Patents

Literature

67results about How to "Improve drinking value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

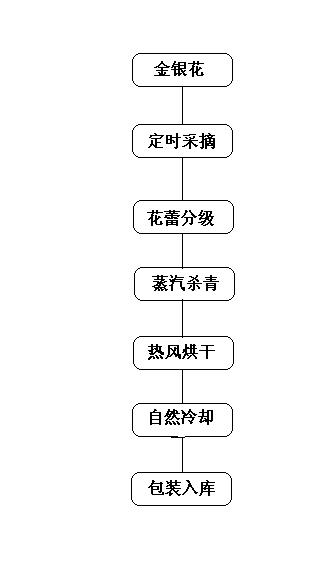

Processing method of honeysuckle tea

InactiveCN102356794ARapid inhibitory activityAvoid decompositionTea substituesCold airChlorogenic acid

A processing method of honeysuckle tea has a technical scheme that the method comprises the following steps of picking at regular time, bud grading, enzyme deactivation by steam, hot air drying, natural cooling, packaging and warehousing; the beneficial effect is that: honeysuckle buds are picked at 8:30-11:00 in the morning everyday, which can ensure that fresh flowers contain the most beneficial components and dew is prevented; grading of the buds can ensure uniform processing; enzyme deactivation by steam can rapidly inhibit the activity of polyphenol oxidase, and effectively prevent the decomposition of honeysuckle chlorogenic acid; direct hot air drying is performed after enzyme deactivation without cooling or cold air dehumidification, which can rapidly remove residual water contained in fresh flowers, destroys the activity of polyphenol oxidase, and allows the honeysuckle tea to be maintained to be undeteriorated for a long time; the honeysuckle tea processed by the method has a jade green color, and a lifelike shape; nutrient components can be maintained to be less lost; the infused tea has a bright and clear soup color, and a complete flower shape; the invention can greatly increase the drinking value and appearance quality of honeysuckle tea.

Owner:重庆市秀山红星中药材开发有限公司

Seacucumber-blueberry instant particles and processing method thereof

ActiveCN101897458ARich in nutrientsSignificant nourishing and health effectsFood preparationNutrientNutritional composition

The invention relates to seacucumber-blueberry instant particles and a processing method thereof. Seacucumber, blueberry and barbary wolfberry fruit are taken as major raw materials, vitamin C, citric acid, xylitol, a sweetener and an excipient are taken as auxiliary raw materials and nutrient components such as zinc gluconate, taurine, vitamin E acetate, collagen, L-carnitine, calcium gluconate and the like are added as required by different people. The method comprises the following steps of: performing pretreatment, biological enzymolysis, extraction and drying on the raw materials; extracting active components in the raw materials; and mixing, pelletizing, drying and disinfecting the active components to obtain the instant particles. Protein in the seacucumber is hydrolyzed to exist in the form of small molecule peptides so that the protein is easy to be absorbed by human bodies, the activities of nutrient substances in a mixture are kept, the active components are stabilized in a product, the original juice, original taste and original colors of the raw materials are kept and the medicinal value, nutrient value and drinking value of the mixture of a plurality of raw materials are enhanced. The particles have the advantages of bright color, uniform form, stable property, rich nutrition, pleasant sweetness and sourness, convenient drinking and remarkable nourishing effect.

