Face angle testing device of rotary tool

A technology for testing devices and rotating tools, which is applied in measurement, wellbore/well parts, earthwork drilling and production, etc. It can solve problems such as inability to rotate drilling, increased risk of drilling tool sticking, and slow drilling speed, etc., to ensure accurate and real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

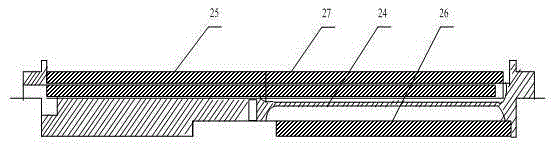

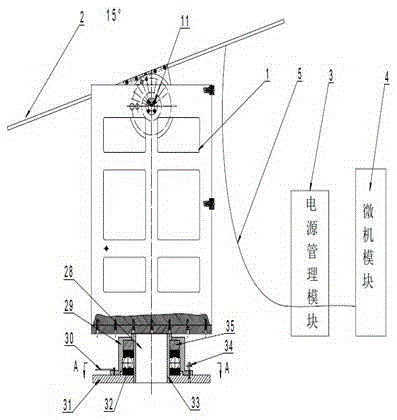

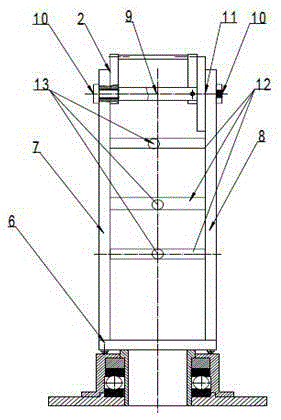

[0020] Such as figure 1 As shown, the rotary tool face angle testing device proposed by the present invention includes: well inclination calibration bench 1, rotary test bench 2, azimuth calibration bench 28, power supply module 3, microcomputer module 4, slip ring line 5, emergency brake 23 . The rotary tool face angle testing system is installed on the rotary test bench 2, and the power supply module 3 supplies power to the entire rotary test bench 2 through the slip ring line 5, including a DC deceleration motor 15, a rotary tool face angle testing system and a grating code disc 17; In addition, the rotating tool face angle test system adjusts the collected signals such as well deviation, azimuth, rotational speed, tool face, etc., and then transmits them to the microcomputer module 4 through the slip ring, realizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com