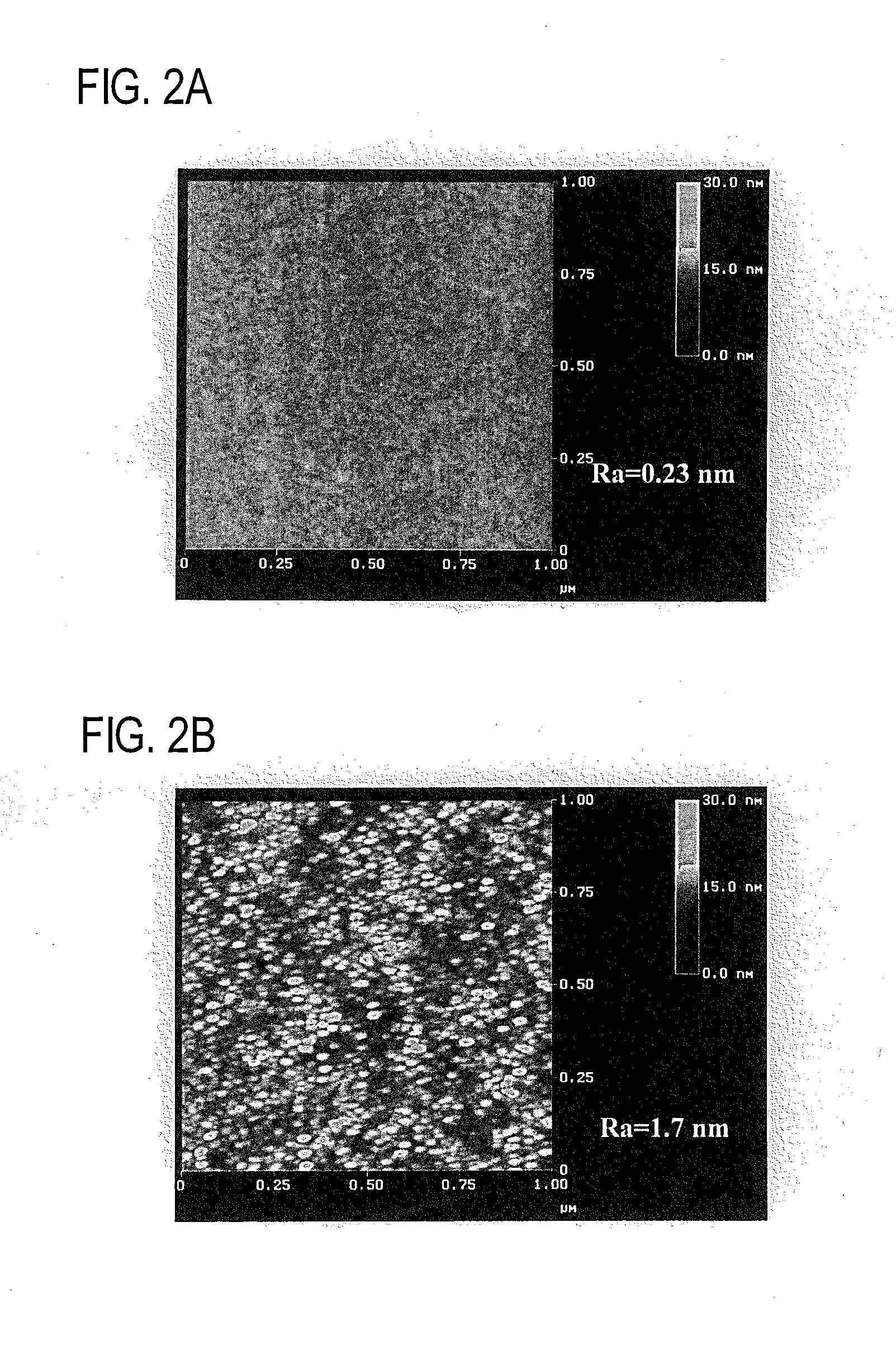

The average roughness Ra of a mold tool surface that comes into contact with a material to be molded measured for a measurement area 10 μm square or smaller is equal to or lower than 5 nm, and fine granular projection structures having diameters ranging from 10 to 80 nm and heights ranging from 10 to 40 nm are formed on the mold tool surface with a density of 400 / μm2 or higher. The frictional force due to the anchoring effect or the digging effect is reduced, and the adhesive force due to meniscus is also reduced. The release resistance is significantly reduced without affecting the dimensional precision of a fine molded product.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

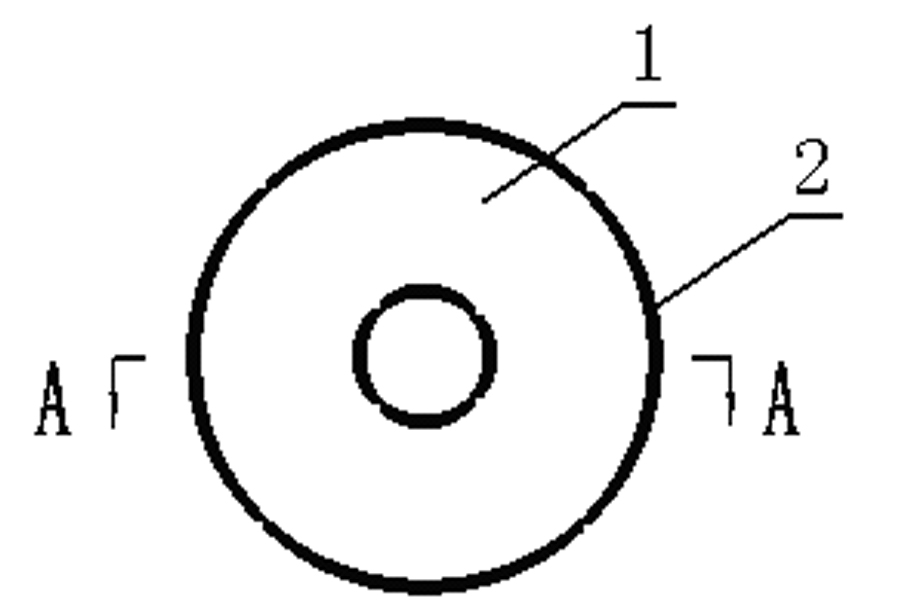

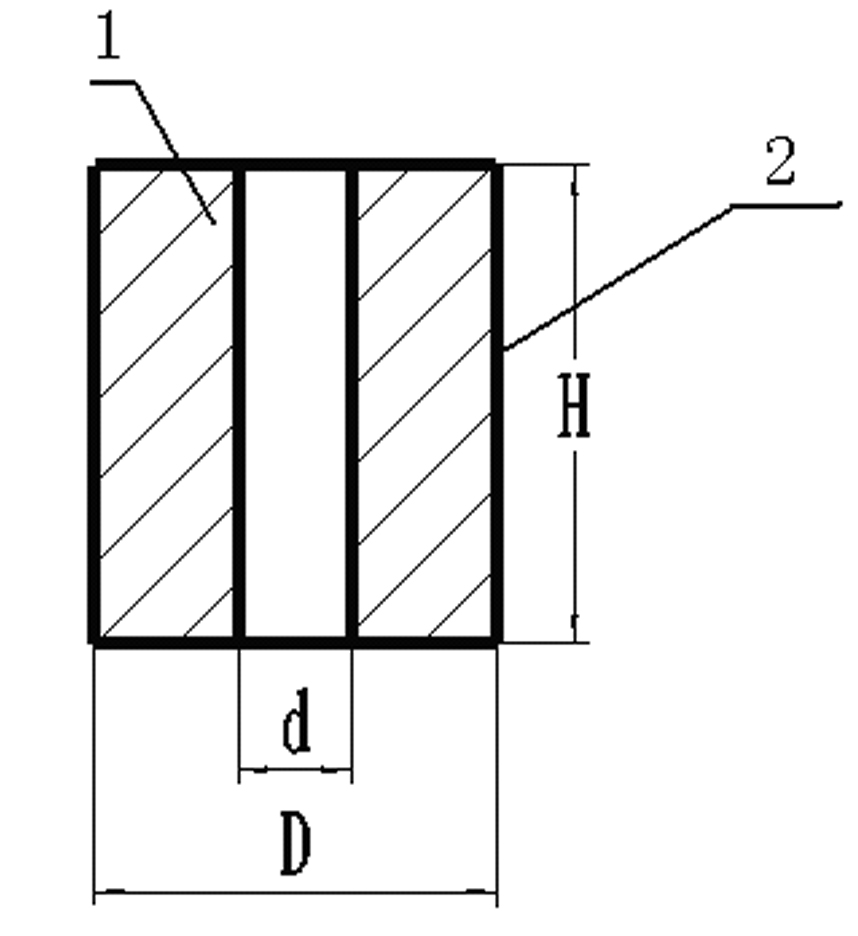

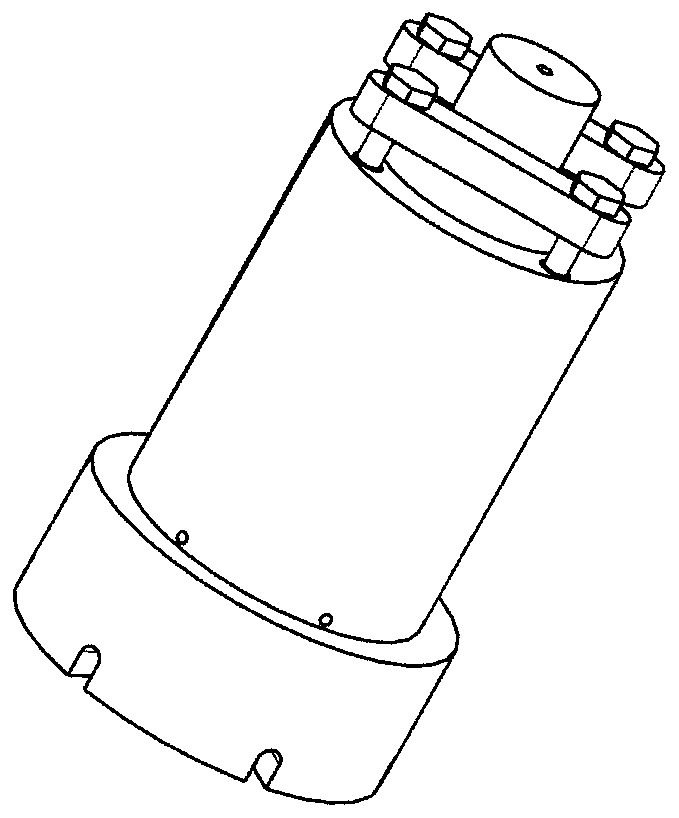

Miniature bonding permanent magnet and production method thereof

InactiveCN102005278AReduced loss of magnetic propertiesImprove magnetismPermanent magnetsInductances/transformers/magnets manufactureMagnetic energyLightness

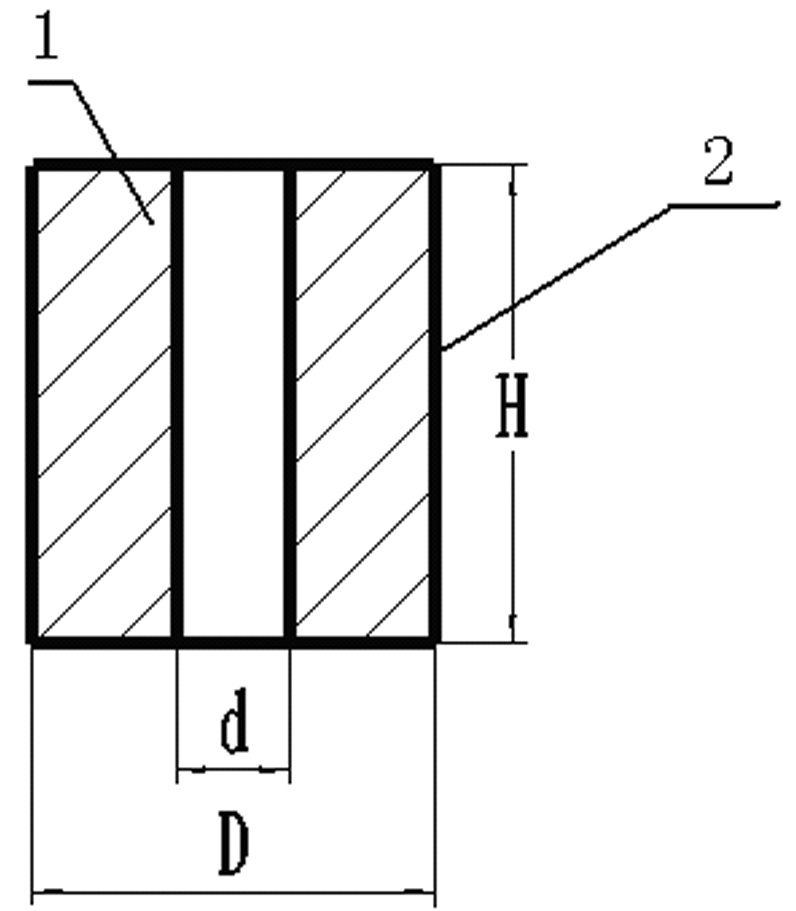

The invention relates to a miniature bonding permanent magnet and a production method thereof. The miniature bonding permanent magnet is a cylinder formed by a one-step formed cylindrical magnetic compact and an anticorrosion coating on the surface of the magnetic compact, wherein the cylindrical inner diameter of the cylindrical magnetic compact is 0.2-1.2 mm, the cylindrical outer diameter is 0.8-3.8 mm, and the height is 0.3-10 mm; and the thickness of the anticorrosion coating is 0.1-25 mum. The maximum magnetic energy product (BH) max of the miniature bonding permanent magnet can reach 76-216 kJ / m<3>. Compared with the traditional miniature bonding permanent magnet, the magnetic property of the miniature bonding permanent magnet is greatly improved, the size of the miniature bonding permanent magnet is greatly reduced, and the precision of the miniature bonding permanent magnet is further higher than that of the present magnet. The experiments shows that the miniature bonding permanent magnet can meet the newest requirements of lightness and thinness of digital cameras and video cameras.

Owner:湖南航天稀土磁有限责任公司

Casting mold surface treatment method and casting mold using said method

ActiveUS20110133053A1Reduced effectivenessLose their effectivenessMaterial nanotechnologyFullerenesCarbon filmCarbon nanotube

A surface treatment method includes covering a surface of a casting mold with a carbon film containing at least one type of nanocarbon selected from the group of carbon nanocoils, carbon nanotubes and carbon nanofilaments, and further applying fullerenes to that surface. With this surface treatment method being performed on a surface (a cavity surface, etc. of a casting mold) making contact with a molten casting material such as aluminum, etc., sticking of the molten casting material to the mold is inhibited, release resistance of the product is reduced, and release effectiveness is improved. The release effectiveness lasts longer than in the case of a conventional carbon film.

Owner:TOYOTA JIDOSHA KK +1

Production method of porous insulating block

ActiveCN102294730ASolve the technical problems of automated productionRealize automated productionCeramic shaping apparatusProduction lineMaterials science

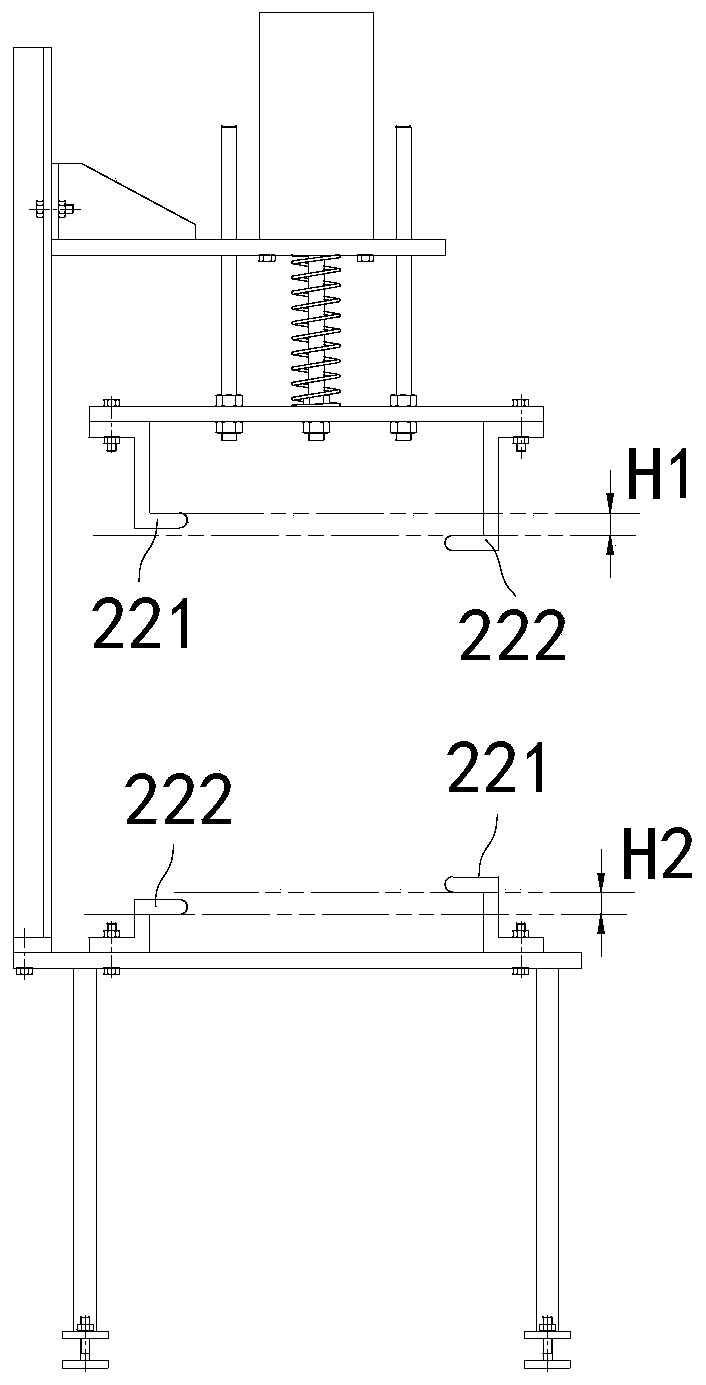

The invention discloses a production method of a porous insulation block. The production method is characterized in that production is carried out on a block production line with a conveying device by utilizing a split-type mould, wherein the mould comprise a male mould, a female mould and a support plate, the male mould is provided with a casting lug used for forming a hole of an insulation block, the male mould is arranged on the lower part of the conveying device of the building block production line, the support plate is provided with a hole matched with the casting lug on the male mould,the female mould is in a frame-type structure and can be assembled on the upper part of the support plate, and the male mould, the support plate and the female mould are assembled into a building block mould during production; then concrete is poured into the mould or hard concrete is placed and distributed in the mould; and then the concrete in the mould is evenly vibrated or shaken; and finallydemoulding is carried out, the male mould moves downward, the female mould moves upward, and the moulded insulation block is demoulded on the support plate of the conveying device. The production method disclosed by the invention is simple and has high production efficiency and good and stable product quality; and by using the production method, full-automatic flow line production can be realized.