Owner:辽宁阿里郎生物工程股份有限公司

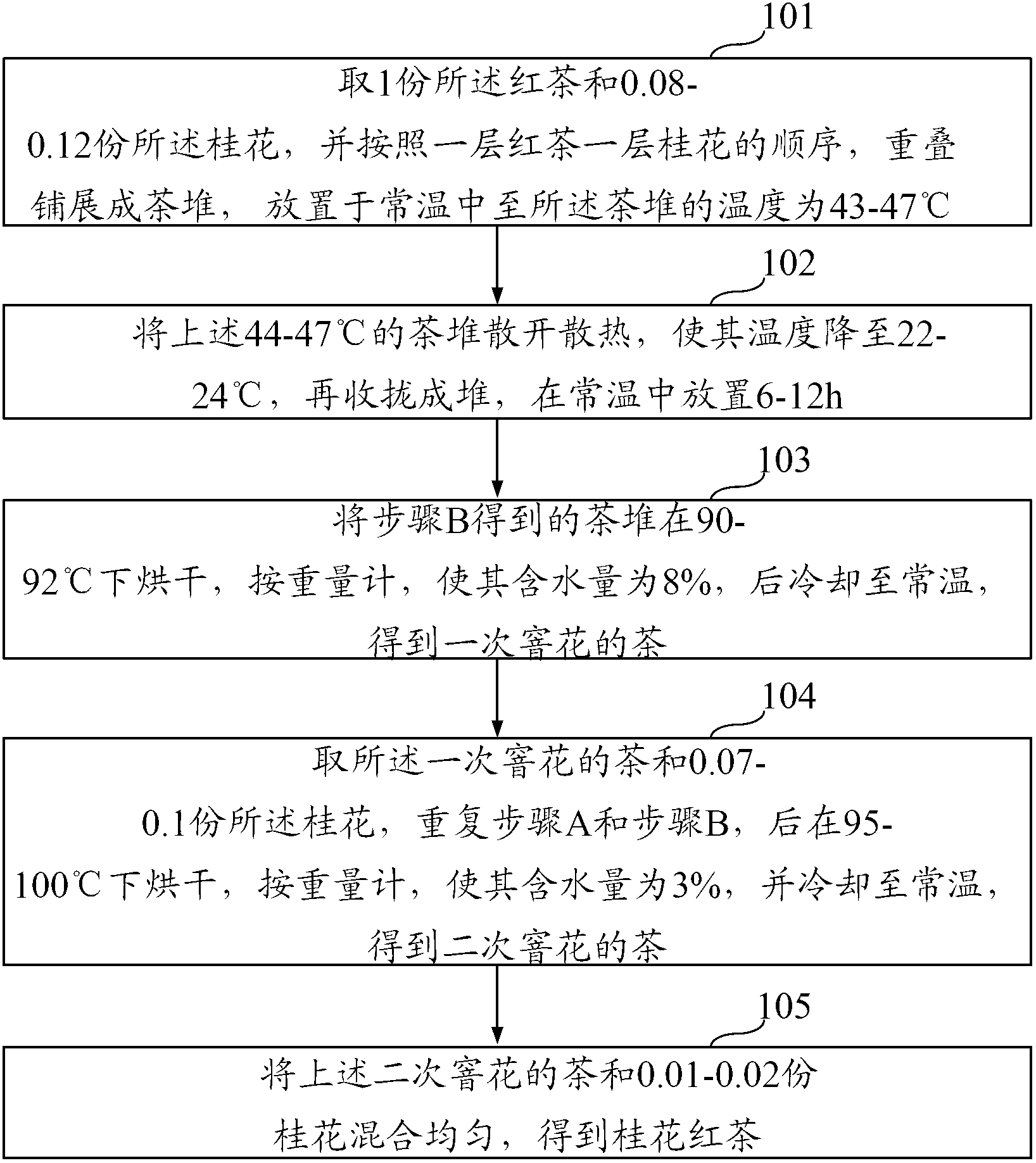

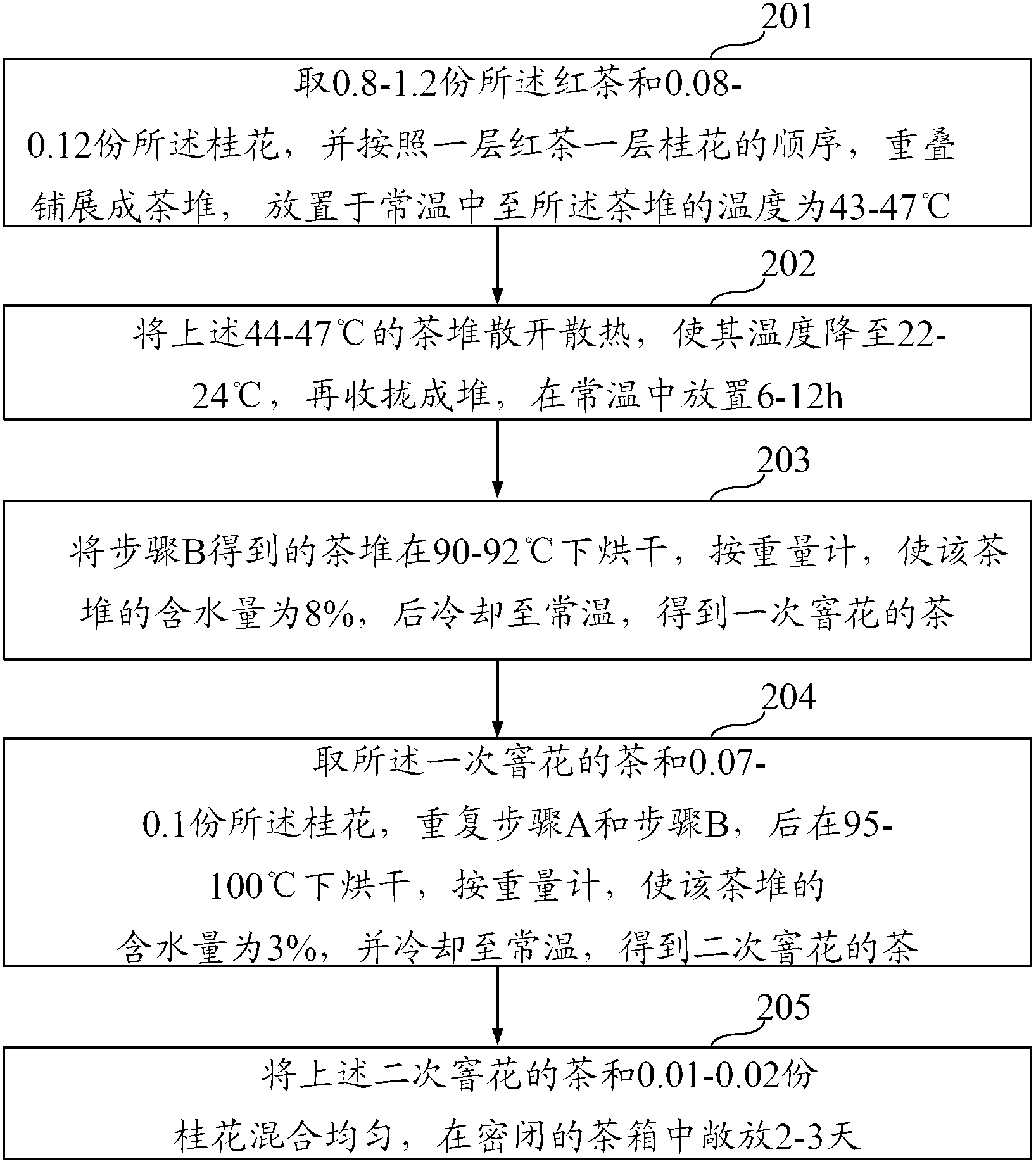

Black tea with sweet osmanthus and scenting method thereof

The invention belongs to the field of making of tea leaves, and particularly relates to black tea with sweet osmanthus and a scenting method thereof. The black tea with sweet osmanthus comprises the following components in parts by weight: 0.8-1.2 parts of black tea and 0.16-0.24 parts of sweet osmanthus. The scenting method comprises the following steps of: spreading 1 part of black tea and 0.08-0.12 parts of sweet osmanthus layer after layer alternatively to form a tea pile, and standing at the normal temperature till the temperature of the tea pile is 43-47 DEG C; spreading for dissipating heat till the temperature is lowered to 22-24 DEG C, gathering into a pile, and standing at the normal temperature for 6-12 hours; drying at the temperature of 90-92 DEG C, and cooling to obtain primarily-scented tea; adding 0.07-1 part of sweet osmanthus, repeating the previous steps, drying at the temperature of 95-100 DEG C and cooling to obtain secondly-scented tea; and adding the left sweet osmanthus, and mixing to obtain the black tea with sweet osmanthus. The black tea with the sweet osmanthus is prepared manually, so that damages of a mechanical way to nutritional ingredients are avoided, and the natural values of the black tea and the sweet osmanthus are kept.

Owner:李德芬

Processing method of tea flowers

The invention discloses a processing method of tea flowers, relating to the technical field of processing. The processing method comprises the following steps: harvesting tea flower buds from the middle ten days of October to the first ten days of December; wiping out receptacles, spreading on a water sieve; freezing the buds in a gauze bag at a temperature of being less than 20 DEG C, freezing for 12-14h; freeze-drying the buds in a vacuum dryer, vacuumizing when the temperature is lower than -20 DEG C, starting an oil heating system when the pressure is vacuumized to -0.1 Mpa, continuously drying for 24-26h by heating until the content of water in the buds is not greater than 4 percent; and baking the buds in a baking machine at a temperature of 90-100 DEG C for 15-20min. According to the processing method, the problem that the quality is not favorably improved because the plumpness is poor, the appearance is unattractive, the color is not fresh and alive, the fragrance is not pure, the color is slightly yellow and not bright, and the like is solved.

Owner:葛智文 +3

Production method of wild honeysuckle flower tea

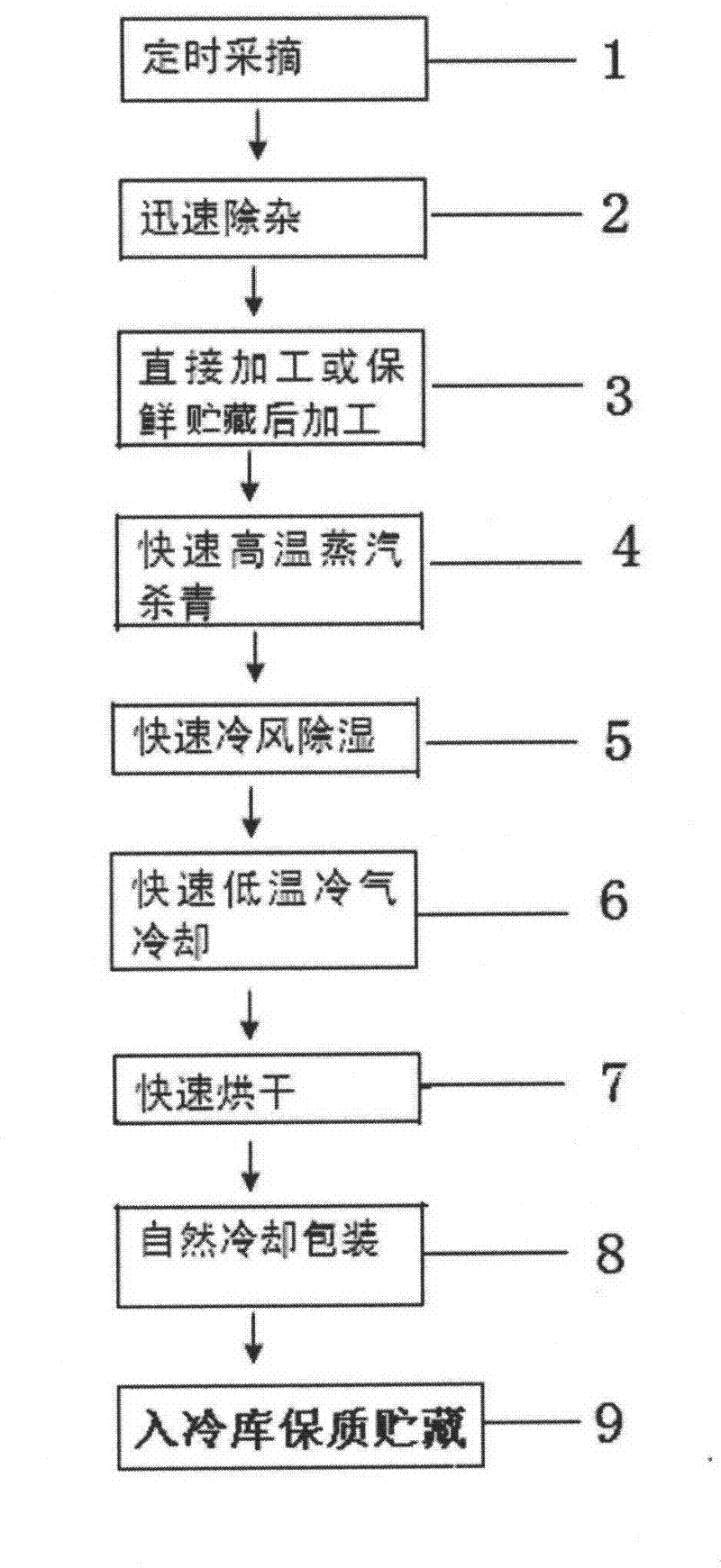

InactiveCN102326648AFull flower shapeComplete flower shapeTea substituesChlorogenic acidDecomposition

The invention discloses a production method of wild honeysuckle flower tea. By adopting the production method, the original color and shape of wild honeysuckle flower can be kept unchanged and stable chlorogenic acid content can be ensured. The production method specifically comprises the following steps: picking at regular time; rapidly removing impurities; directly processing; carrying out rapid enzyme deactivation by high-temperature steam; rapidly dehumidifying by cold air; rapidly cooling by low-temperature cold air; rapidly drying by high-temperature hot air; naturally cooling and packaging; and warehousing for storage so as to guarantee quality. The production method has the beneficial effects of rapidly destroying activity of polyphenol oxidase in the wild honeysuckle flower, effectively avoiding decomposition of the beneficial substance namely chlorogenic acid contained in the wild honeysuckle flower, preventing the wild honeysuckle flower from browning, avoiding the procedures of turnover as well as pickup and placement, and ensuring that the appearance of the wild honeysuckle flower is not damaged and the flower shape is complete. The wild honeysuckle flower tea processed by the method has the advantages of green color, new shape and less loss of the chlorogenic acid; and the brewed wild honeysuckle flower tea has the advantages of light green and bright and clean color, delicious taste as well as complete and lifelike flower shape. Therefore, the drinking value and appreciation grade of the wild honeysuckle flower tea are obviously improved by adopting the production method.

