High-wear-resisting high-strength ultra-high molecular weight polyvinyl artificial articular material and preparation method thereof

An ultra-high molecular weight, polyethylene-based technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of increasing UHMWPE melt viscosity, secondary deterioration of mechanical properties, and processing difficulties, so as to avoid post-melting processing , promote the movement of molecular chains, and the effect of good melt processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

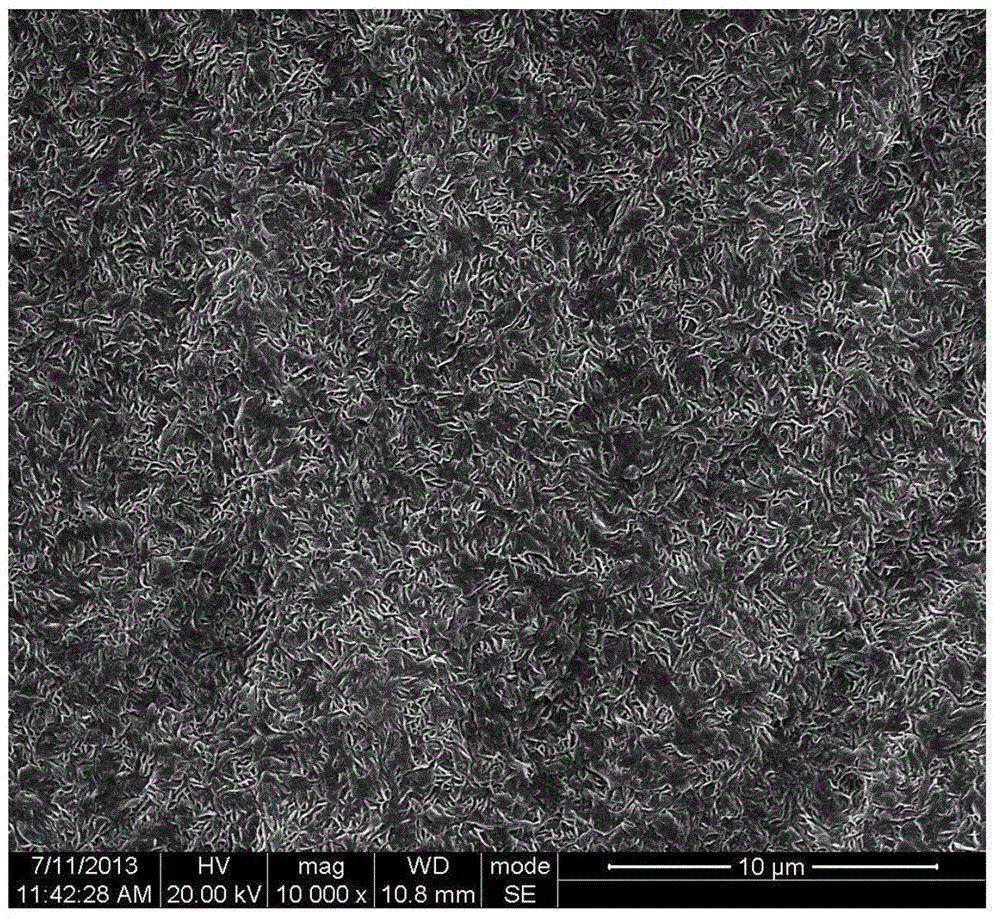

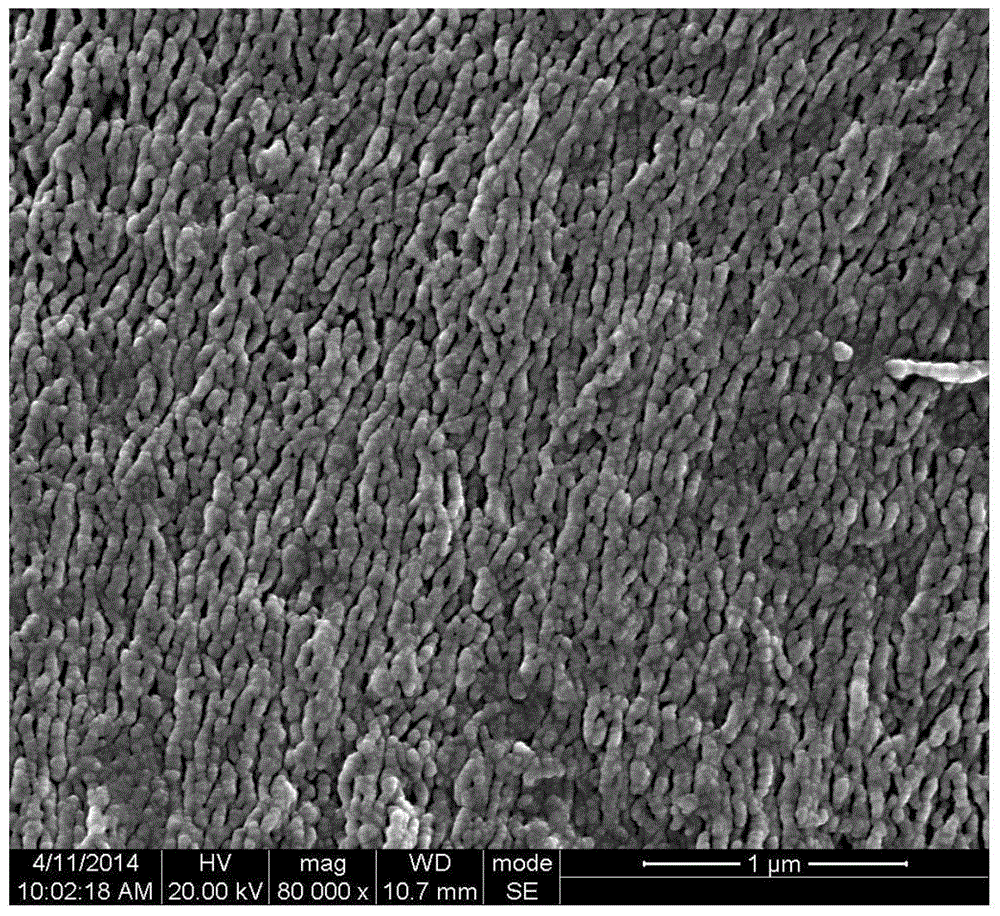

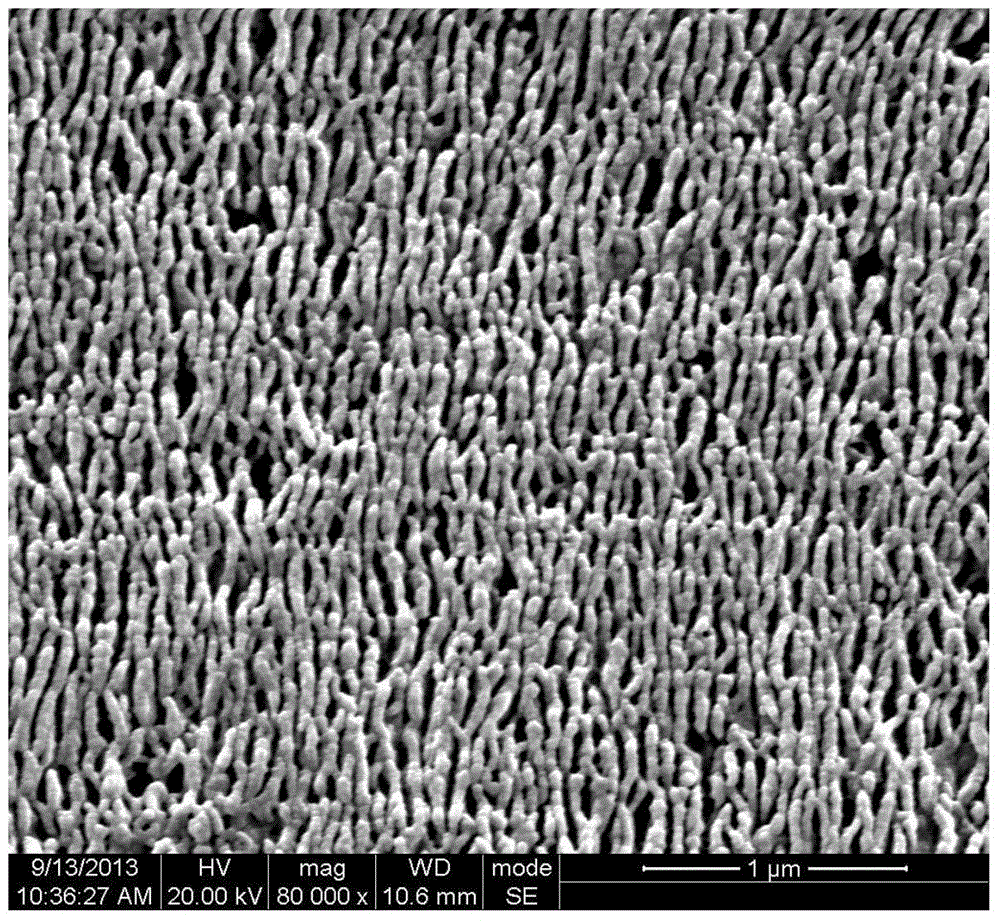

Image

Examples

Embodiment 1

[0028] (1) Preparation of irradiation cross-linked UHMWPE: UHMWPE powder is subjected to electron beam irradiation treatment with an irradiation dose of 50kGy, and after irradiation, it is evacuated and stored at a low temperature of -10°C to prevent its oxidative degradation;

[0029] (2) Preparation of cross-linked UHMWPE and ULMWPE blend: After mechanically mixing 95% cross-linked UHMWPE and 5% ULMWPE, put them in a twin-screw extruder for melt blending and extrusion, and the extruder