Lead screw nut pair transmission control device and method, nut subassembly processing method

A screw nut and lead screw technology, applied in the field of nut processing, can solve the problems of immature technology development, high cost, large ball screw transmission error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

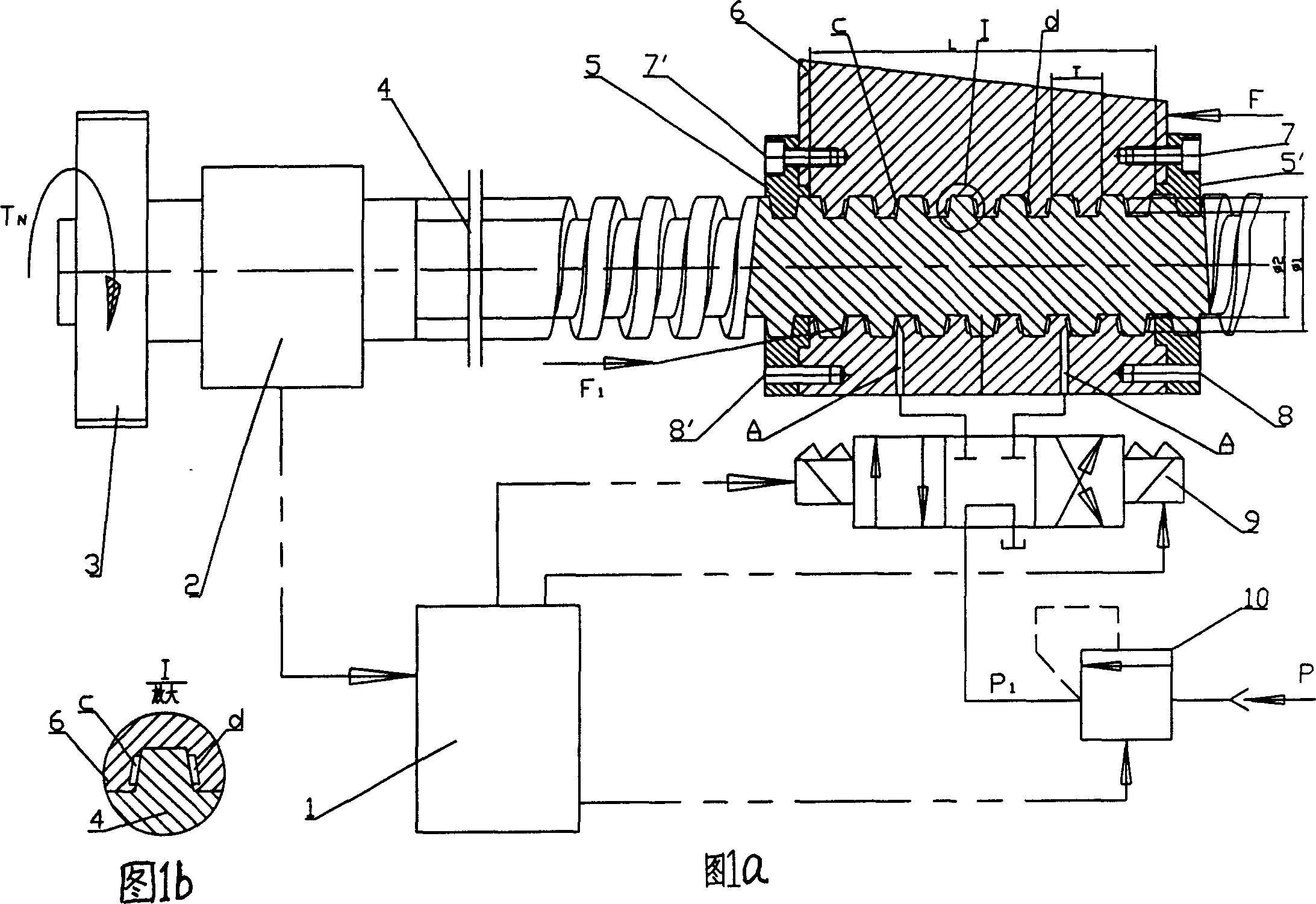

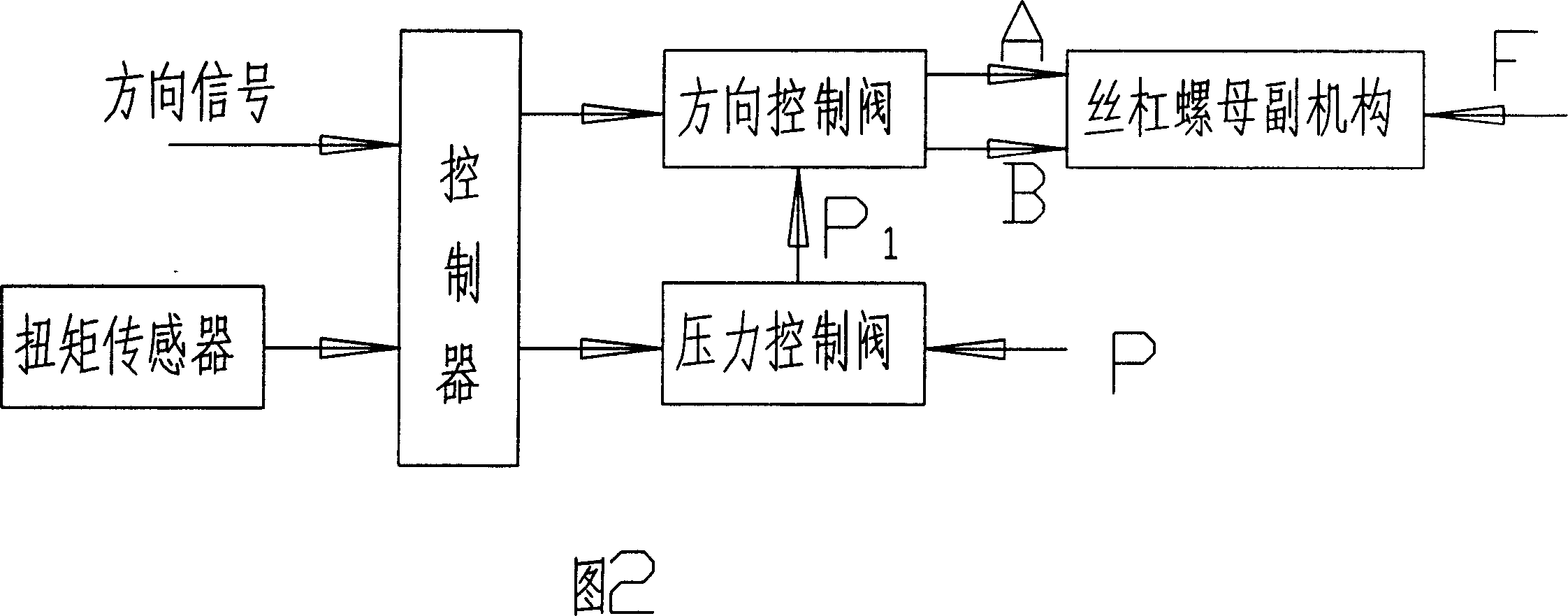

[0015] As shown in Figure 1a, the lead screw nut auxiliary transmission device of the present invention is composed of a hydraulic control mechanism and a mechanical transmission mechanism, wherein the lead screw 4 rotates together with the transmission wheel 3, and the lead screw nut pair drives the nut 6 to perform a straight line along the lead screw 4. The hydraulic control mechanism is composed of a controller 1, a pressure control valve 10, a three-position four-way electromagnetic reversing valve 9, and a torque sensor 2. The torque sensor 2 is installed between the power transmission wheel 3 and the nut 6. The torque sensor 2 connects the wire The torque T transmitted by bar 4 N It is converted into a signal and transmitted to the controller 1. The controller 1 uses a single-chip microcomputer or PLC as the core to realize control. The controller 1 adds the oil circuit reversing control signal to the three-position four-way electromagnetic reversing valve 9, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com