A series of anti-wave design for seaports or harbours

A technology that resists wind, waves and seaports. It is used in coastline protection, jetty, pier, etc., and can solve problems such as loss of ships and other equipment and personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

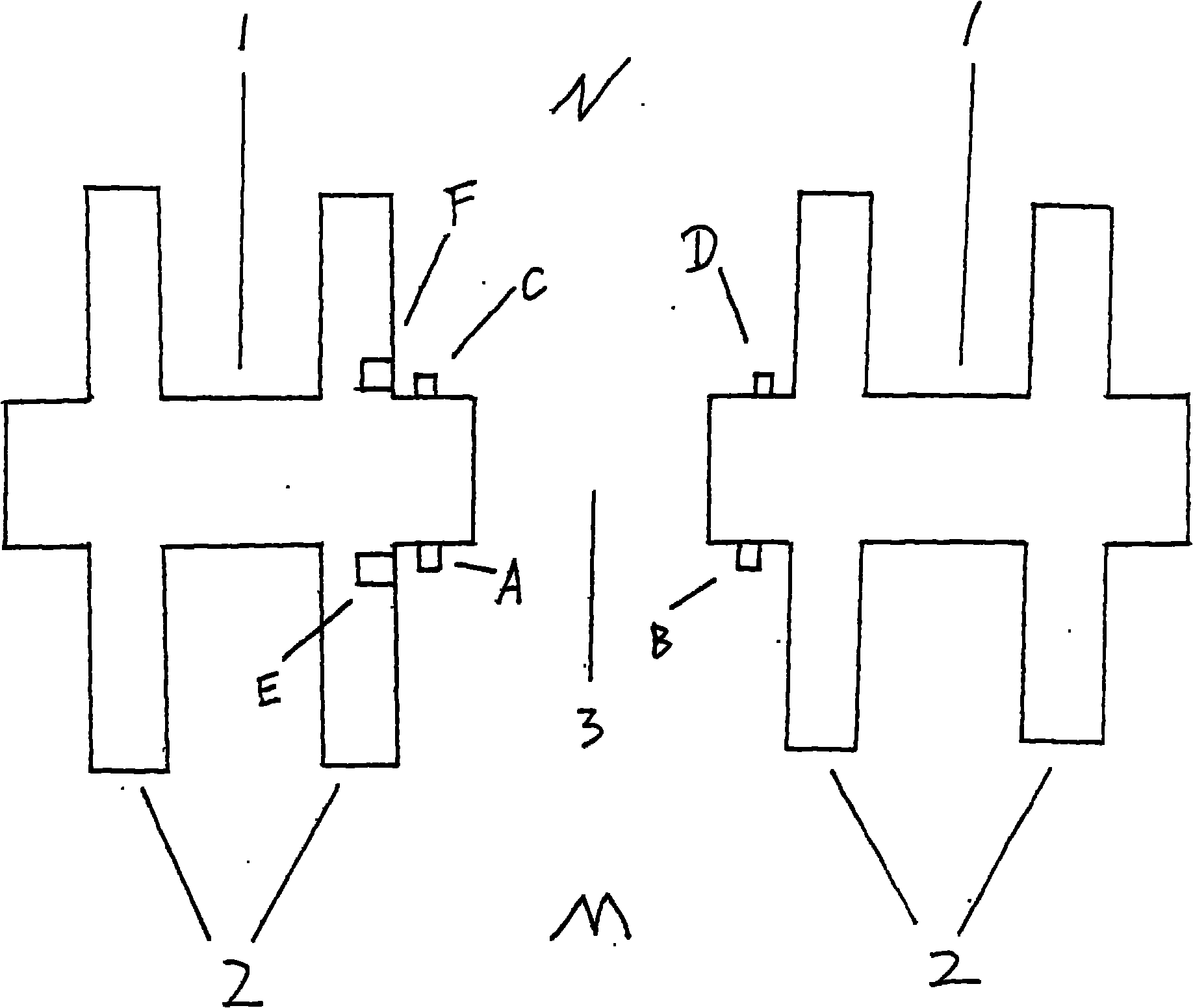

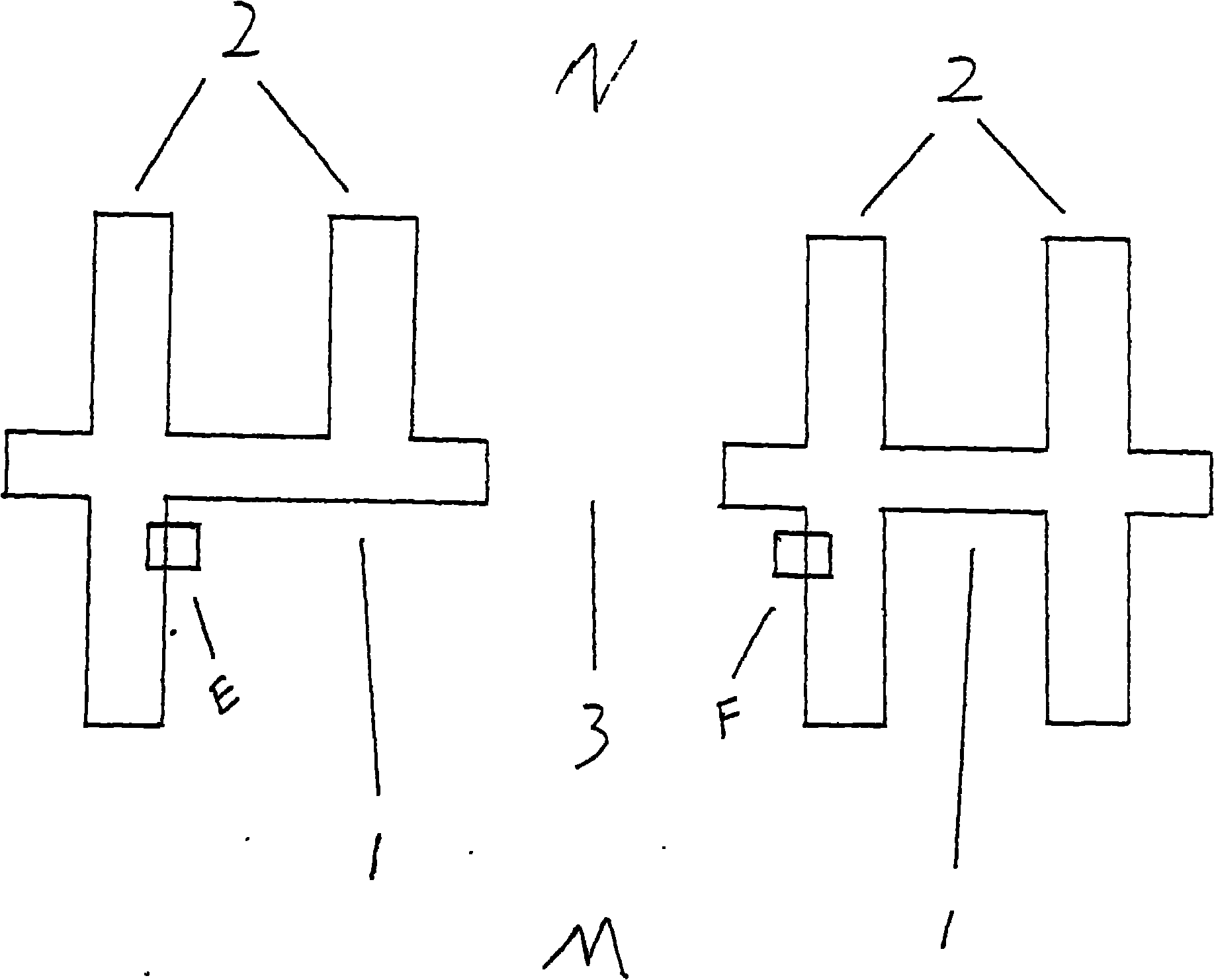

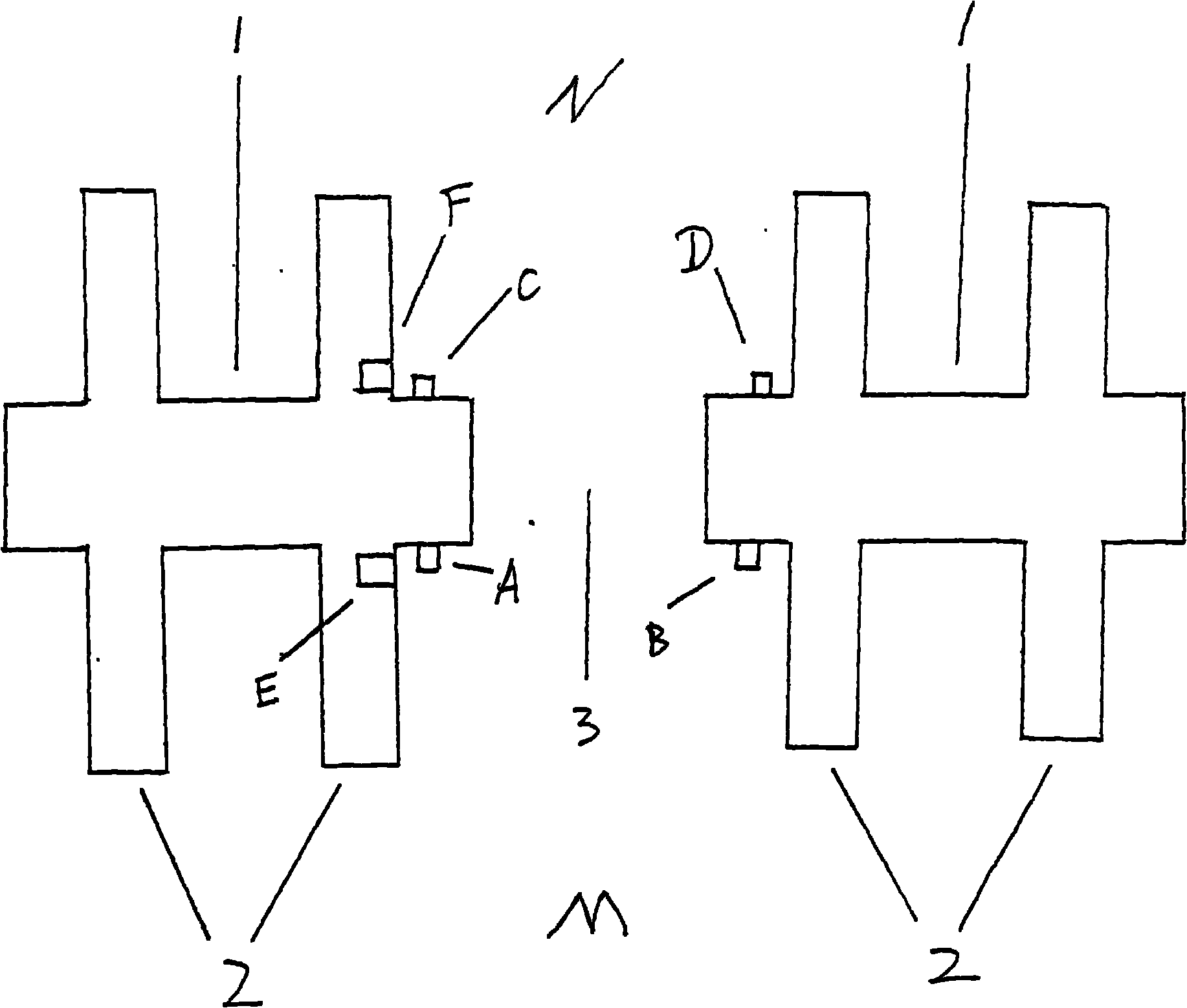

[0015] Embodiment one, see figure 1 . Build a wave-proof wall at the appropriate position of the harbor and harbor. Surround the ports and harbors where ships are moored. The anti-wave wall 1 has reinforced supporting structures 2 in two directions perpendicular to the central axis of the wall. In order to resist strong wind and waves, it will not be