Ignition driving system of high-overload test device used for solid-propellant rocket engine

A solid rocket and test device technology, which is applied in the field of aerospace, can solve problems such as acceleration impact, achieve the effect of reducing the radius of rotation, solving the impact of tangential acceleration impact, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific implementation

[0027] The present invention will be further explained below in conjunction with the drawings and embodiments:

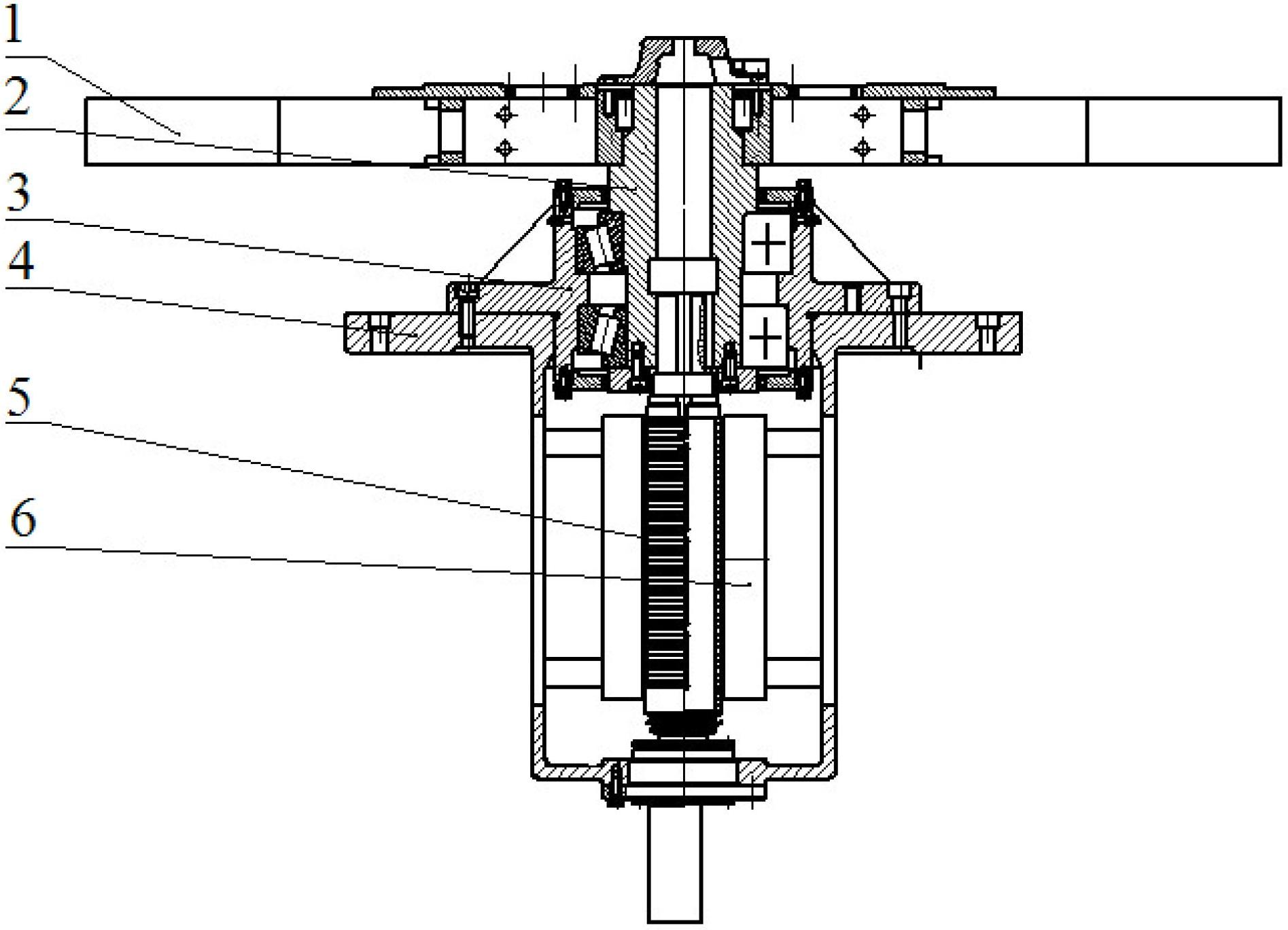

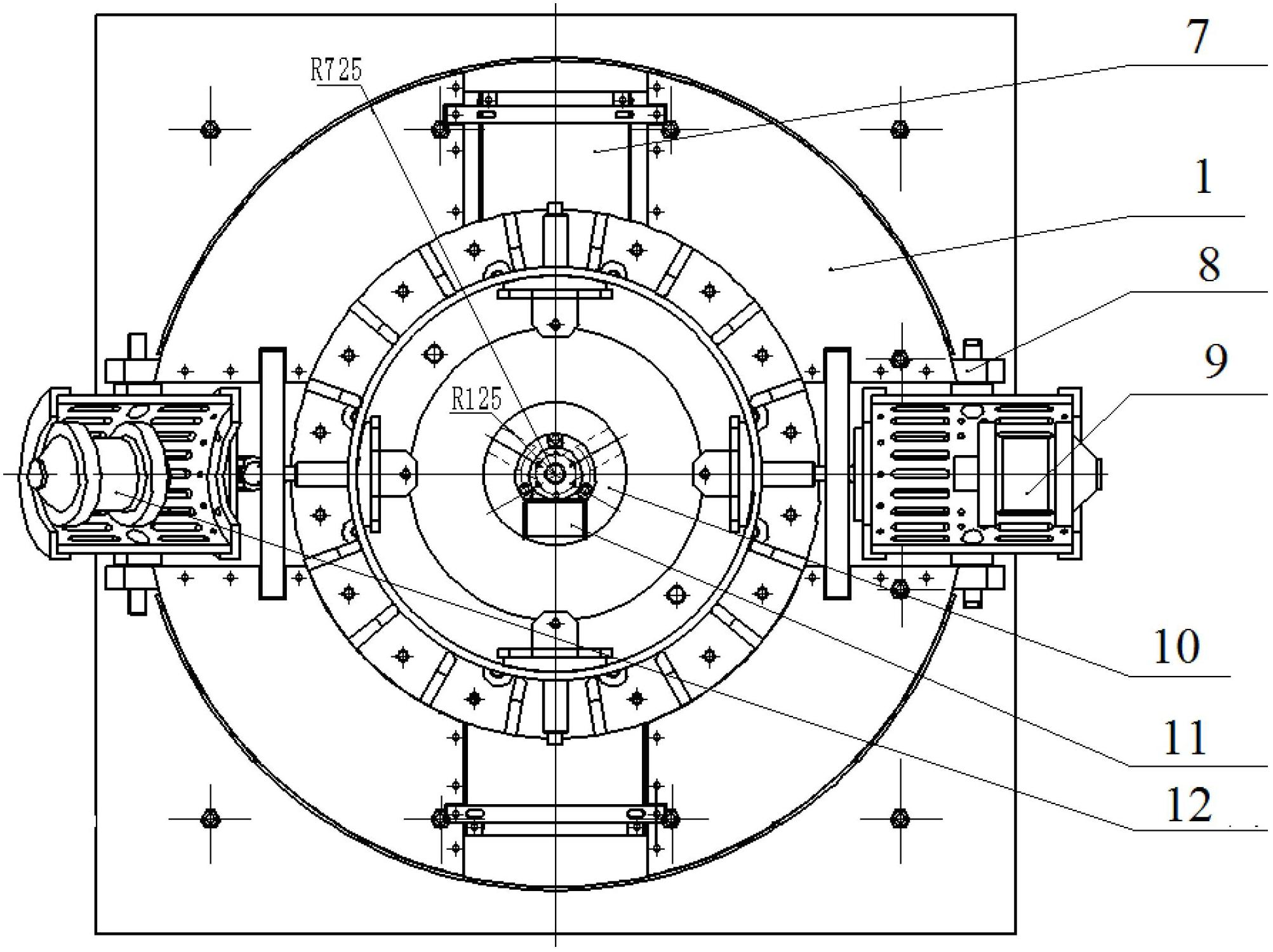

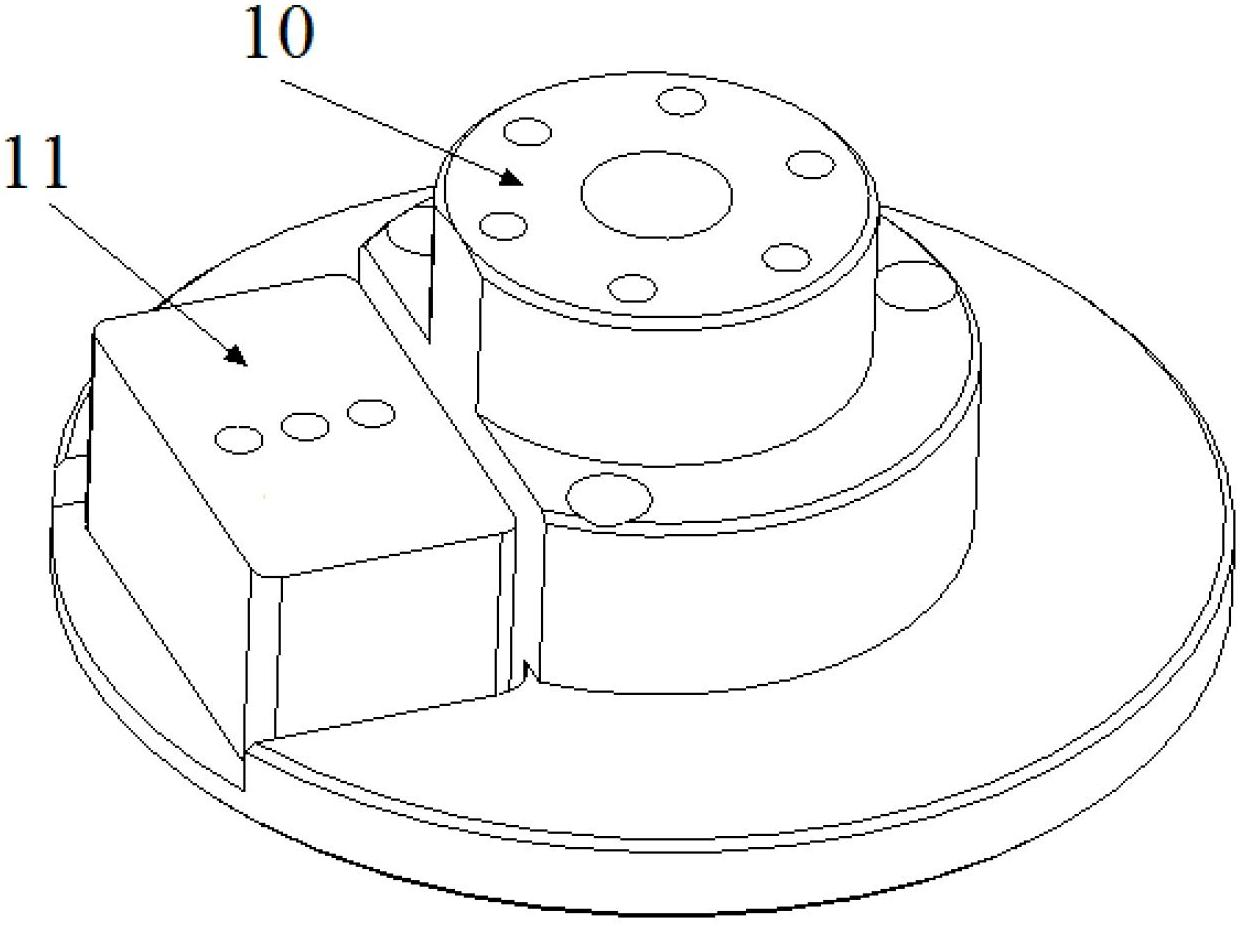

[0028] The entire high overload test system consists of two parts: mechanical system and electrical system. The rotating test bench is the main body of the mechanical system of the high-overload test device, which is used to provide the necessary rotating conditions for the test and to withstand the load generated when the engine is working. Such as figure 1 As shown, the rotating test bench adopts a vertical structure, and includes a rotating table 1, a bearing shaft assembly 2, a bearing assembly 3, a frame 4, a transmission shaft assembly 5, and a slip ring assembly 6. Its working principle is: the motor is connected with the drive shaft assembly 5 through a coupling to provide the power required for rotation of the rotating test bench; the load of the rotating test bench is mainly borne by the bearing shaft assembly 2; the bearing sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com