Analyzing and modelling method of milling force of flat spiral end milling cutter

A modeling method and end mill technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as time-consuming calculation process, unfavorable cutting mechanism research, and difficulty in mesh production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention and are not used for Limit the invention.

[0051] An analytical modeling method for milling force of a flat-bottomed spiral end mill includes the following steps:

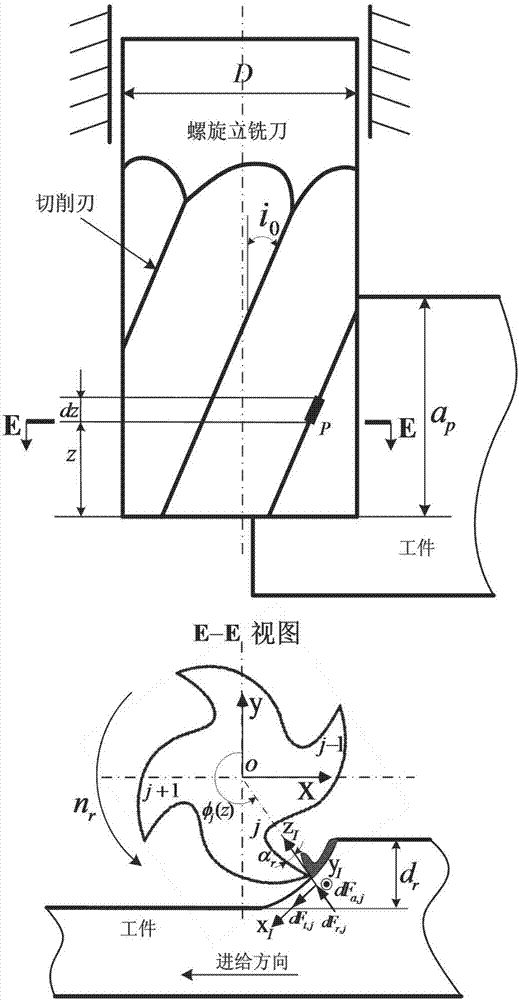

[0052] Step 1. Determine the geometric parameters of the flat-bottomed spiral end mill: the diameter of the milling cutter D, the unit is mm; the number of teeth N t , The unit is tooth; helix angle i 0 , The unit is deg; the rake angle of the tool α r , The unit is deg; selected cutting parameter: spindle speed n r , The unit is rpm; the feed per tooth f t , The unit is mm / z; radial cutting width d r , The unit is mm; the axial depth of cut a p , The unit is mm;

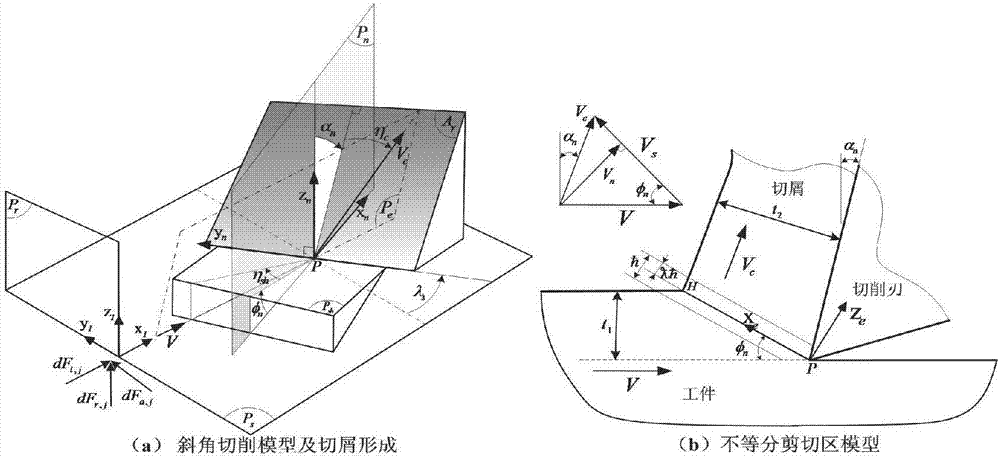

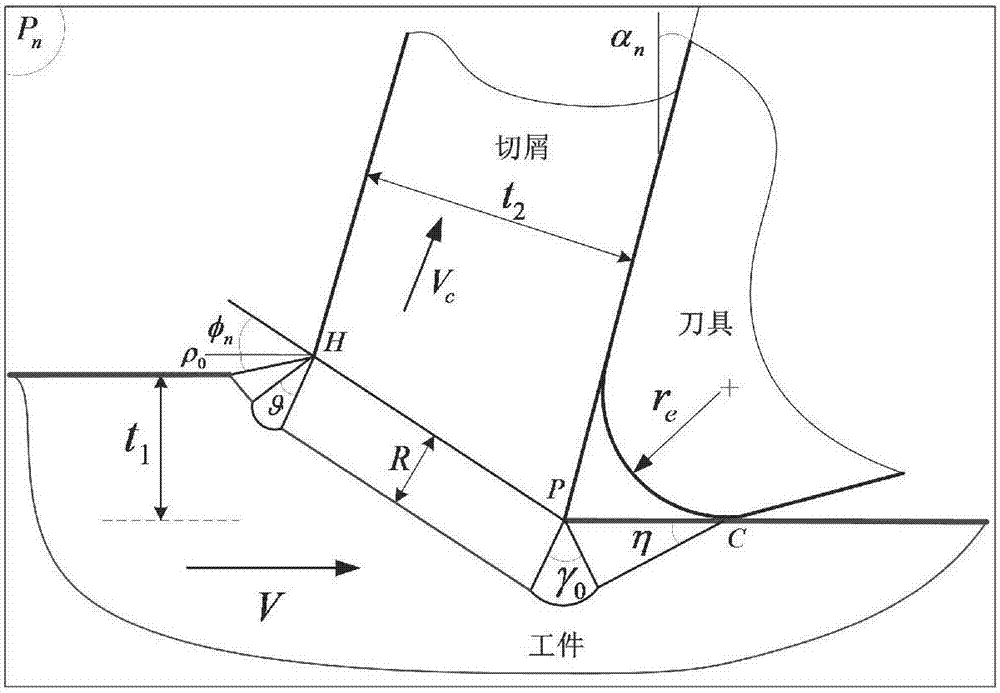

[0053] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com