Nanotube Polymer Composite Composition and Methods of Making

a composite composition and nanotube technology, applied in the field of nanotube polymer composite composition and, can solve the problems of increasing the cost of nanocomposite, difficulty in dispersing nanotubes, and hampered achievement of the full potential of single-wall carbon nanotube properties in polymers, and achieve the effect of less particles and less expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0136]Single walled nanotubes (SWNTs) from supplier CNI (Carbon Nanotechnologies Inc, Houston Tex.) were used without sonication.

[0137]The resistivity of an extruded sample prepared as in Example 1 was measured and was 105 to about 106 ohm / sq. The extruded sample output was fed back into the extruder for 5, 10, 15, 20 additional extrusion cycles as illustrated in FIG. 11A. A sample of extruded material was taken after 5th 10th, 15th and 20th cycles and the resistivity and G′ of the sample measured. There was essentially no increase in the measured storage modulus illustrating that the dispersion of the SWNTs in the polymer was stable and essentially invariant and that the properties did not change over time within the variation of the processing conditions. This result illustrates that the extrusion compounded composition is insensitive to shear history.

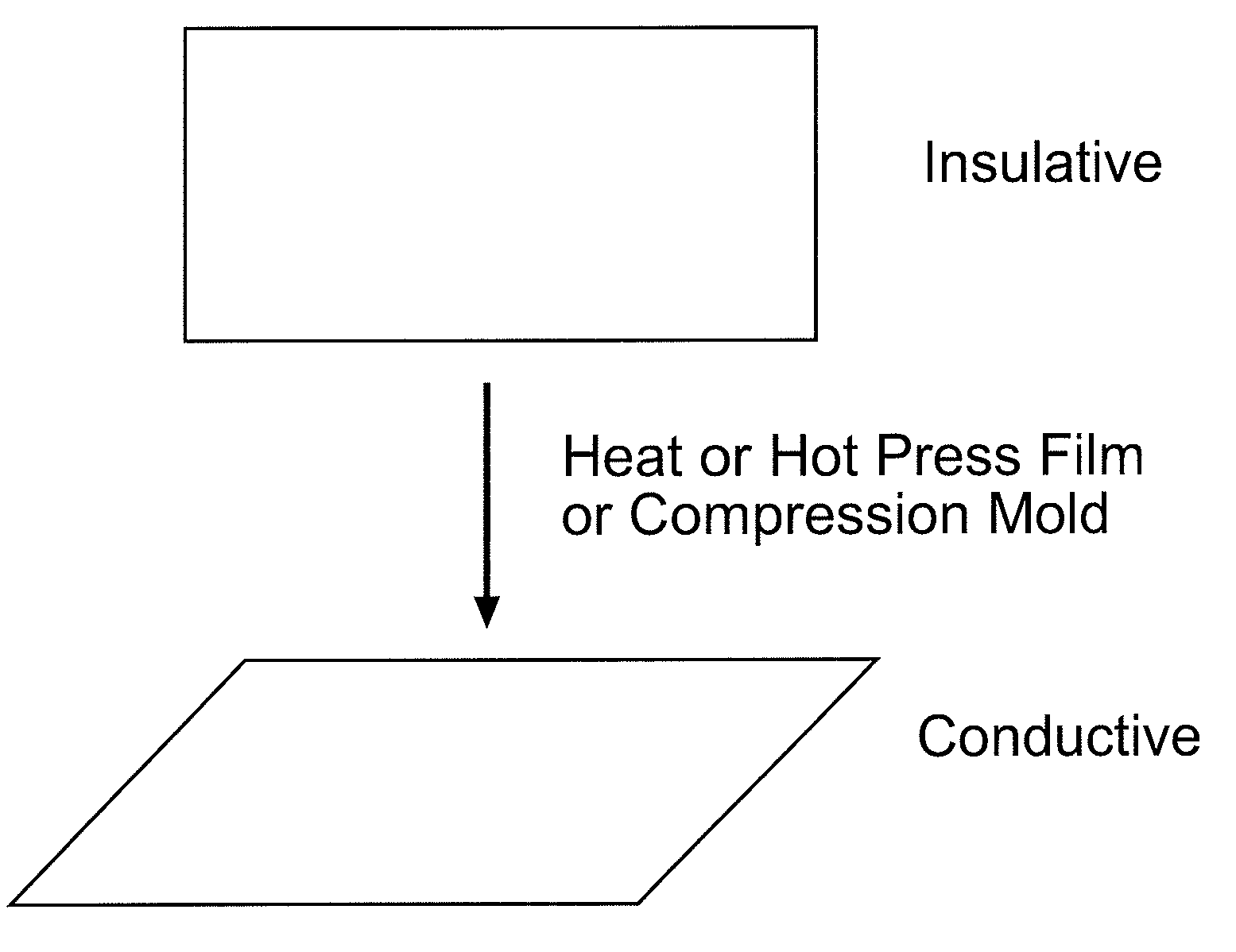

[0138]The properties of a molded article of this extrusion compounded nanotube and polymer composition could be modified by the she...

example 3

[0139]Single walled nanotubes (SWNTs) from supplier CNI (Carbon Nanotechnologies Inc, Houston Tex.) were used without sonication and combined with PEEK thermoplastic as in Example 1 by injection molding. The extractables of the composite were determined by ICP-MS on acid digested samples as shown in the Table 2 below.

[0140]The extractables can be determined via Microwave Digestion and filtration. For example, weigh 1.0 gram polymer and SWNT composite sample pellets and place pellets in 125-ml PFA sample digestion vessel. Add 10 ml 16.0 N HNO3, cap and seal vessel(s). Place vessel(s) in insulated sleeves and into sample vessel carousel. Place in microwave digestion oven which can be heated according to the Oven profile: (Stage 1) Heat at 50% power to 20 p.s.i. and hold 10 minutes. (Stage 2) Heat at 50% power to 50 p.s.i and hold 10 minutes. (Stage 3) Heat at 50% power to 90 p.s.i. and hold 10 minutes. (Stage 4) Heat at 50% power to 100 p.s.i. and hold 10 minutes. (Stage 5) Heat at 50...

example 4

[0141]Single walled nanotubes (SWNTs) from supplier CNI (Carbon Nanotechnologies Inc, Houston Tex.) were used without sonication and combined with PEEK thermoplastic as in Example 1.

[0142]Squeeze flow or Gap testing was performed on a melt of the sample using an Advance Rheometric Expansion System (ARES) Rheometer at 380° C. in a nitrogen atmosphere. FIG. 6 illustrates force gap test results on a melt of the samples heated to 380° C. FIG. 6 illustrates the squeeze flow rheometry for SWNT dispersion on the properties of the materials prepared. NT4 is prepared by the dry melt method, NT1 is side stuff method. FIG. 6 illustrates the behavior of NT1 and NT4 under constant normal force and an initial gap of about 4 mm. A sample of the material was placed between the plates and heated above the melting or glass transition temperature, for example to 380° C. The initial behavior (to about 75 sec) may be due to the sample filling the void between the plates, the void between the plates is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Dimensionless property | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com