conveys the compression section and the melting section And the metering section temperature is set to 220 ° C, 260 ° C and 240 ° C, the host speed is set to 135 rpm, the feeding speed is 5 rpm, then the blend is forced to cool and pelletized, and at 100 ° C Drying to a moisture content not higher than 0.01% of its own weight;

[0030] (3) Vibration-shear injection molding: Vibration-shear injection molding is performed on the extruded pellets after drying. The barrel and nozzle temperatures o...

Embodiment 2

[0032] (1) Preparation of irradiation cross-linked UHMWPE: UHMWPE powder is subjected to electron beam irradiation treatment with an irradiation dose of 50kGy, and after irradiation, it is evacuated and stored at a low temperature of -10°C to prevent its oxidative degradation;

[0033](2) Preparation of cross-linked UHMWPE and ULMWPE blend: 90% cross-linked UHMWPE and 10% ULMWPE are mechanically mixed, then placed in a twin-screw extruder for melt blending and extrusion, and the extruder conveys the compression section and the melting section And the metering section temperature is set to 230 ℃, 240 ℃ and 245 ℃, the speed of the main engine is set to 137 rpm, the feeding speed is 4.7 rpm, then the blend is forced to cool and pelletized, and at 100 ℃ Drying to a moisture content not higher than 0.01% of its own weight;

[0034] (3) Vibration-shear injection molding: Vibration-shear injection molding is performed on the above-mentioned dried extruded pellets. The barrel and nozz...

Embodiment 3

[0036] (1) Preparation of UHMWPE and ULMWPE blends: After mechanically mixing 90% UHMWPE and 10% ULMWPE, they are placed in a twin-screw extruder for melt blending and extrusion. Set at 230°C, 250°C and 240°C, the speed of the host machine was set at 130 rpm, and the feeding speed was 4 rpm, then the blend was forced to cool and pelletized, and dried at 100°C until it contained The amount of water is not more than 0.01% of its own weight;

[0037] (2) Vibration-shear injection molding: Vibration-shear injection molding is performed on the above-mentioned dried extruded pellets. The barrel and nozzle temperatures of the injection molding machine are set at 250°C and 240°C, respectively, and the temperature of the hot runner is set at 250°C. , and the mold temperature was set to 40 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com