Owner:XIUSHAN SHENGDA AGRI DEV

High-protein tea lozenge

InactiveCN102422914ALow in soluble proteinHigh nutritional valuePre-extraction tea treatmentNutritive valuesAdditive ingredient

The invention discloses a high-protein tea lozenge, which consists of the following components in percentage by mass: 18 to 90 percent of tea powder prepared by an enzyme processing process, 8.9 to 80 percent of protein powder or milk powder and 1 to 10 percent of walnut powder. Compared with the prior art, the high-protein tea lozenge has the advantages that: (1) the content of soluble protein in tea prepared by the conventional process is low, the protein powder or the milk powder is added into ingredients and the walnut powder is mixed in order to enhance the nutritive value of the tea lozenge, and thus, the tea lozenge is nutritional health-care food; (2) by enzyme processing, cellulose, insoluble protein, ester catechin and the like in the tea are hydrolyzed, so that the content of soluble ingredients is increased; and (3) due to the hydrolysis of the ester catechin, the bitter and astringent taste of the tea is easy to reduce, and due to the addition of peroxidase and catalase, the content of theaflavin and thearubigins is increased, the drinking value and health-care value of black tea are improved, and the taste of the black tea is improved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Processing method for dismantling scented tea

InactiveCN101965882APromotes opening and exhalingPromote opennessPre-extraction tea treatmentSINGLE LOBEBoiling point

The invention discloses a processing method for dismantling scented tea. In the method, single-lobe Jasmine flower spell and a tea billet are applied, first-time, second-time and third-time scenting are adopted, second drying operation after every time of scenting is carried out, and then flower frying is carried out after third-time second drying; the flower frying comprises two steps of fourth-time scenting and frying; and when in frying, firstly frying is carried out at the temperature of 85-90 DEG C, a dehumidifying fan is started intermittently in the process of high-temperature frying, then slow frying is carried out at the temperature of 70-80 DEG C, the tea and the flower are rolled and blended and are mixed uniformly, the tea absorbs the scent of the flower fully, and the tea and the flower are removed from heat when the flower is dried, thus a finished product can be obtained. The processing method not only is beneficial for the tea to absorb more fragrant components with low boiling point, but also is beneficial to improving the fragrance freshness degree, simultaneously, is more beneficial to absorbing more concentrated fragrance type fragrant components and increasing concentration and endurance of the fragrance and soaking resistance, and has high drinking value. When in making, the dried flower absorbs water to expand and bloom slowly, and is suspended in a cup, which is vivid and has unique appreciation value.

Owner:SICHUAN WENG TEA IND

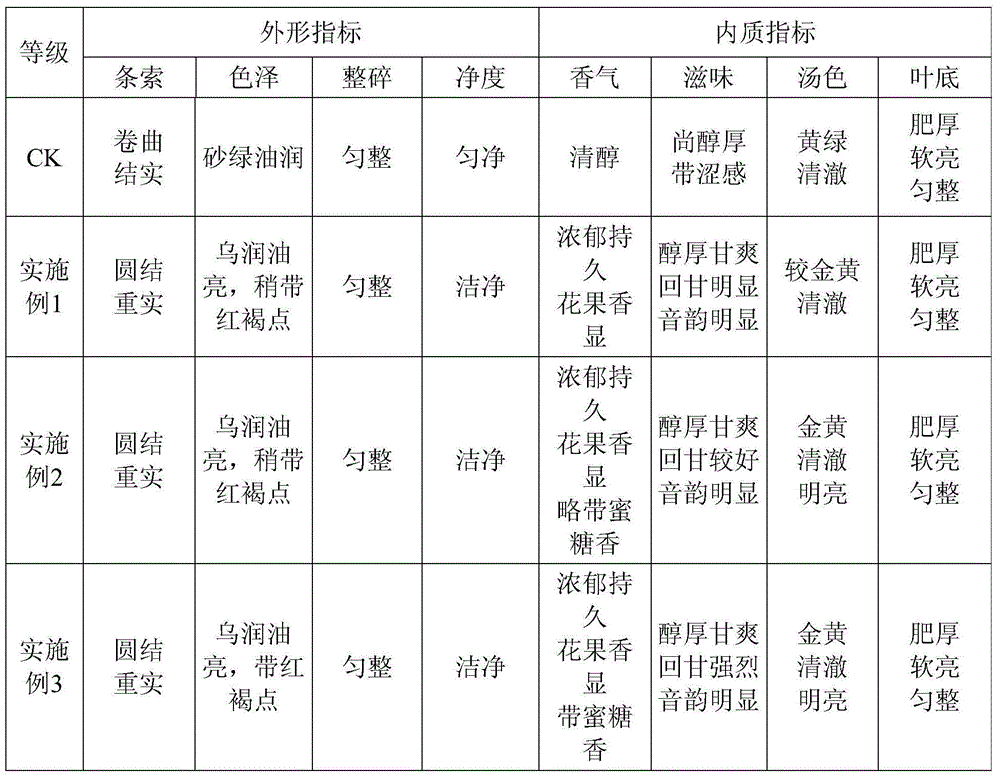

Temperature-varying baking method for Anxi tieguanyin

The invention discloses a temperature-varying baking method for Anxi tieguanyin. The method successively includes an impurity-removing stage, a converting stage and a forming stage. A temperature of the impurity-removing stage is 140-150 DEG C and a lasting time of the impurity-removing stage is 30-40 min; a temperature of the converting stage is 165-170 DEG C and a lasting time of the converting stage is 30-40 min; and a temperature of the forming stage is 160-165 DEG C and a lasting time of the forming stage is 70-80 DEG C. A temperature-increasing speed from the impurity-removing stage to the converting stage is 0.5-1 (DEG C) / min and a temperature-decreasing speed from the converting stage to the forming stage is 0.3-0.5 (DEG C) / min. Anxi tieguanyin baked through the method in the invention is round and plump in an external shape, is black in color, is rich and persistent in nectar fragrance, is smooth and sweet in taste and is distinct in quality characteristic. The baked Anxi tieguanyin is different from Da Hung Pao which is backed through a conventional baking method, is non-persistent and thin in taste and is heavy in bitter taste due to insufficient duration and degree of heating or has a burnt smell. Safety and tasting value of the tea is improved. Problems that a conventional baking process is single and quality of the tea cannot satisfy a demand of consumers are solved.

Owner:XIAMEN TEA IMPORT & EXPORT

Preparation method for Jasmine Tea

ActiveCN103181426AQuality improvementImprove drinking valuePre-extraction tea treatmentTea flavoringGardeniaJasminum tortuosum

The invention relates to a preparation method for tea, in particular to a preparation method for Jasmine Tea. The preparation method aims to overcome the defects in the prior art, and is a processing method capable of improving fragrance concentration of the Jasmine Tea through fragrance adjustment of gardenia. According to the invention, the gardenia is adopted to prepare the Jasmine Tea through scenting so as to improve the fragrance concentration of the Jasmine Tea through fragrance adjustment and foil the freshness degree of the floral fragrance; when the jasmine flowers are subjected to scenting, gardenia in right quantity and the jasmine flowers are put together, as more gardenia easily cause magnoma; a small amount of gardenia is put together with the jasmine flower, so as to perform flower refinement; and during flower scenting, in order to keep perfume fresh and pure, the temperature is controlled through radiating, so that the scented tea is high in concentration and freshness degree, good in quality, low in cost, high in fresh flower utilization rate, and favorable for industrialized production.

Owner:FUZHOU FUMIN TEA

Preparation process of quantum activated water and quantum activator thereof

InactiveCN106315961AStrong nutritional and physiological functionsHigh activityTreatment involving filtrationWater/sewage treatment by ion-exchangeFiltrationSoftened water

The invention discloses a preparation process of quantum activated water. The preparation process comprises the following steps: S1: filtering and softening, namely sequentially carrying out coarse filtration with a coarse filtering device, fine filtration with a fine filtering device and refined filtration with a refined filtering device on water, and softening filtered water with a softening device to obtain softened water; S2: magnetizing, namely magnetizing the softened water with a permanent magnetic magnetizing device to obtain magnetized water; S3: carrying out quantum water activating treatment, namely, feeding the magnetized water into a quantum activator, wherein cutting the water entering the quantum activator by light quantum in the quantum activator at a certain speed, so as to change macromolecule water into small molecule water; and S4: carrying out microcrystal treatment, namely enabling the small molecule water to pass through a container containing microcrystal, and carrying out several times of activated dissolving so as to obtain the finished product of quantum activated water. The invention further discloses a quantum activator. The preparation process and the quantum activator have the benefits of improving water quality, increasing the number of small molecular groups, and enhancing the activity of water molecules.

