State recognition and prediction method for spindle characteristic test bench based on deep learning

A characteristic test and state recognition technology, which is applied in mechanical bearing testing, character and pattern recognition, testing of mechanical components, etc., can solve problems such as data information deviation information and insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

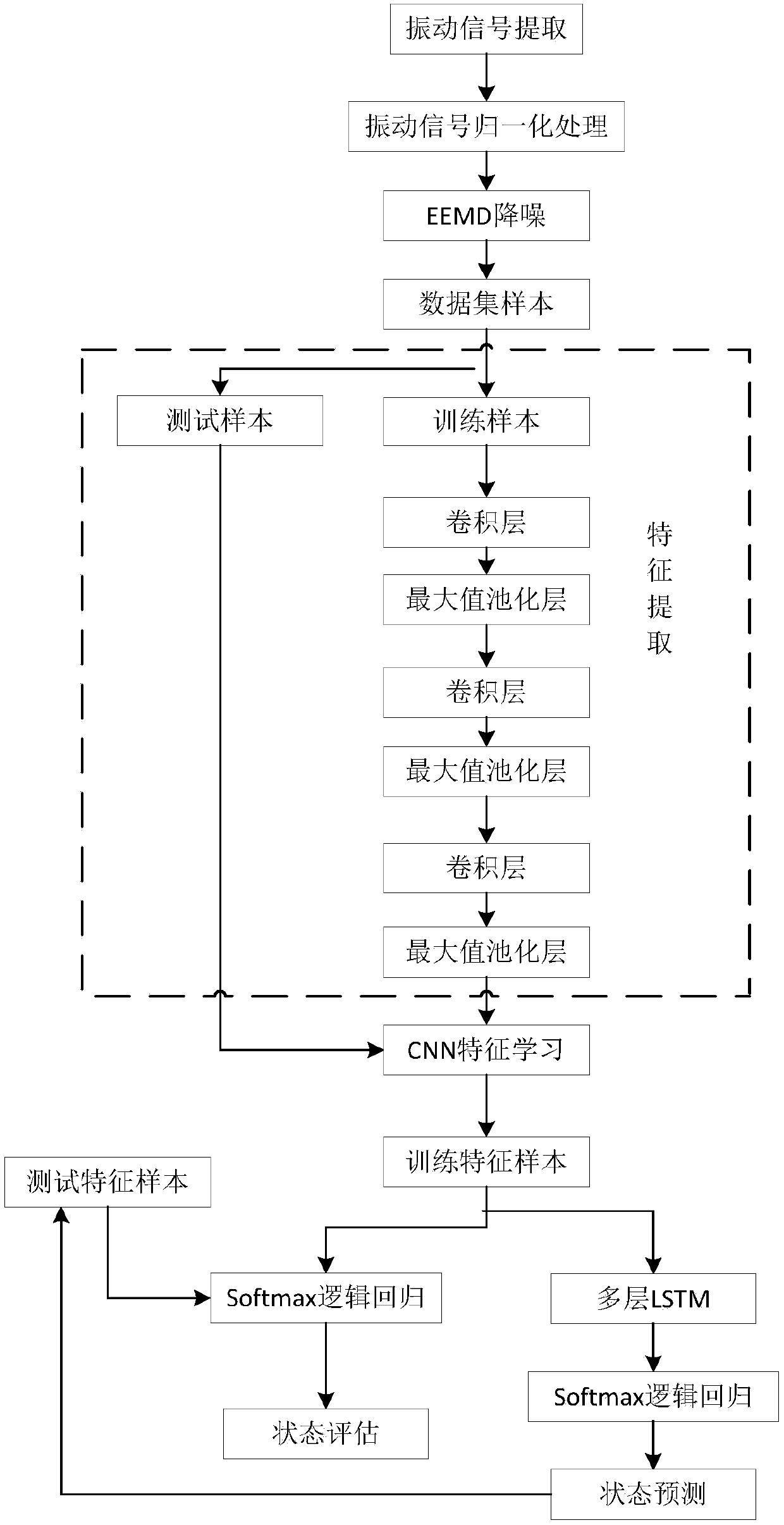

Method used

Image

Examples

Embodiment

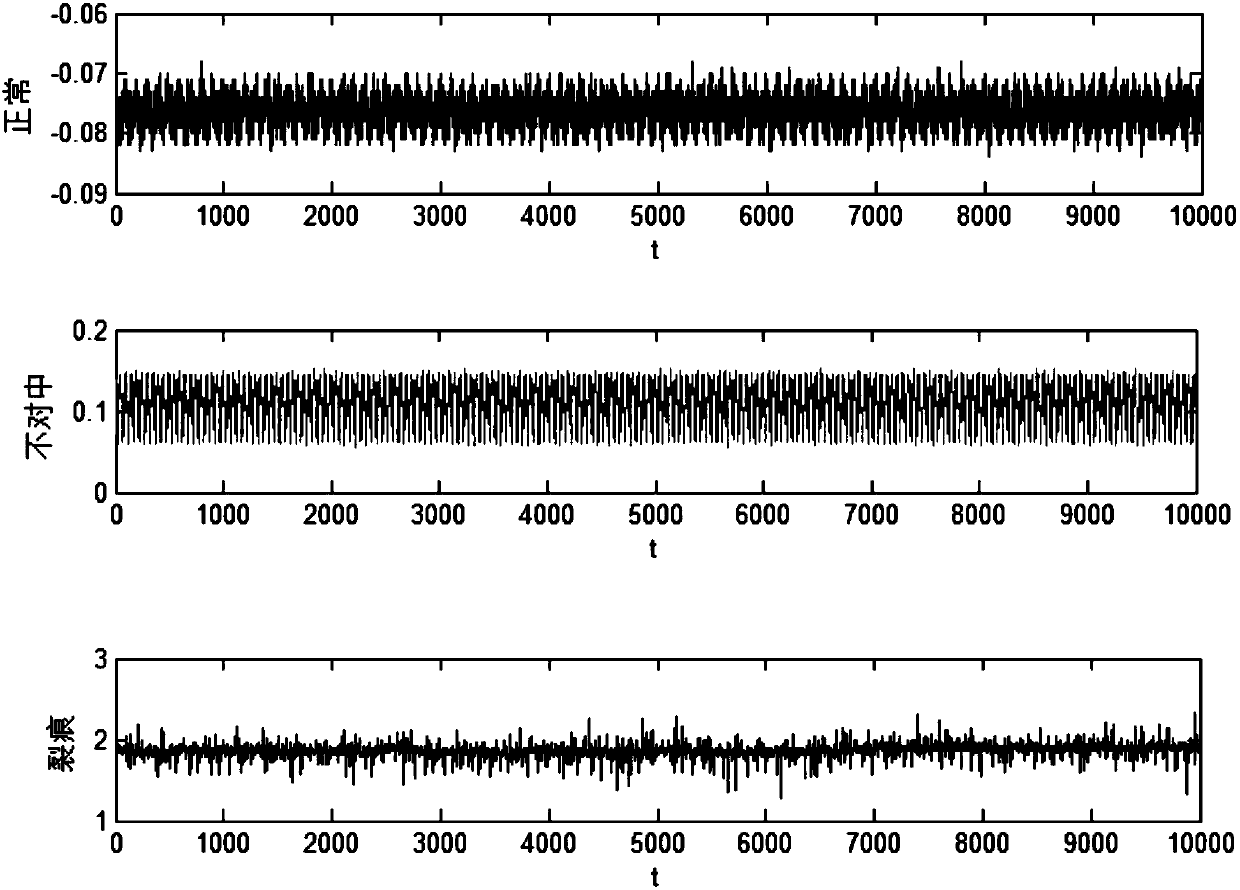

[0096] In this embodiment, the feasibility verification is carried out through the collected sample data for the spindle characteristic test bench. The test platform consists of a servo drive mechanism, a hydraulic loading mechanism, a tested bearing, an acceleration vibration sensor and a signal acquisition system. Through the load change of hydraulic loading, the signal data of two staggered directions X / Y are collected to realize the state identification and prediction of the three operating states of the spindle system and the bearing under test: normal, misaligned, and bearing cracks. During the test, the sampling frequency was 1024Hz, the rotor speed was accelerated from 600r / min, 900r / min until 3300r / min, and the sampling length was 100000. The data set composition of the spindle characteristic test bench is shown in Table 1.

[0097] Table 1 Rotor dataset

[0098]

[0099] There are 64 data samples in each state, of which 32 samples are used as the test set, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com