A wall formwork suitable for intelligent construction of shafts

A formwork and shaft technology, which is applied in the field of wall formwork for intelligent construction of shafts, can solve problems such as the inability to meet intelligent construction of shafts, the quality of well wall pouring cannot be evaluated, and the difficulty of meeting engineering requirements, etc., to achieve real-time dynamic evaluation functions, The effect of reducing the number of underground operators and quick demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

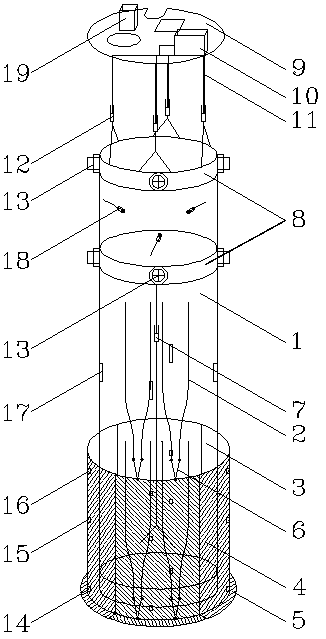

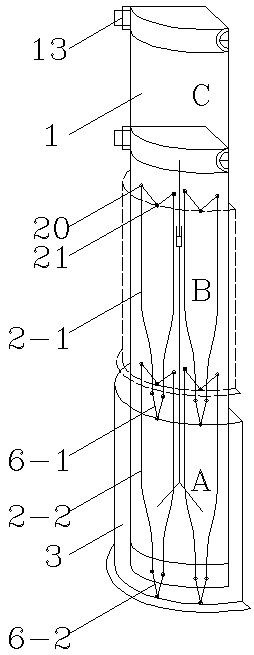

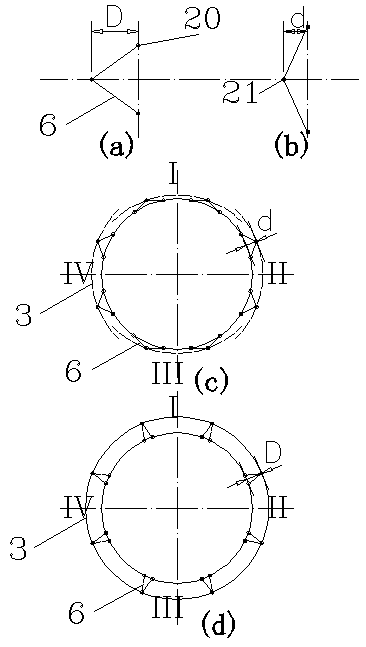

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0036] Such as figure 1 As shown, the present invention proposes a formwork for building walls suitable for intelligent construction of shafts, including a core frame tube 1, a piece sliding form 3 and a curved slide rail 2. Among them, the core frame tube 1 provides a benchmark reference for formwork centering, leveling and rounding, and is also the parasitic mother body of the segmented sliding form 3. The curved slide rail 2 not only provides the vertical up and down travel path of the piece sliding form 3, but also realizes the possibility of its radial contraction, and then realizes the supporting and demoulding actions of the formwork. The split sliding form 3 mainly plays the role of concrete pouring support and quality assessment.

[0037] The height of the core frame tube 1 is about three times the height of the concrete pouring sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com