pushed down by strong wind and waves. The breakwater wall reserves one export 3 and one import 3 of the ship. Perhaps export 3, import 3 are all on a hole 3, and hole 3 stays wider. Secondly, when a big storm comes, after the ship docks, the outlet 3 and the inlet 3 of the wave wall are sealed with wave-dissipating facilities. The anti-wave wall and wave-dissipating facilities can make the momentum and energy of wind and waves disappear. However, water can be freely passed through the wave-dissipating facilities. The first type of wave-dissipating facility is to overlap multiple layers of fine-mesh nets to make wave-dissipa...

Embodiment 2

[0018] In the second embodiment, on the basis of the first embodiment, the overlapping multi-layer fine mesh is replaced with a soft single-layer mesh object with the same function. The thickness of the mesh object can be about one centimeter or more than one centimeter. This way the energy of the water can also be digested as it passes through it. This wave dissipating facility can be installed about two.

Embodiment 3

[0019] Embodiment 3, on the basis of Embodiment 1, the overlapping multi-layer fine meshes are replaced with hard boards that are pressed one by one. The hard board is that the bottom of the last row of hard boards is pressed on the top of the next row of hard boards. In this way, water can pass freely, and the energy of wind and waves can be digested. Only one piece of this wave-dissipating facility is installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com