Owner:周发昌

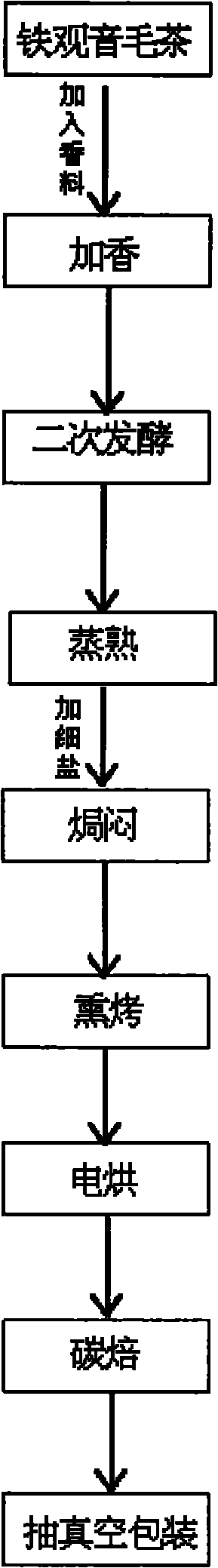

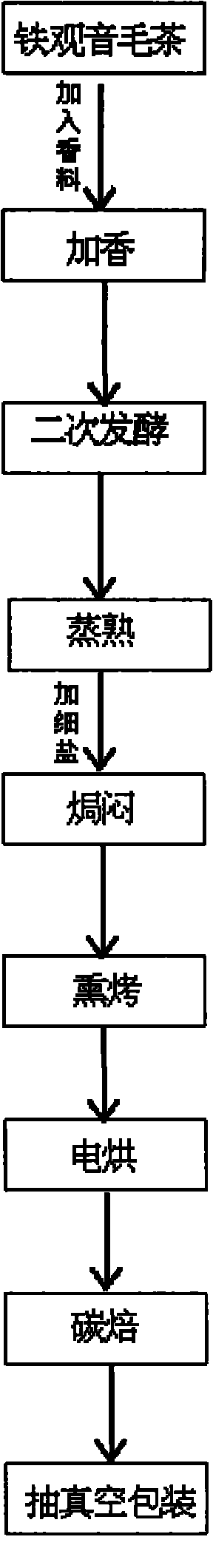

Method for preparing tieguanyin health tea

InactiveCN101904381AIncrease glycol levelImprove drinking valuePre-extraction tea treatmentCooking & bakingExcellent preparation

The invention relates to a method for preparing tieguanyin health tea, and belongs to the technical field of tea processing. In the method for preparing the tieguanyin health tea, finished crude tieguanyin tea is subjected to the processing steps of flavoring, secondary fermentation, steaming, baking and braising, roasting, electric baking and charcoal baking first and then products are classified according to quality, and finally the products are subjected to vacuum packing. By centralizing the excellent preparation processes of the four famous tea and adopting the brewing methods of certain traditional Chinese medicines, the caffeine content, tea tannin content and harmful substance content of the tea are reduced, the glycol degree and drinking value of the tea are greatly improved and the tea has good health-care effect.

Owner:林 森木

Method for preparing fermented sea cucumber and blueberry mixed health wine

InactiveCN101899375AFull of nutritionGreat tasteAlcoholic beverage preparationMicroorganism based processesNutritionFood flavor

The invention discloses a method for preparing fermented sea cucumber and blueberry mixed health wine, and belongs to the technical field of wine making. The method comprises the following steps of: adding waste liquid of the sea cucumber, slag of blueberry fruit or a mixture of the liquid of the sea cucumber and the slag of the blueberry fruit into a culture medium directly; then inoculating ethanol-producing strains, and fermenting at normal temperature; decomposing protein in wastes obtained by processing the sea cucumber and the blueberry into small polypeptide and amino acid molecules which are easily digested and absorbed; meanwhile, maintaining active ingredients such as polysaccharide, saponin and the like in the sea cucumber and the blueberry; and filtering and removing the slag after fermentation to obtain low health wine, or blending high health wine by using high-purity pure-grain wine. The health wine has the advantages of stable form, uniform liquid, rich nutrition, no fishy smell, good taste, quick nourishing effect and convenient drinking. The processing method has the advantages of maintaining the activity of nutrients in the sea cucumber and the blueberry, stabilizing the active ingredients in a liquid state, retaining original flavor and color of raw materials, simultaneously improving industrial value of the sea cucumber and the blueberry, and increasing medicinal value, nutrient value and drinking value of the raw materials.

Owner:DALIAN UNIV OF TECH

Hippophae rhamnoides tea and manufacture method

InactiveCN101204184ARich sourcesTaste slightly bitter and sweetTea substituesFood preparationDiseaseCoronary heart disease

The invention relates to a beverage tea of seabuckthorn leaves, which takes fresh and wild seabuckthorn leaves on Ningxia Highland as only material and processes a beverage tea which can be drunken after boiled in water. The processing method includes the processes like picking, selecting, desquamation, water removing in steam, cleaning, kneading and twisting, shaping and drying. The invention is characterized in that: the processes of desquamation, water removing and drying in low temperature in the processing course well keep the effective contents in the seabuckthorn leaves without squama, thus bringing the pharmacological characteristics into full play. After long-term drinking, the invention can prevent various diseases such as hypertension, coronary heart disease and atherosclerotic arterial disease, and improve the organism immunity function; therefore, the invention is an excellent beverage and health-keeping product.

