Joint construction method and construction device for horizontal partition of flexible bridge pier

A construction method and technology for bridge piers, which are applied to bridges, bridge parts, bridge construction, etc., can solve the problems of high cost, shallow depth, and easy damage of decorative blocks, and achieve the effects of simple structure, simple construction process and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

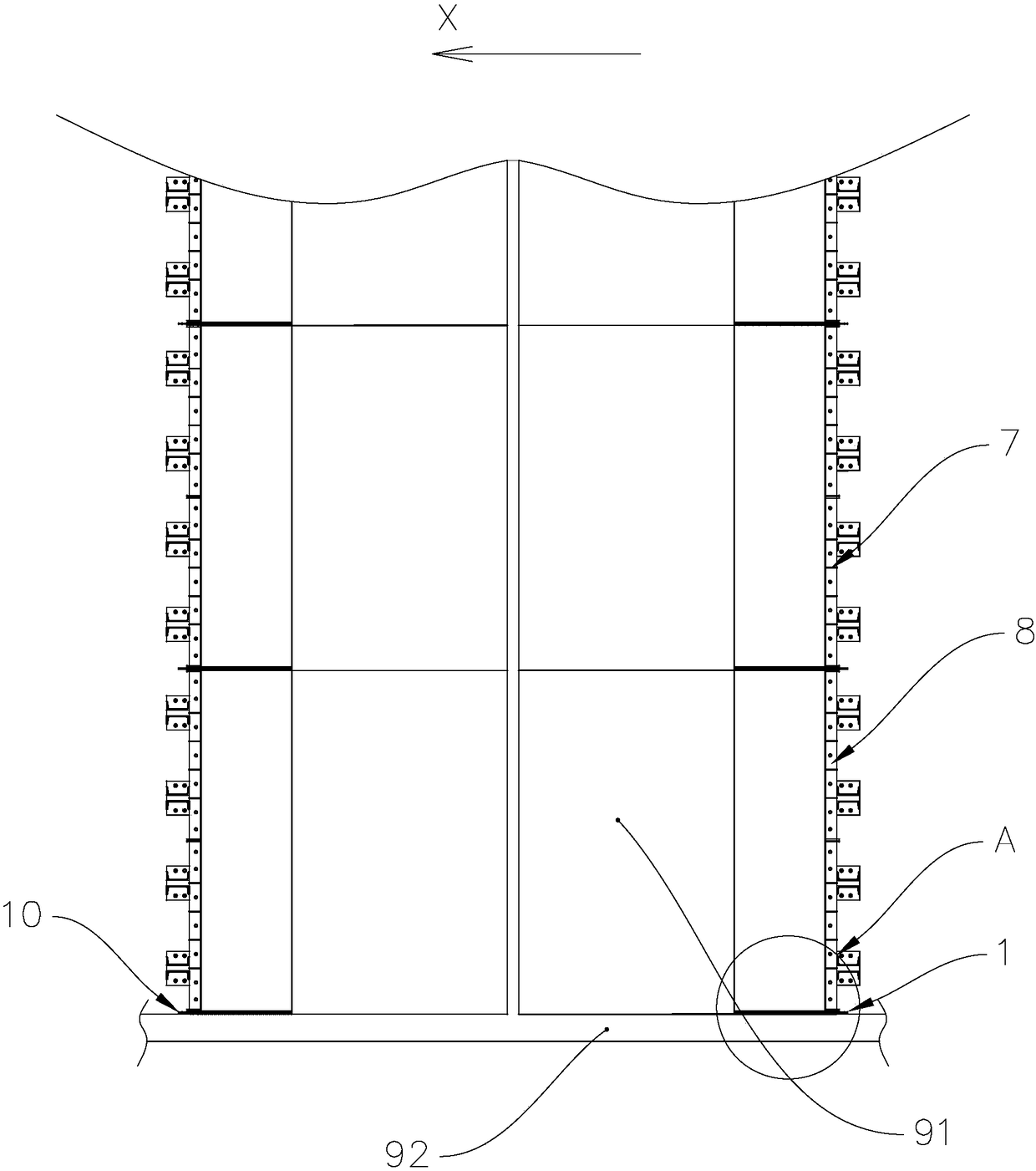

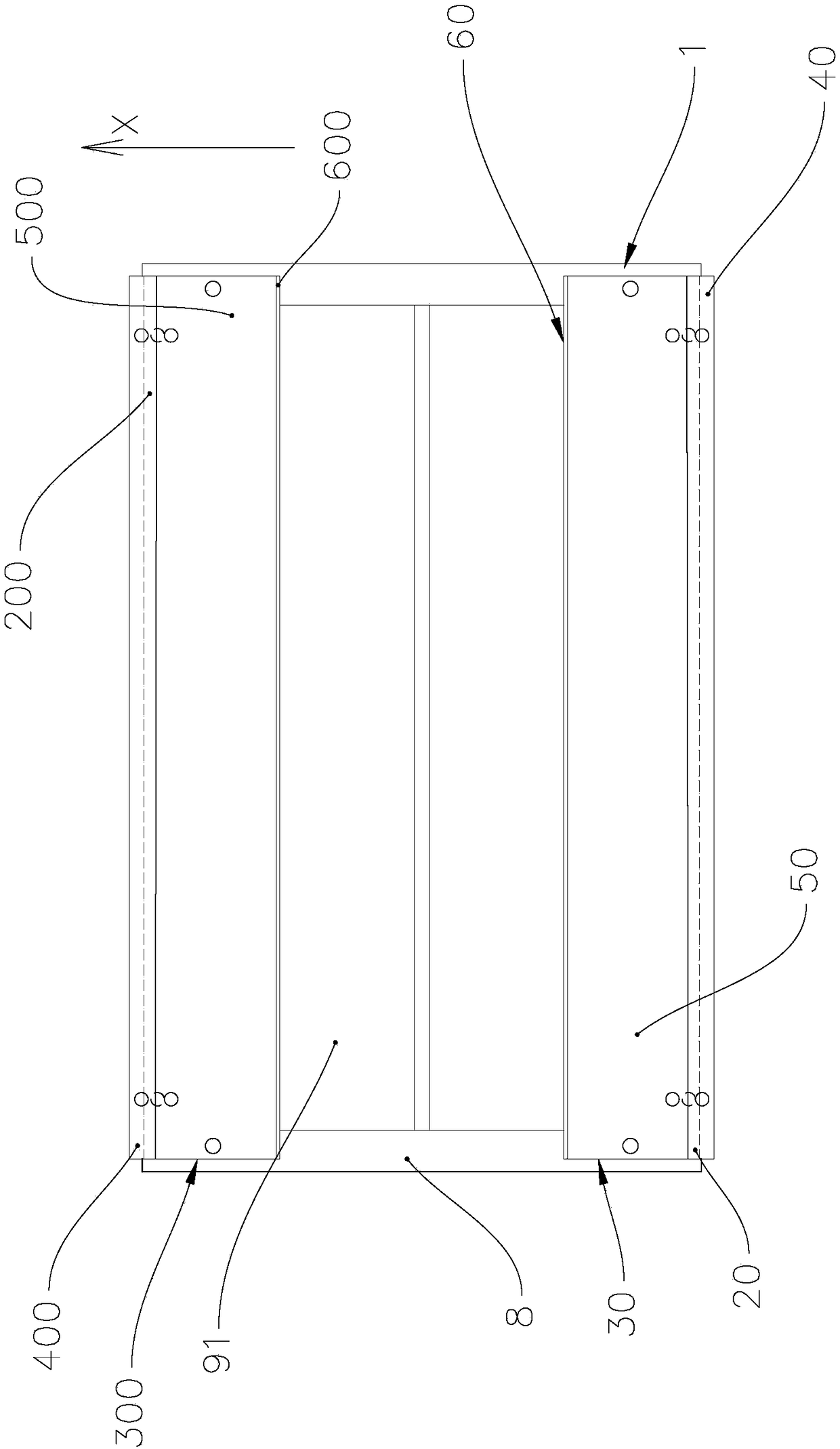

[0050] Reference figure 2 with image 3 The construction method for the horizontal separation of flexible bridge piers is carried out using the flexible bridge pier horizontal separation and fracture construction device in the above-mentioned embodiment as a tool. Among them, the first bottom draw plate 20, the first rigid foam board 30, and the first seal The edge extraction board 40, the first top extraction board 50, and the first film material 60 are respectively connected with the second bottom extraction board 200, the second rigid foam board 300, the second edge sealing extraction board 400, the second top extraction board 500, and the second bottom extraction board 200, respectively. The two film materials 600 have the same structure. Reference Figure 4 to Figure 8 , Take the first bottom extraction board 20, the first rigid foam board 30, the first edge sealing extraction board 40, the first top extraction board 50 and the first film material 60 as examples to illust...

no. 2 example

[0070] Reference Picture 9 with Picture 10 And combine figure 2 , Applying the inventive concept of the first embodiment of the flexible bridge pier horizontal partitioning method, the second embodiment of the flexible bridge pier horizontal partitioning method is different in that the flexible bridge pier horizontal partitioning method of the second embodiment of the construction The method can also include the following steps:

[0071] Pretreatment steps:

[0072] Clean up the construction area 96 of the pier on the cap 92, so that the construction area 96 can adhere to the concrete to be poured, and improve the connection between the pier unit section and the construction area 96 on the cap 92 Quality, thereby improving the construction quality of the bridge piers and ensuring the safety of the bridge piers in later use. In addition, the steel bars of the pier unit section to be poured are pre-embedded in the construction area 96 of the cleaned pier, and the pre-embedded ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com