Owner:山东七星实业有限公司

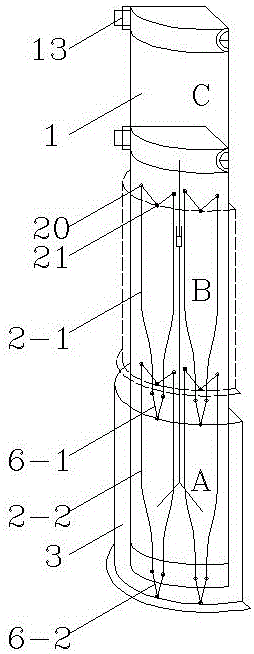

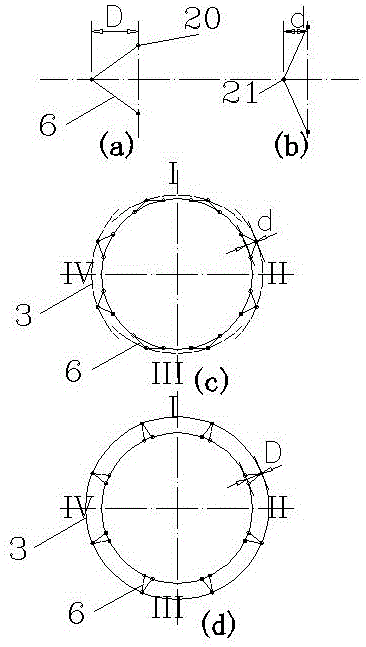

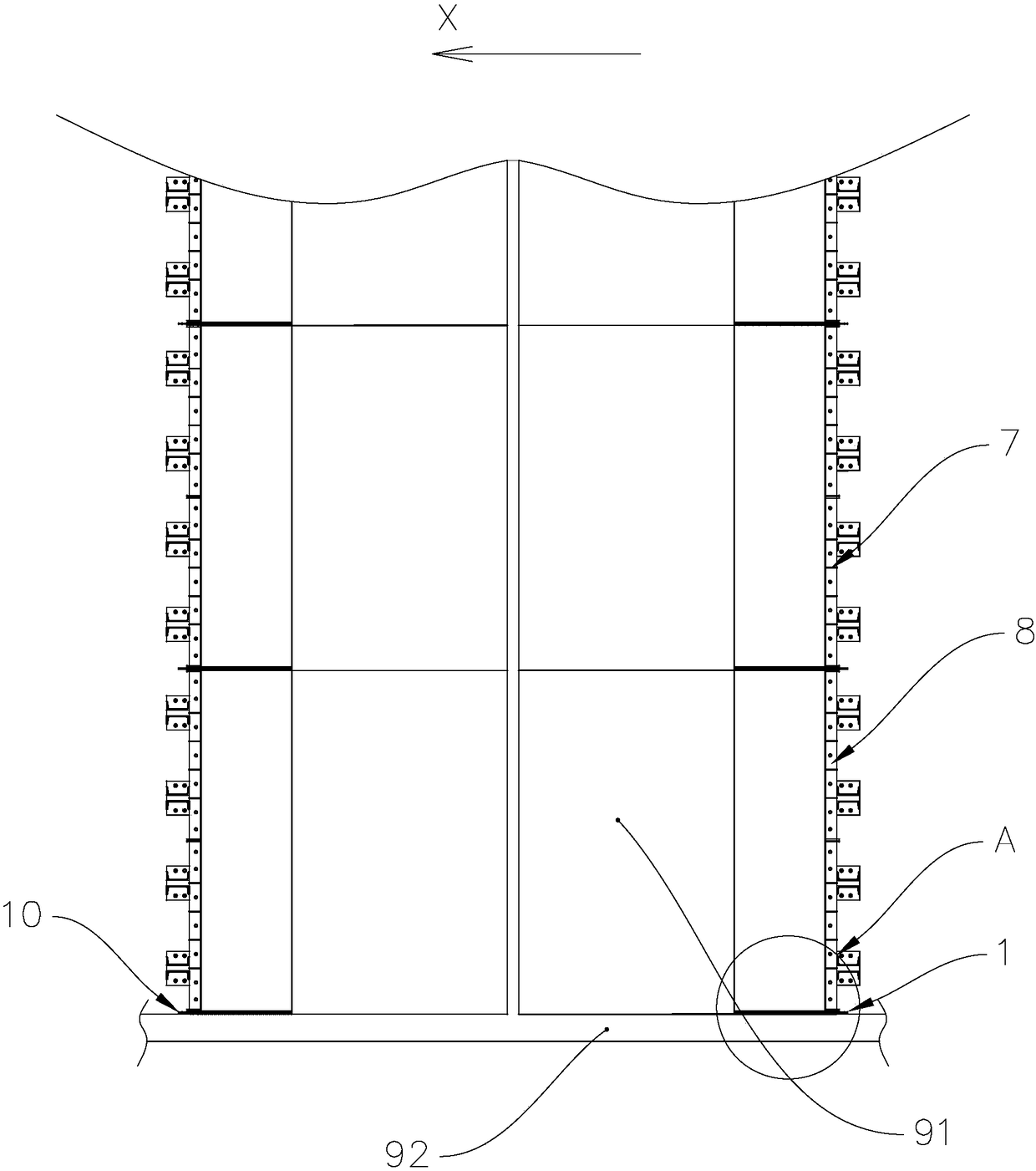

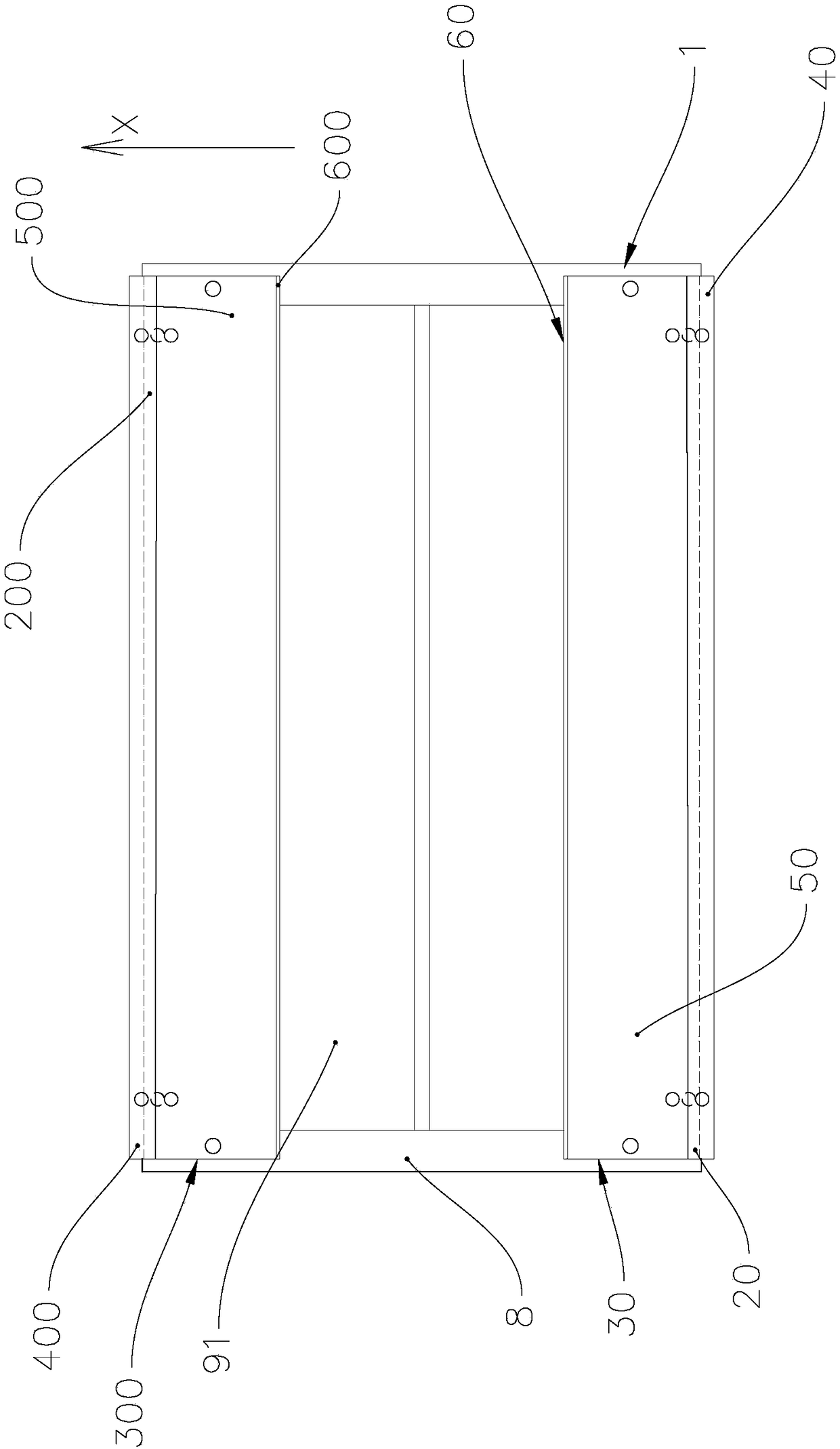

Wall building formwork applicable to intelligent construction of vertical shaft

ActiveCN106351673ASimple structureReduce demoulding resistanceUnderground chambersTunnel liningMeasurement pointStructural engineering

The invention discloses a wall building formwork applicable to intelligent construction of a vertical shaft. The outer surface of the formwork is coated with a Teflon coating; a main body comprises a core frame cylinder, curve sliding rails and segmental sliding forms, and formwork supporting and releasing actions of the segmental sliding forms are realized by the aid of radial contraction indirectly produced by vertical traveling of the segmental sliding forms in the longitudinal direction through the curve sliding rails. Leveling and centering of the formwork are subjected to servo adjustment by corresponding hydraulic oil cylinders after pose determination by sensors, and circularity regulation is not needed. The formwork has basic function of a concrete pouring envelop structure as well as capacity of monitoring and evaluating the quality and an evolution process of cast-in-place concrete by means of setting of pressure, temperature, moisture and ultrasonic measurement points on the outer surface of the formwork. The formwork has the characteristics of being reasonable in structure, reliable in work, quick in action and capable of performing automatic centering and leveling and evaluating the pouring quality of the concrete in real time, and realizes intelligence of the construction process of the vertical shaft.

Owner:CHINA UNIV OF MINING & TECH

Quick-drying mold release agent for resin sand casting mold and preparation process thereof

ActiveCN104117627AEasy to useHigh casting productivityFoundry mouldsFoundry coresEthyl acetateStearic acid

The invention discloses a quick-drying mold release agent for a resin sand casting mold and a preparation process thereof. The mold release agent comprises the components by the mass percentage: 5-10% of low-melting-point paraffin, 1-5% of rosin, 1-5% of stearic acid, 0.5-3% of polyethylene wax, 0.5-5% of vaseline, 0.1-1% of JFC, and the balance a mixed solvent, wherein the mixed solvent is a mixture of ethyl acetate and dichloroethane. The mold release agent is used for mold release of the resin sand casting mold, has a significant lubricating effect, can significantly reduce mold release resistance, prolongs the service life of a model, and makes the casting production rate higher. Moreover, the mold release agent is clean and neat, is beneficial for improving a working environment, is safe to human bodies, can achieve one-time coverage and multiple consecutive mold release, and makes the casting production rate higher. The use of the mold release agent can greatly improve the production rate, and the mold release agent has good economic benefits.

Owner:CHINA ENERGY CONSTR GRP SHAANXI ELECTRIC POWER DESIGN INST CO LTD

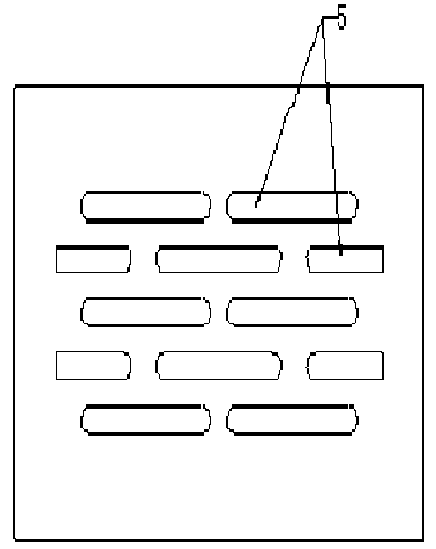

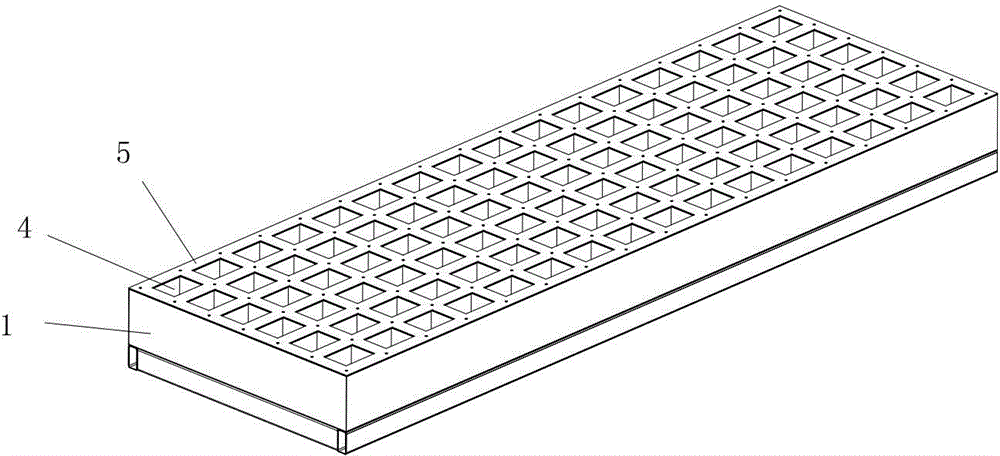

Easy-to-release anti-blocking original-side ceramic tile forming mould

ActiveCN104647573APrecise size controlPrevents stasis and even cloggingCeramic shaping apparatusBrickMaterials science

The invention discloses an easy-to-release anti-blocking original-side ceramic tile forming mould and belongs to the technical field of powder forming. The easy-to-release anti-blocking original-side ceramic tile forming mould comprises an upper mould core, side plates and a lower mould core which define a mould cavity. The easy-to-release anti-blocking original-side ceramic tile forming mould is characterized in that a ventilating path and a plurality of gas vent holes are formed in the upper mould core, wherein one end of each gas vent hole is communicated with the bottom surface of the upper mould core, the other end of each gas vent hole is communicated with the ventilating path, the ventilating path is connected with a gas exhausting branch and a gas blowing branch; the side plates comprise long side plates and short side plates which are enclosed in two adjacent long side plates, wherein first inclined positions which are outwards inclined from top to bottom are formed in the inner walls of the long side plates and the short side plates; second inclined positions are formed in the two ends of each short side plate; the long side plates and the short side plates can be tightly assembled together through the first inclined positions and the second inclined positions. A ceramic brick green body finished product pressed out by the forming mould does not need edging processing; moreover, in the pressing process, the gas exhausting system can be prevented from being blocked, the demoulding is easy to carry out and the mould is prevented from being blocked, so that the forming quality of the original-side ceramic tiles can be improved.

Owner:淄博沃德机械科技有限公司 +2

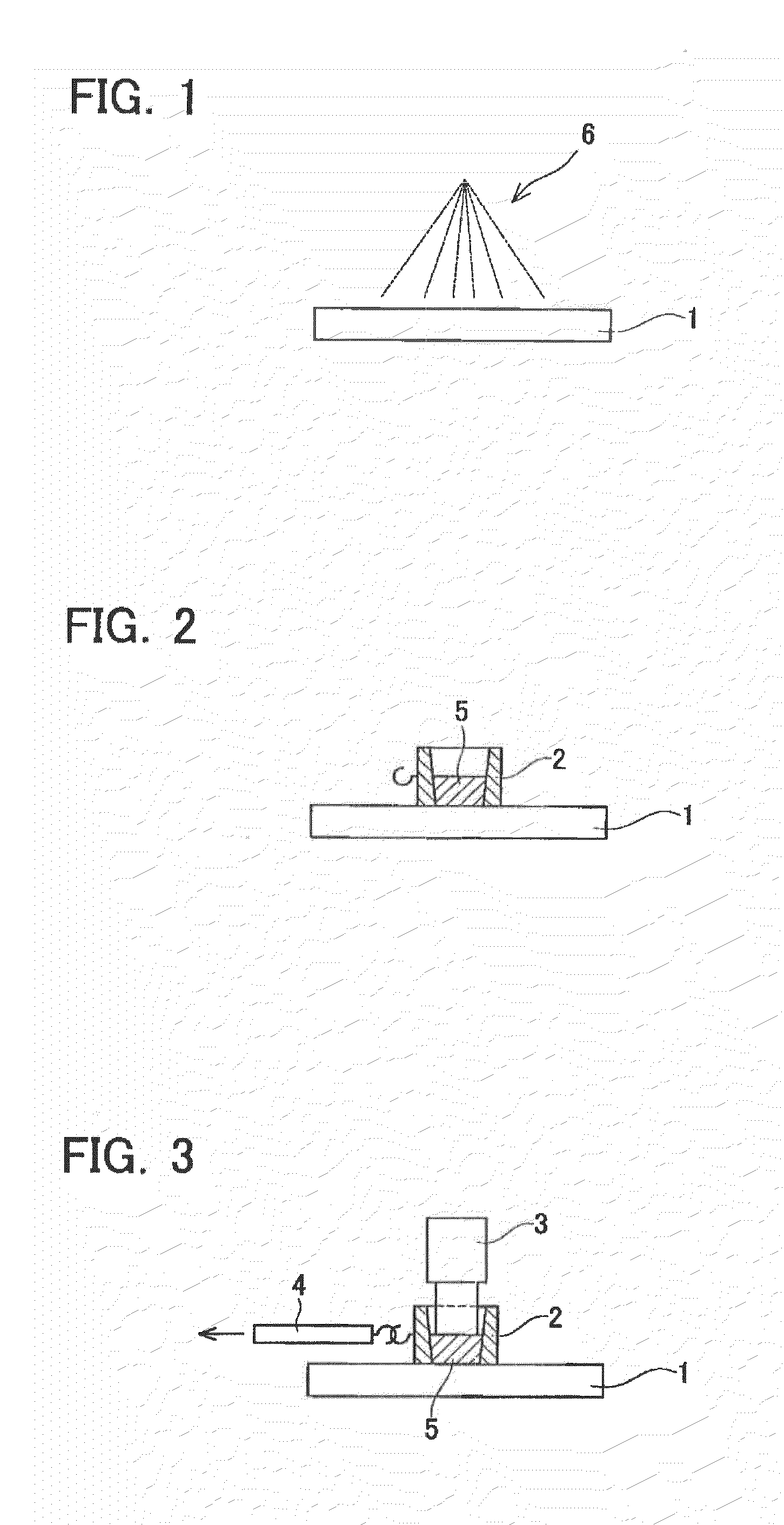

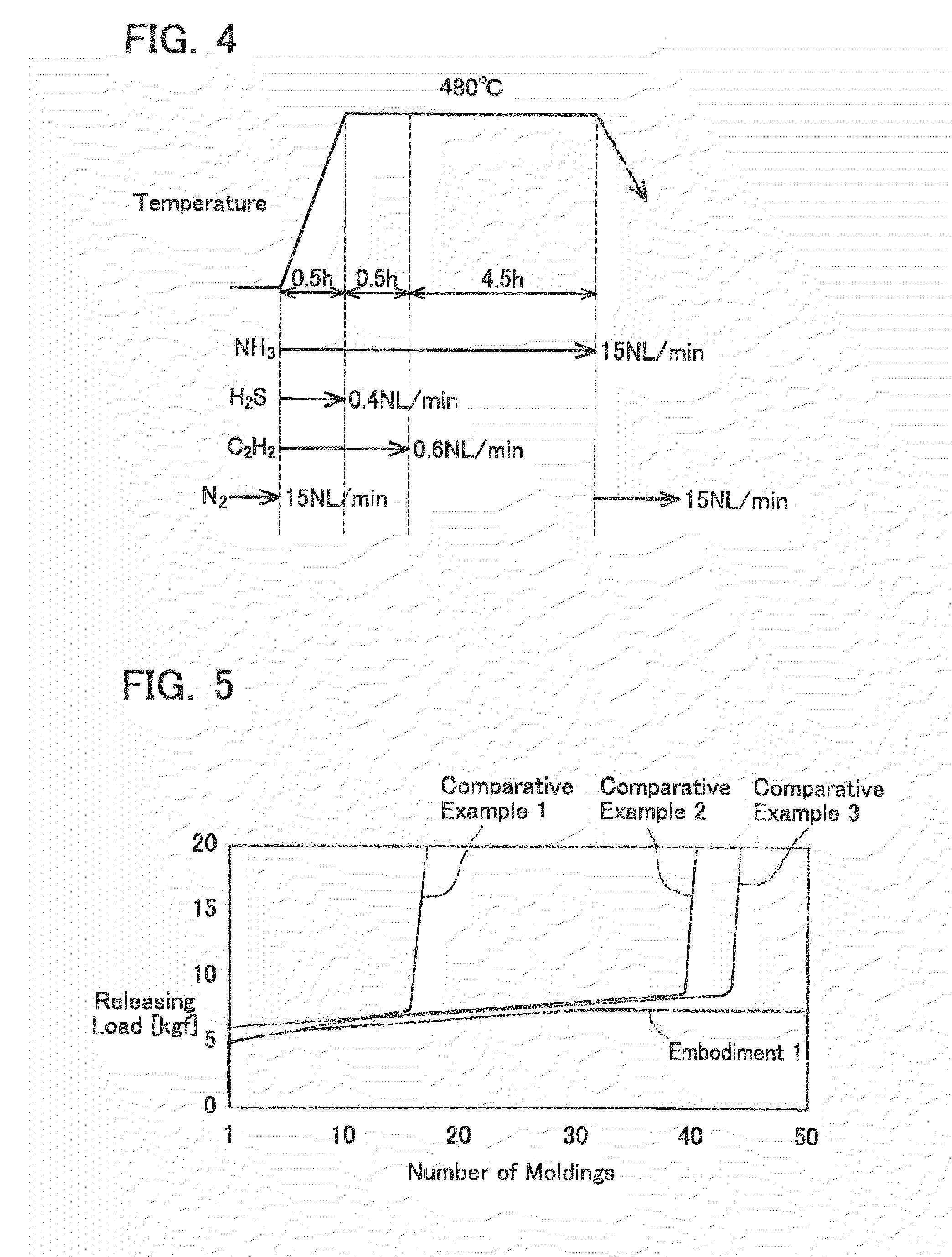

Mold Tool and Treatment Method for Mold Tool Surface

The average roughness Ra of a mold tool surface that comes into contact with a material to be molded measured for a measurement area 10 μm square or smaller is equal to or lower than 5 nm, and fine granular projection structures having diameters ranging from 10 to 80 nm and heights ranging from 10 to 40 nm are formed on the mold tool surface with a density of 400 / μm2 or higher. The frictional force due to the anchoring effect or the digging effect is reduced, and the adhesive force due to meniscus is also reduced. The release resistance is significantly reduced without affecting the dimensional precision of a fine molded product.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