Owner:张爱平

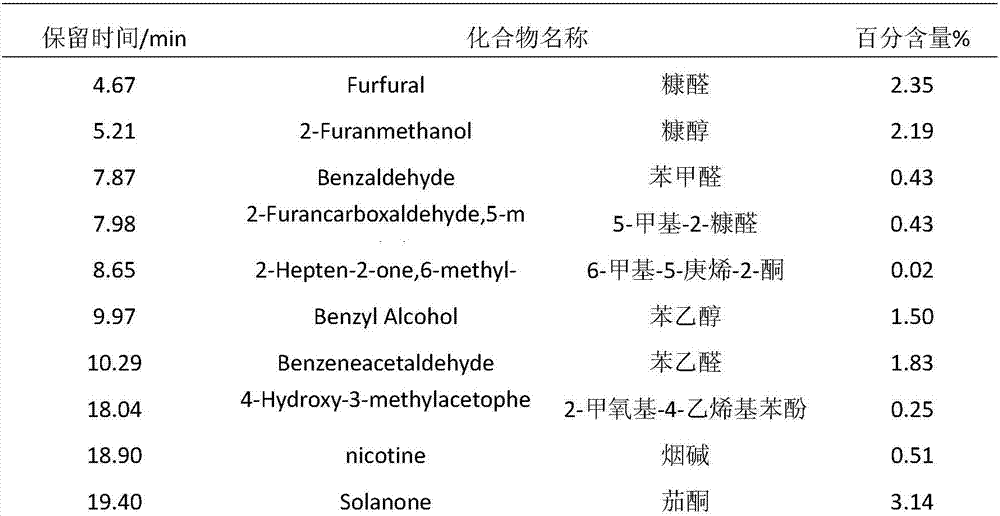

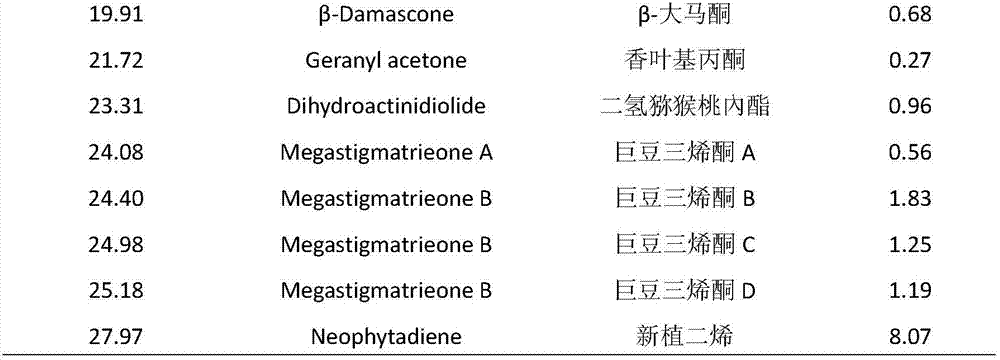

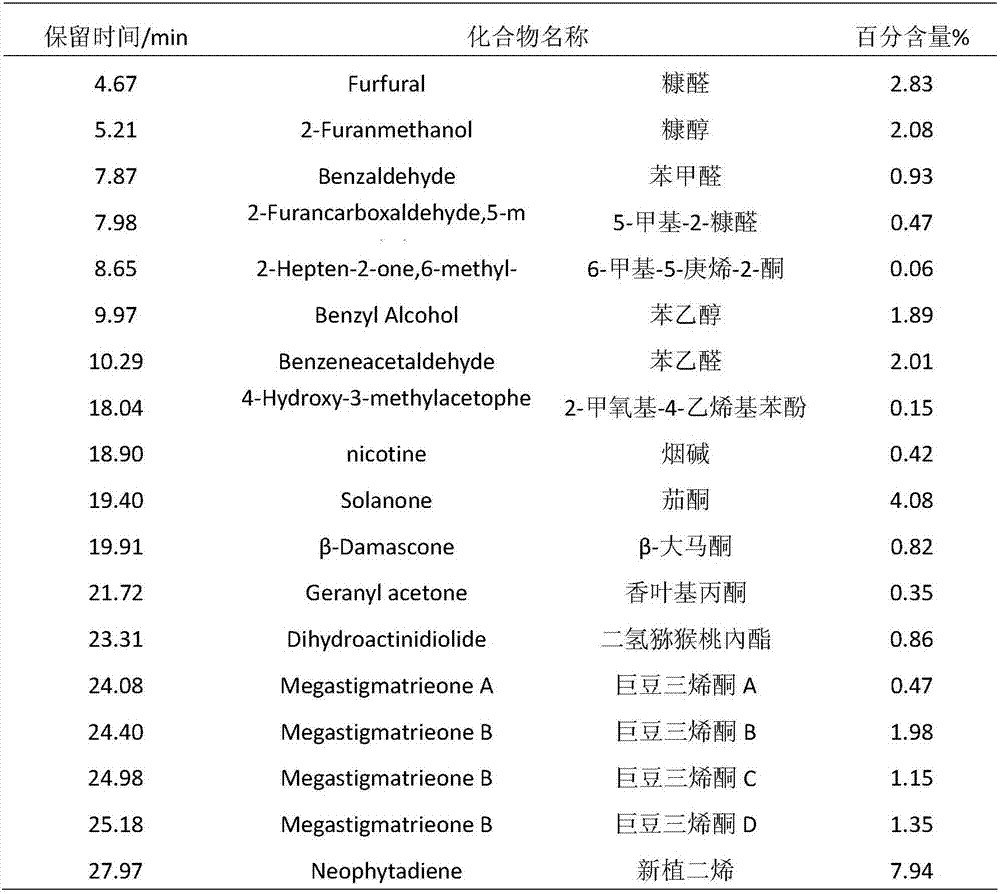

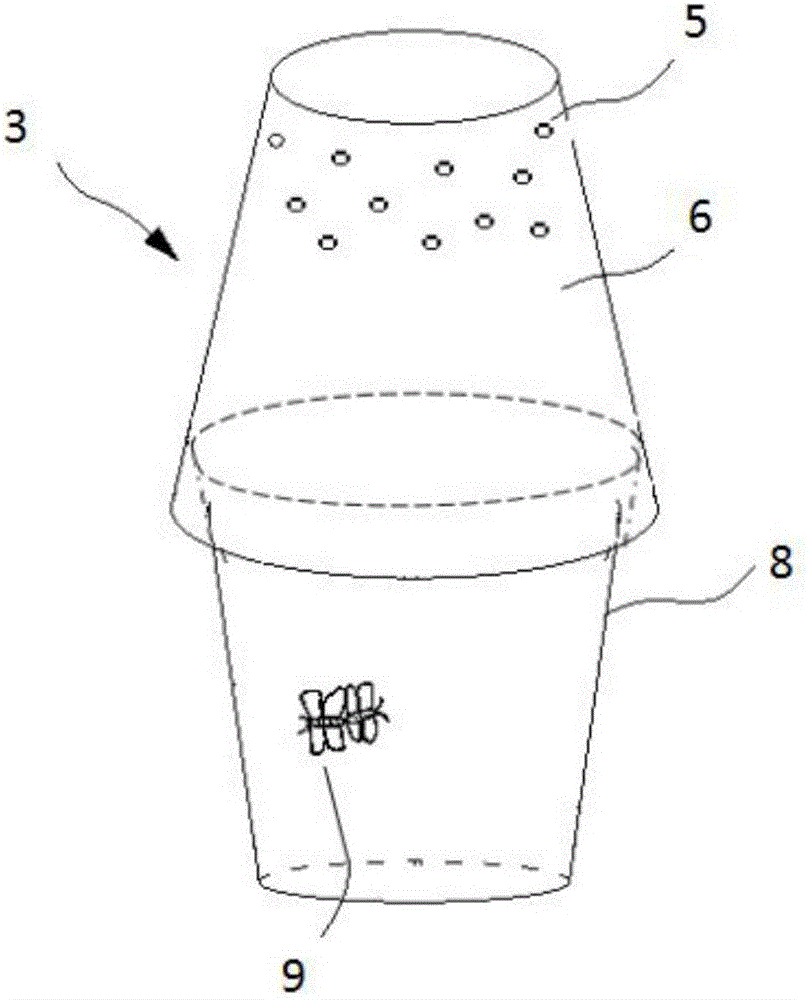

Drinking-type tobacco product

ActiveCN107224005APhysical health injuryNo harmTobacco treatmentNatural extract food ingredientsHazardous substanceFreeze-drying

The invention discloses a drinking-type tobacco product. A tobacco extract with safe nicotine content and special tobacco aroma ingredients is extracted from high-quality flue-cured tobacco leaves, and the liquid tobacco extract is made into instant crystal powder through freeze drying. The product can be instantly dissolved in water and is drunk in a hot-water brewing mode. Furthermore, the tobacco extract instant crystal powder is added into an instant tea medium, a tea-flavored drinking cigarette is prepared through a blending process, has a better taste and clear, bright and thorough color and luster, can meet the physiological need of cigarette customers, does not produce hazardous substances such as tar and carbon monoxide due to tobacco burning, and does not harm a consumption environment and consumers' health. While the tobacco consumption populations are met, the product meets the demands of different consumption populations by utilizing mature and diversified fine processing and blending means, is higher in safety and richer in taste and is more easily to be accepted.

Owner:CHINA TOBACCO YUNNAN IND

Method for simply and efficiently preparing tea worm

ActiveCN106172243ASimple processEase of industrial productionPre-extraction tea treatmentTea substituesResource utilizationSugar

The invention discloses a method for simply and efficiently preparing tea worm and belongs to the technical field of tea resource utilization. According to the method provided by the invention, the edible tea insects are taken as production insects for tea worm, the food of the tea worm is free from complex pretreatment and the tea resource can be efficiently converted. According to the method provided by the invention, 18 tons of tea worms can be produced in each year in a 100m<2> workshop. The tea worm acquired according to the invention has high yield and high quality; the indexes, such as toxicology, are basically consistent to the indexes of tea leaves; the tea worm contains crude protein, crude fat, sugars, vitamins, various mineral elements and 20 amino acids; the tea worm has excellent nutritional and health effects and ultrahigh drinking value.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Process method of optimizing Huangshan Maofeng aged tea

ActiveCN107348054AImprove the quality of color and fragranceMeet the damagePre-extraction tea treatmentFlavorChange color

The invention provides a process method of optimizing Huangshan Maofeng aged tea. The process method comprises the following steps of: adding black tea into aged Huangshan Maofeng tea to enhance aroma, then humidifying and softening the tea by ultrasonic waves; adding carotene to change color, and performing pile fermentation to remove stale taste; then performing reciprocating sifting to remove ends, electrically heating and primarily drying the tea, electrically heating and neatening the strips, spreading for cooling for resurgence, performing winnowing to remove impurities, and performing electromagnetic aroma enhancement and the like to obtain the reproduced Huangshan Maofeng tea with enhanced flavor and taste.

Owner:黄山光明茶业有限公司

Eight ingredient tea, and preparation method thereof

InactiveCN105265667ARich in nutrientsImprove drinking valueTea substituesNutrient contentPericarpium citri reticulatae

The invention discloses a preparation method of a health care tea, and more specifically discloses an eight ingredient tea and a preparation method thereof. The eight ingredient tea is prepared from, by weight, 12 to 15 parts of sterculia lychnophora, 6 to 8 parts of lonicera japonica, 6 to 8 parts of pericarpium citri reticulatae, 10 to 12 parts of apricot kernel, 11 to 13 parts of longan, 10 to 13 parts of Chinese wolfberry, 5 to 7 parts of rhizoma gastrodiae, 6 to 10 parts of walnut, 9 to 11 parts of angelica sinensis, and 5 to 25 parts of rock sugar. According to the preparation method, a reasonable raw material formula is adopted; raw materials, such as Chinese wolfberry, rhizoma gastrodiae, walnut, and angelica sinensis, which possess traditional Chinese medicine properties are selected, and are mixed with the raw materials such as sterculia lychnophora, so that development of phamaceutical value of the ingredients is realized as far as possible; and the eight ingredient tea is abundant in nutrients, and is high in drinking value.

Owner:ZHENJIANG WUFENG TEA PLANTATION

Processing method of natural menthol low-degree ice yellow wine

ActiveCN102517187AHigh in nutrientsImprove drinking valueAlcoholic beverage preparationMentholFlavor

The invention relates to a processing method of natural menthol low-degree ice yellow wine, which belongs to the technical field of brewing. Based on the production process of tan-fan rice wine, glutinous rice, red rice, sweet-scented osmanthus red skin wheat koji and natural mint serve as raw materials, colorless tan-fan rice wine punching cylinder, Gunanfeng traditional small cylinder low-temperature and long-time fermentation and other special brewing technologies are adopted, so that the effective nutrition of the glutinous rice, red rice and mint is dissolved during the fermentation process, semi-dry yellow wine which is fashionable, refreshing, has unique flavor and is suitable to drink in four seasons is brewed, and the nutrition and drinking value of the yellow wine are improved.

