Patents

Literature

135 results about "Condition-based maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

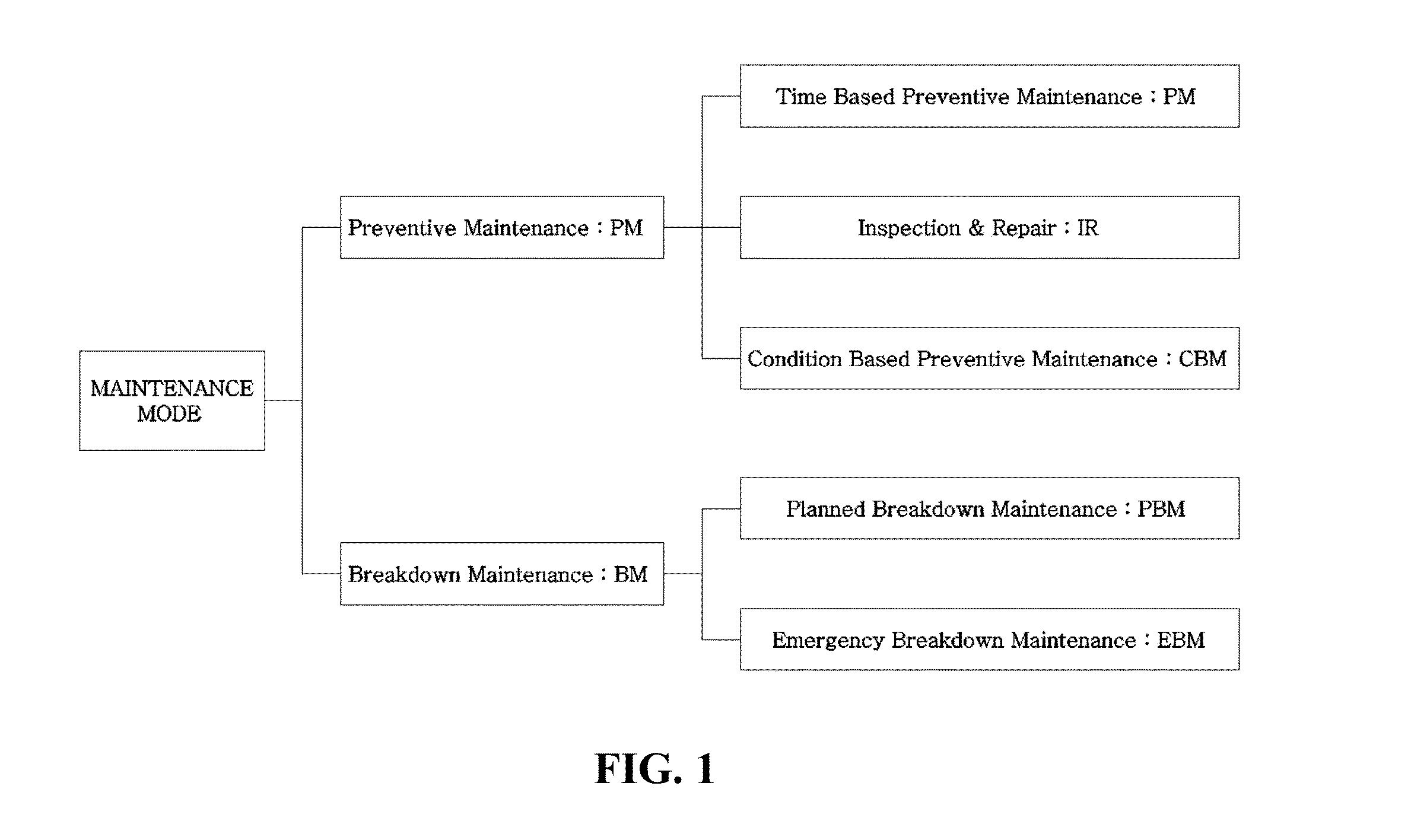

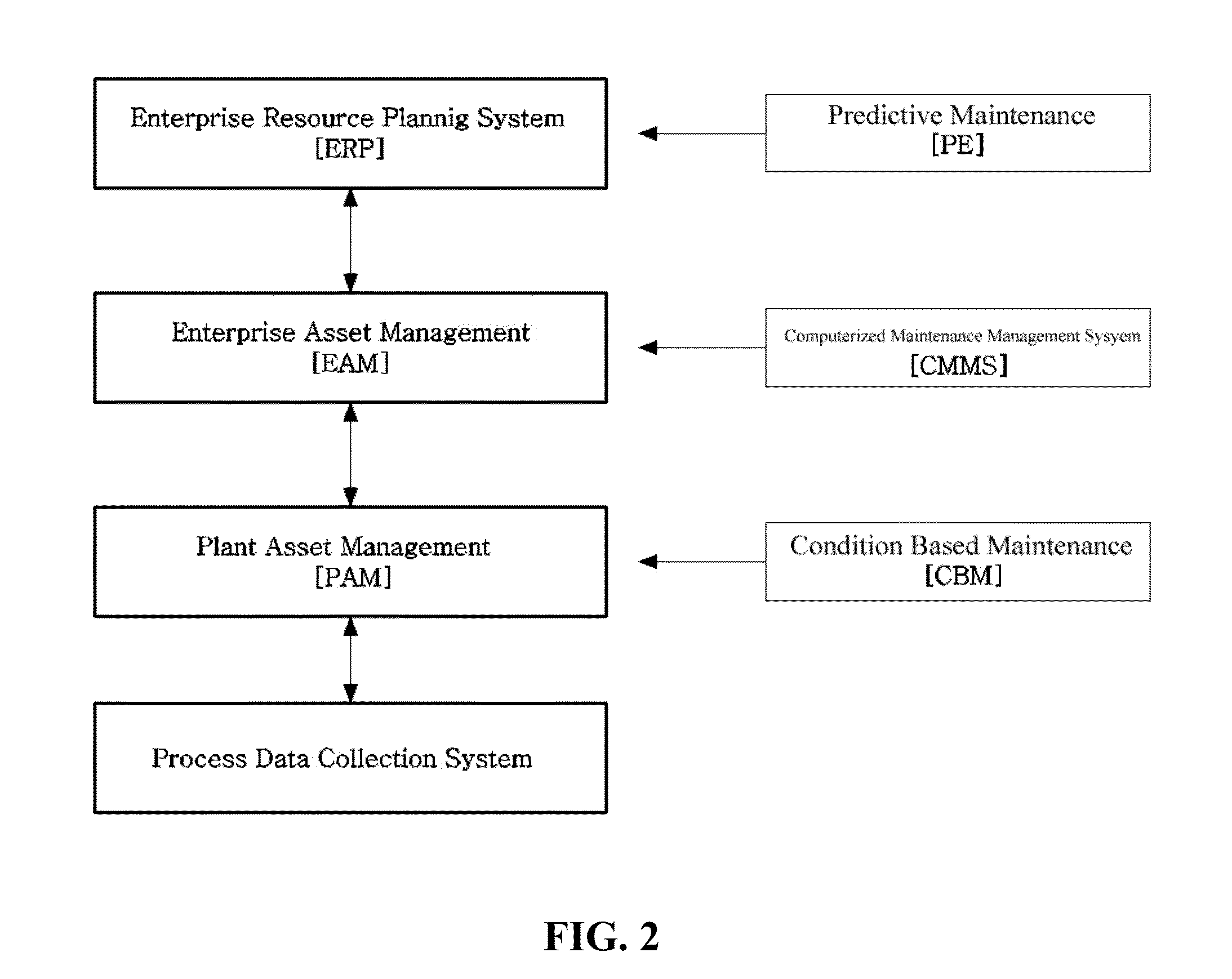

Condition-based maintenance, shortly described, is maintenance when need arises. This maintenance is performed after one or more indicators show that equipment is going to fail or that equipment performance is deteriorating. This concept is applicable to mission critical systems that incorporate active redundancy and fault reporting. It is also applicable to non-mission critical systems that lack redundancy and fault reporting. Condition-based maintenance was introduced to try to maintain the correct equipment at the right time. CBM is based on using real-time data to prioritize and optimize maintenance resources. Observing the state of the system is known as condition monitoring. Such a system will determine the equipment's health, and act only when maintenance is actually necessary. Developments in recent years have allowed extensive instrumentation of equipment, and together with better tools for analyzing condition data, the maintenance personnel of today are more than ever able to decide what is the right time to perform maintenance on some piece of equipment.

