Water-based sand-coated multi-color paint and preparation method thereof

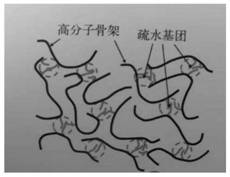

A technology of colorful paint and sandbags, which is applied in the field of paint, can solve the problems of easy sagging and material consumption of colorful paint, and achieve the effects of good simulation, good sag resistance, and saving processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

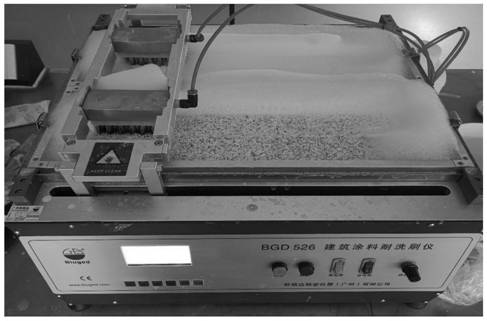

Method used

Image

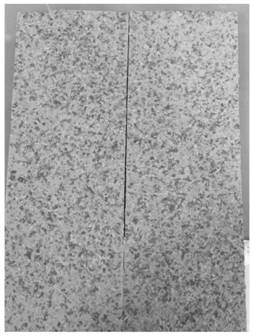

Examples

Embodiment Construction

[0048] The following is further described in detail by specific embodiments:

[0049] The water-based sand-coated sand colorful paint of the present invention is composed of 5-6 parts of A (sand-containing base material), 2-2.5 parts of B (continuous phase), and 2-2.5 parts of C (second grade sand). According to different needs, A B C within the above range can be used for coating composition.

[0050] The components of A (sand-containing base material) and the parts by mass of the components: 30-40 parts of water, 0.5-1.5 parts of cellulose ether, 0.2-0.5 parts of dispersant, 0.1-0.2 part of wetting agent, defoaming agent 0.2-0.5 part of antifungal agent, 0.2-0.4 part of fungicide, 0.2-0.4 part of antifungal agent, 1-2 parts of propylene glycol, 0.1-0.15 part of PH adjuster, 1-2 parts of titanium dioxide, 2-5 parts of kaolin, the first 30-40 parts of graded sand, 20-30 parts of pure acrylic emulsion, 0.8-1 part of film-forming aid, 5-15 parts of silica sol;

[0051] Compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com