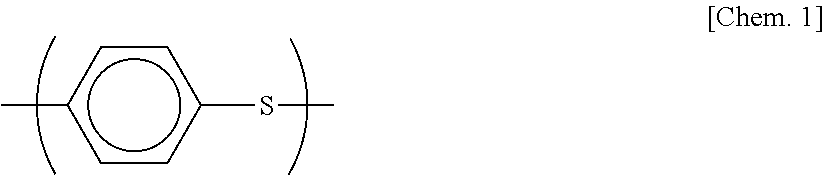

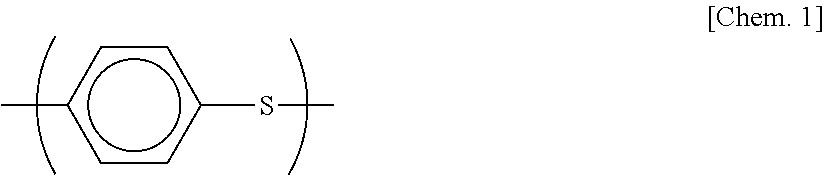

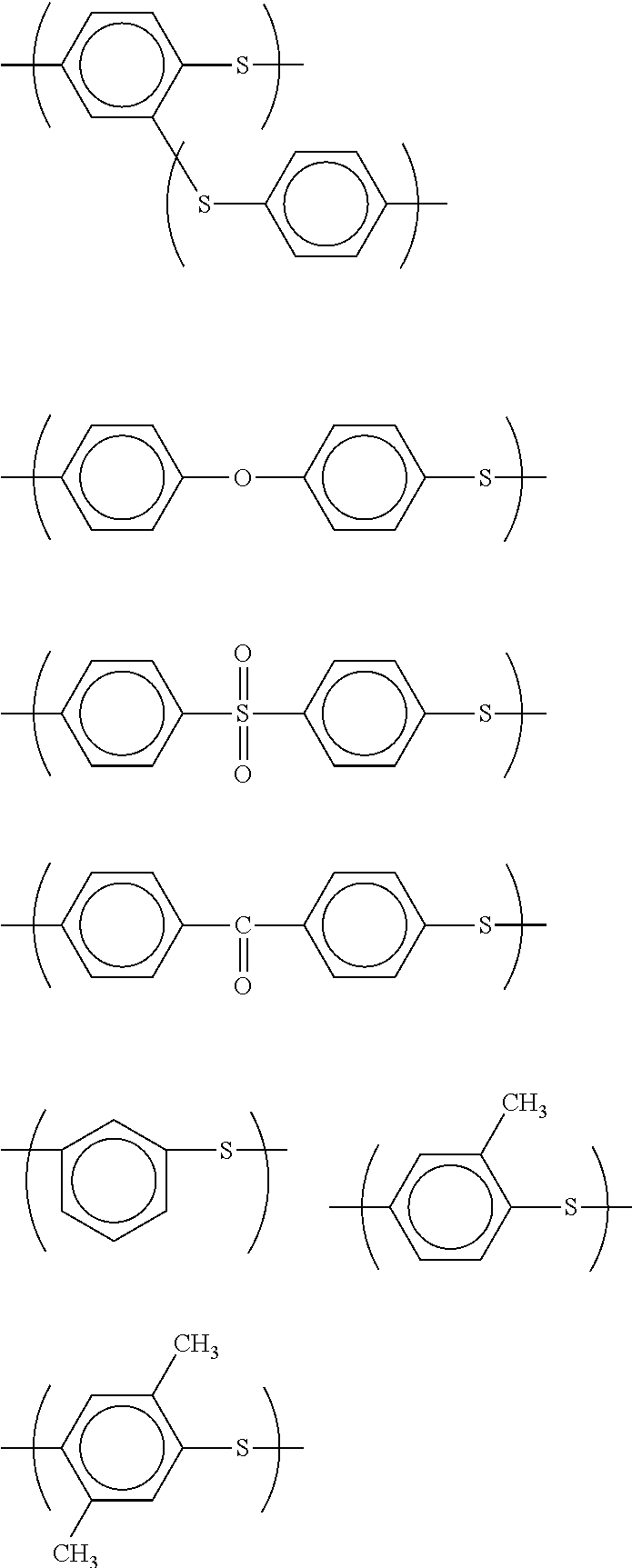

Polyphenylene sulfide resin composition and molding comprising same

ActiveUS9074096B2Increase resistanceReduce demoulding resistanceSemiconductor/solid-state device detailsSolid-state devicesWaxElastomer

The invention provides a polyphenylene sulfide resin composition including: 1 to 100 parts by weight of an olefin elastomer (B); and 0.01 to 10 parts by weight of a carboxylic acid amide wax mixture (C), relative to 100 parts by weight of a polyphenylene sulfide resin (A), wherein the carboxylic acid amide wax mixture (C) is obtained by adding 0.01 to 5 parts by weight of an antioxidant to 100 parts by weight of a carboxylic acid amide wax produced by reaction of a higher aliphatic monocarboxylic acid, a polybasic acid and a diamine.

Owner:TORAY IND INC

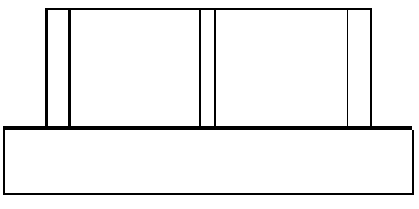

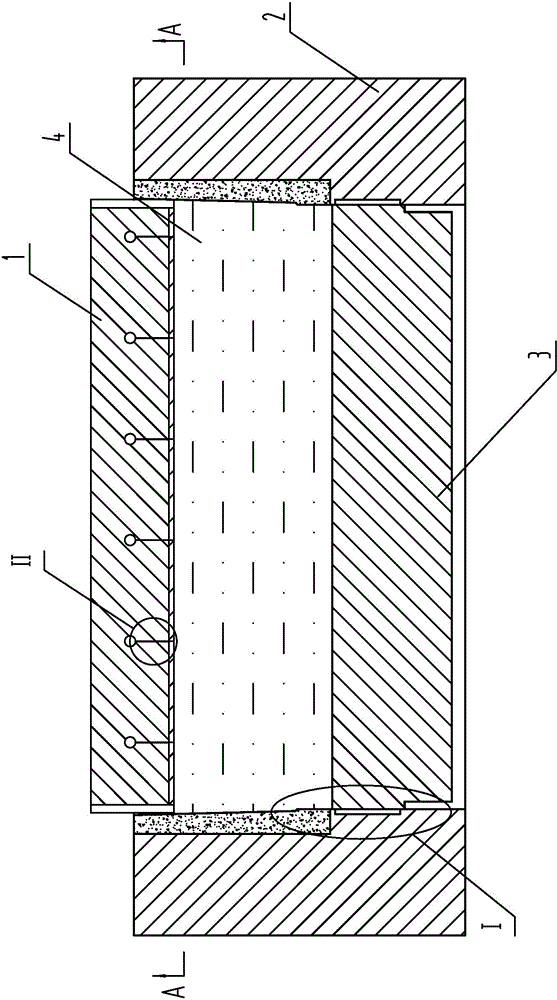

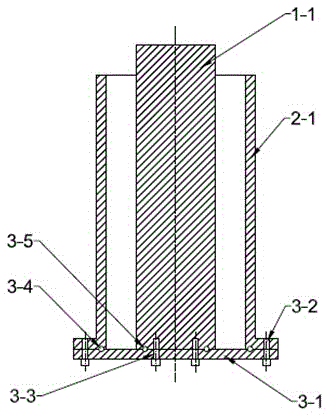

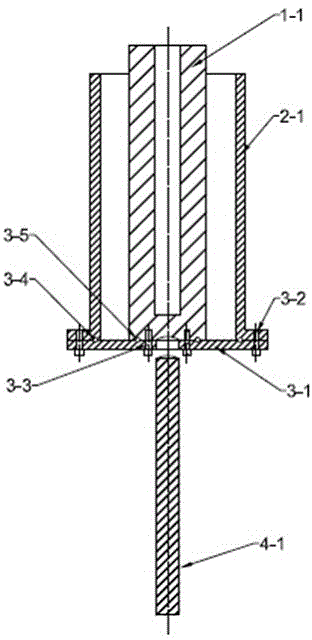

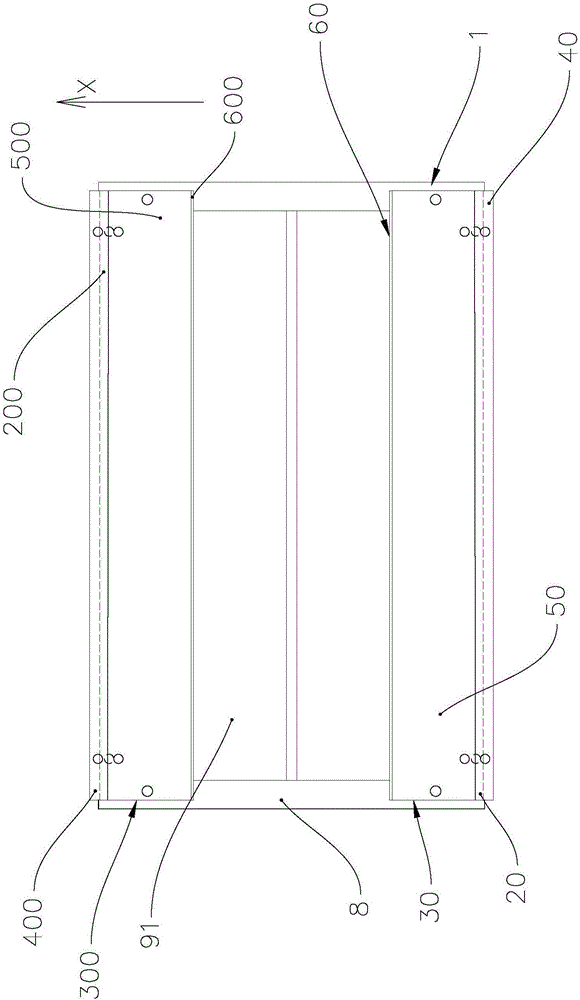

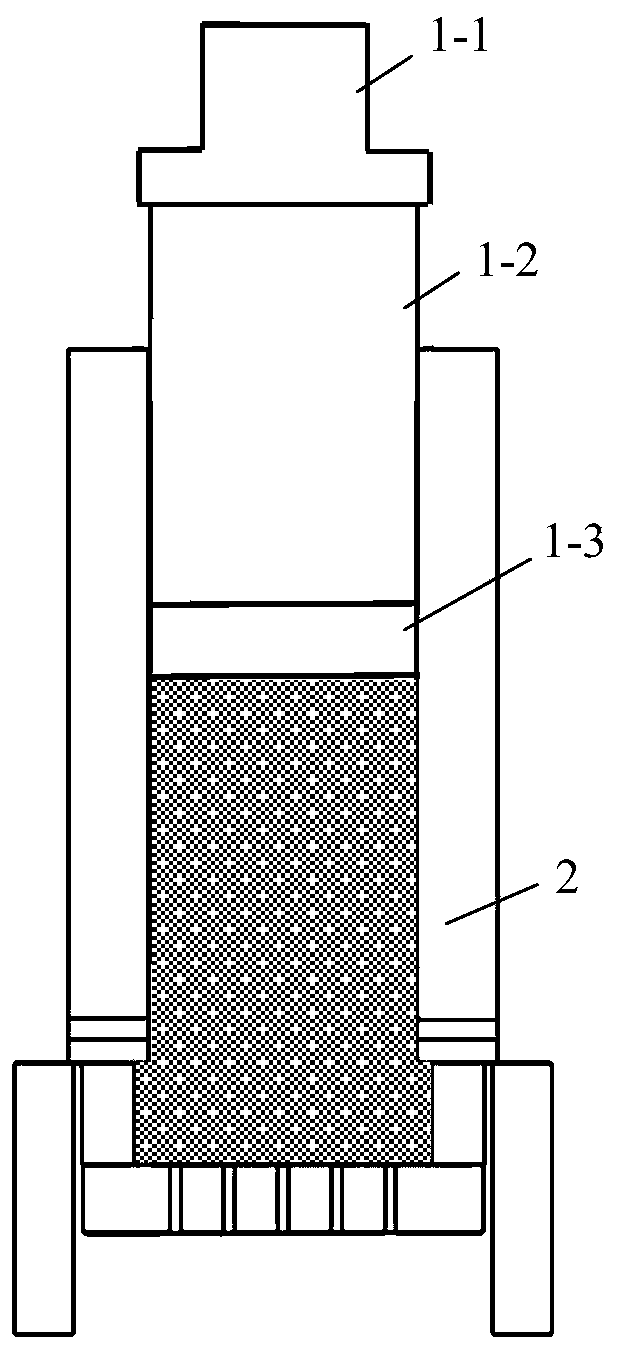

Die for preparing large-size tubular green bodies through gel casting

InactiveCN106313276AEasy to disassembleReduce demoulding resistanceSlip casting mouldsEngineeringGel casting

The invention discloses a die for preparing large-size tubular green bodies through gel casting. The die comprises a chassis, an outer die and an inner core. The outer die is detachably installed on the chassis. The outer die is provided with a cylindrical inner cavity. The inner core is located in the inner cavity of the outer die, and the inner core and the outer die are coaxially installed on the chassis. The space formed among the inner wall of the outer die, the outer wall of the inner core and the chassis is used as a die cavity where slurry is injected. The die for preparing the large-size tubular green bodies through gel casting is applied to the water-based gel casting technology and is convenient to disassemble and small in die removal resistance, and the green bodies are not likely to be deformed and cracked when dried.

