Production method of porous insulating block

A technology for thermal insulation blocks and production methods, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of unstable product quality, low production efficiency, large mold pullout resistance, etc., and achieve good appearance quality and internal quality, maintenance. The effect of lowering and lowering the demolding resistance is required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

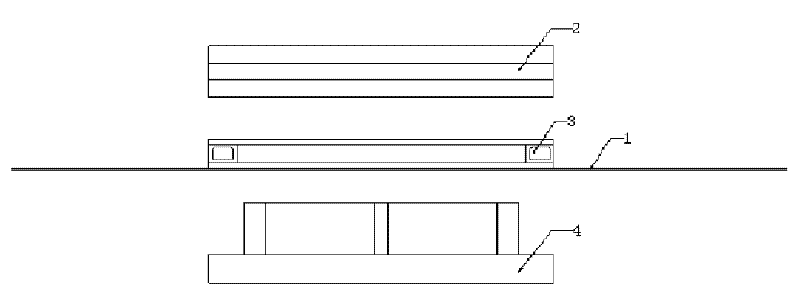

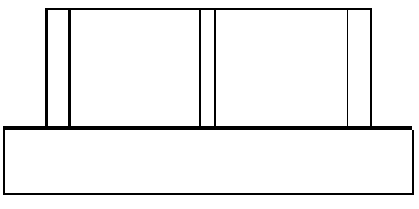

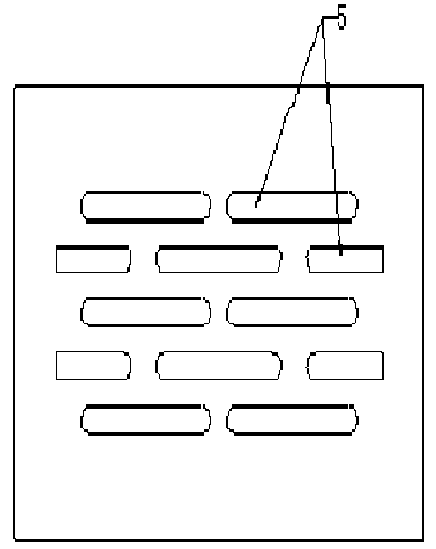

[0024] As shown in the accompanying drawings, a production method of a porous thermal insulation block is produced on a block production line with a conveying device 1 by using a split mold. The split mold includes a male mold 4, a female mold 2, and a supporting plate 3. The male mold 4 has a protruding block 5 for forming a hole of a thermal insulation block. The male mold 4 is arranged at the bottom of the conveying device 1. Supporting plate 3 is a perforated flat plate, and it has the hole that fits with the protruding block 5 on the male mold 4 . The female mold 2 is a frame structure, which can be assembled on the top of the supporting plate 3 . This embodiment takes Figure 8 The shown porous thermal insulation block is taken as an example. The quantity and arrangement of the protruding blocks 5 on the male mold 4 can be determined according to the design of the holes of the thermal insulation block actually produced, and the shape of the female mold 2 can be determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com