Owner:安徽古南丰实业股份有限公司

Preparation method for Jasmine Tea

ActiveCN103181426BQuality improvementImprove drinking valuePre-extraction tea treatmentTea flavoringGardeniaJasminum tortuosum

The invention relates to a preparation method for tea, in particular to a preparation method for Jasmine Tea. The preparation method aims to overcome the defects in the prior art, and is a processing method capable of improving fragrance concentration of the Jasmine Tea through fragrance adjustment of gardenia. According to the invention, the gardenia is adopted to prepare the Jasmine Tea through scenting so as to improve the fragrance concentration of the Jasmine Tea through fragrance adjustment and foil the freshness degree of the floral fragrance; when the jasmine flowers are subjected to scenting, gardenia in right quantity and the jasmine flowers are put together, as more gardenia easily cause magnoma; a small amount of gardenia is put together with the jasmine flower, so as to perform flower refinement; and during flower scenting, in order to keep perfume fresh and pure, the temperature is controlled through radiating, so that the scented tea is high in concentration and freshness degree, good in quality, low in cost, high in fresh flower utilization rate, and favorable for industrialized production.

Owner:FUZHOU FUMIN TEA

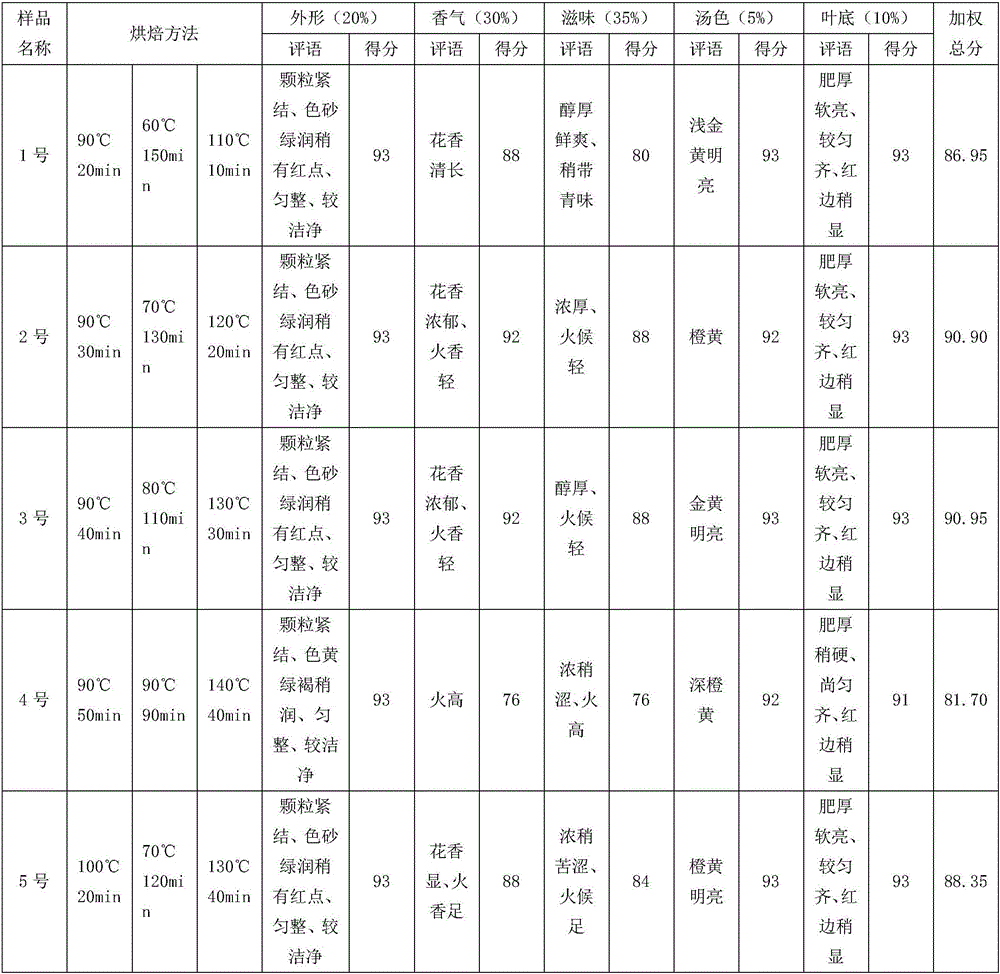

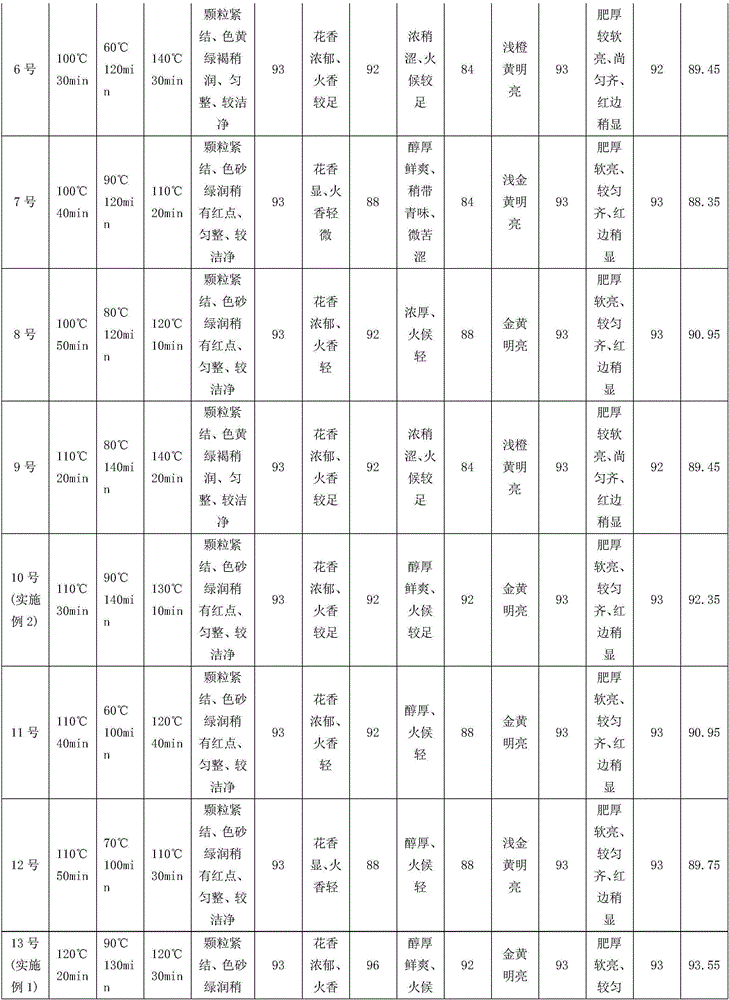

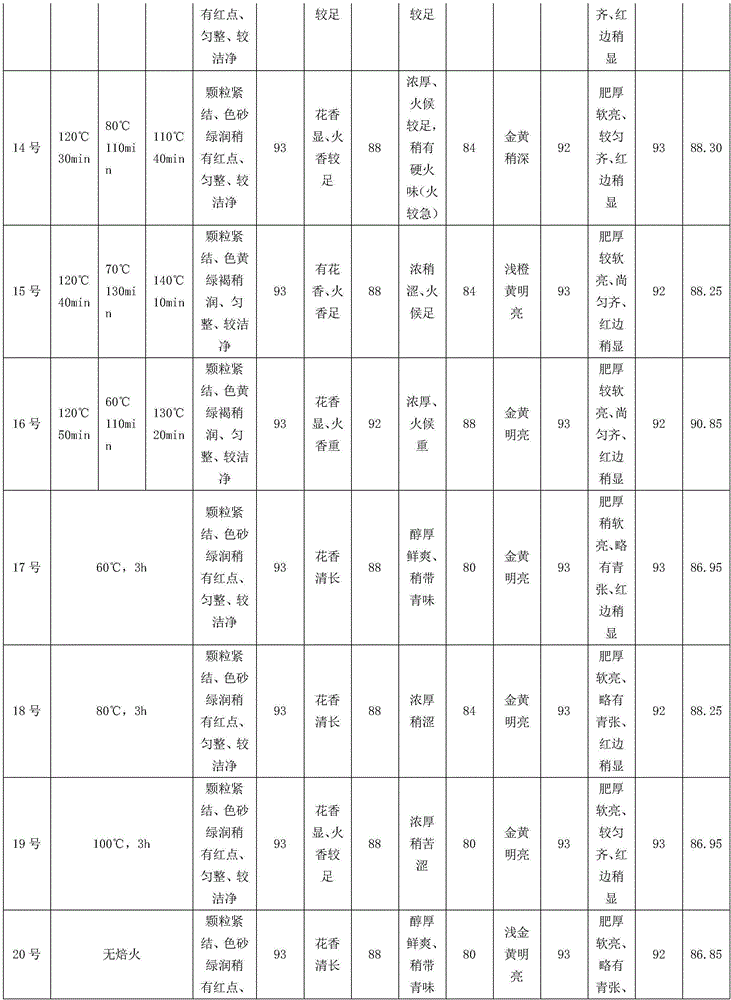

Temperature-changeable baking method of orange osmanthus oolong tea

The invention provides a temperature-changeable baking method of orange osmanthus oolong tea, and belongs to the technical field of tea leaf baking. The orange osmanthus oolong tea is granular orange osmanthus oolong tea which is obtained by removing stems and bracts after refining; the temperature-changeable baking method of the orange osmanthus oolong tea comprises the following steps: (1) removing impurities at high temperature, wherein the temperature is 110 DEG C to 120 DEG C and the lasting time is 20min to 30min; turning and stirring for one time during the process; (2) slowly baking at low temperature, wherein the temperature is 90 DEG C and the lasting time is 130min to 140min; turning and stirring for 1 to 2 times during the process; (3) improving the aroma at high temperature, wherein the temperature is 120 DEG C to 130 DEG C and the lasting time is 10min to 30min; turning and stirring for one time during the process. The method provided by the invention has the advantages that (1) the baked orange osmanthus oolong tea has relatively low water content, the aroma of tea leaves is improved, and the bitter and green tastes of the tea leaves are reduced; (2) baked tea grains are tight, have rich flower aroma, have mellow and fresh taste and have thick, soft and bright leaves after being brewed.

Owner:TEA RES INST OF FUJIAN ACADEMY OF AGRI SCI

Drying processing method of chrysanthemum flowers for flower tea with healthcare functions

InactiveCN109123007AImprove the efficiency of processing and dryingQuality improvementTea substituesChrysanthemum FlowerMoisture

The invention discloses a drying processing method of chrysanthemum flowers for flower tea with healthcare functions. The method comprises the steps as follows: S1, picking and sorting: picking chrysanthemum flowers, during picking, keeping integrity of chrysanthemum flowers as far as possible, and then sorting the chrysanthemum flowers; S2, spreading: uniformly spreading selected fresh chrysanthemum flowers on an airing plate, putting the airing plate in a room at 25-50 DEG C, and spreading the chrysanthemum flowers until the moisture content is 55%-60%; S3, rocking: rocking the spread chrysanthemum flowers, controlling the temperature in a rocking machine between 230-250 DEG C, making the rocking machine at the speed of 3-8 rpm for 15-40 turns, then, stopping the rocking machine for 20 min, and starting the rocking machine to rotate for 15-40 turns. The nutrient value of the chrysanthemum flower tea and the processing drying efficiency can be improved, the immune function of the human body can be improved, the processing time can be shortened, besides, the final product can keep good flower shapes, the product quality can be improved, the preservation time can be prolonged, and the better color and taste can be effectively kept.

Owner:黄山市钰农食品有限公司

Production method of original-taste honeysuckle tea

The invention relates to a production method of original-taste honeysuckle tea and belongs to the technical field of tea processing. The method includes: using chitosan to prepare chitosan fixing syrup, mixing preprocessed honeysuckle with the chitosan fixing syrup and deionized water to allow the honeysuckle to be evenly dispersed in the chitosan fixing syrup; subjecting the honeysuckle to heating, heat preservation, filtering and washing, natural airing and the like after the honeysuckle is evenly dispersed, and performing vacuum freeze drying on the collected honeysuckle to obtain the original-taste honeysuckle tea. The production method has the advantages that the honeysuckle tea is emerald green, the shape of the honeysuckle tea is like fresh honeysuckle and complete, nutrient content loss is reduced, and the drinking value and appearance quality of the honeysuckle tea can be increased greatly; the honeysuckle tea has effects of clearing away heat and toxic materials, diminishing inflammation and sterilizing and lowering blood pressure; the production method is simple in procedure and low in cost.