Owner:HANERGY CO INNO MOBILE ENERGY INVESTMENT CO LTD

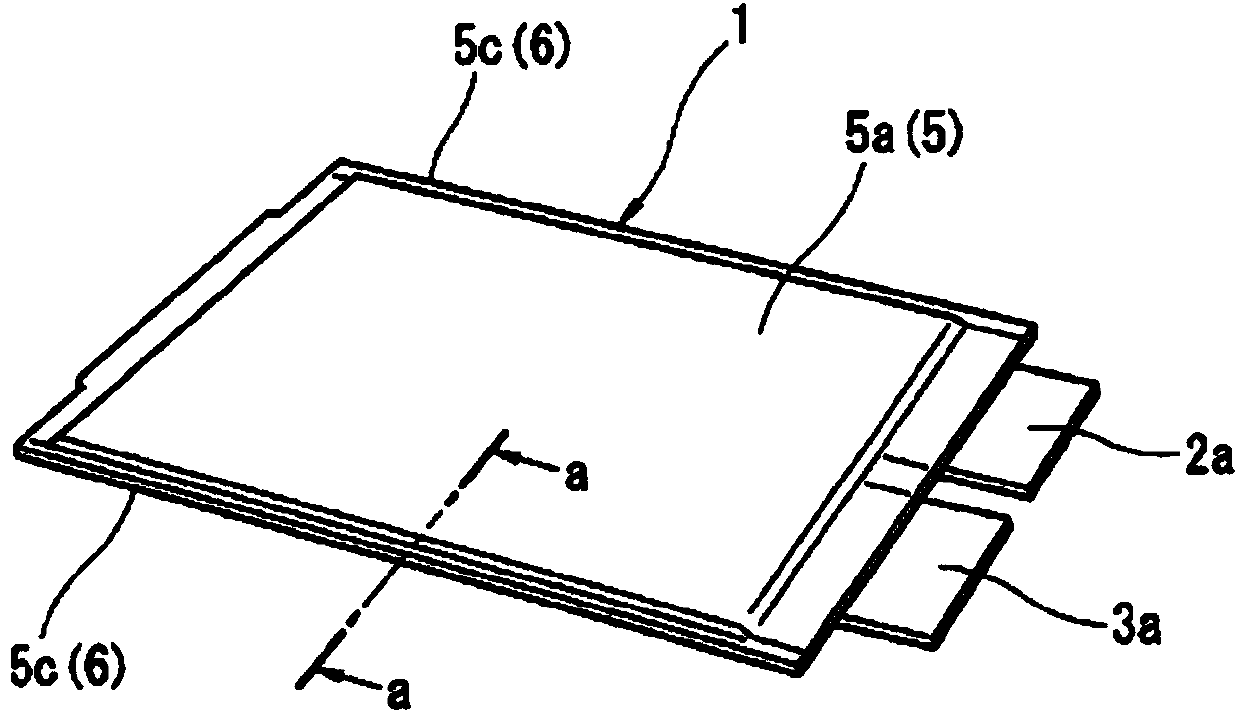

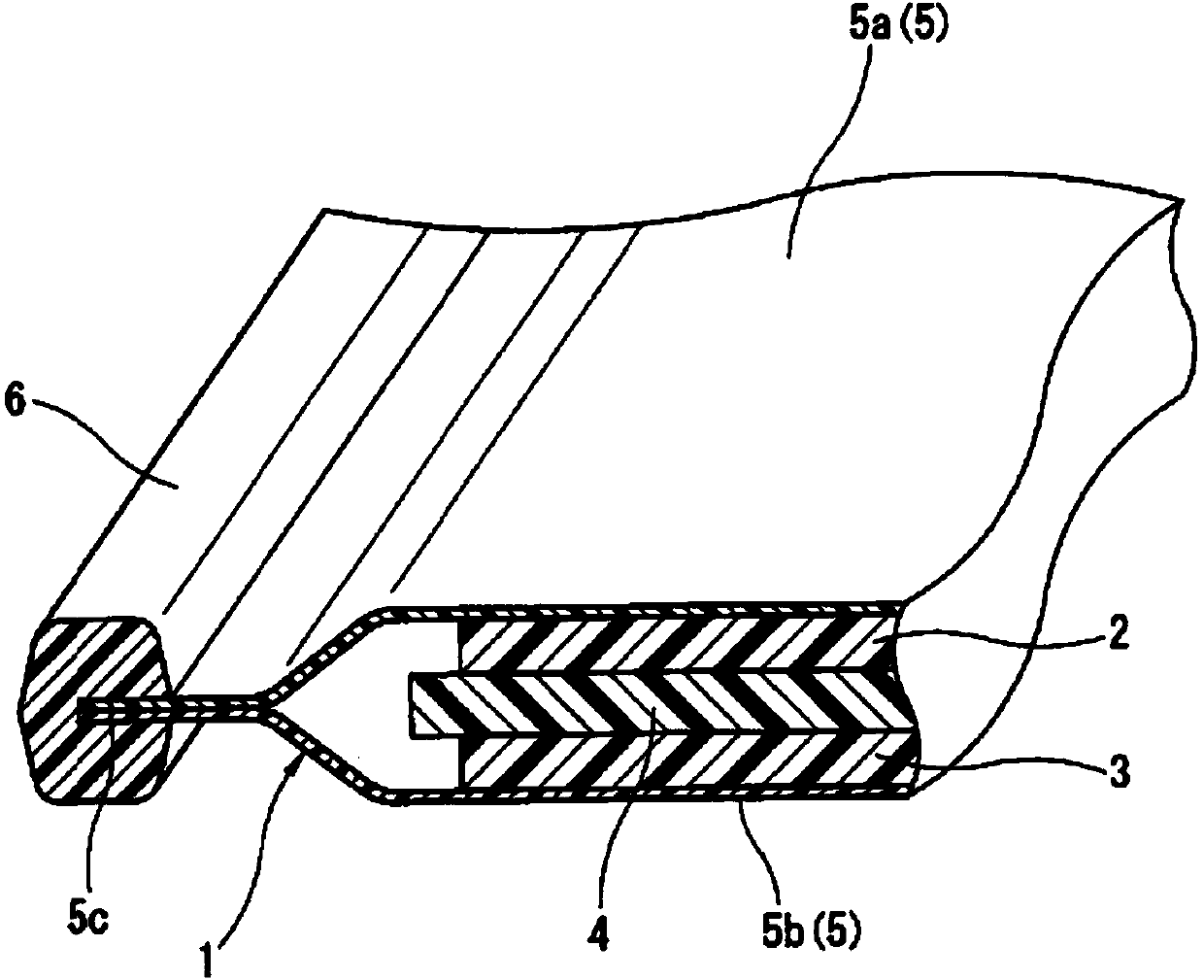

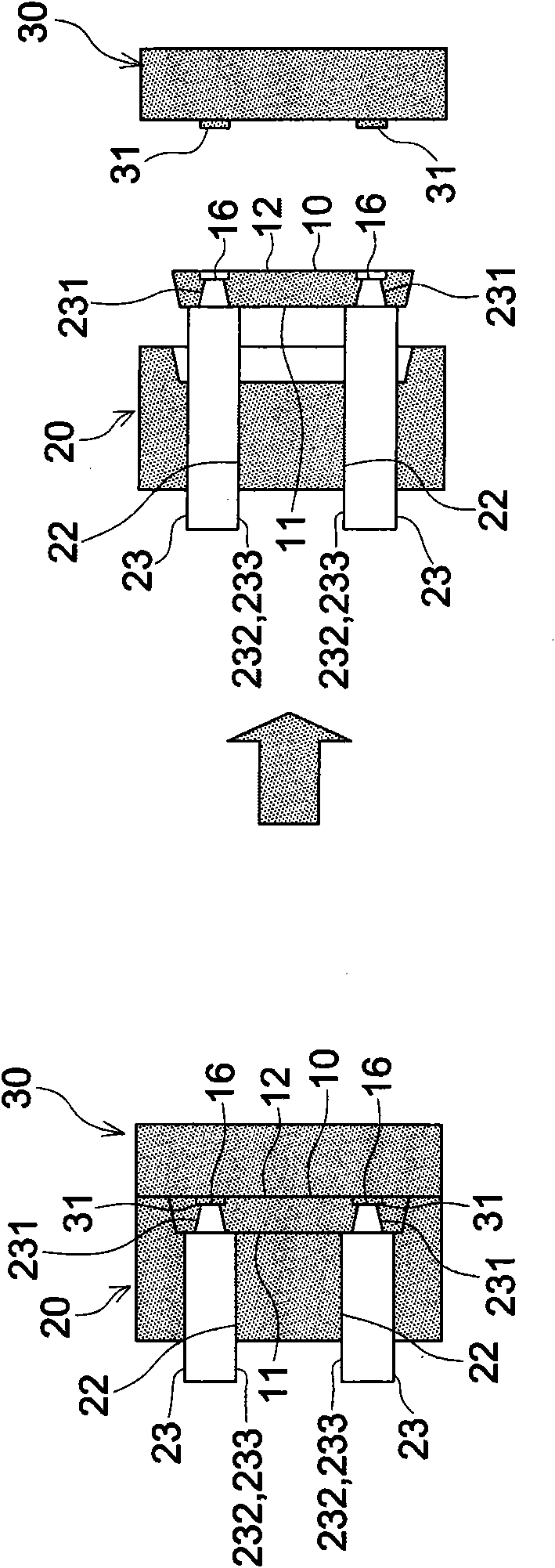

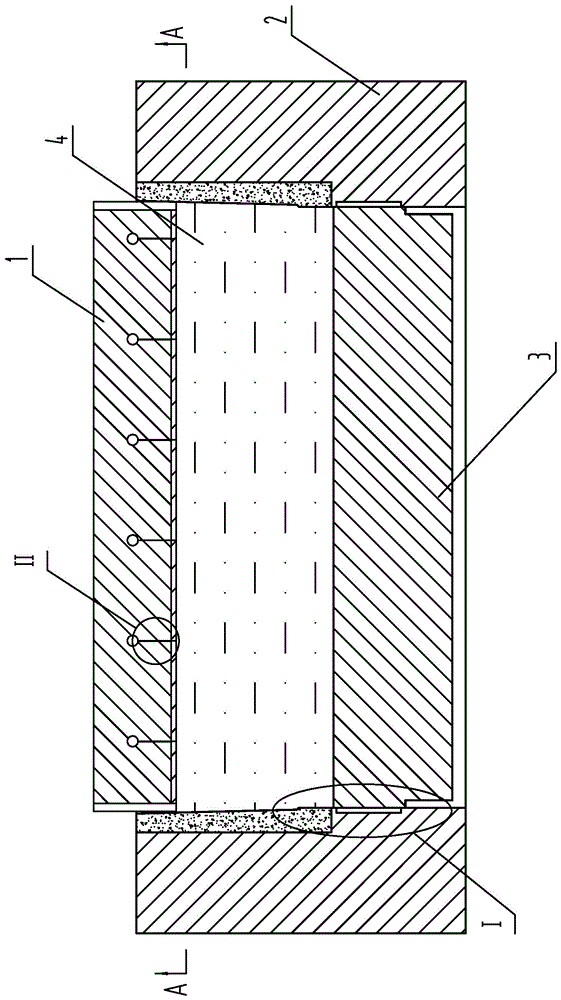

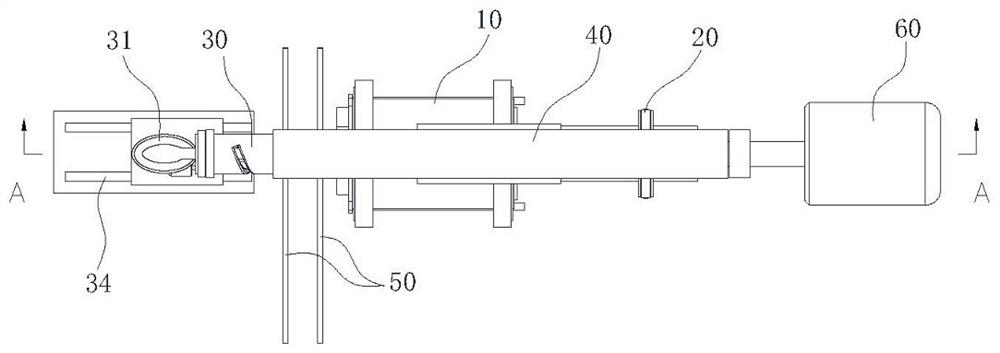

Fabrication method for laminated-type secondary battery

ActiveCN103875093AReduce contact areaImprove cooling effectFinal product manufactureSecondary cellsBead shapeHot melt

In the present invention, after filling or injecting a hot melt resin material into a product shaped space (12) in a metal mold (7) and before the hot melt falls below the softening point, compressed air from an air ejection port (14) is injected between the mold that isolates the product shaped space (12) and the surface of the hot melt resin layer. By means of the injection of compressed air, a "regress" is forcibly generated on the surface of the edge protector (6) thereby forming a concave section (Q), and at the same time a space (G) is formed between the hot melt and the mold surface. By doing this, the bead-shaped edge protector (6) is integrally formed by the thermoplastic hot melt resin material at a long-side thermal bonding part (5c) of a laminated-film housing case (5), thus improving mold releasability.

Owner:ENVISION AESC JAPAN LTD

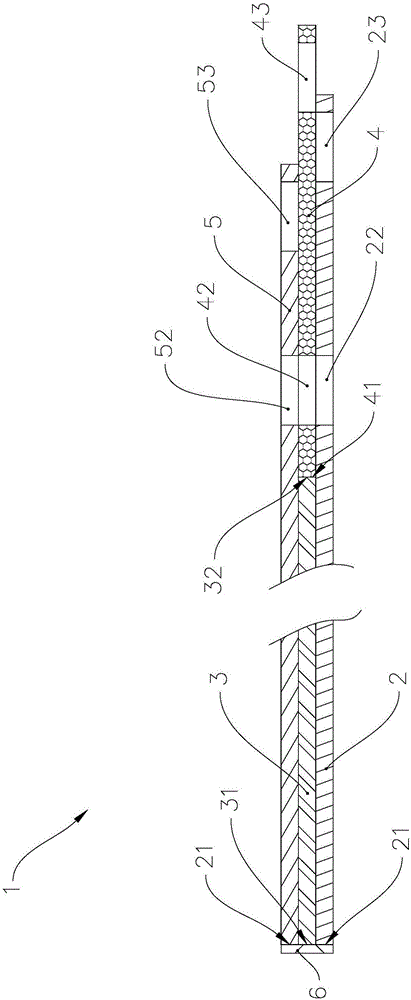

Pultrusion sectional material mould with embedded core mould

The invention provides a pultrusion sectional material mould with an embedded core mould. The pultrusion sectional material mould comprises an upper mould body, the core mould and a lower mould body. The upper mould is arranged on the lower mould, and the lower end face of the upper mould is attached to the top end face of the lower mould. A positioning groove is formed in the lower end face of the upper mould. The core mould is embedded in the positioning groove and the upper mould and is in connection with the upper mould through a first bolt. A plurality of demoulding bolt holes used for pushing out the core mould are uniformly formed in the upper mould. The upper mould and the lower mould are positioned through a positioning pin and connected through a second bolt. The upper mould, the core mould and the lower mould together form moulding grooves used for making a sectional material. Rectangular grooves are formed in end face mould close joint of the upper mould and the lower mould correspondingly, and corresponding rectangular grooves form mould opening grooves together. A plurality of temperature measuring holes are formed in the side of the upper mould. According to the pultrusion sectional material mould with the embedded core mould, the embedded core mould design is adopted, positioning is accurate, the number of the parting faces and the assembling faces are small, the assembling difficulty is low, the close joint is tight, and the special demoulding bolt holes for pushing out the core mould are designed to reduce the difficulty of taking out the core mould.

