Control of electrolyte hydrodynamics for efficient mass transfer during electroplating

A technology of electrolyte and electroplating equipment, applied in the direction of electrolysis components, electrolysis process, current insulation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

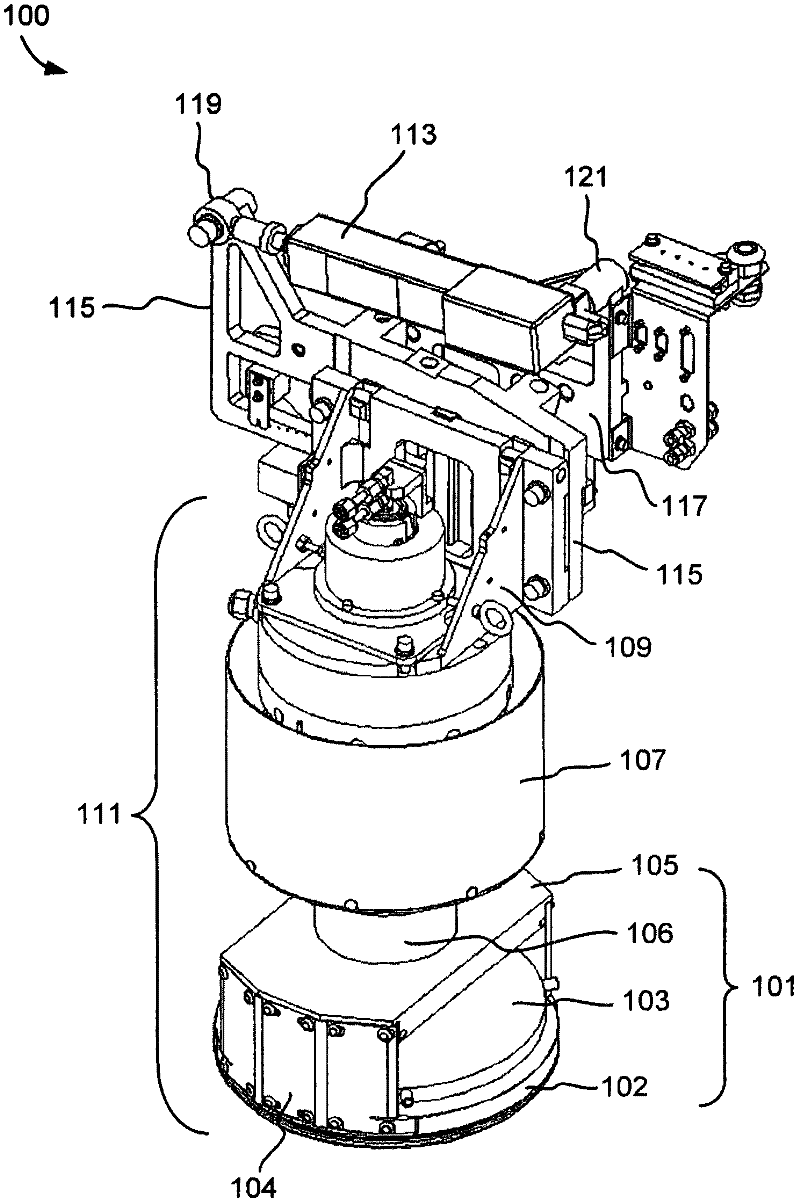

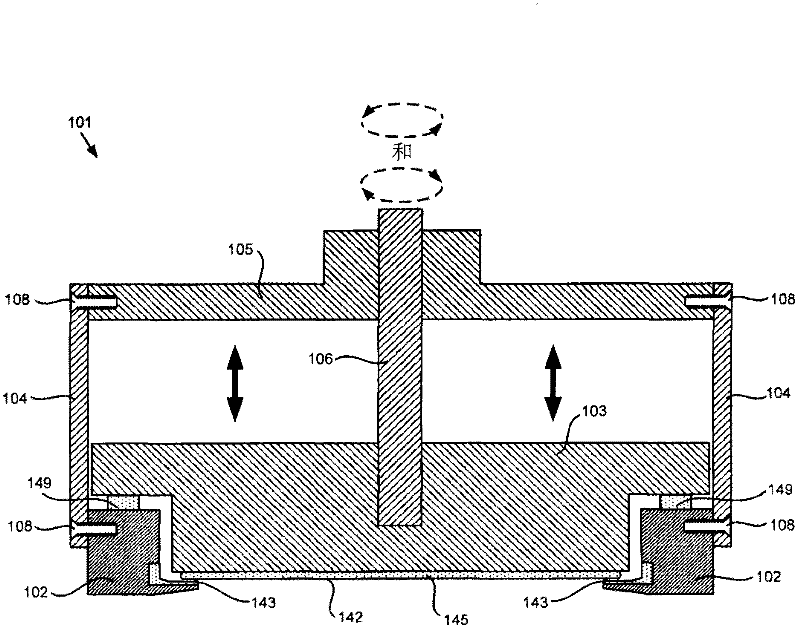

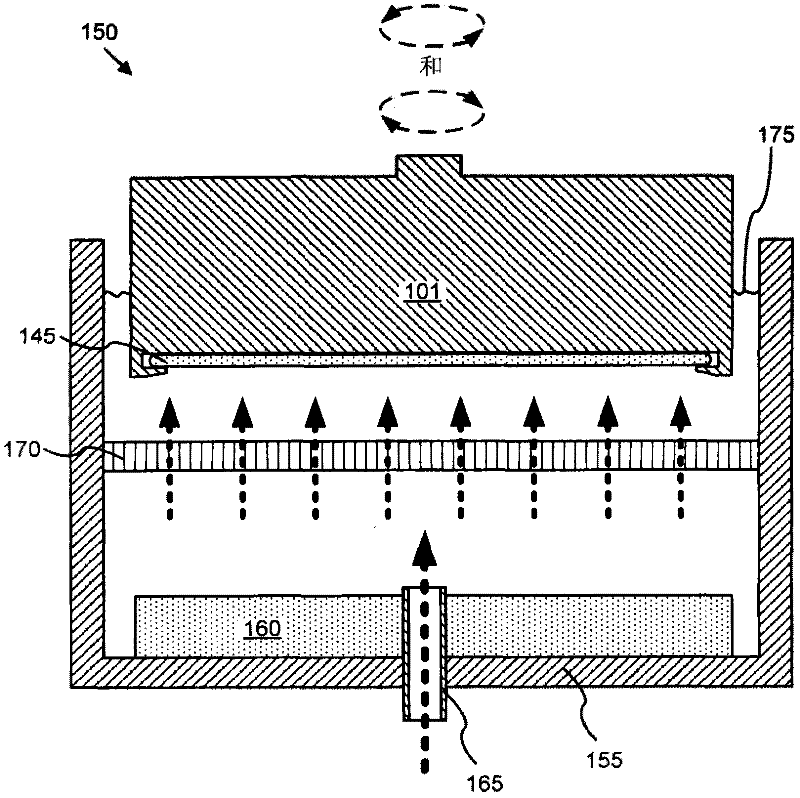

[0047] A. General Device Context

[0048] Figure 1A and Figure 1B The following description provides some general non-limiting context for the devices and methods described herein. Various features presented in the following discussion are also present in one or more of the above figures. The following discussion of such features is intended only as an addition to the description of the embodiments included herein. The particular focus in the last few figures is towards the wafer holder assembly in relation to the various flow shaping plates and flow diverters, and exemplary positioning mechanisms, rotation mechanisms and wafer holders are thus described.

[0049] Figure 1A A perspective view of a wafer holding and positioning apparatus 100 for electrochemically processing semiconductor wafers is provided. Device 100 has various features shown and described in subsequent figures. For example, apparatus 100 includes a wafer engaging assembly (sometimes referred to here...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com