Owner:JIANGSU JINYU ENVIRONMENTAL ENG

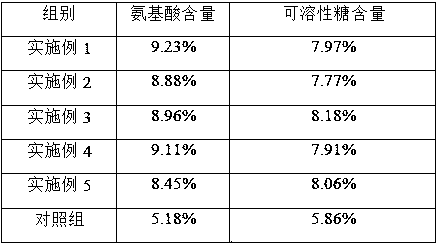

Processing method of Anji white tea

InactiveCN109864148AMultiple Physiologically Active IngredientsImprove drinking valuePre-extraction tea treatmentCooking & bakingAir separation

The invention relates to the technical field of processing of tea products, in particular to a processing method of Anji white tea. The processing method of Anji white tea comprises the following steps of performing cleaning, performing spreading, performing fixation, performing air separation, performing strip tidying, performing spreading for airing, performing first baking and performing baking. The processing method of Anji white tea is simple in technology and easy to realize, and the prepared Anji white tea is high in safety, high in amino acid content and soluble sugar content, rich inscent and fresh, brisk and pure in tea soup taste.

Owner:ANHUI DONGFANG TEA

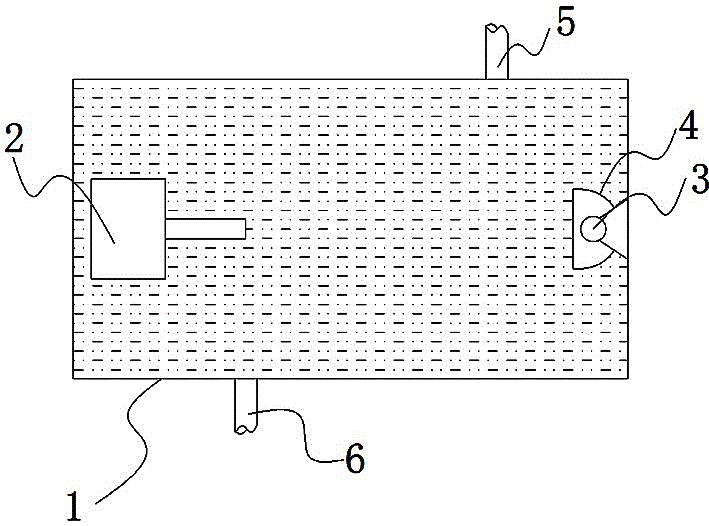

Health-preserving drink making method of a food processor

ActiveCN113440025AFacilitated DiffusionAvoid volatile lossFood thermal treatmentBeverage vesselsEngineeringProcess engineering

The invention relates to a health-preserving drink making method of a food processor, the food processor comprises a heating device, a water supply part, a vacuumizing part and a stirring cup, the water supply part is used for feeding water and / or steam into the stirring cup, and the invention at least comprises the following stages: a high-temperature infiltration stage: heating water and food materials in a preset mass ratio in the stirring cup to T1, keeping the liquid temperature T1 in the stirring cup for t1 time, wherein T1 is greater than or equal to 75 DEG C; and a decompression internal sudden boiling stage: feeding water into the stirring cup by the water supply part to reduce the liquid temperature in the stirring cup to T2, then vacuumizing the stirring cup to a preset vacuum degree P1 by the vacuumizing part, so that the interior of the food material is suddenly boiled; and keeping the preset vacuum degree P1 for t2. According to the technical scheme, the functional components of the food materials can be mildly and efficiently extracted, and the drinking value of the health-preserving drink is improved.

Owner:HONGYANG HOME APPLIANCES

Preparing methods of red raspberry seed extract product and red raspberry polymerization fruit juice and applications thereof

The invention relates to preparing methods of a red raspberry seed extract product and red raspberry polymerization fruit juice, and belongs to the field of fruit juice type drinks. Red raspberry fruits and red raspberry seeds are adopted as main raw materials. The red raspberry polymerization fruit juice with a special flavor is obtained by juicing the red raspberry fruits to obtain red raspberry fruit juice; extracting the red raspberry seeds by an edible ethanol solvent to obtain the red raspberry seed extract product; purifying the red raspberry seed extract product with AB-8 macroporous adsorption resin; and adding the purified red raspberry seed extract product into the red raspberry fruit juice. The obtained polymerization fruit juice has a light red color, and drinking value and nutrition value of the red raspberry fruit juice are improved. The methods are simple in operation. The obtained products have high health care functions and a wide market prospect.

Owner:DALIAN ZHONGCHAO FOOD CO LTD

Production method of Qifo dark green tea

PendingCN110692754ASolve scrapExtended shelf lifePre-extraction tea treatmentFood shapingBiotechnologyGreen teas

The invention discloses a production method of Qifo dark green tea. The production method includes: classifying aged tea, re-drying, sprinkling water to the re-dried tea to wet the tea, fermenting, performing die shaping, drying, packaging. The production method has the advantages that the aged green tea is subjected to secondary modification through the late-period biological fermentation technology, the aged green tea is fermented into the aged dark green tea, the shelf life of the tea can be effectively prolonged, the drinking value and commercial value of the tea can be effectively increased, the problem that the drinking value and commercial value of the aged tea caused by dull sale are lowered can be solved effectively, and the problem that a large amount of aged tea is scrapped is solved effectively.