Owner:HENGSHEN

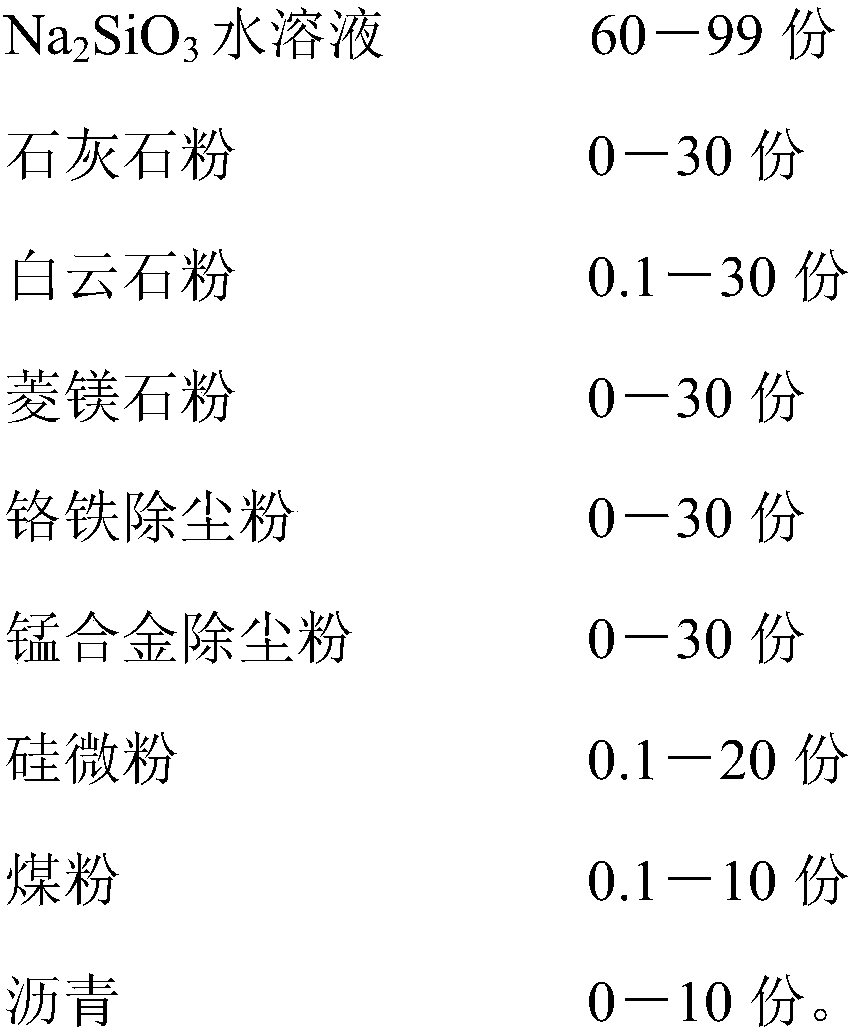

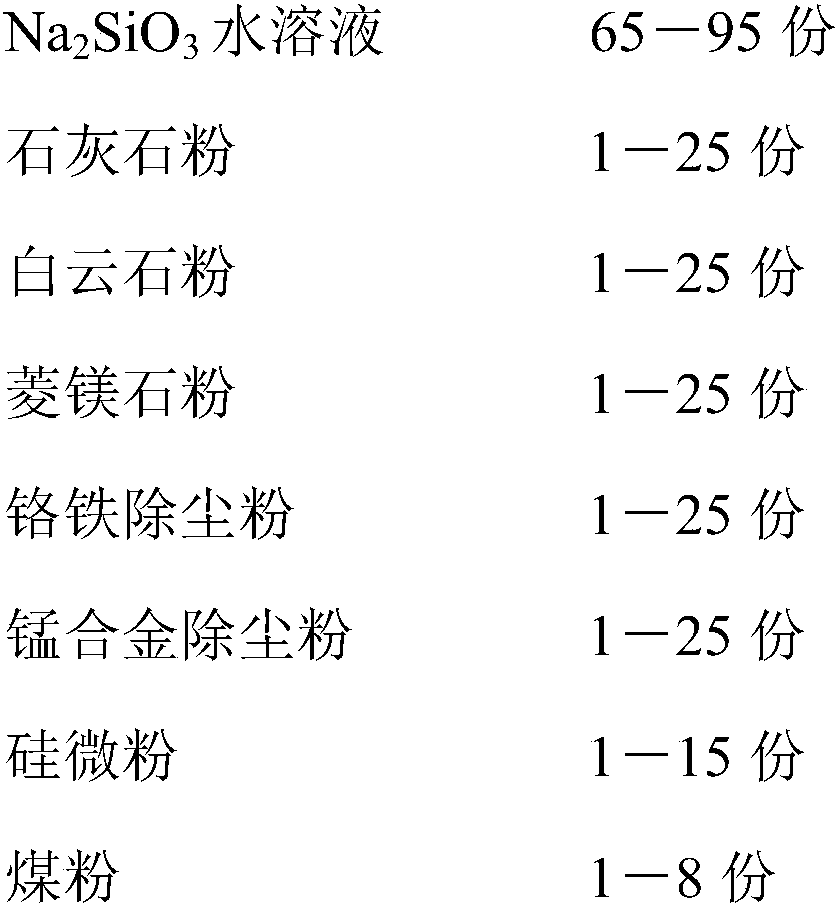

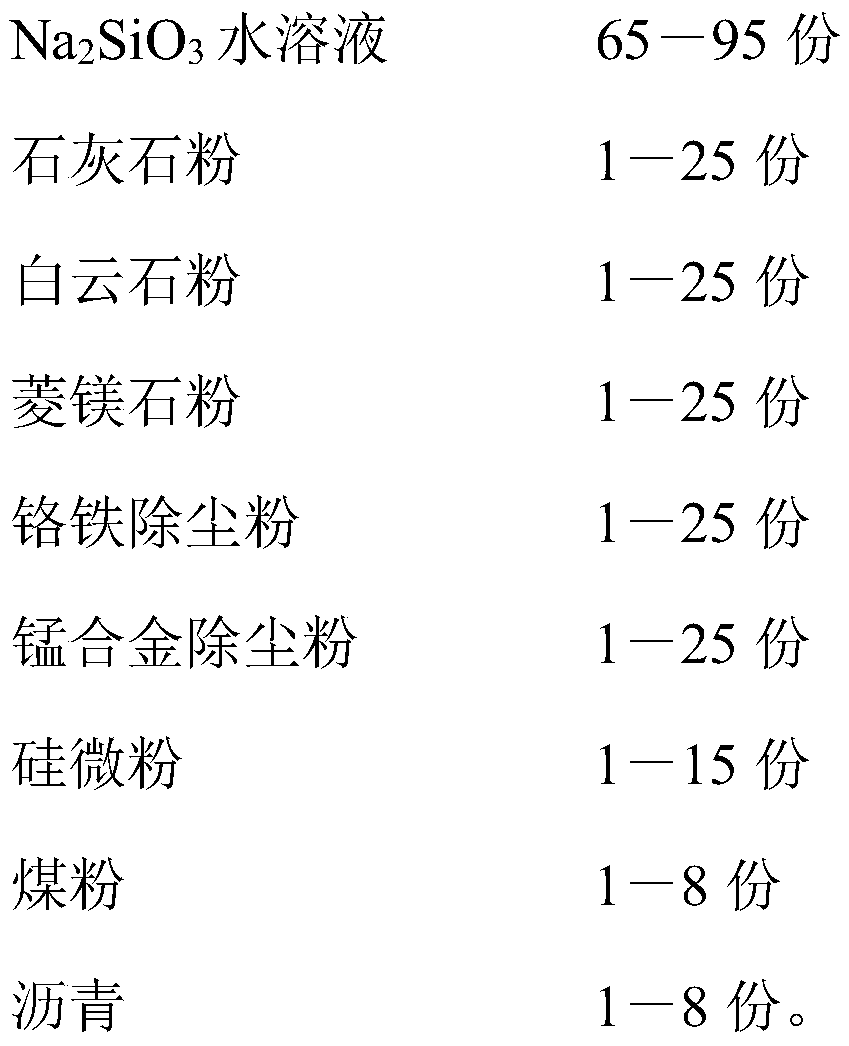

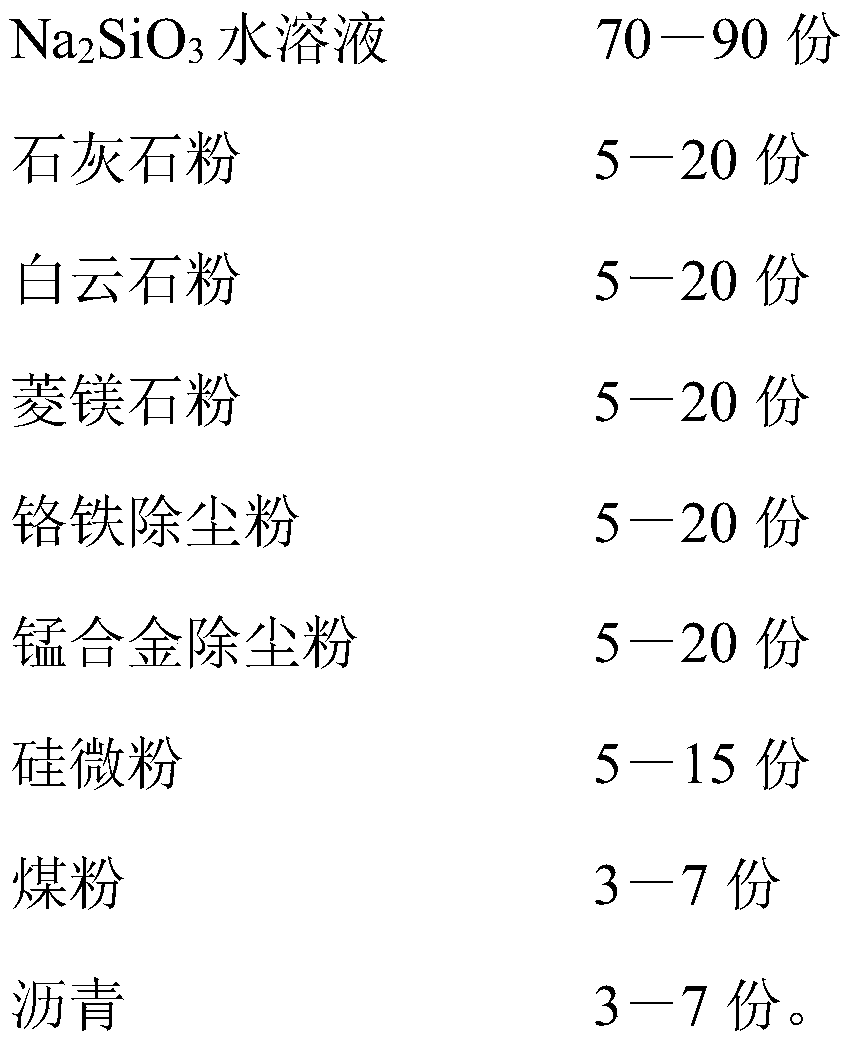

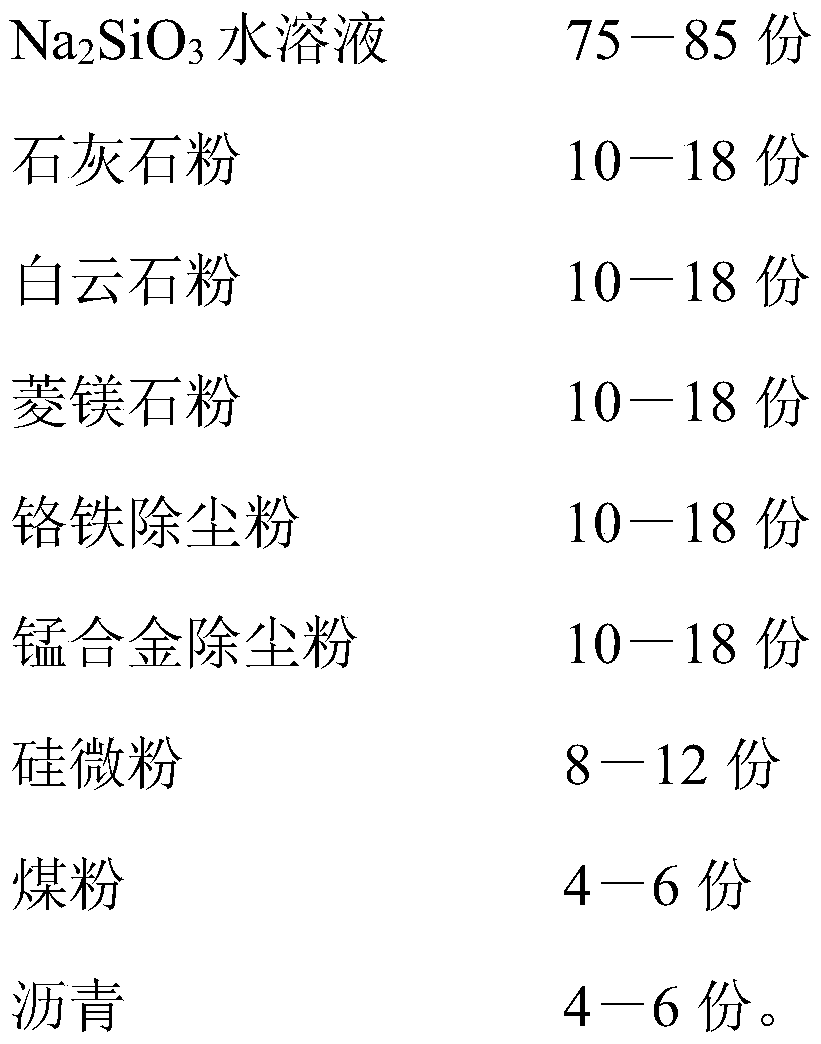

Metal mold environment-friendly coating for carbon ferroalloy casting based on oxidation-reduction reaction and preparation process thereof

ActiveCN108213328AEasily damagedCold crystallization is beneficialFoundry mouldsFoundry coresTinningHigh carbon

The invention relates to the technical field of coating, in particular to metal mold environment-friendly coating for carbon ferroalloy casting based on oxidation-reduction reaction and a preparationprocess thereof. The environment-friendly coating comprises, by weight, 0.1-30 parts of limestone powder, 0.1-30 parts of dolomite powder, 0-30 parts of magnesite powder, 0-30 parts of ferrochrome dust removal powder, 0-30 parts of manganese alloy dust removal powder, 0.1-20 parts of silica powder, 0.1-10 parts of pulverized coal and 0-10 parts of asphalt powder. The preparation process comprisesthe steps of grinding limestone powder and dolomite powder, diluting a Na2SiO3 aqueous solution, and conducting stirring, testing, tinning, and packaging. The environment-friendly coating is mainly used for the metal mould casting of ferroalloy with low carbon requirements, such as high carbon ferrochrome, high carbon ferromanganese and manganese silicon alloys, and the problems that a mold is stuck and the damage to the mold is serious in casting of the alloys are solved; and the preparation process is high in production efficiency and facilitates large-scale production.

Owner:上海宝叶冶金技术有限公司 +1

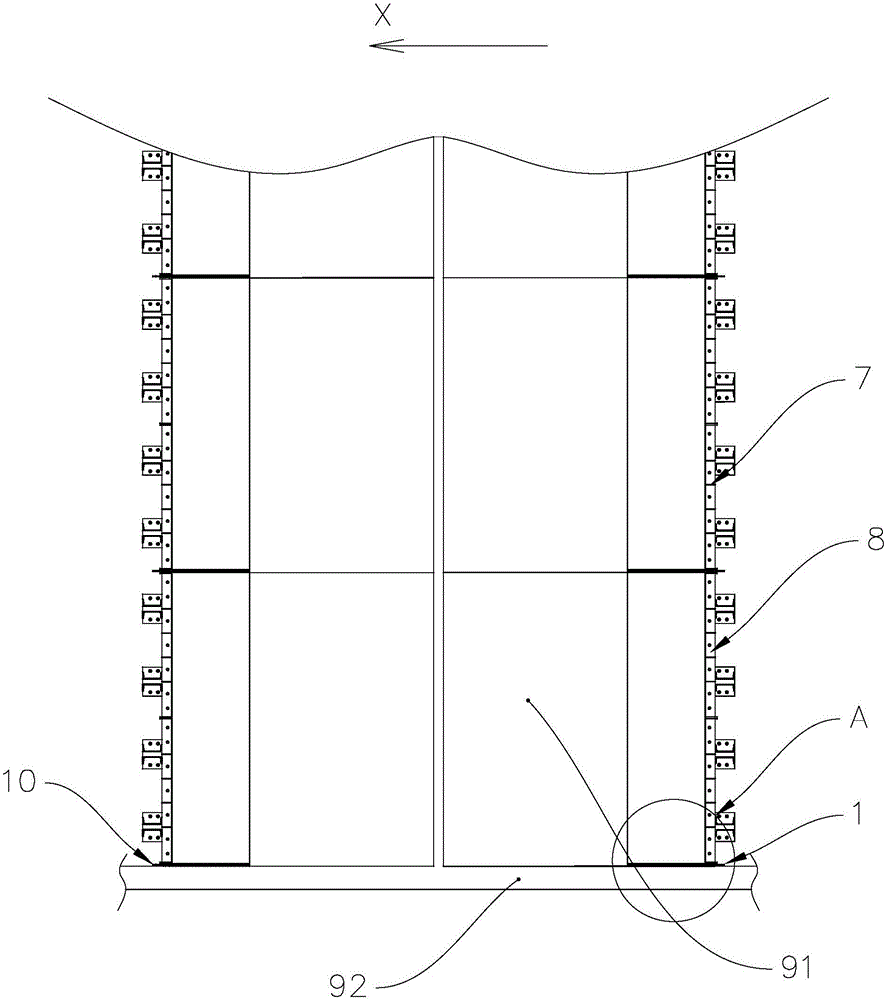

Flexible-pier horizontal separation seam construction method and construction device

ActiveCN106835988APrevent inflowEasy to demouldBridge structural detailsBridge erection/assemblyEngineeringEdge banding

The invention discloses a flexible-pier horizontal separation seam construction method and construction device. The flexible-pier horizontal separation seam construction device comprises a combined drawing plate, the combined drawing plate comprises bottom drawing plates, hard foam plates, edge sealing drawing plates and top drawing plates, the hard foam plates are positioned above the bottom drawing plates and adjacently connected with the bottom drawing plates, first side faces of the hard foam plates are flushed with second side faces of the bottom drawing plates, the edge sealing drawing plates are positioned above the bottom drawing plates and adjacently connected with the bottom drawing plates, third side faces of the edge sealing drawing plates are adjacently connected with fourth side faces of the hard foam plates, the fourth side faces and the second side faces are oppositely arranged, the top drawing plates are positioned above the hard foam plates and the edge sealing drawing plates and adjacently connected with hard foam plates and the edge sealing drawing plates, fifth sides of the top drawing plates are top drawing plates are flushed with the first side faces. The construction method and the construction device have the advantages of deep seam, high seaming accuracy and good seaming accuracy.

