Rotary testing device for vortex-induced vibration for oblique riser under shear current

A test device and vortex-induced vibration technology, applied in the field of marine engineering, can solve the problems of inability to simulate the vortex-induced vibration of a riser in a stepped flow field, difficult vortex-induced vibration testing, and small test distances, etc. Install, increase the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

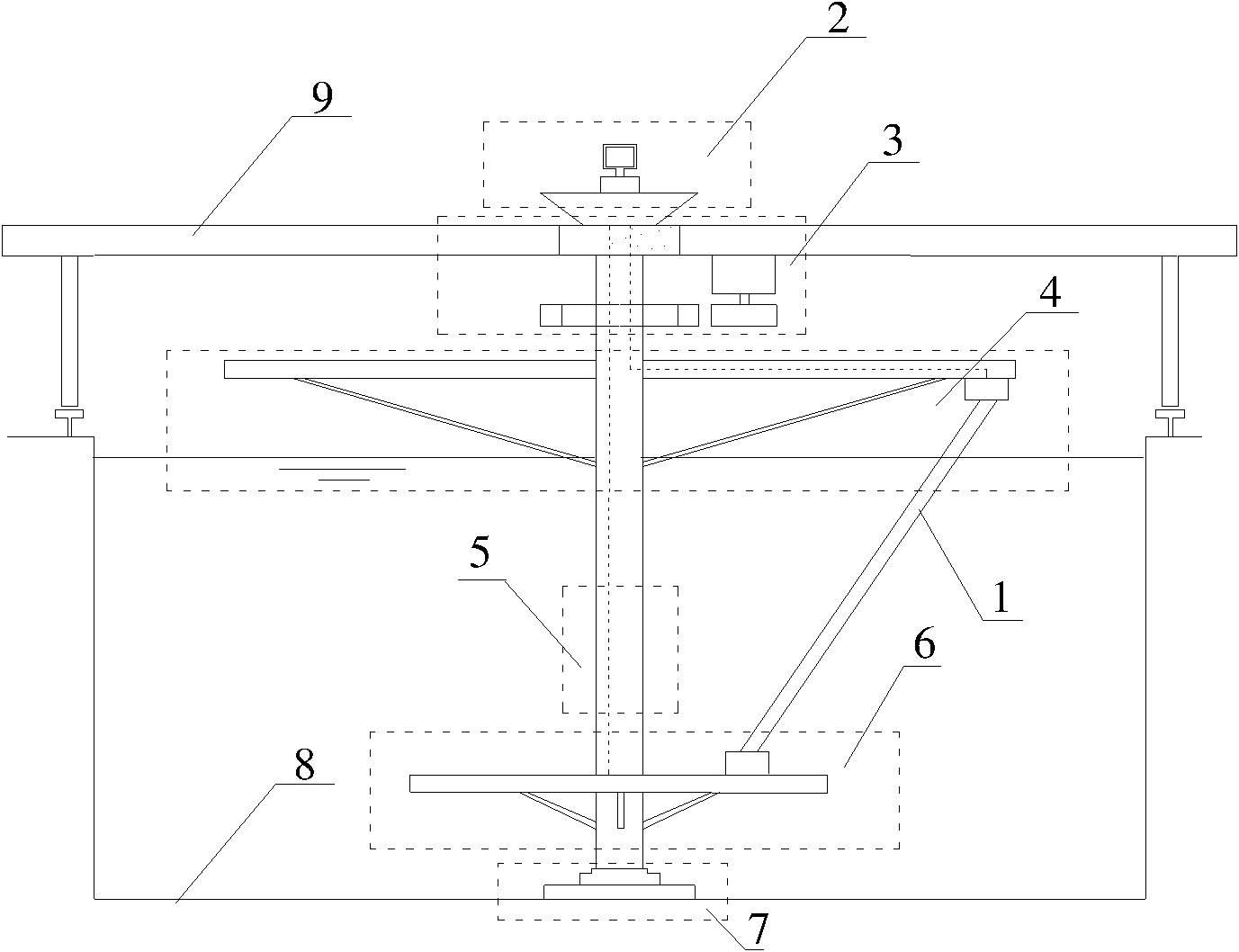

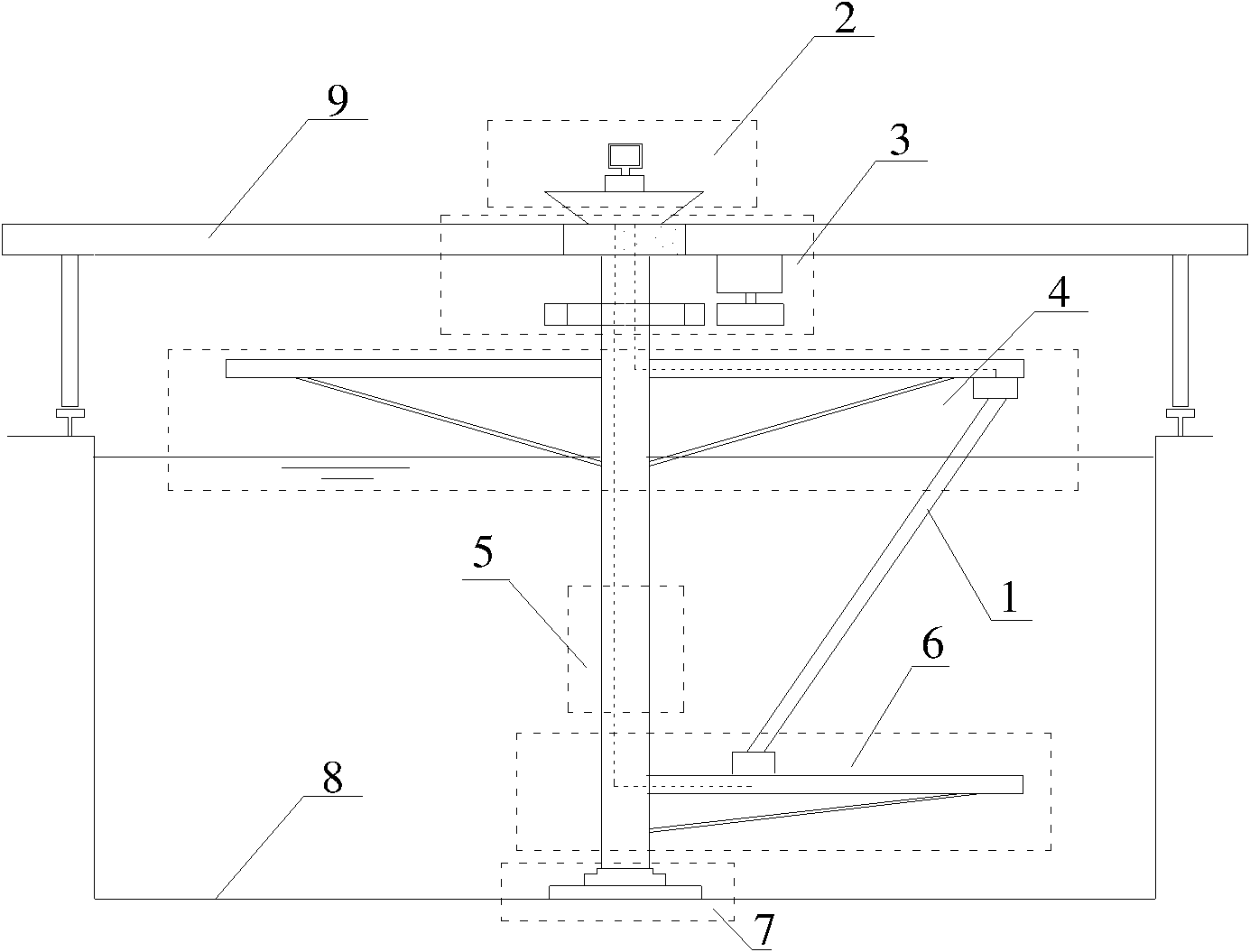

[0055] Such as Figure 1b As shown, the bottom riser fixing module 6 in this embodiment includes: a connecting flange 24, a bottom fixing cylinder shaft 25, a rectangular steel truss 44 and a rectangular support plate 45, wherein: one end of the rectangular support plate 45 is fixed to the bottom The cylindrical shaft 25 is connected, and the other end is connected with the lower end of the riser model 37. The upper part of the bottom fixed cylindrical shaft 25 is connected with the cylindrical shaft segment module 5 through the connecting flange 24, and the lower part is connected with the bottom supporting flange 26. Connected with the bottom support module 7, the connecting flange 24 is installed at the upper end of the bottom fixed cylindrical shaft 25 and connected with the cylindrical shaft segment module 5, and the rectangular steel truss 44 is installed at the lower position of the rectangular support plate 45 and connected to the bottom The fixed cylindrical shaft 25 ...