Owner:青川县嘉发茶业有限公司

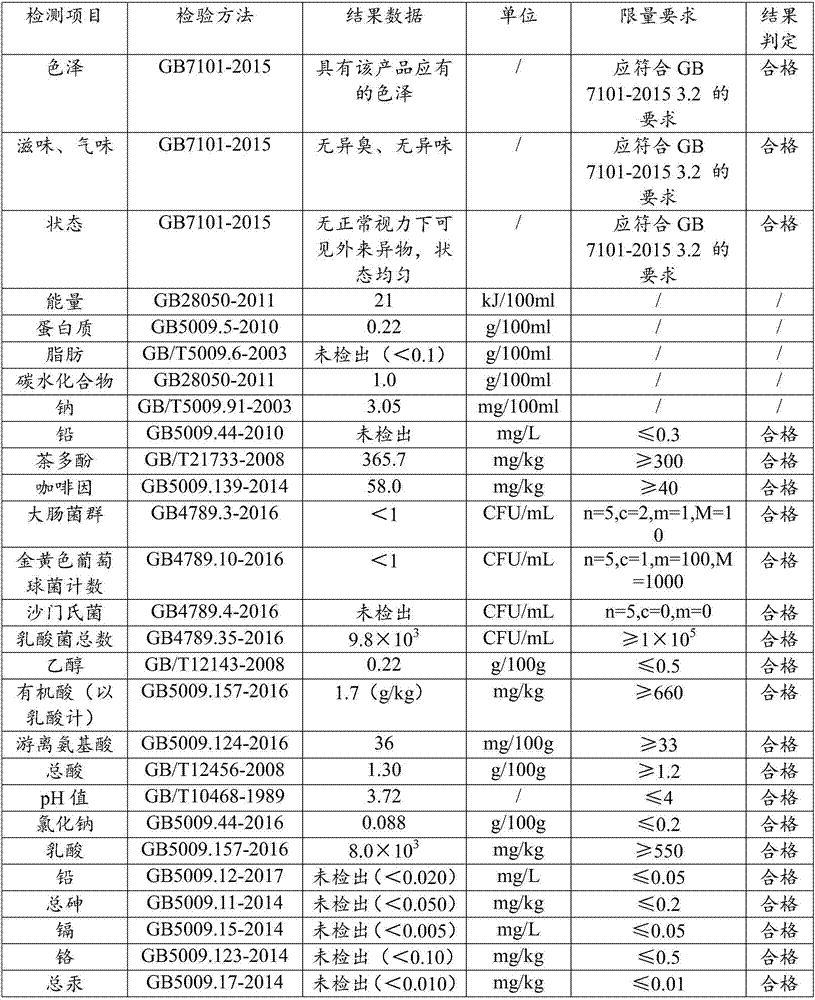

Tea ferment beverage and preparation method thereof

Belonging to the technical field of tea processing and fermentation, the invention discloses a tea ferment beverage and a preparation method thereof. The tea ferment beverage includes the following raw materials by mass percentage: 10-25% of tea, 1-5% of momordica grosvenori, 1-5% of passiflora edulis, 1-5% of leek, 3-12% of brown sugar, 2-8% of grape juice, 50-80% of purified water, 1-8% of plantlactobacillus, and 1-8% of yeast. The preparation method includes: raw material preparation, primary fermentation, secondary fermentation, tertiary fermentation, stock solution filling and other steps. The tea ferment beverage has unique taste and rich nutrition, can balance human body internal circulation, clean intestines, enhance immunity and promote metabolism, has high health care value, andis suitable for various groups to drink.

Owner:广东东方翠健康科技有限公司

Processing method of tea tree flowers

The invention discloses a method for processing tea tree flowers, relating to the technical field of processing, comprising the following steps: harvesting tea tree flower buds from mid-October to early December; cutting off the receptacles and spreading them on a water sieve; Freeze inside, the temperature is lower than minus 20°C, and freeze for 12-14 hours; then put the flower buds into a vacuum dryer for freeze drying, when the temperature is lower than minus 20°C, vacuumize until the pressure is -0.1Mpa, turn on the oil Heating system, the heating temperature is 50°C~52°C, continue heating and drying for 24~26 hours, until the water content of the flower buds is ≤4%; put the flower buds into the baking machine for baking, the temperature is 90°C~100°C, and the time is 15~ 20 minutes. The invention solves the problems that the tea tree flower processed products are not full in appearance, not beautiful, not fresh in color, low in aroma and not pure, yellowish in color and not bright in soup, which are not conducive to quality improvement.

Owner:葛智文 +3

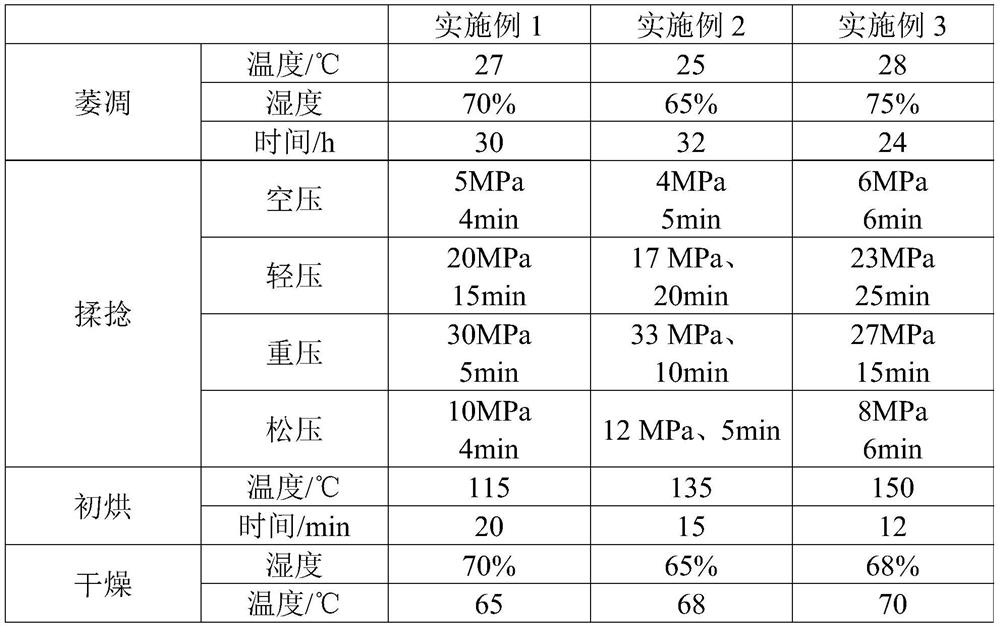

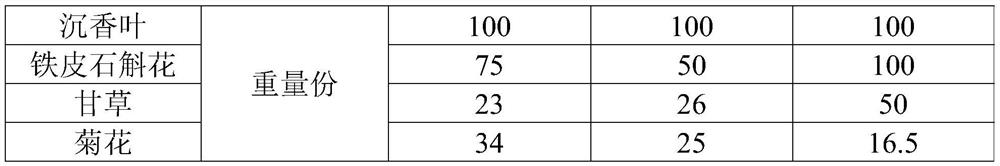

Agilawood compound tea and preparation method thereof

The invention relates to the field of tea products, in particular to agilawood compound tea and a preparation method thereof. The agilawood compound tea is composed of agilawood leaves, dendrobium officinale flowers, liquorice and chrysanthemum, and relative to 100 parts by weight of agilawood leaves, the content of dendrobium officinale flowers is 50-100 parts by weight, the content of liquorice is 12.5-50 parts by weight, and the content of chrysanthemum is 12.5-50 parts by weight. The agilawood compound tea provided by the invention is softer in overall taste, stronger in fragrance, rich in layering and less in oxidation resistance loss.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Functional beverage for protecting eyesight and alleviating visual fatigue

InactiveCN109619328AProtect eyesightRelieve visual fatigueNatural extract food ingredientsFood ingredient functionsFlavorSide effect

The invention provides a functional beverage for protecting eyesight and alleviating visual fatigue, and relates to the technical field of functional beverage production. The functional beverage is prepared from the following raw materials in parts by weight: 8-12 parts of carrot, 4-8 parts of sweet potato, 2-4 parts of pumpkin, 6-10 parts of orange, 4-8 parts of citrus, 2-6 parts of mango, 4-8 parts of Chinese wolfberry, 4-8 parts of semen cassiae, 2-6 parts of senecio scandens ham., 2-6 parts of chrysanthemum, 2-4 parts of citric acid, and 2-4 parts of white granulated sugar. The shortcomings of the prior art are overcome, and the functional beverage not only has the functions of caring health and alleviating physical fatigue, but also has the functions of protecting eyesight and alleviating visual fatigue. By adopting of a variety of natural plants and fruits, the functional beverage is safe and healthy, has no side effects, and has high nutritional value and good flavor.

Owner:上海兰明食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com