Owner:GUANGZHOU ENG CO LTD OF CHINA RAILWAY 19TH BUREAU GRP

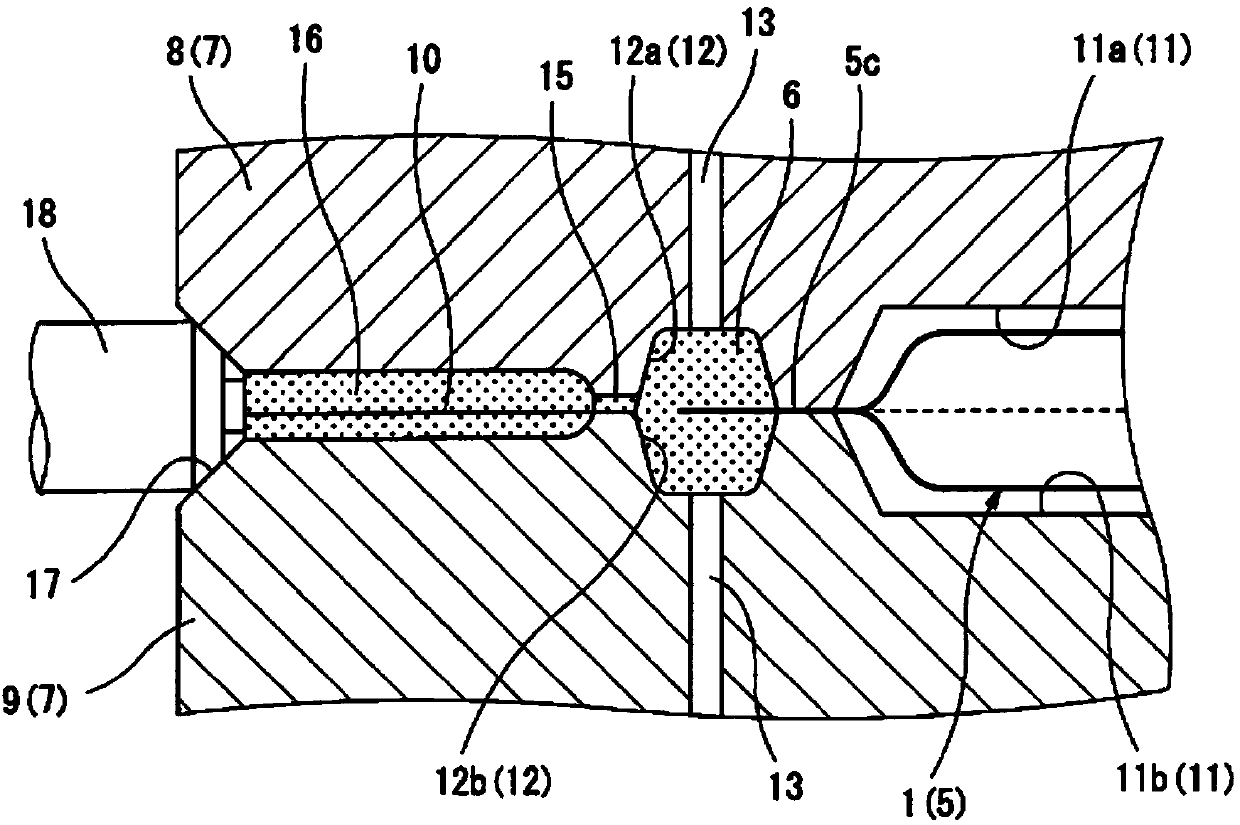

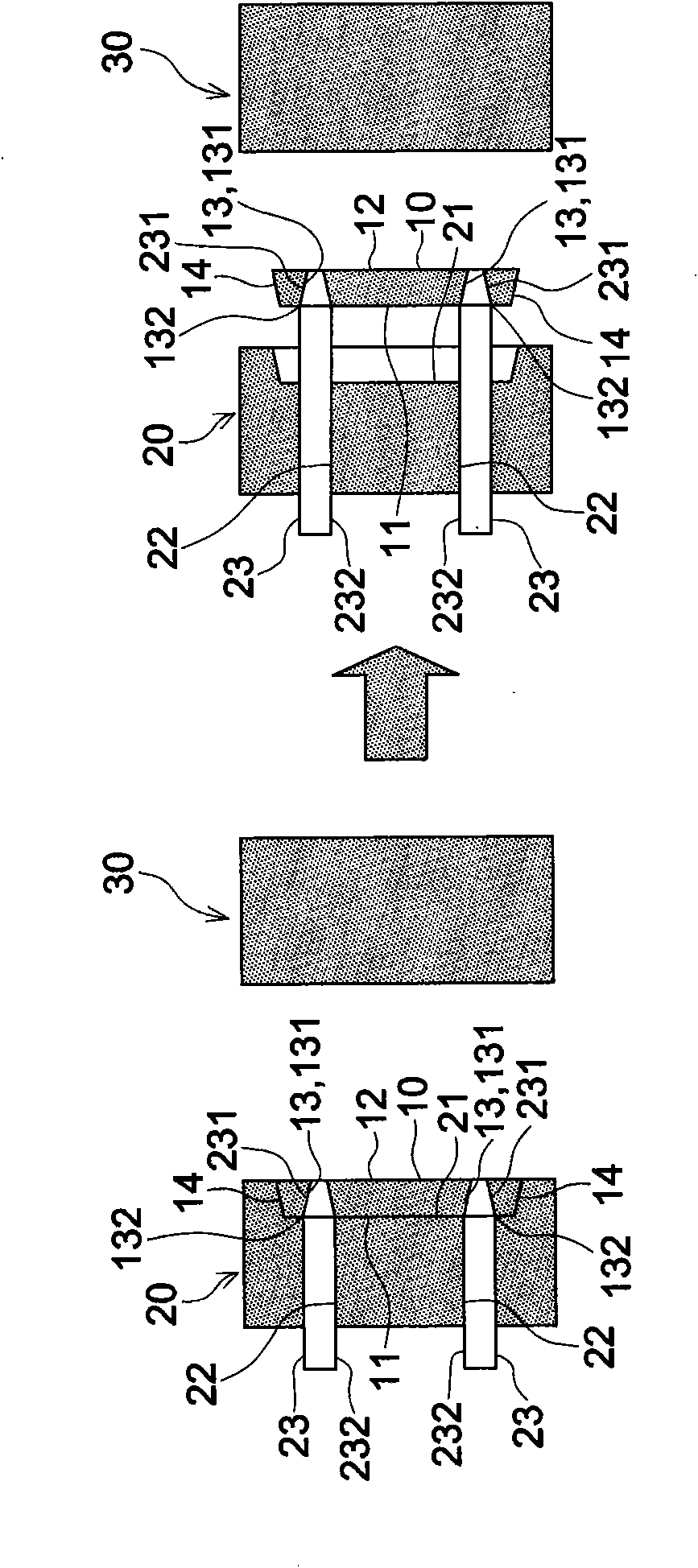

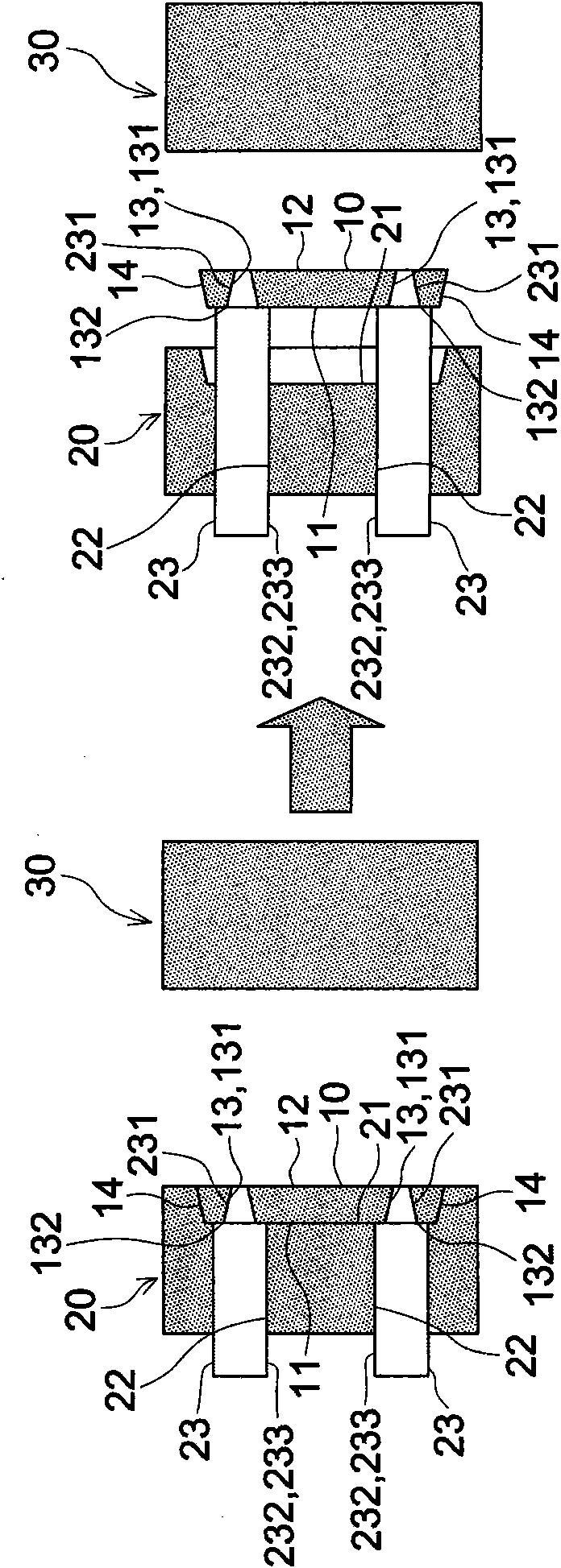

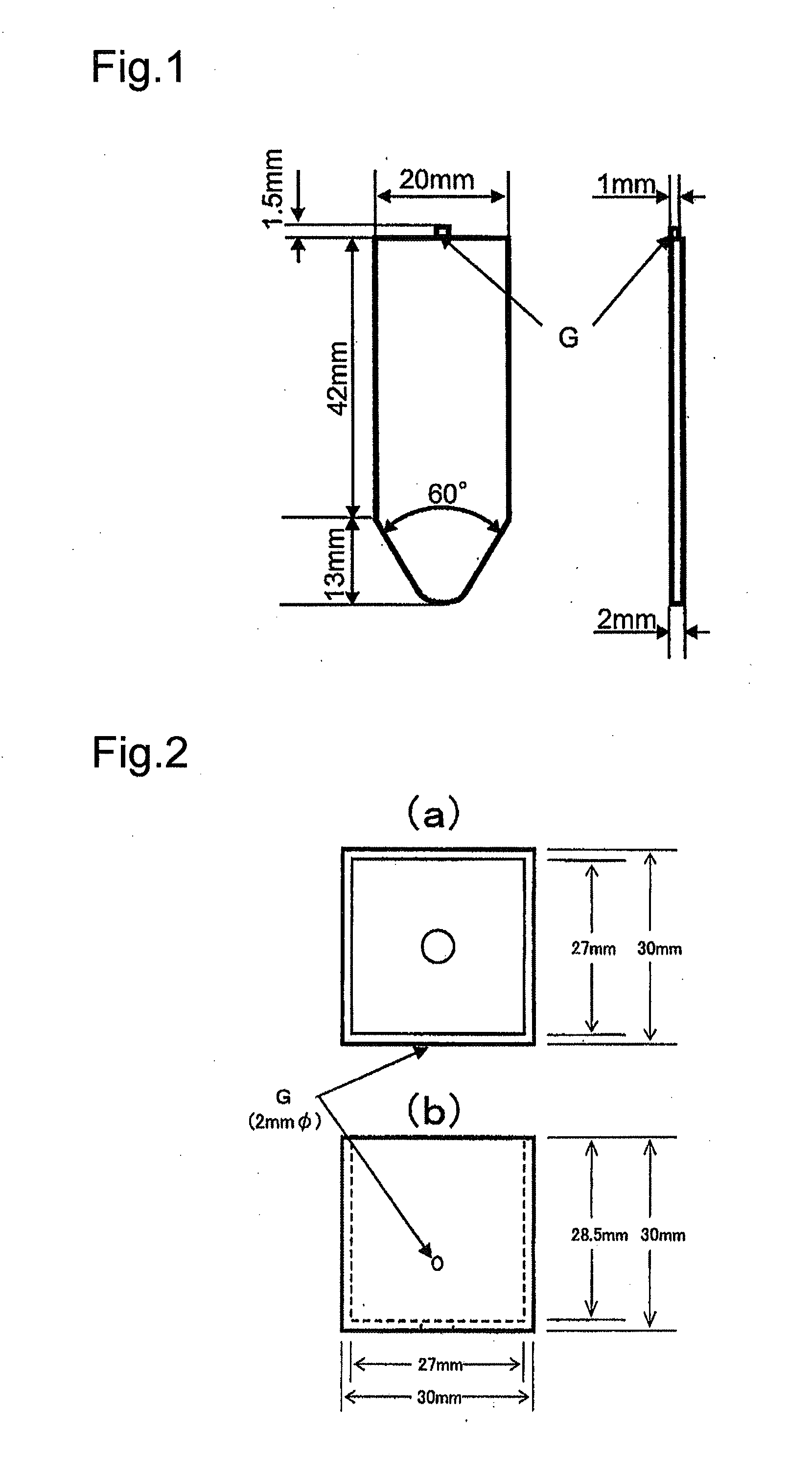

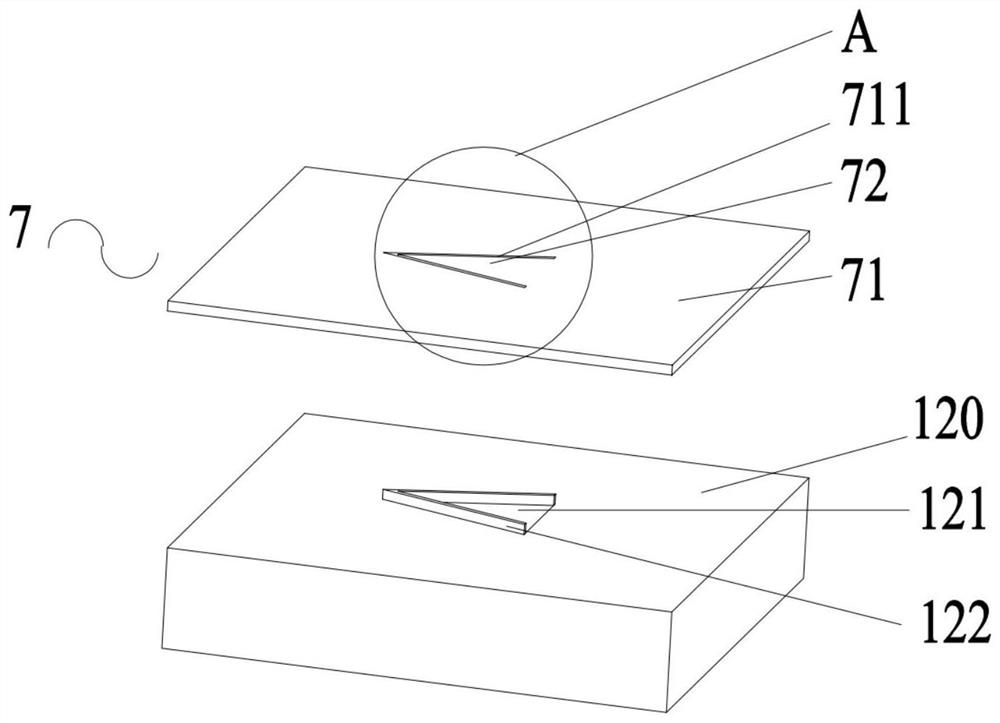

Injection molding method and injection molding die

InactiveCN101977749AReduce demoulding resistanceRelieve deformationMaterial analysisInjection molding machineMaterials science

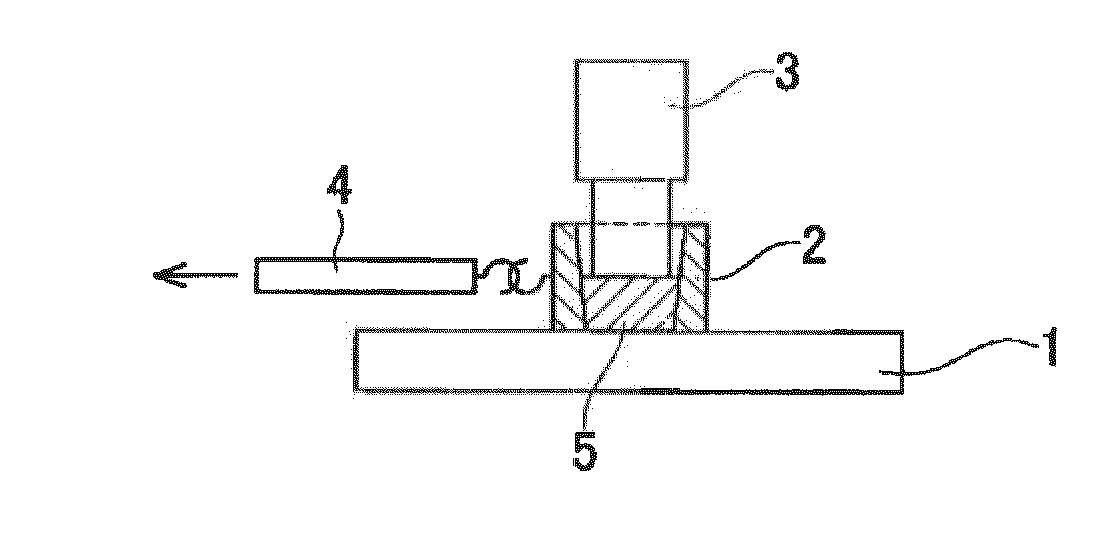

Provided is an injection molding method for a resin substrate, wherein: through-holes are provided on a plate-shaped substrate so that they are penetrated from one surface of the substrate in the direction of the other surface in a way such that the diameter of the hole gradually becomes smaller; and micro-passages that connect to the through-holes are provided on the other surface of the substrate. A cavity is formed by joining a first molding die that forms one surface with a second molding die that forms the other surface. One part of the first molding die that forms the through-holes comprises taper pins that protrude from the first molding die towards the second molding die. The substrate is formed by filling the cavity with resin material, and the substrate is released from the second molding die by separating the first molding die from the second molding die. By pushing out the inner walls of the through-holes with the taper pins that are projected further towards the second molding die, the substrate is released from the first molding die.

Owner:KONICA MINOLTA OPTO

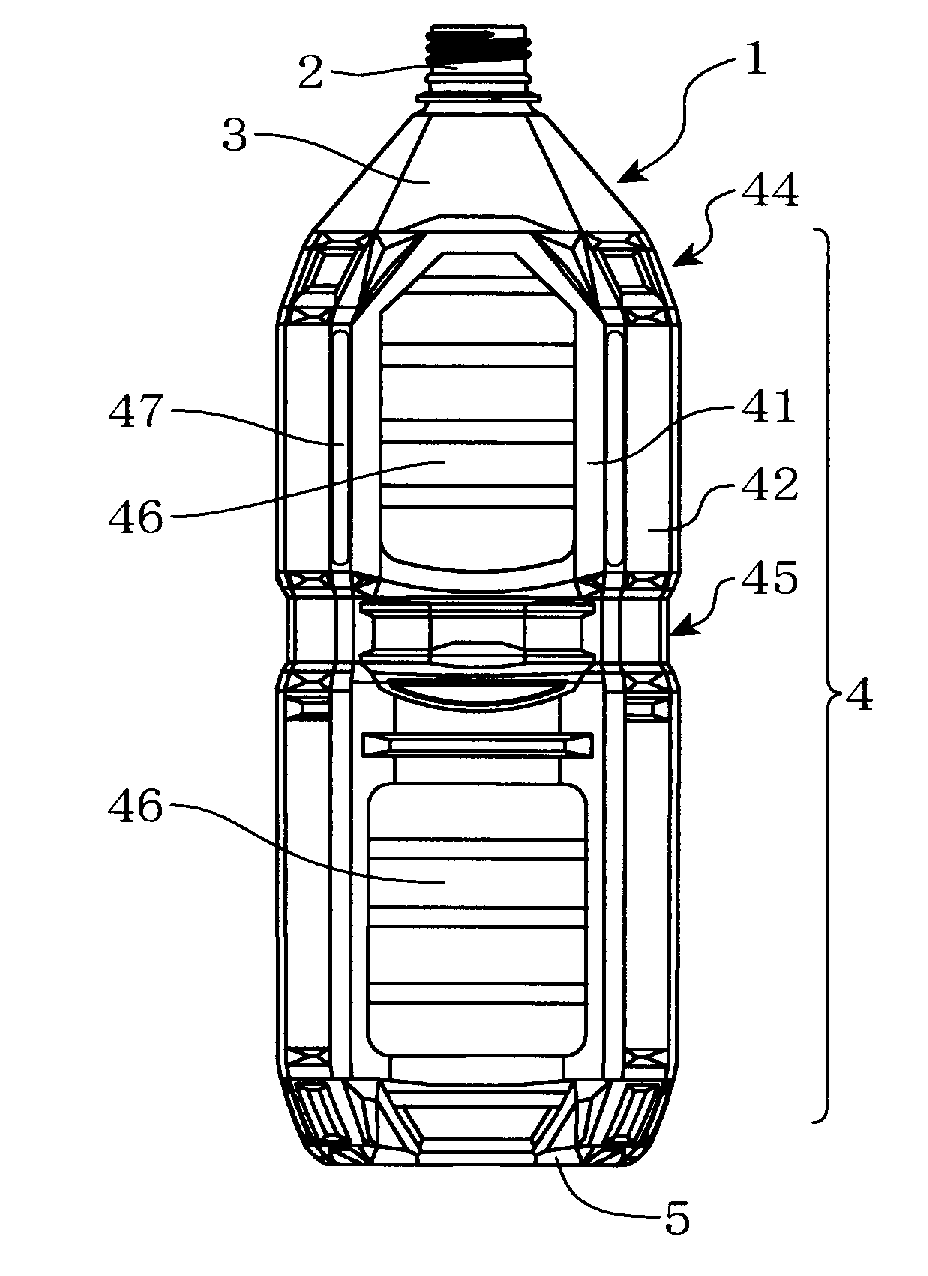

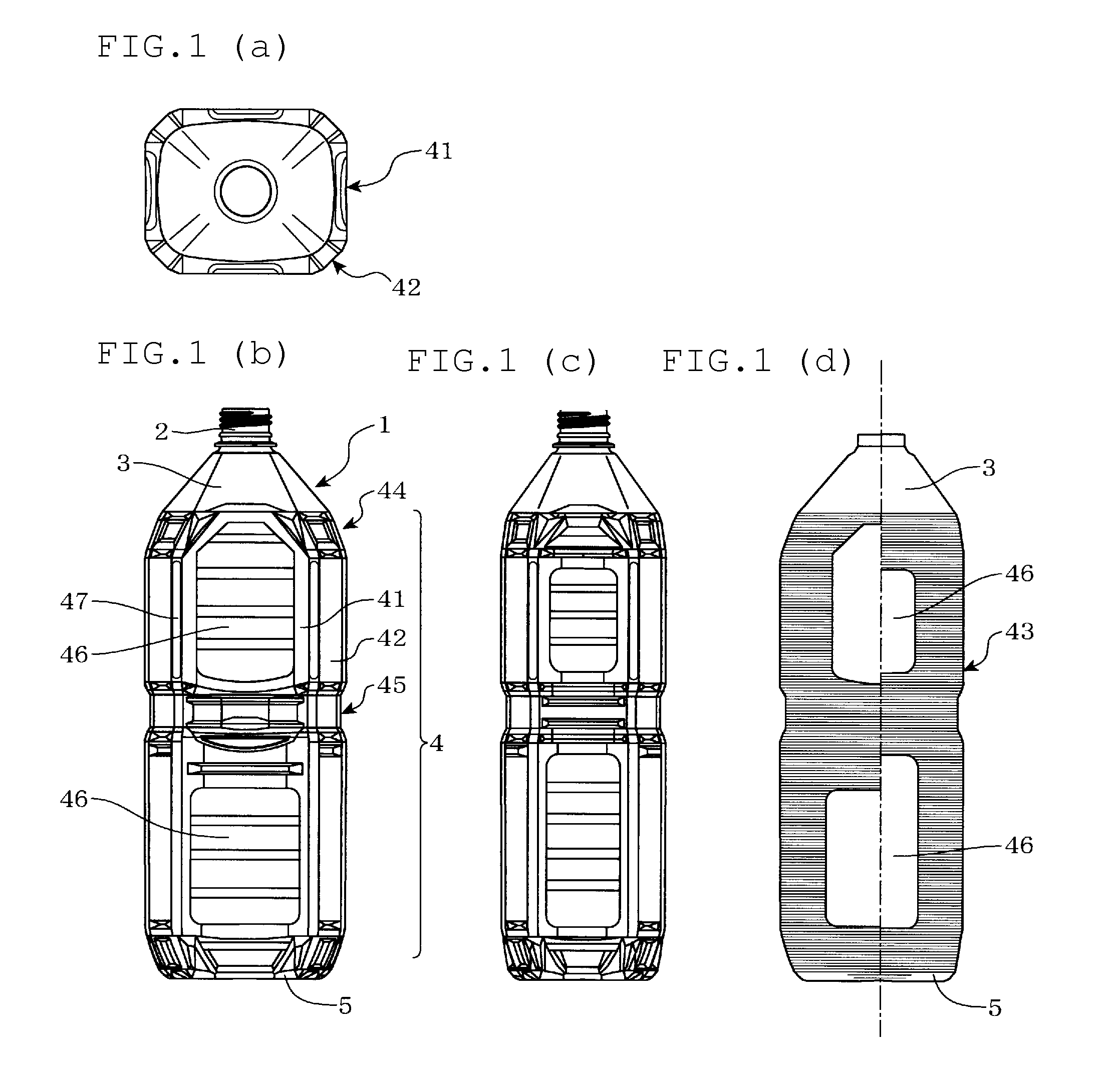

Angular resin container and blow molding die

ActiveUS20140224814A1Nice appearanceHigh transparencyLarge containersDomestic articlesBlow moldingMaterials science

Provided are an angular resin container, which while being thin, retains excellent appearance in respect of luster, transparency or the like, as well as a blow molding die for subjecting the container to biaxial stretch blow molding. Biaxial stretch blow molding is conducted with a blow molding die having a scallop height for the surface of the blow molding die, that corresponds to the side wall part of the body part of the angular resin container, of 3 to 30 μm, thereby to obtain an angular resin container having a thickness of the body part of 0.5 mm or less and in which a horizontally-directed processed part having a depth of 3 to 30 μm is formed on the outer surface of the side wall part of the body part.

Owner:TOYO SEIKAN GRP HLDG LTD

A kind of easy-off and anti-blocking original edge ceramic tile forming mold

ActiveCN104647573BPrecise size controlPrevents stasis and even cloggingCeramic shaping apparatusBrickMaterials science

The invention discloses an easy-to-release anti-blocking original-side ceramic tile forming mould and belongs to the technical field of powder forming. The easy-to-release anti-blocking original-side ceramic tile forming mould comprises an upper mould core, side plates and a lower mould core which define a mould cavity. The easy-to-release anti-blocking original-side ceramic tile forming mould is characterized in that a ventilating path and a plurality of gas vent holes are formed in the upper mould core, wherein one end of each gas vent hole is communicated with the bottom surface of the upper mould core, the other end of each gas vent hole is communicated with the ventilating path, the ventilating path is connected with a gas exhausting branch and a gas blowing branch; the side plates comprise long side plates and short side plates which are enclosed in two adjacent long side plates, wherein first inclined positions which are outwards inclined from top to bottom are formed in the inner walls of the long side plates and the short side plates; second inclined positions are formed in the two ends of each short side plate; the long side plates and the short side plates can be tightly assembled together through the first inclined positions and the second inclined positions. A ceramic brick green body finished product pressed out by the forming mould does not need edging processing; moreover, in the pressing process, the gas exhausting system can be prevented from being blocked, the demoulding is easy to carry out and the mould is prevented from being blocked, so that the forming quality of the original-side ceramic tiles can be improved.