Embodiment 3

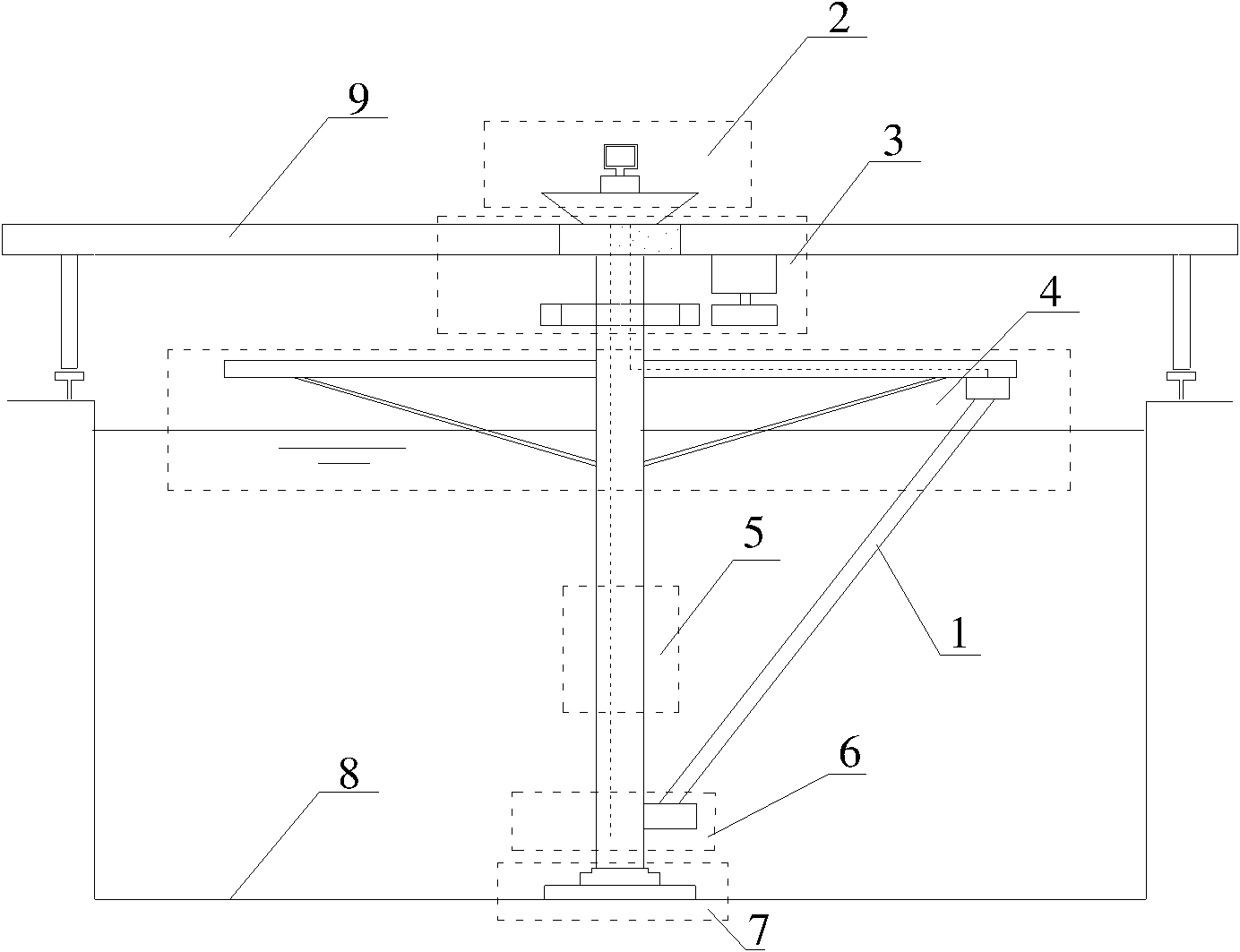

[0057] Such as Figure 1c As shown, the bottom riser fixing module 6 in this embodiment includes: a connecting flange 24, a bottom fixing cylinder shaft 25, a bottom fixing end 46 of the riser, an opening 47 on the bottom fixing cylinder shaft, a bottom fixing cylinder shaft The lower opening 48, wherein the upper part of the bottom fixed cylindrical shaft 25 is connected to the cylindrical shaft segment module 5 through the connecting flange 24, and the lower part is connected to the bottom supporting module 7 through the bottom supporting flange 26. The riser model 37 is fixed inside the bottom fixed cylinder shaft 25 through the bottom fixed end 46 of the riser through the upper opening 47 of the bottom fixed cylinder shaft and the lower opening 48 of the bottom fixed cylinder shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com