A mold for forming a stepped carbon fiber bonded body and its use method

A carbon fiber and step-type technology, which is applied in the field of step-type carbon fiber bonded body molding molds, can solve the problems of unreasonable structure and size, large resistance in the forming process, and large forming resistance, so as to achieve smooth downward movement of the upper mold and easy release. The effect of small mold resistance and small molding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

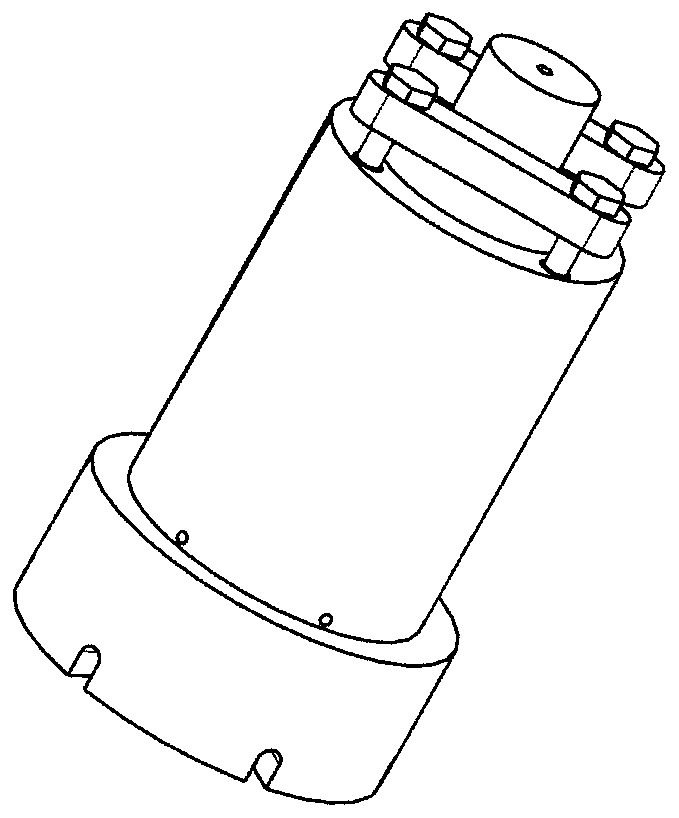

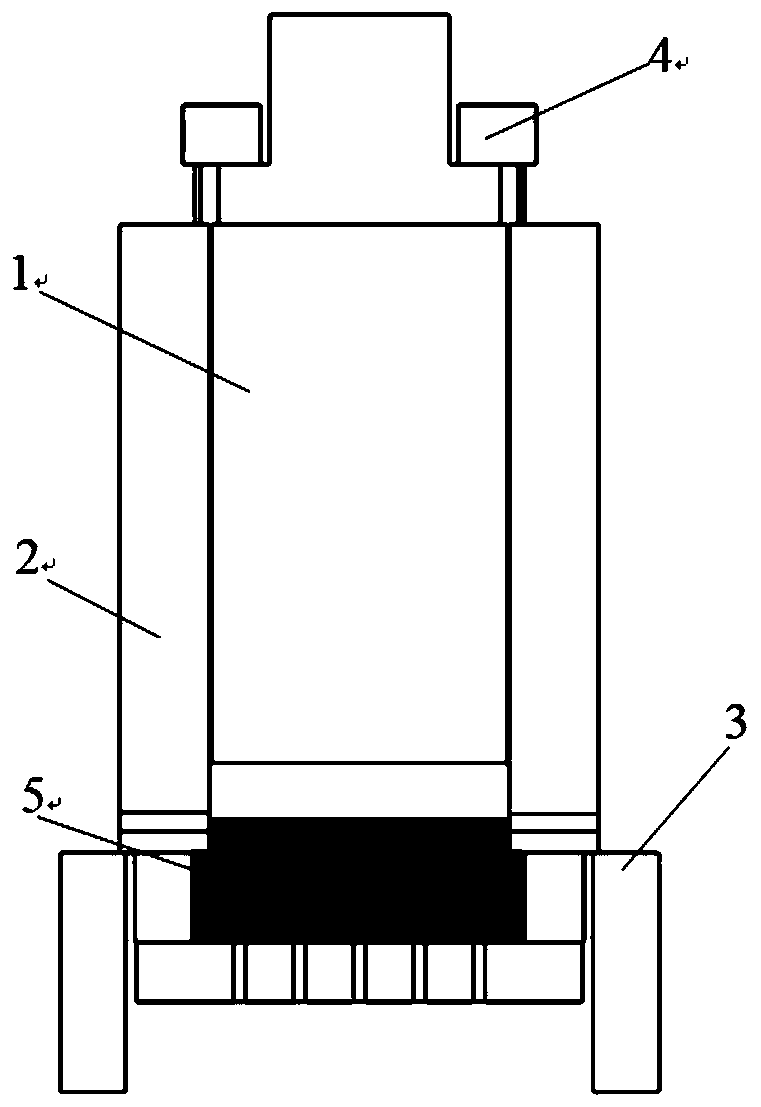

[0030] A mold for forming a stepped carbon fiber bonded body. It consists of an upper mold 1, a lower mold 2, a base 3 and a locking part 4.

