Mold and method of producing the same

a technology of mold and dough, applied in the direction of dough shaping, manufacturing tools, instruments, etc., can solve the problems of long time-consuming and labor-intensive, complex devices, and difficult to realize devices for accomplishing active alignment maintaining the desired accuracy,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

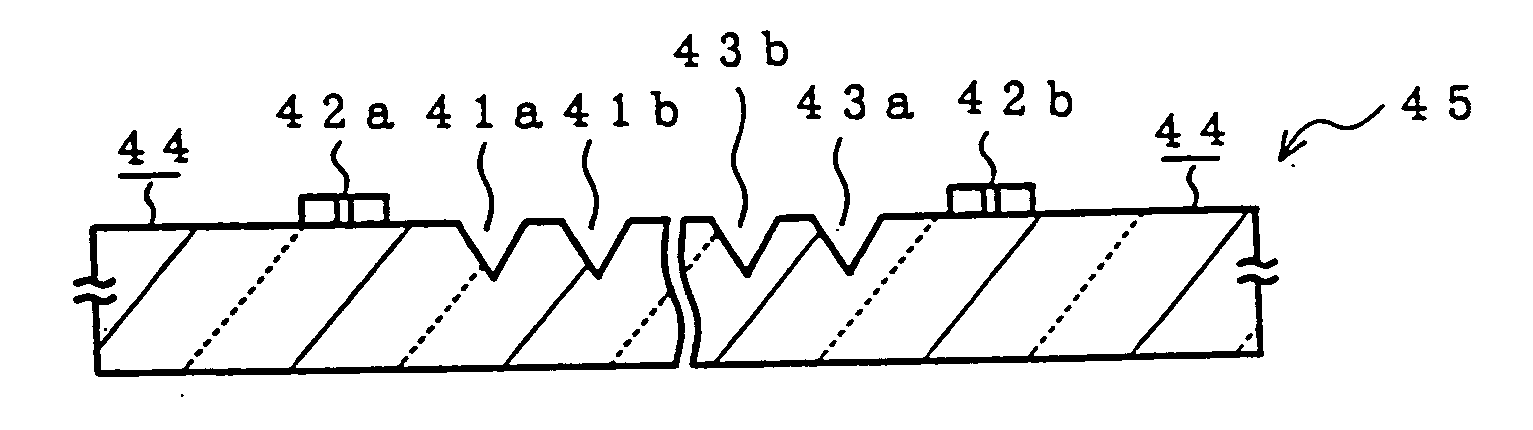

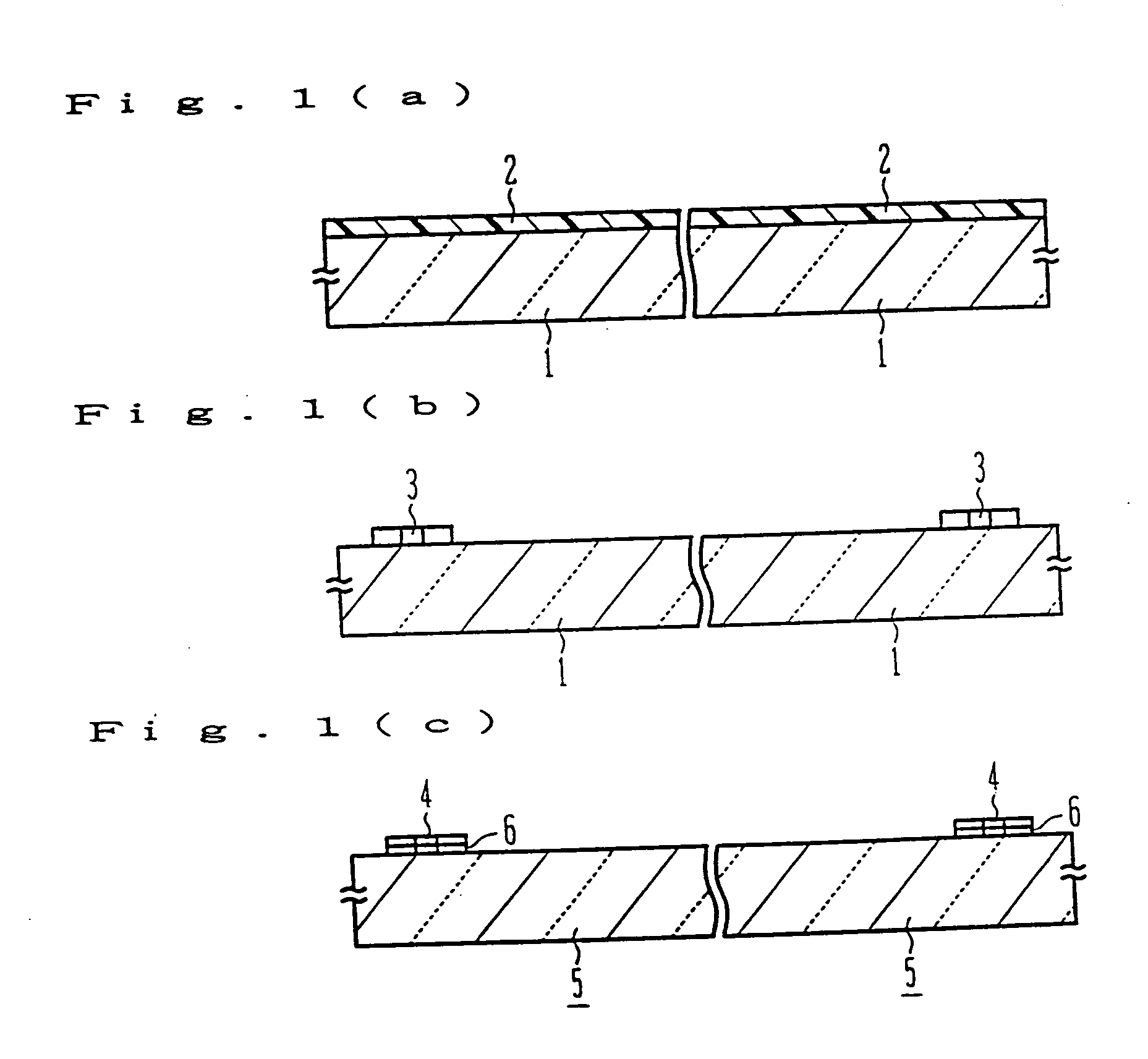

[0195] (1) Preparation of a First Mold by the Method aI.