Owner:淄博沃德机械科技有限公司 +2

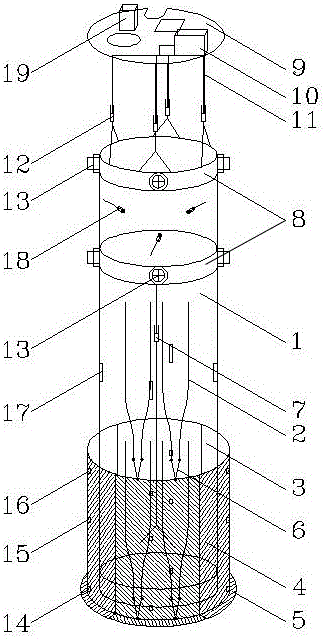

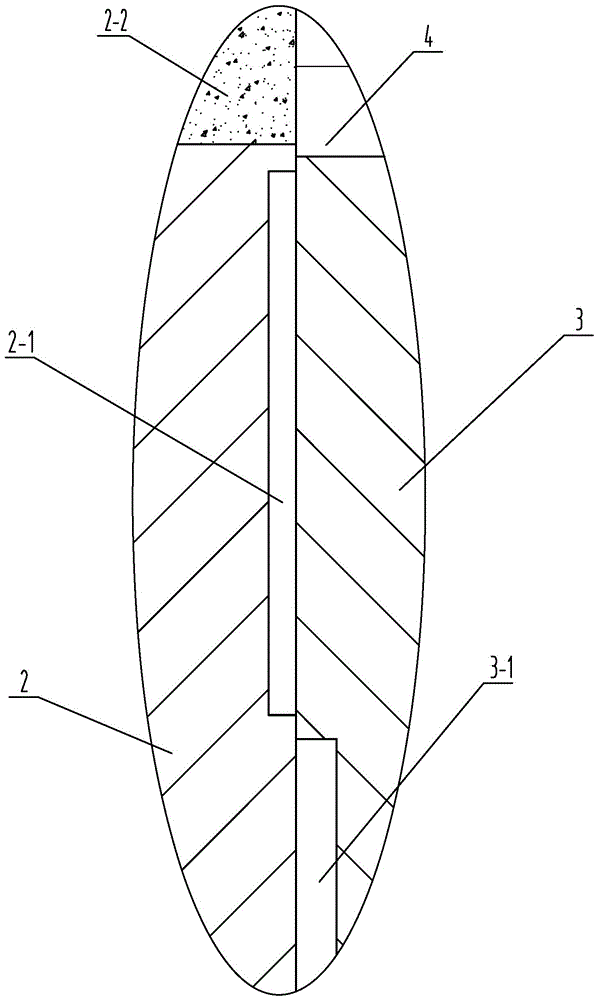

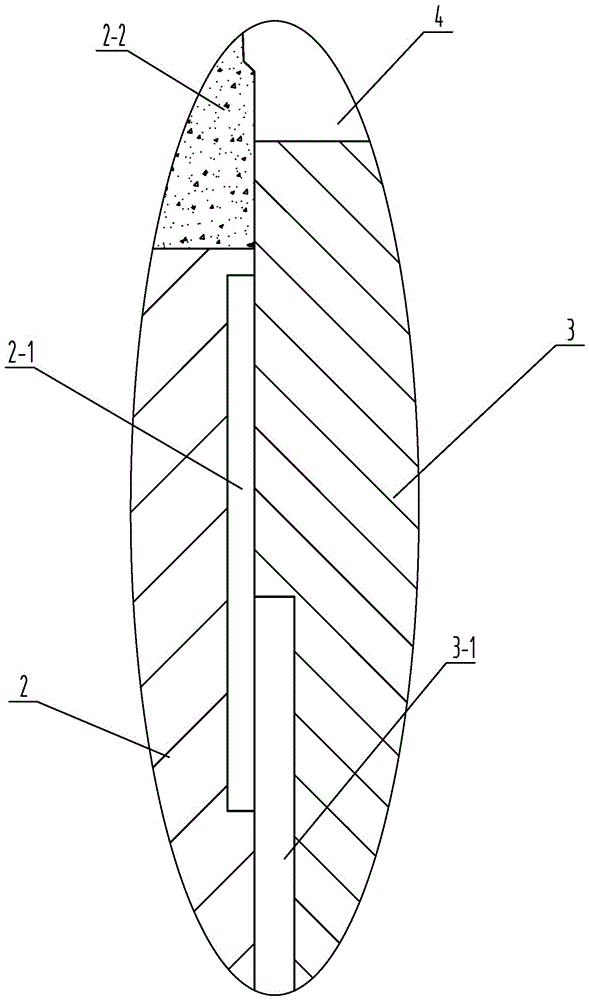

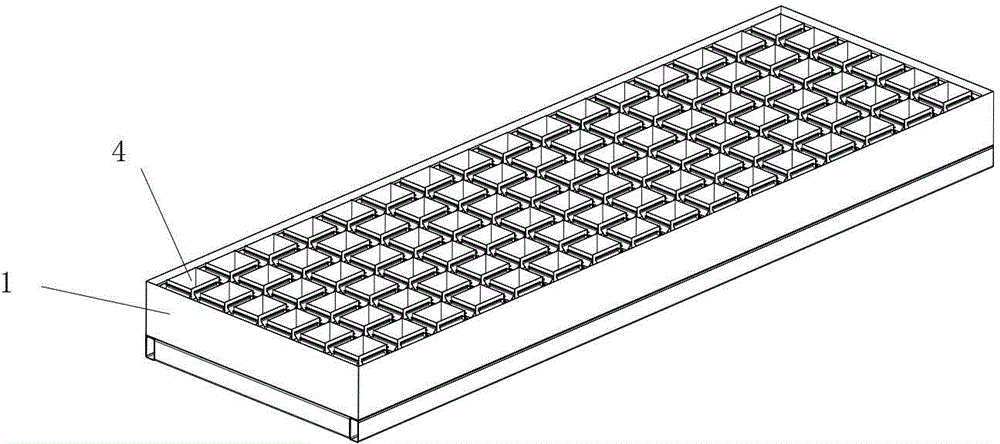

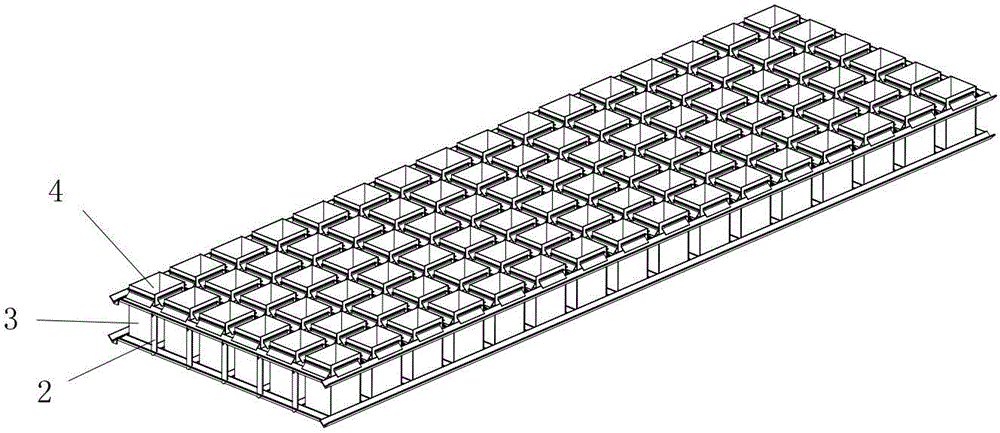

Joint construction method and construction device for horizontal partition of flexible bridge pier

ActiveCN106835988BPrevent inflowEasy to demouldBridge structural detailsBridge erection/assemblyEngineeringBuilding construction

A flexible-pier horizontal separation seam construction method and a construction apparatus therefor. The flexible-pier horizontal separation seam construction apparatus (1) comprises a combined drawing plate. The combined drawing plate comprises s bottom drawing plate (2), a hard foam plate (3), edge sealing drawing plate (4), and a top drawing plate (5); the hard foam plate (3) is located above the bottom drawing plate (2) and adjacently connected to the bottom drawing plate (2); a first side surface (31) of the hard foam plate (3) is flushed with a second side surface (21) of the bottom drawing plate (2); the edge sealing drawing plate (4) is located above the bottom drawing plate (2) and adjacently connected to the bottom drawing plate (2); a third side surface (41) of the edge sealing drawing plate (4) is adjacently connected to a fourth side surface (32) of the hard foam plate (3); the fourth side surface (32) is provided opposite to the second side surface (21); the top drawing plate (5) is located above the hard foam plate (3) and the edge sealing drawing plate (4) and adjacently connected to the hard foam plate (3) and the edge sealing drawing plate (4) respectively; a fifth side surface (51) of the top drawing plate (5) is flush with the first side surface (31). Also provided is a construction method for the construction apparatus. The flexible-pier horizontal separation seam construction method and the construction apparatus therefor both have the advantages of high seaming depth, high seaming accuracy, and good seaming quality.

Owner:GUANGZHOU ENG CO LTD OF CHINA RAILWAY 19TH BUREAU GRP

Polyphenylene sulfide resin composition and molding comprising same (as amended)

ActiveUS20140100306A1Improve balanceImprove heat resistanceGroup 5/15 element organic compoundsSemiconductor/solid-state device detailsElastomerWax

The invention provides a polyphenylene sulfide resin composition including: 1 to 100 parts by weight of an olefin elastomer (B); and 0.01 to 10 parts by weight of a carboxylic acid amide wax mixture (C), relative to 100 parts by weight of a polyphenylene sulfide resin (A), wherein the carboxylic acid amide wax mixture (C) is obtained by adding 0.01 to 5 parts by weight of an antioxidant to 100 parts by weight of a carboxylic acid amide wax produced by reaction of a higher aliphatic monocarboxylic acid, a polybasic acid and a diamine.

Owner:TORAY IND INC

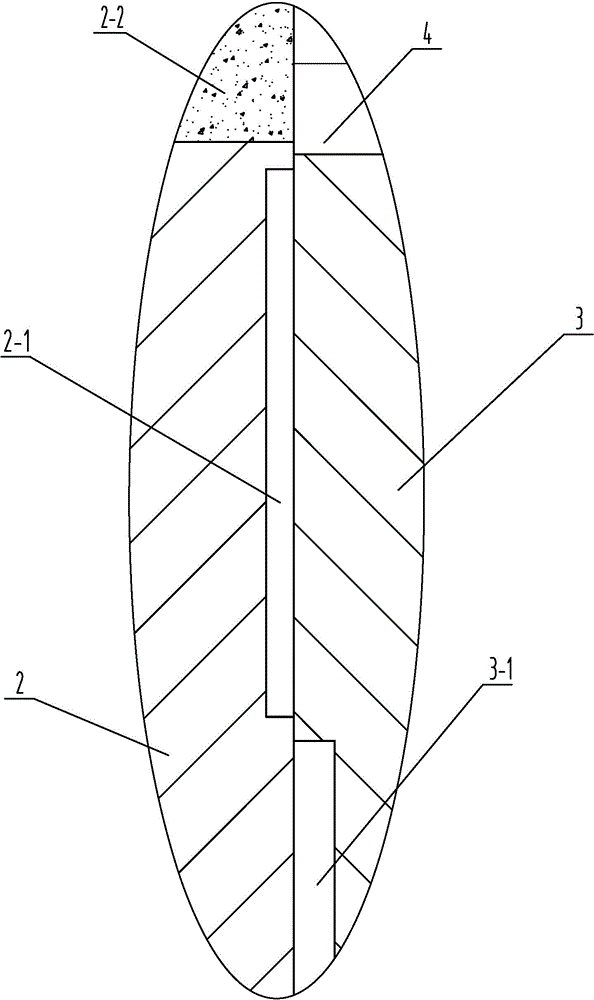

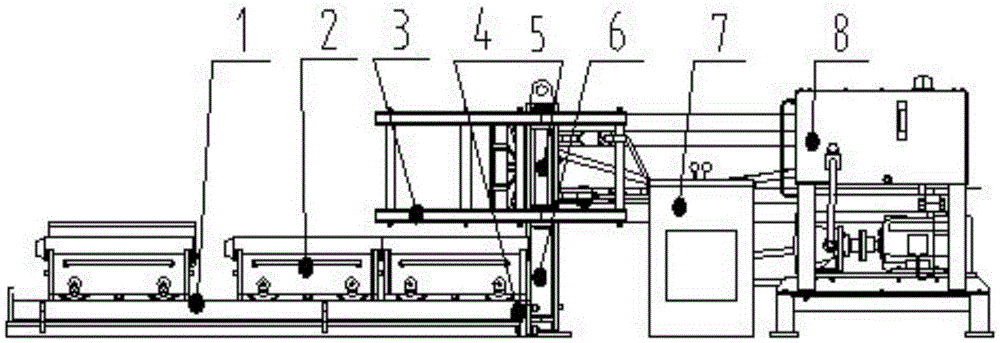

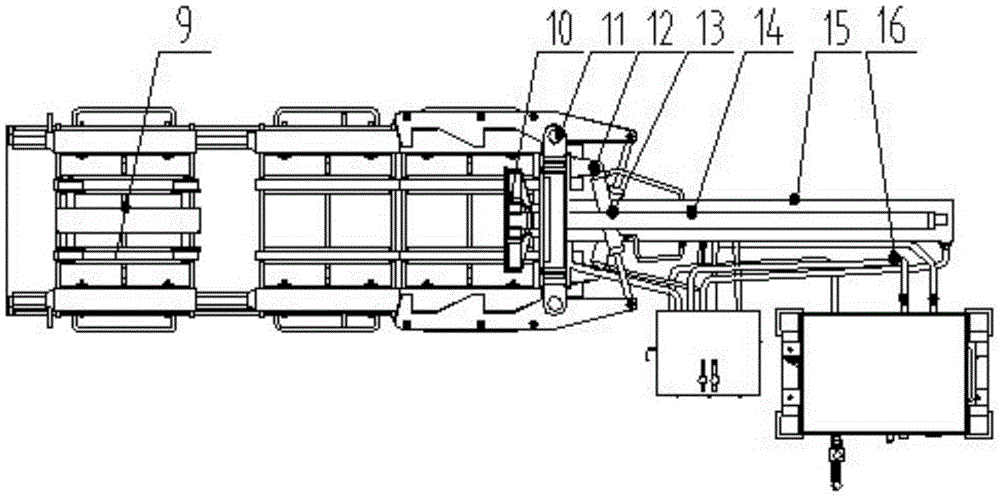

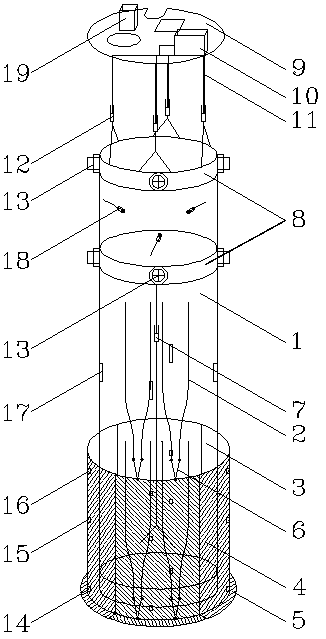

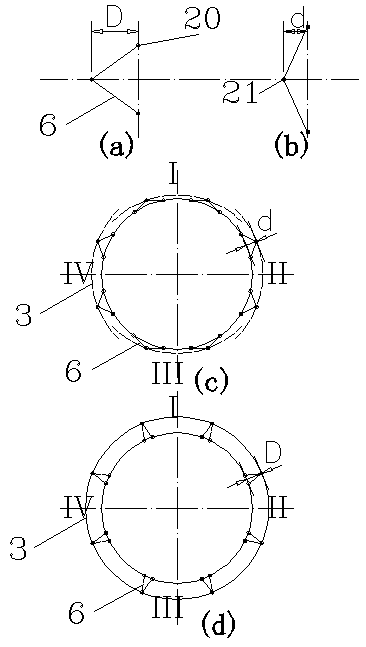

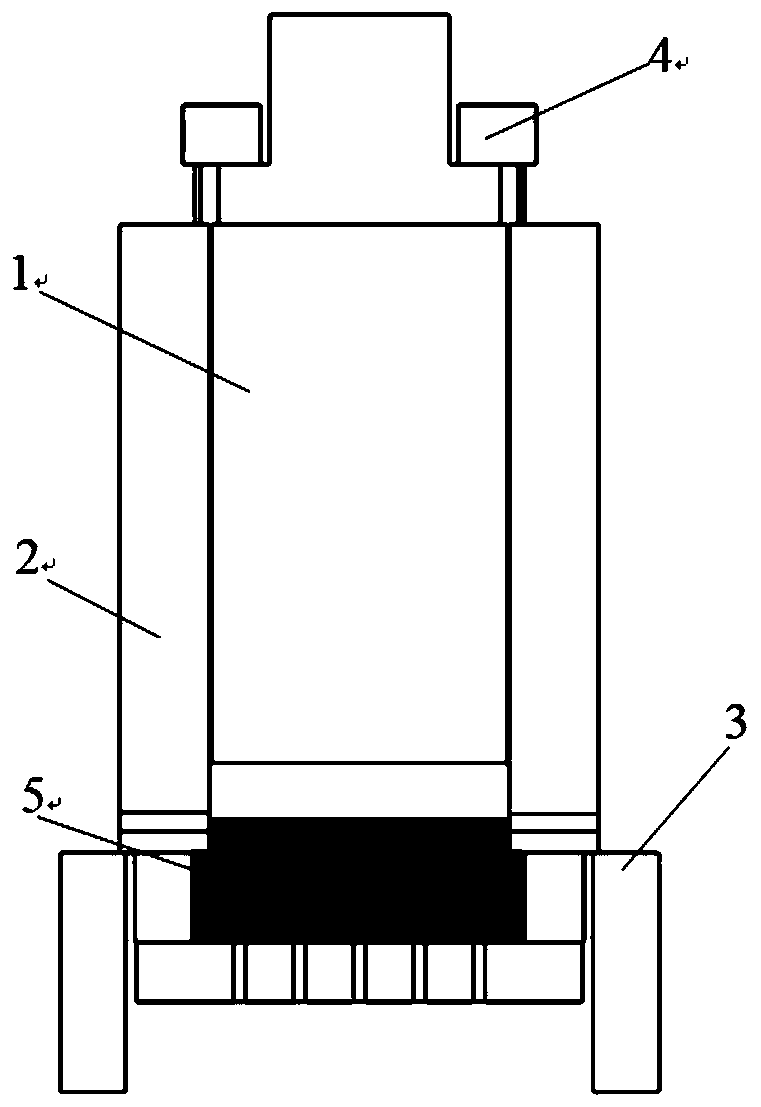

Metal mold casting demolding machine for tubular shells

The invention relates to a metal mold casting demolding machine for tubular shells. The metal mold casting demolding machine for tubular shells is characterized in that: three support trolleys (2) are arranged on a guide rail of a landing guide rail workbench (1), a prop-up trolley (9) is arranged on the guide rail of the support trolley (2) on the left, the right end plate of the workbench (1) is connected with an oil cylinder mounting base (6) by a screw (4), and left and right hydraulic tightening mechanisms (3) are connected with four fixed supports (11) by two rotating shafts (5). The metal mold casting demolding machine for tubular shells has the beneficial effects that: the metal mold casting demolding machine for tubular shells can realize casting mold demolding by turning twice, the demolding force is reduced, and the energy-saving and noise-reduction purpose is achieved; and besides, one-stage metal contour demolding requirement is satisfied, the shell is effectively prevented from damage, a new all-steel train guide rail structure is used, the support trolley can realize centering and also can change sliding friction into rolling friction so as to move along with the casting mold, the demolding resistance is reduced and the energy consumption is reduced.

Owner:KUNMING SHIPBUILDING EQUIP

Treatment Method for Mold Tool Surface

The average roughness Ra of a mold tool surface that comes into contact with a material to be molded measured for a measurement area 10 μm square or smaller is equal to or lower than 5 nm, and fine granular projection structures having diameters ranging from 10 to 80 nm and heights ranging from 10 to 40 nm are formed on the mold tool surface with a density of 400 / μm2 or higher. The frictional force due to the anchoring effect or the digging effect is reduced, and the adhesive force due to meniscus is also reduced. The release resistance is significantly reduced without affecting the dimensional precision of a fine molded product.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