[0031] The upper mold 1 cooperates with the lower mold 2, and the lower mold 2 is placed on the base 3. The locking part 4 locks the upper die 1 and the lower die 2 .

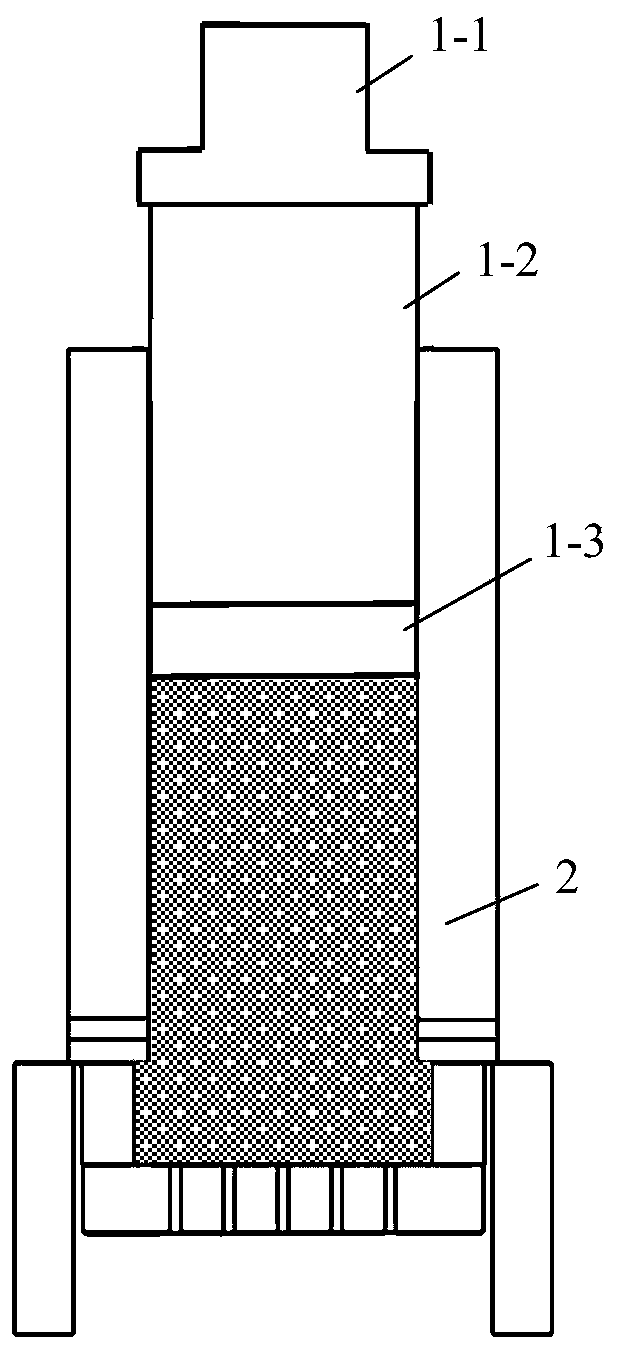

[0032] The upper mold is composed of upper mold fixing plate 1-1, cylindrical indenter 1-2 and cushion block 1-3, the upper mold fixing plate 1-1 and cylindrical indenter 1-2 are connected by screws, and the cushion block 1-3 is placed Cylindrical indenter 1-2 bottom.

[0033] The upper mold fixing plate 1-1 is stepped, and both ends of the upper mold fixing plate 1-1 can be connected with the cylindrical indenter 1-2 by screws, the outer diameter of one end is larger than the inner diameter of the molding cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com