Instrument for testing friction and wear performance of coating

A friction and wear tester technology, applied in the direction of testing wear resistance, etc., can solve the problems of unstable operation, low measurement accuracy, and large volume, and achieve the effects of good stability, high measurement accuracy, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

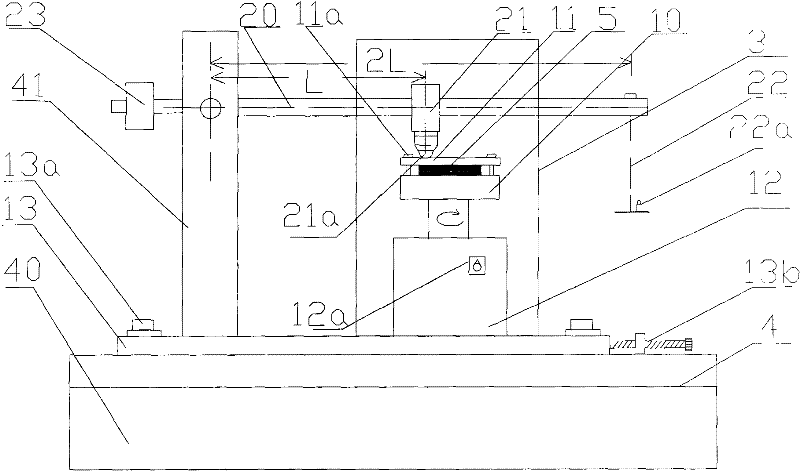

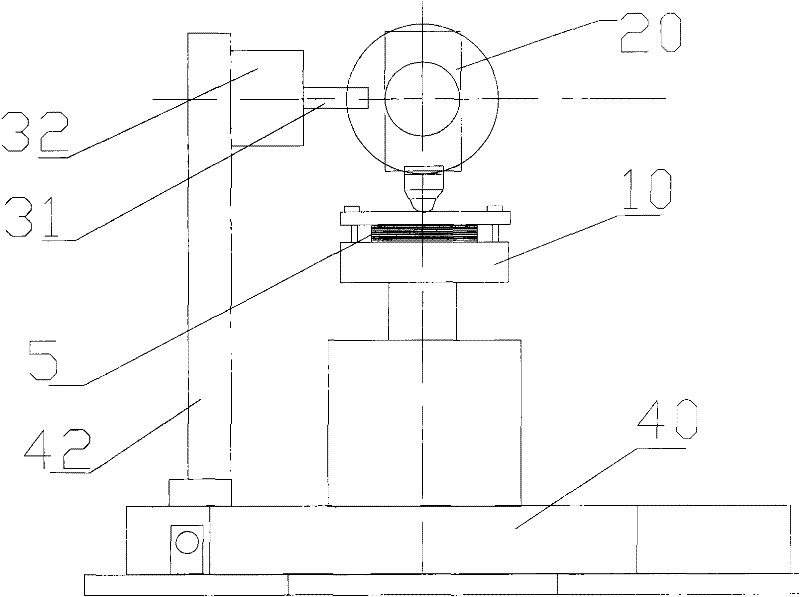

[0033] Below in conjunction with accompanying drawing embodiment, illustrate the structural principle of the present invention as follows:

[0034] like figure 1 , figure 2 As shown, the structure of the coating friction and wear performance tester of the present invention is composed of four parts: a rotating test table, a loading friction beam, a friction detector and a frame. Among them, the rotating test table is used to place, reinforce, and rotate the tested sample; loading friction beam: used to set friction steel balls on the surface of the tested sample and apply appropriate pressure to generate friction tracks; friction detector: used to measure friction , Generate friction signal and input it into computer; frame: used to install and support various components. The structural features of each part are described below:

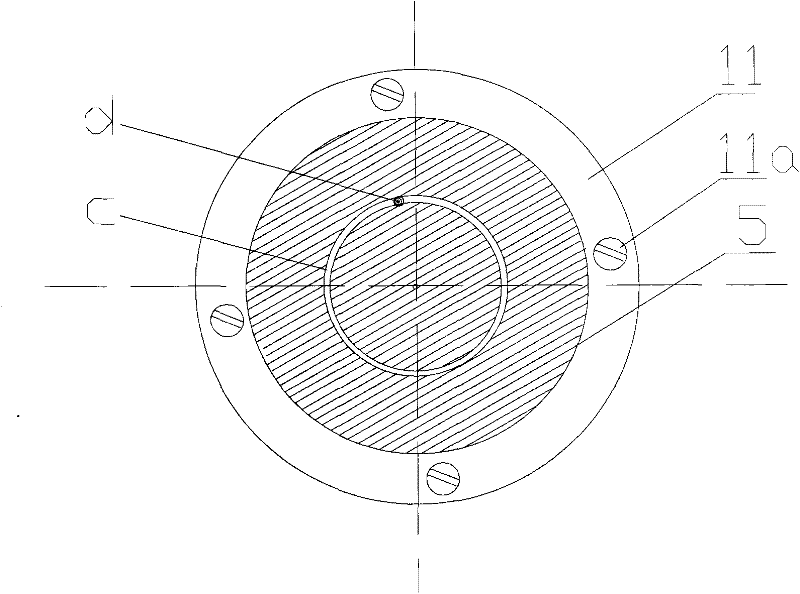

[0035] 1. Rotary test bench

[0036] like figure 1 As shown, the rotary test bench includes a test bench 10 , a test bench top cover 11 , a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com