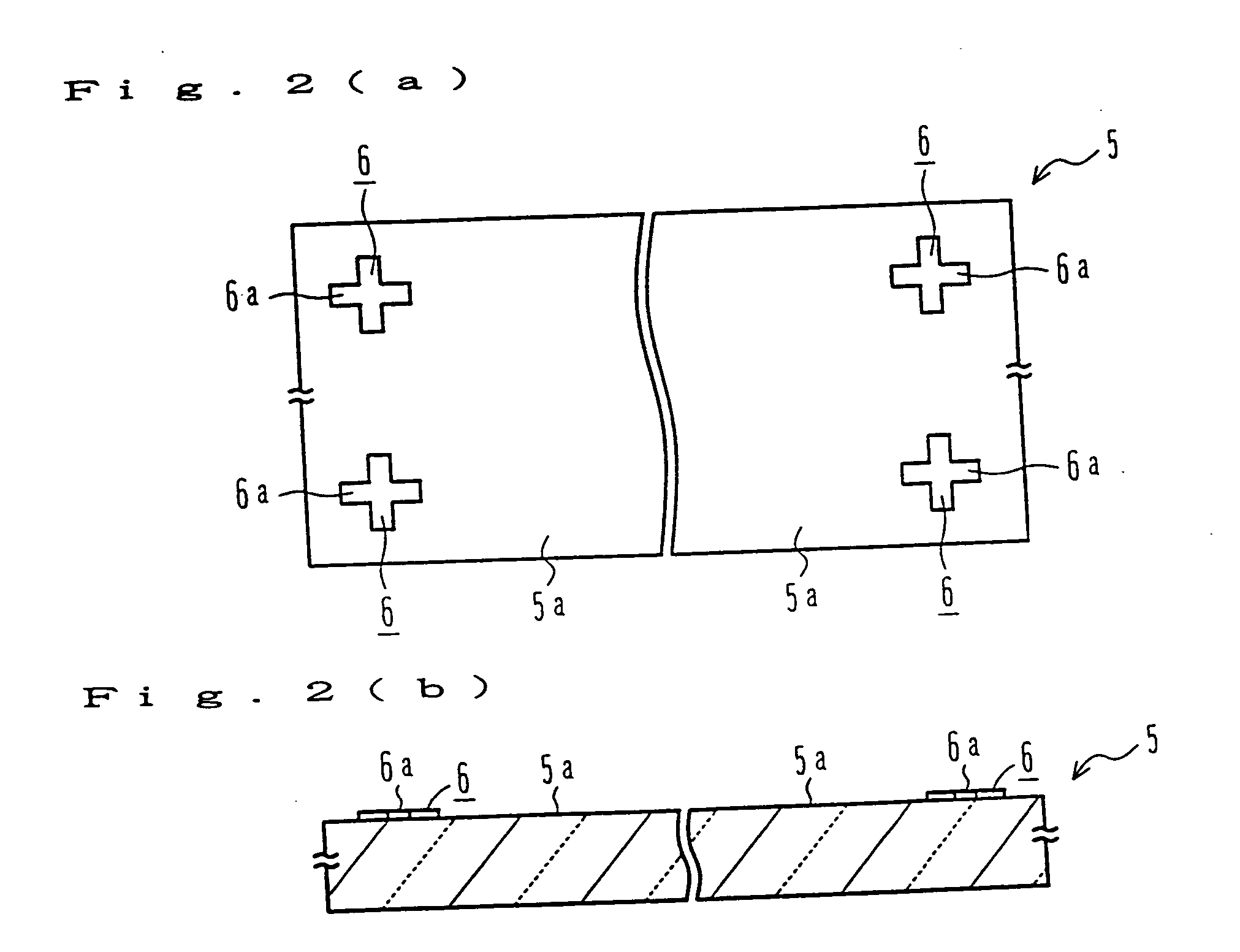

[0196] First, a hard material containing WC is used as a mold material. The mold material has the shape of a flat plate measuring 30.0 mm long, 20.0 mm wide, 1.0 mm thick and having a maximum surface roughness of 100 angstroms. Next, resist patterns of a crossed shape measuring 10 .mu.m long, 10 .mu.m wide, 2.0 .mu.thick and having a line width of 3.0 .mu.m as viewed on a plane are formed at four corners on one surface of the mold material quite in the same manner as in Example 1(1).

[0197] The resist patterns are post-baked at 120.degree. C. for 60 minutes. Then, by using these resist patterns as masks, one surface of the mold material is dry-etched for 10 minute. The dry-etching is effected by using a reactive etching apparatus of the type of Inductively Coupled Plasma, and an Ar gas and a CF, gas are used as etching gases. The etching conditions consist of a coil bias of 600 W, a substrate bias of 600 W, an Ar gas flow rate o...

example 3

[0212] (1) Preparation of a First Mold by the Method aII.

[0213] First, amorphous carbon is used as the mold material. The mold material has the shape of a flat plate measuring 20.0 mm long, 10.0 mm wide, 3.0 mm thick and having a maximum surface roughness of 200 angstroms. Next, a negative-type electron beam resist (ZEP7000 produced by Nippon Zeon Co.) is applied by a spin-coating method onto one surface of the mold material to form a resin layer maintaining a thickness of 1.5 .mu.m on one surface of the mold material.

[0214] Next, by using an electron beam (exposure of 55 .mu.C / cm.sup.2), equilateral triangles of a side of 50 .mu.m long (each side having a line width of 5.0 .mu.m) are drawn at four corners on the resin layer as viewed on a plane. The resin layer after drawn with the electron beam is developed by being immersed in a predetermined developing solution (ZEP500 produced by Nippon Zeon Co.) for 90 seconds.

[0215] The portion of the resin layer that is not drawn with the el...

example 4

[0230] (1) Preparation of a First Mold by the Method aI.

[0231] First, a hard material of the same composition as the hard material used in Example 1 is used as the mold material. The mold material has the shape of a flat plate measuring 20.0 mm long, 10.0 mm wide and 2.0 mm thick. One edge in the direction of length on one surface of the mold material is cut and removed into a predetermined width and a thickness to form a flat surface (hereinafter, the flat surface that is polished as described later is referred to as "flat surface for forming a first transfer portion"). Furthermore, both edges (excluding the flat surface for forming the first transfer portion) in the direction of width on the surface of the mold material are cut and removed over a predetermined width and thickness to form flat surfaces (a total of two flat surfaces; hereinafter these flat surfaces after polished are generally referred to as "flat surfaces for forming second transfer portions"), and these flat surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com