Hydroxyl copper chloride material and synthesizing method thereof

A technology of copper hydroxychloride and copper chloride, applied in the direction of copper chloride, copper halide, etc., can solve the problems of unstable chemical properties, shortening the service life of the reactor, and easily generating other by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

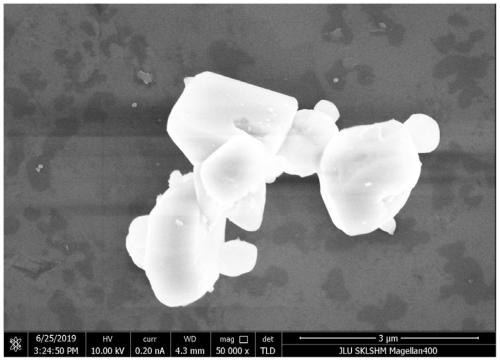

[0023] Copper chloride crystal particles and copper oxide powder are used as raw materials. First weigh 5.683g of copper chloride crystal particles (CuCl 2 2H 2 O) and 2.652g of copper oxide powder (CuO) are poured into the mortar, and the two solid powders are fully ground, and the grinding time is 2h, so that the reactants are mixed evenly; the solid mixture is poured into the polytetrafluoroethylene lining, put Seal it in a stainless steel high-pressure reaction kettle, and react at a reaction temperature of 180°C for 12 hours. After the reaction is completed, wait for it to cool to room temperature, pour the reactant into a mortar, and grind and collect it for 1 hour; the above-mentioned heating, cooling, The process of grinding and collecting was repeated 4 times, the total grinding time was 5 hours, and the total reaction time was 60 hours. That is, the copper hydroxychloride Cu(OH)Cl product of dark green powder is obtained.

[0024] The reaction equation of the prep...

Embodiment 2

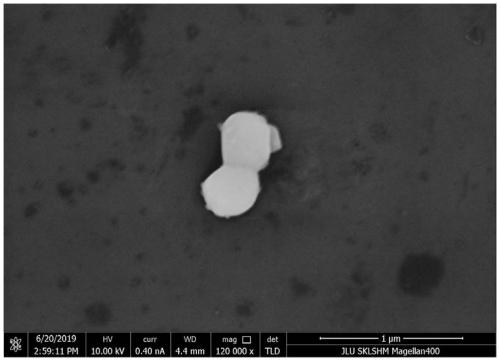

[0028] Copper chloride crystal particles and copper oxide powder are used as raw materials. First weigh 5.683g of copper chloride crystal particles (CuCl 2 2H 2 O) and 2.652g of copper oxide powder (CuO) are poured into the mortar, and the two solid powders are fully ground, and the grinding time is 2h, so that the reactants are mixed evenly; the solid mixture is poured into the polytetrafluoroethylene lining, put Seal the stainless steel high-pressure reaction kettle, and seal the reaction temperature at 100°C for 36 hours; every time the reaction is heated for 12 hours, wait for it to cool to room temperature, pour the sample into a mortar, grind for 1 hour, and collect; the above-mentioned heating, cooling, grinding, and collection Process, repeat the operation 2 more times, the total grinding time is 3h, and the total reaction time is 36h. That is, the copper hydroxychloride Cu(OH)Cl product of dark green powder is obtained.

[0029] Figure 6 Given the XRD spectrum of...

Embodiment 3

[0031] Copper chloride crystal particles and copper oxide powder are used as raw materials. First weigh 5.683g of copper chloride crystal particles (CuCl 2 2H 2 O) and 2.652g of copper oxide powder (CuO) are poured into the mortar, and the two solid powders are fully ground, and the grinding time is 2h, so that the reactants are mixed evenly; the solid mixture is poured into the polytetrafluoroethylene lining, put Seal the stainless steel high-pressure reaction kettle, and seal the reaction temperature at 120°C for 36 hours; every 12 hours of heating and reaction, wait for it to cool to room temperature, pour the sample into a mortar, grind for 30 minutes, and collect; the above heating, cooling, grinding, and collection process, repeat the operation 2 more times, the total grinding time is 1.5h, and the total reaction time is 36h. That is, the copper hydroxychloride Cu(OH)Cl product of dark green powder is obtained.

[0032] Figure 7 Given the XRD spectrum of the prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com