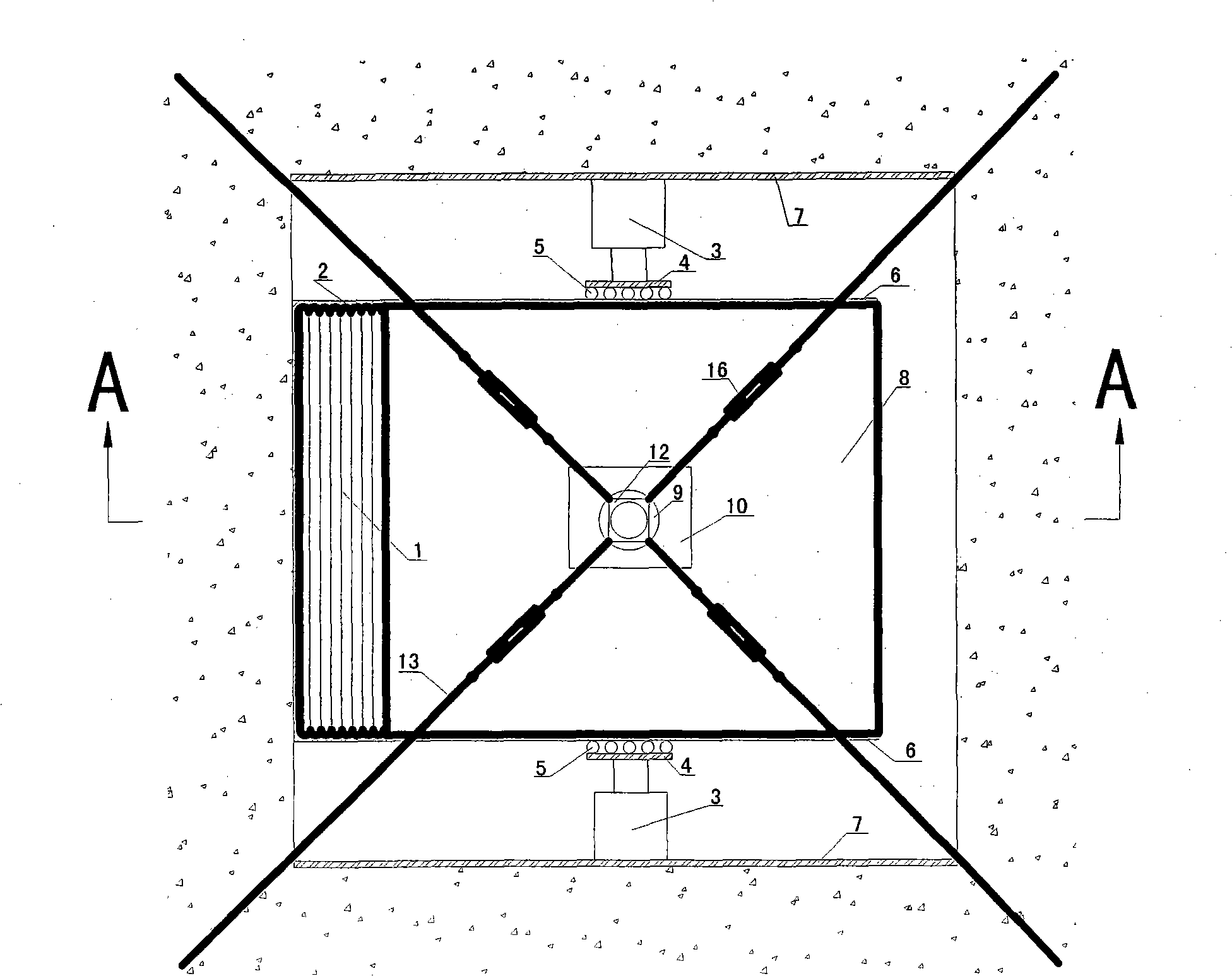

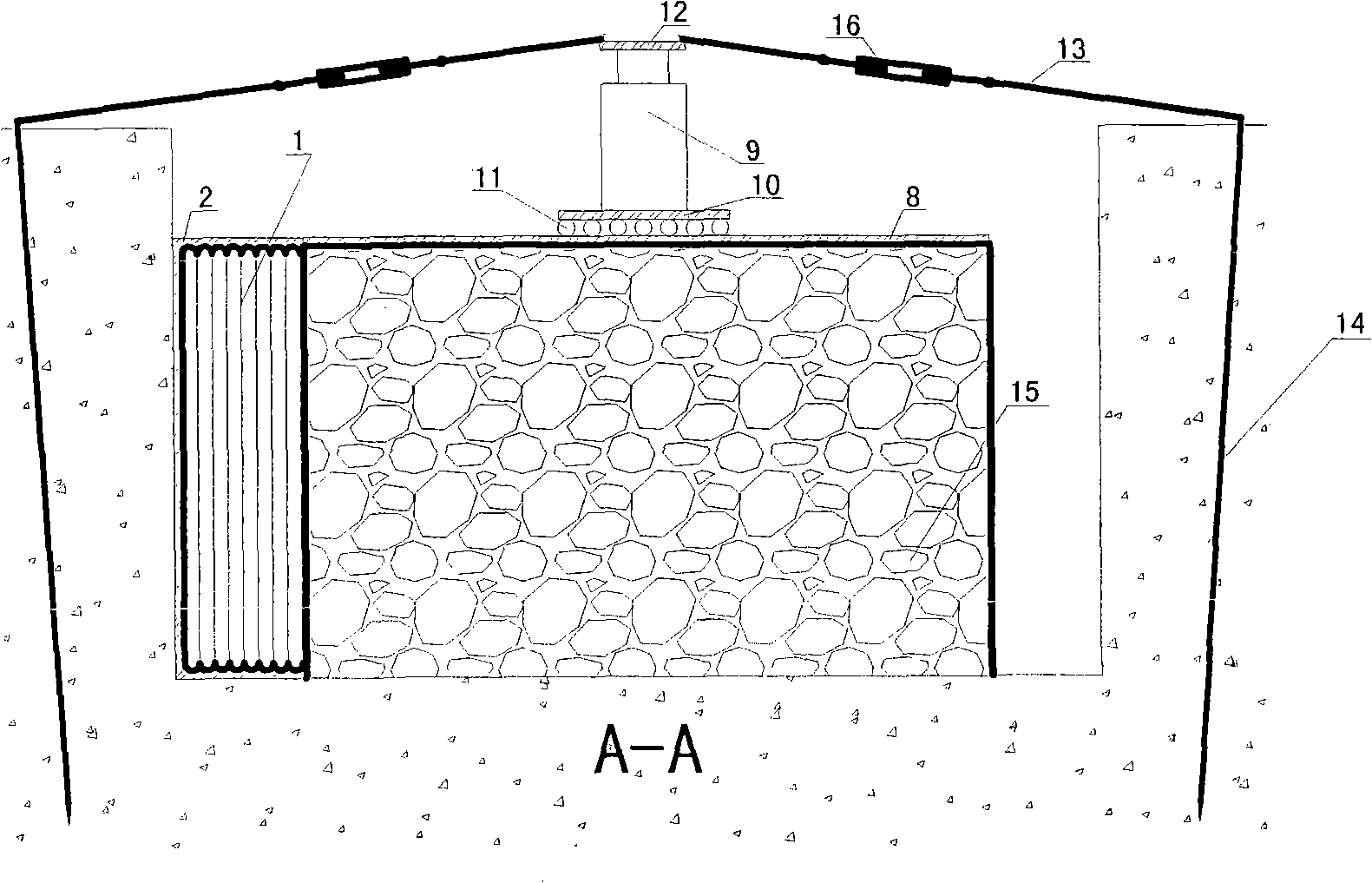

Airbag type soil-rock mixture in-situ compression shear test device

A technology of soil-rock mixture and test device, which is applied in the direction of using stable shear force to test the strength of materials, and can solve the problems of unsuitable, unsuitable soil-rock mixture, and large deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] 1. First apply a normal load to the normal jack 9 through the pressurized oil pump, and stop the pressurization after the pressure reaches the predetermined value, and then continue to pressurize unless the normal load drops significantly during the application of the shear load to the predetermined value;

[0014] 2. The air bag 1 is pressurized by an air pump, and the speed of pressurization is controlled so that the speed of the dial gauge remains basically constant. The barometer records a set of data every time it rotates about 50Kpa, including the pressure gauge reading of the air bag 1, the pressure gauge reading of the normal jack 9, and the pressure gauge reading of the lateral jack 3;

[0015] 3. When the reading of the airbag 1 pressure gauge reaches the maximum value and then the pressure gauge begins to drop, the sample 15 has been sheared and damaged, and the readings of each gauge at the peak value are recorded;

[0016] 4. Change the magnitude of the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com