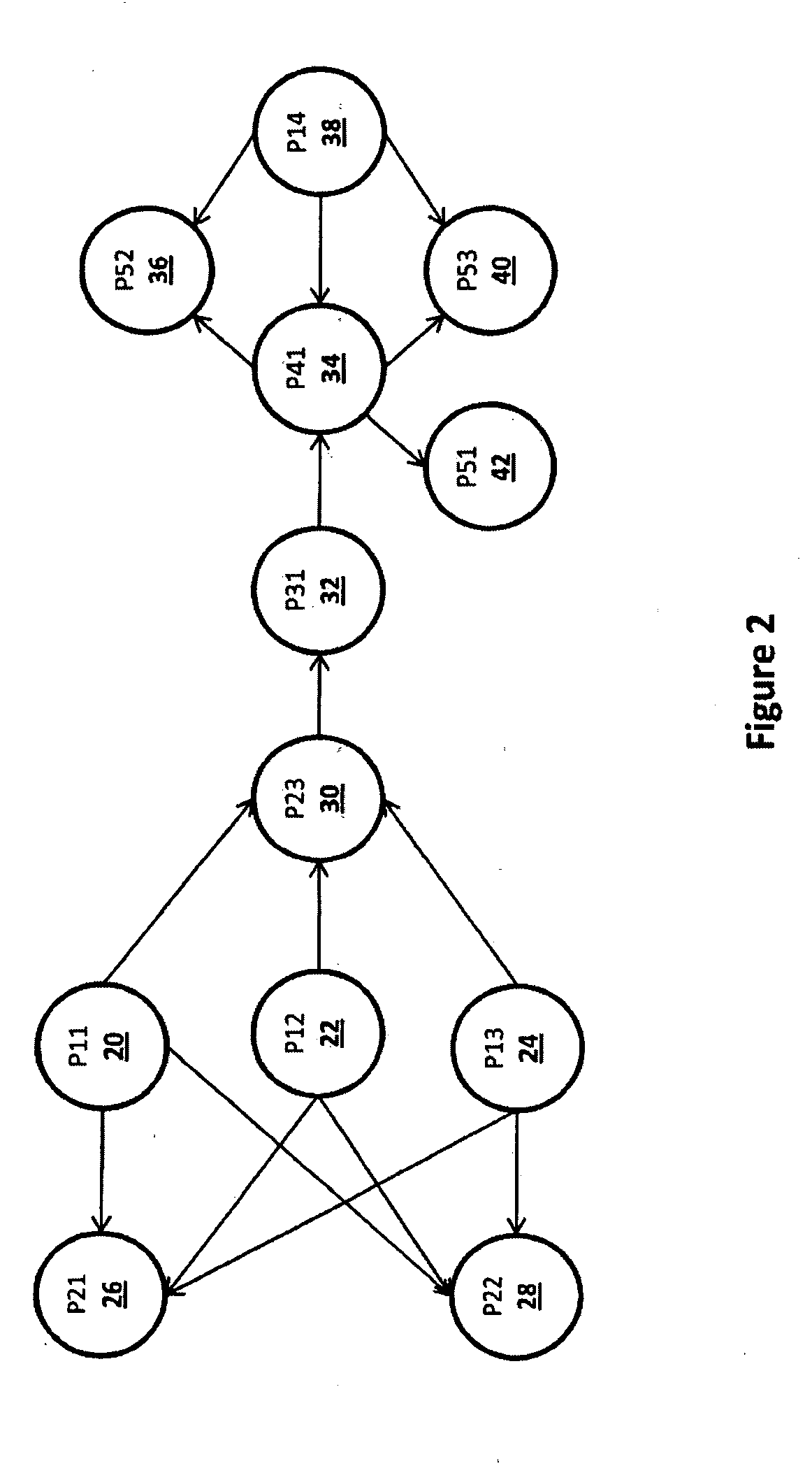

Intelligent model-based diagnostics for system monitoring, diagnosis and maintenance

InactiveUS20060064291A1Improve accuracyImprove consistencyAmplifier modifications to reduce noise influenceTesting/monitoring control systemsElectric power systemCompound (substance)