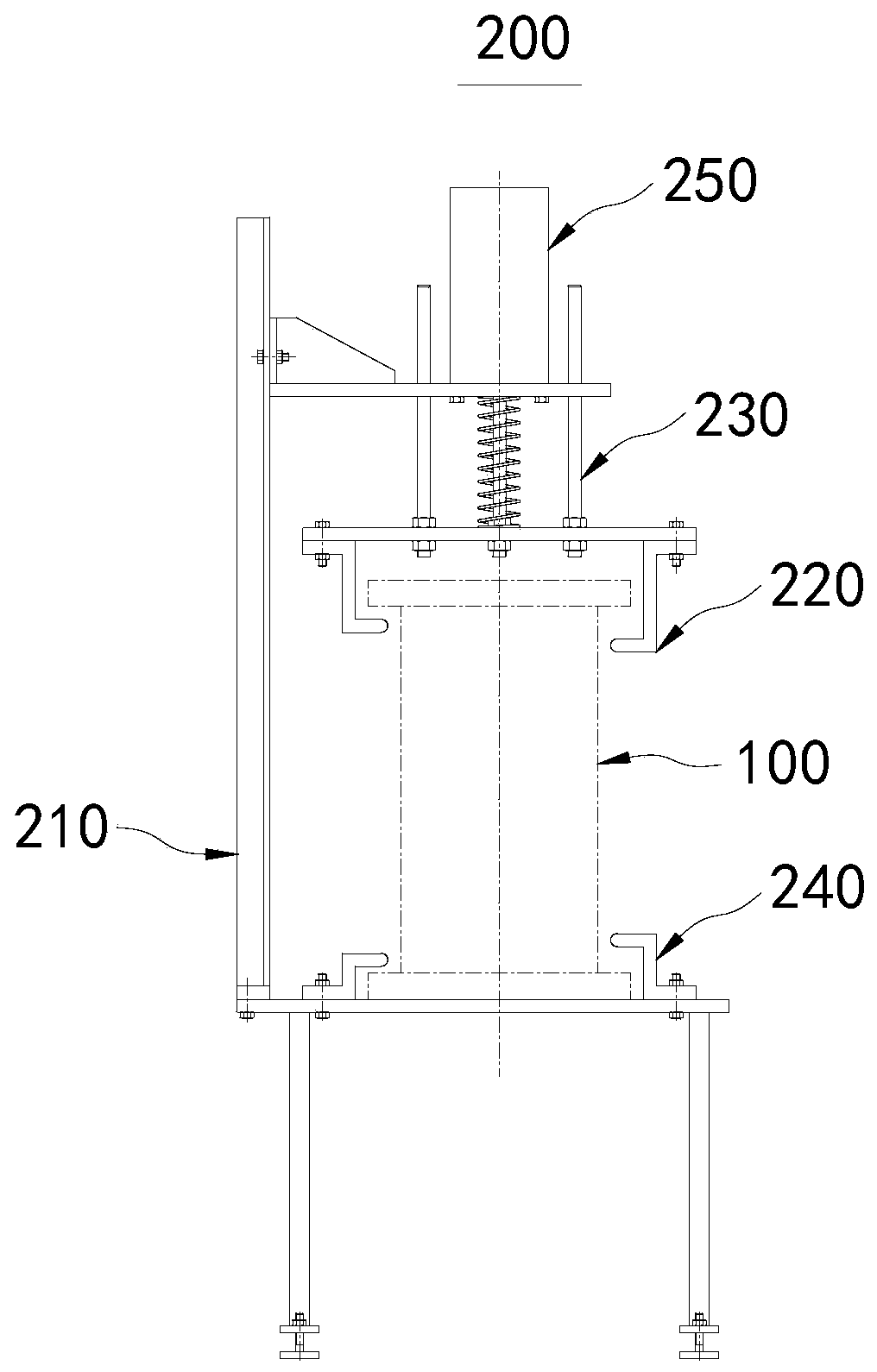

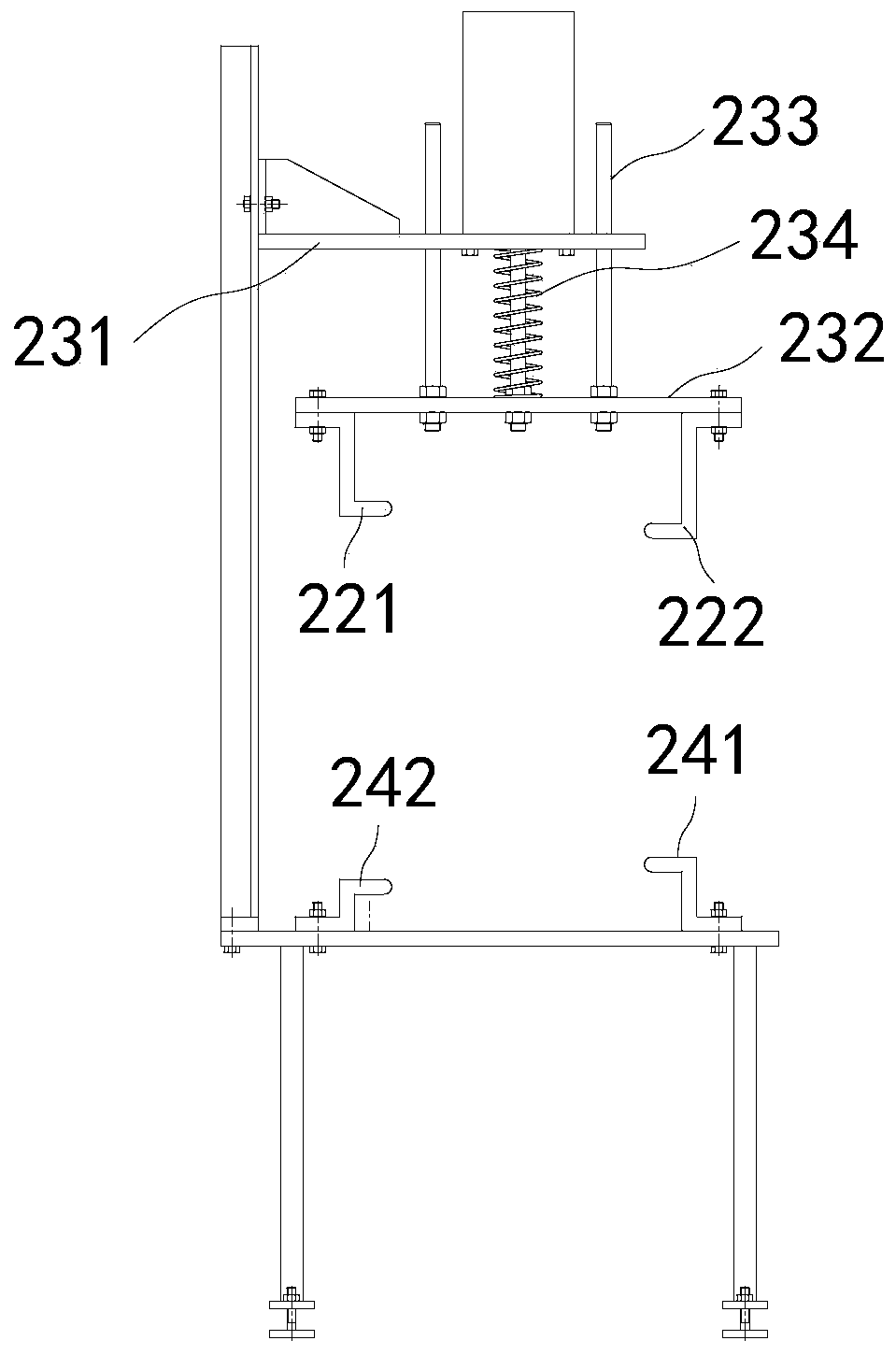

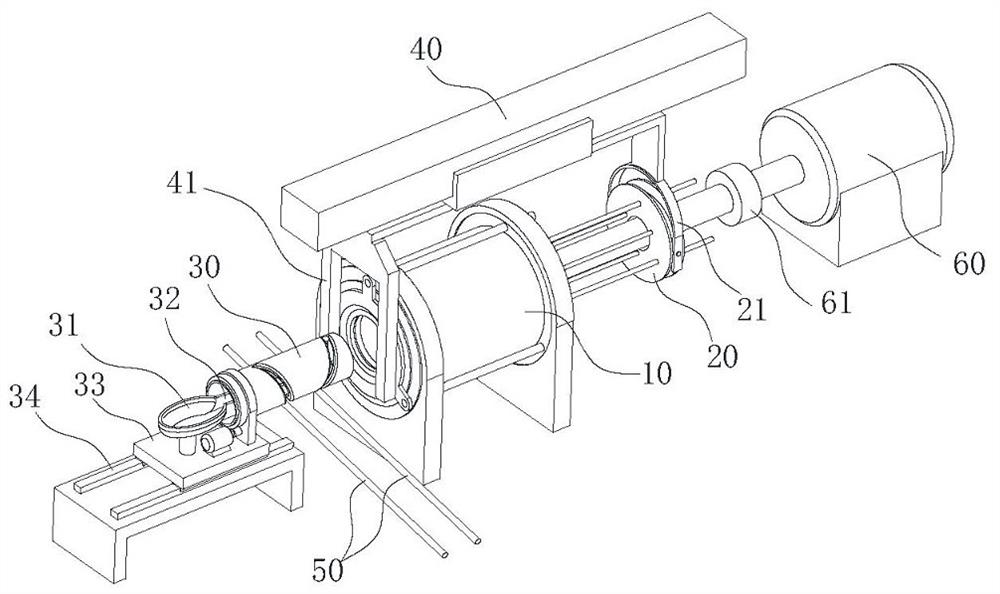

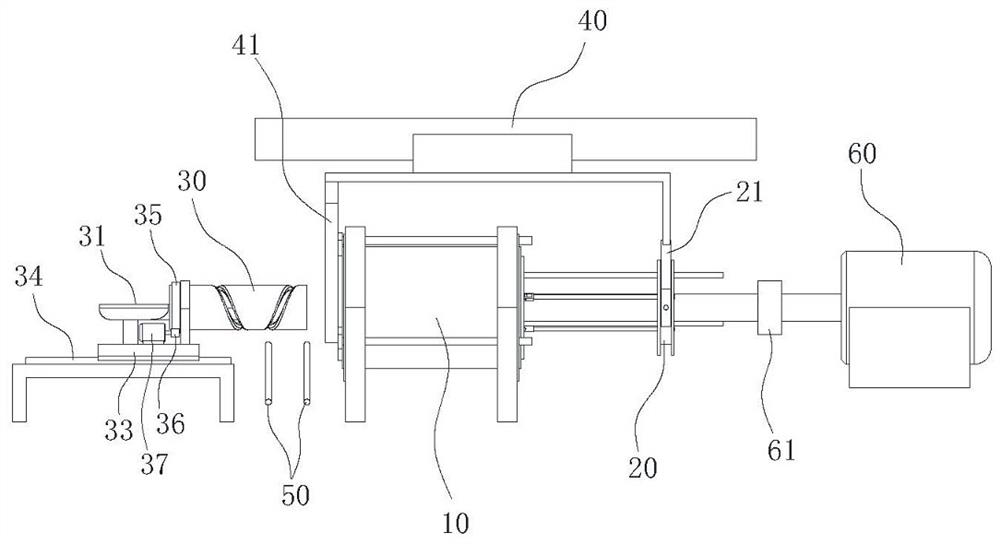

Demolding device and automatic demolding equipment

The invention relates to the technical field of molds, in particular to a demolding device and automatic demolding equipment. The demolding device comprises a rack and a demolding assembly. The rack is used for installing a mold. The demolding assembly is movably connected with the rack and comprises a first abutting part and a second abutting part, and the first abutting part and the second abutting part are used for abutting against the mold, the height of the first abutting part is larger than that of the second abutting part in the mold opening direction of the mold, and the demolding assembly is used for moving in the mold opening direction of the mold relative to the rack under the action of external force, so that the mold is opened. The demolding device is simple in structure, operation difficulty can be lowered, demolding efficiency is improved, meanwhile demolding quality is improved, and damage to the mold is lowered.

Owner:SUOTE TRANSMISSION EQUIP

A kind of short fiber reinforced carbon/resin composite material hot pressing molding demoulding method

ActiveCN112157929BImprove surface qualityExcellent anti-hot pressure sticking performancePolyethylene glycolBoron nitride

The invention discloses a short fiber reinforced carbon / resin composite material hot pressing molding demoulding method, which includes the following contents: (1) C and N co-infiltration technology on the surface of a 65Mn separator for hot pressing molding demoulding, adopting dripping methanol to pass ammonia The 65Mn separator is carbonitrided by the gas method; (2) a mold release agent for hot pressing molding, the specific components are 10%-30% flake graphite powder, 20%-40% nano-scale cubic nitriding The mixed powder of boron powder and 30%-50% nano-scale zirconia powder is composed of polyethylene glycol as a binder. The process of the invention is simple, the process parameters are easy to control, the smoothness after grinding and polishing of the separator for hot-pressing molding, the anti-hot-pressing inlay performance and the anti-hot-pressing die-bonding performance are improved, and the hot-pressed short fiber reinforced carbon / mold is significantly improved. Surface quality and production efficiency of resin composites.

Owner:湖南科嘉新材料有限公司 +3

A kind of metal mold environmental protection coating for carbon-iron alloy casting and preparation process thereof

ActiveCN108213328BEasily damagedCold crystallization is beneficialFoundry mouldsFoundry coresTinningSilicon alloy

The invention relates to the technical field of coating, in particular to metal mold environment-friendly coating for carbon ferroalloy casting based on oxidation-reduction reaction and a preparationprocess thereof. The environment-friendly coating comprises, by weight, 0.1-30 parts of limestone powder, 0.1-30 parts of dolomite powder, 0-30 parts of magnesite powder, 0-30 parts of ferrochrome dust removal powder, 0-30 parts of manganese alloy dust removal powder, 0.1-20 parts of silica powder, 0.1-10 parts of pulverized coal and 0-10 parts of asphalt powder. The preparation process comprisesthe steps of grinding limestone powder and dolomite powder, diluting a Na2SiO3 aqueous solution, and conducting stirring, testing, tinning, and packaging. The environment-friendly coating is mainly used for the metal mould casting of ferroalloy with low carbon requirements, such as high carbon ferrochrome, high carbon ferromanganese and manganese silicon alloys, and the problems that a mold is stuck and the damage to the mold is serious in casting of the alloys are solved; and the preparation process is high in production efficiency and facilitates large-scale production.

Owner:上海宝叶冶金技术有限公司 +1

A wall formwork suitable for intelligent construction of shafts

ActiveCN106351673BSimple structureReduce demoulding resistanceUnderground chambersTunnel liningBrickMeasurement point

Owner:CHINA UNIV OF MINING & TECH

Release device

ActiveCN111014609BImprove casting efficiencyRealize automatic demouldingEngineeringMechanical engineering

Owner:ANHUI PROVINCE YUEXI CYLINDER

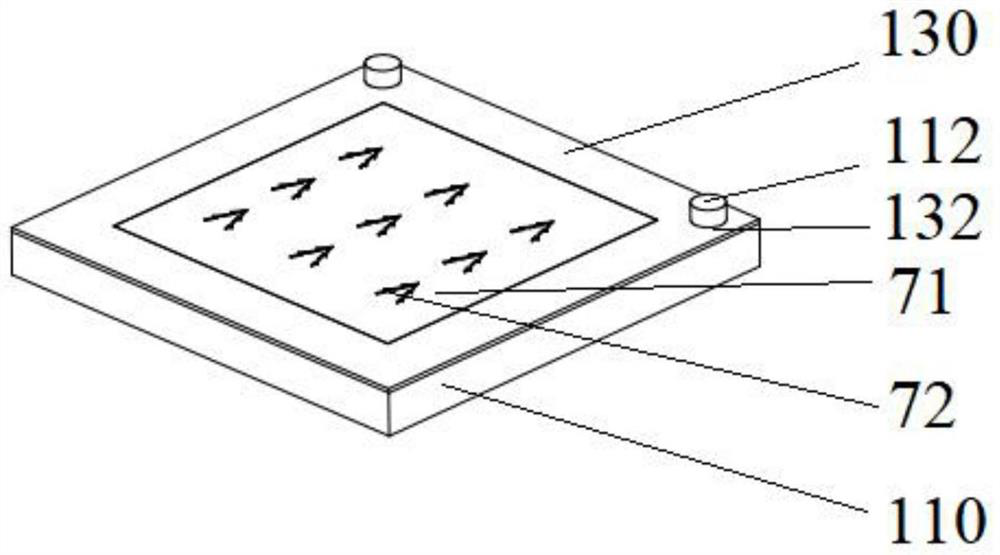

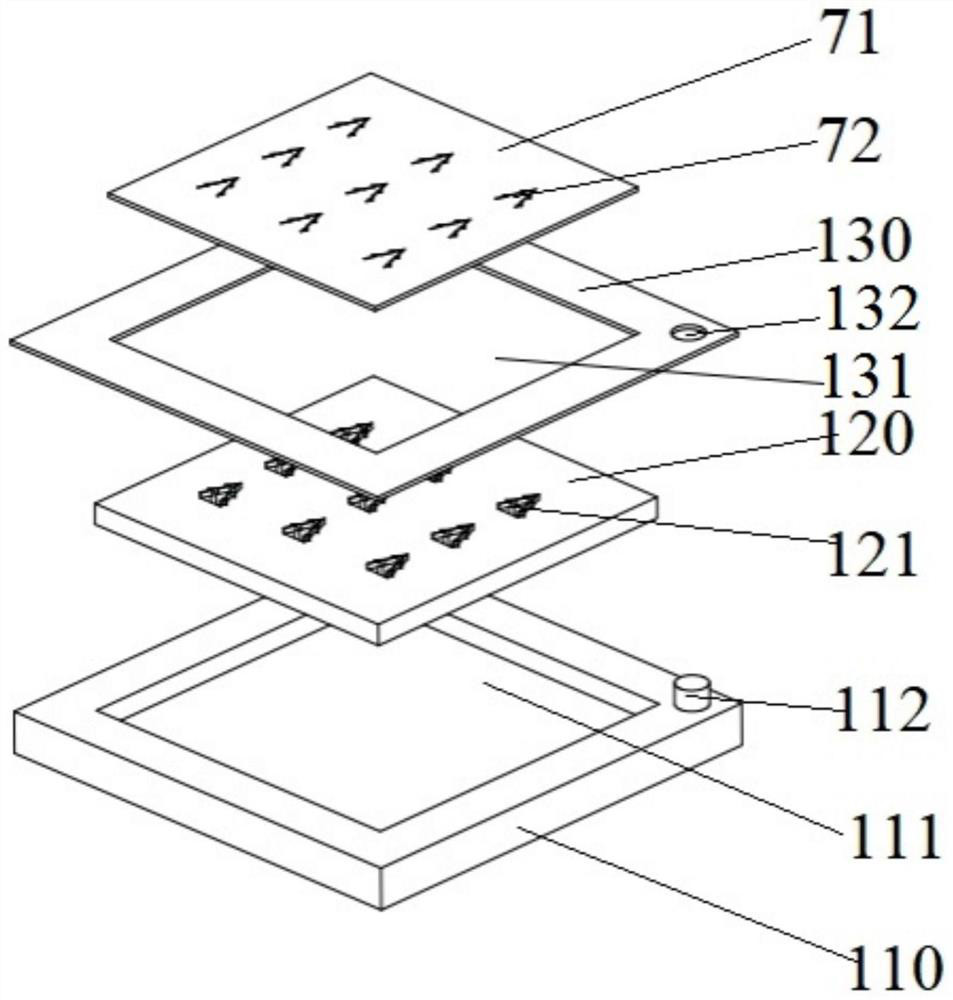

Planar microneedle, microneedle patch, manufacturing equipment, vertical equipment and preparation method

PendingCN114748783AAvoid breakingImprove yield rateMicroneedlesMedical devicesEngineeringMaterials science

The invention relates to a planar microneedle which comprises a substrate layer and a microneedle body arranged on the substrate layer in a turnover mode, the microneedle body comprises a needle tip, a needle base and a middle part connecting the needle tip and the needle base, and the direction, facing the needle base, of the needle tip is the same as the extending direction of the substrate layer. The invention also relates to manufacturing equipment of the planar microneedle, a preparation method of the planar microneedle, a microneedle patch and vertical equipment of the microneedle patch. The micro-needle has the beneficial effects that the direction of the needle point groove towards the needle seat groove is the horizontal direction, so that the depth of the forming groove and the ratio of the maximum depth to the maximum length of the forming groove are reduced, medicine carrying liquid is conveniently and accurately poured into the needle point groove of the forming groove, the situation that the medicine carrying liquid splashes to pollute the middle groove and the needle seat groove is avoided, and the formed micro-needle only carries medicine at the needle point.

Owner:YOUWE ZHUHAI BIOTECH CO LTD

A mold for forming a stepped carbon fiber bonded body and its use method

The invention discloses a mold for forming a step-shaped carbon fiber cohesive body and an application method thereof, and belongs to the technical field of inorganic nonmetallic material forming. Themold comprises an upper mold body, a lower mold body, a base and a locking part; the upper mold body is composed of an upper mold fixing plate, a cylindrical pressure head and a cushion block, wherein the upper mold fixing plate and the cylindrical pressure head are connected through screws, and the cushion block is arranged at the lower part of the cylindrical pressure head; the lower mold bodyis composed of a circular ring, a forming cavity and a lower mold fixing plate, wherein the circular ring is in interference fit with the forming cavity, and the lower mold fixing plate is connected to the lower end surface of the circular ring; the base plays a supporting role; the locking part is used for locking the upper mold body and the lower mold body; the upper mold body is matched with the lower mold body; and the lower mold body is arranged on the base. The mold has the advantages that the structure is compact and reasonable, in the forming process of the step-shaped carbon fiber cohesive body, no carbon fiber escapes, the fluidity of resin is good, the forming resistance is small, the upper mold body moves downwards smoothly, the step-shaped carbon fiber cohesive body prepared through the mold is completely formed, and the use is safe and reliable.

Owner:DALIAN UNIV OF TECH

An automatic loading and unloading device

InactiveCN103624867BSimple structureDoes not destroy shapeDischarging arrangementMould separation apparatusEngineeringUltimate tensile strength

The invention discloses an automatic die-filling and die-stripping device, which comprises a framework, wherein a molded skeleton is arranged in the framework, a die cavity which is formed by splicing at least two movable templates is arranged in the skeleton, the top of the skeleton is provided with a pressure block and a resilient cushion block, the position, adjacent to the upper end, of the skeleton is provided with a positioning oblique guide groove which is inclined inwards and upwards, the position, adjacent to the bottom, of the skeleton is provided with a depression bar with a corresponding angle; the position, adjacent to the upper end, of the movable template is provided with a sliding limiting guide block which is matched with the positioning oblique guide groove; a corresponding angle is formed between sliding limiting guide block and the positioning oblique guide groove, and the position, adjacent to the bottom, of the movable template is provided with a positioning cushion block which is matched with the depression bar; and a corresponding angle is formed between positioning cushion block and the depression bar. By adopting the automatic die-filling and die-stripping device, multiple concrete prefabricated members can be produced in one step and integrally demoulded in one step. The automatic die-filling and die-stripping device is simple in structure, the machine is used for substituting the manual steps for installing the die, stripping the die and the like, the labor production efficiency can be greatly improved, the completeness of the concrete prefabricated member can be guaranteed, the rejected products can be reduced, and the labor intensity of workers can be alleviated.

Owner:钟赖安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com