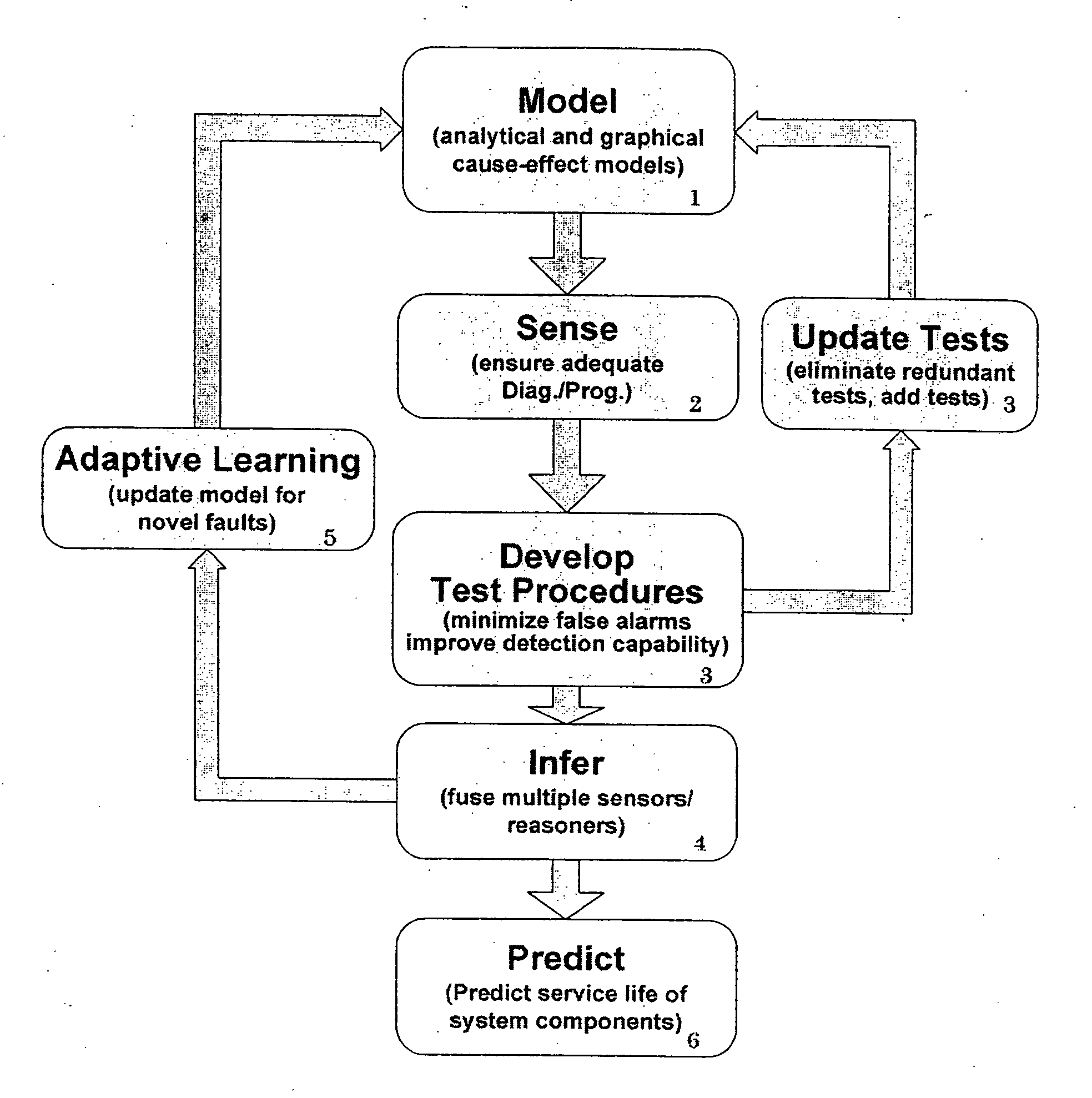

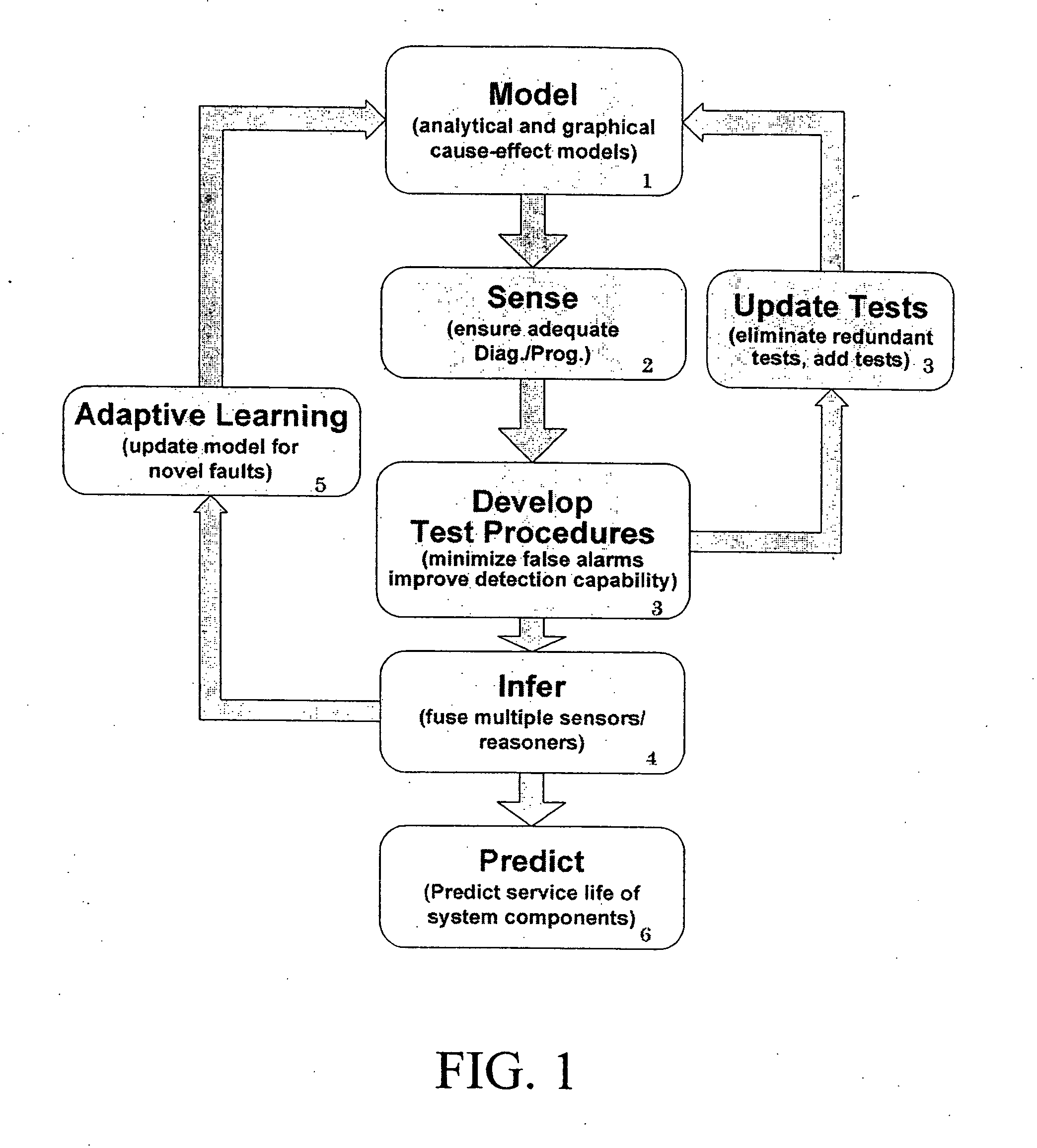

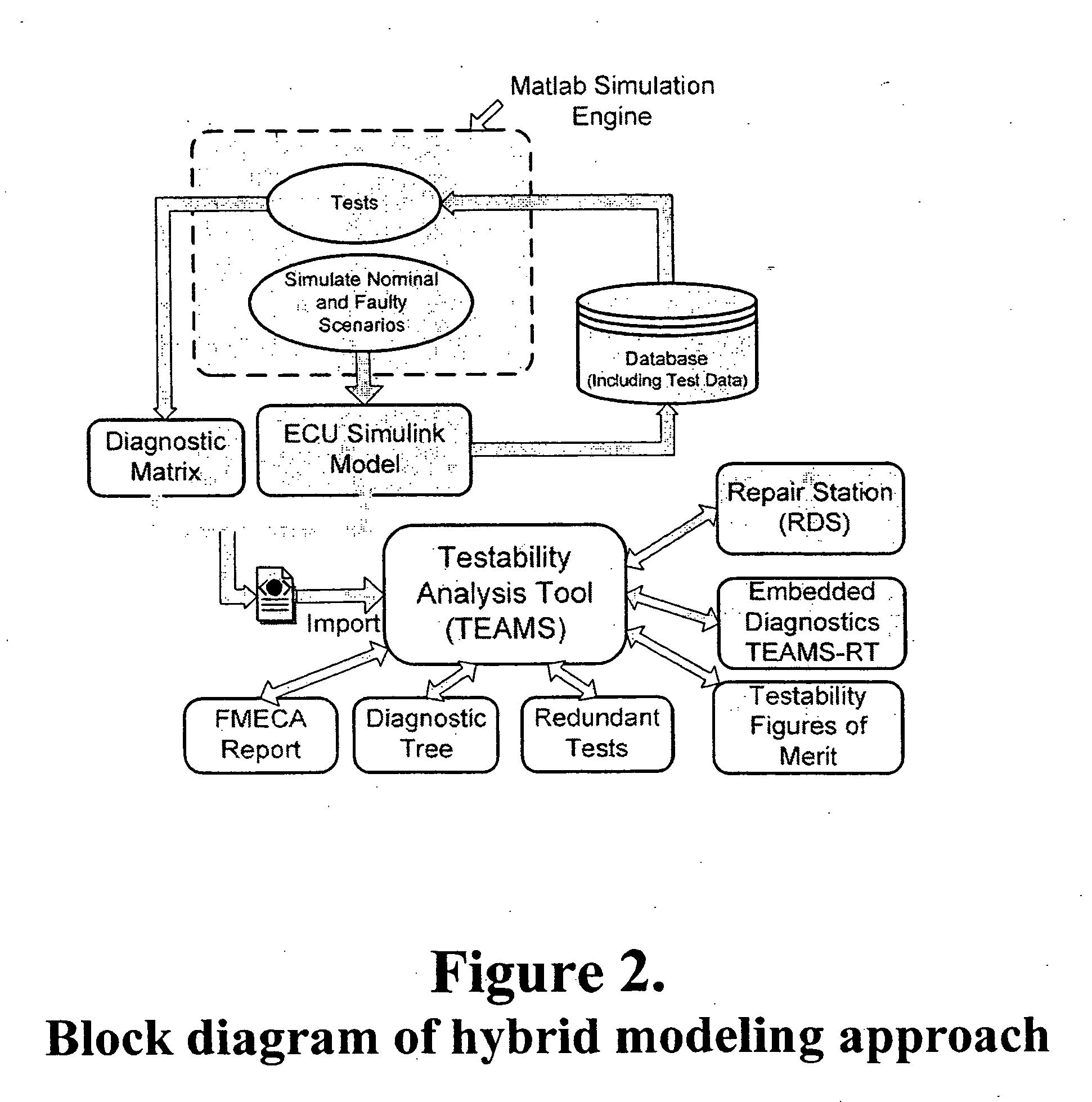

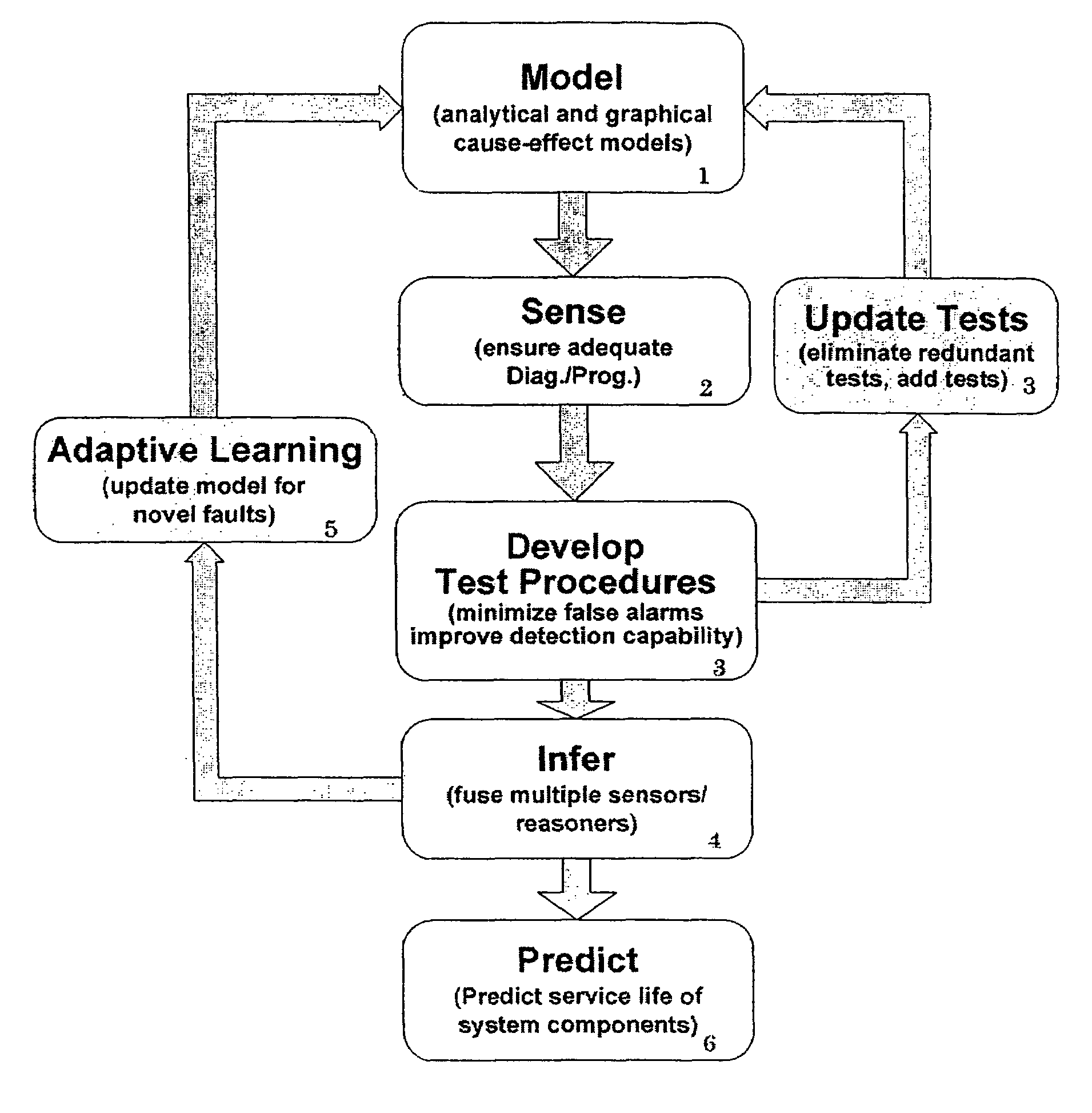

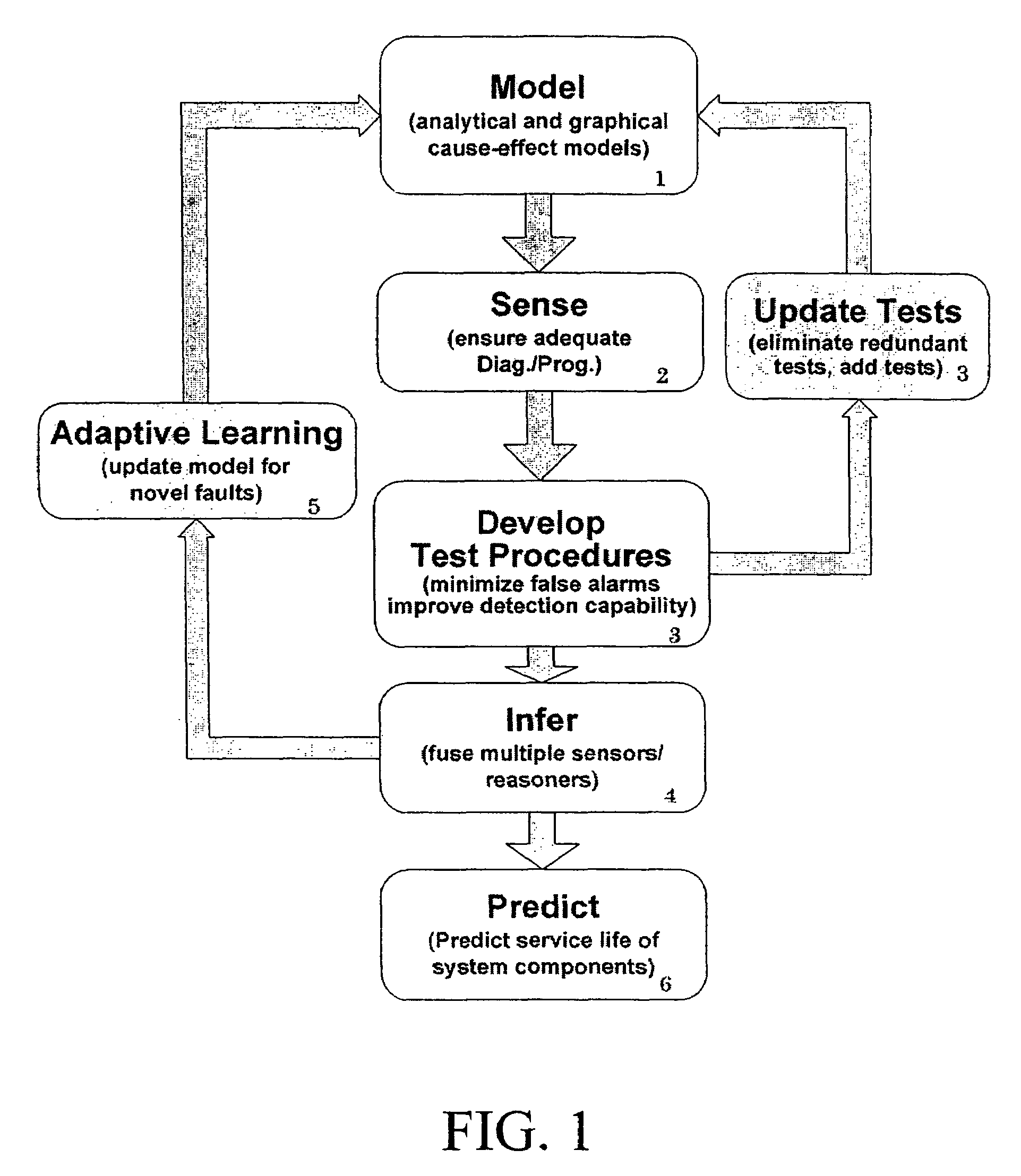

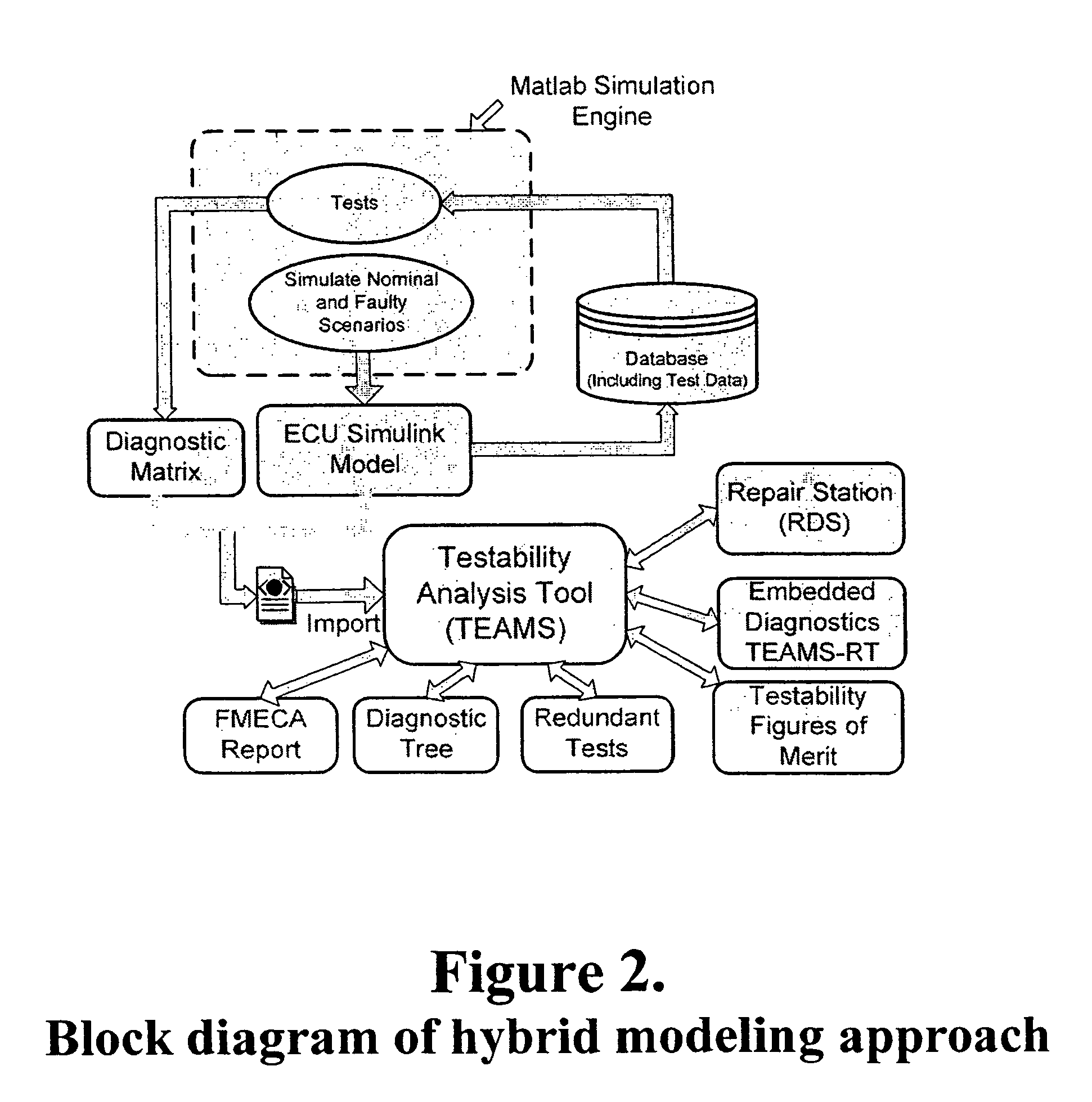

Systems and methods are provided for monitoring, diagnosis and condition-based maintenance of mechanical systems. The disclosed systems and methods employ intelligent model-based diagnostic methodologies to effectuate such monitoring, diagnosis and maintenance. According to exemplary embodiments of the present disclosure, the intelligent model-based diagnostic methodologies combine or integrate quantitative (analytical) models and graph-based dependency models to enhance diagnostic performance. The disclosed systems and methods may be employed a wide variety of applications, including automotive, aircraft, power systems, manufacturing systems, chemical processes and systems, transportation systems, and industrial machines / equipment.

Owner:TOYOTA TECHN CENT USA +1

Intelligent model-based diagnostics for system monitoring, diagnosis and maintenance

InactiveUS7260501B2Improve accuracyImprove consistencyAmplifier modifications to reduce noise influenceTesting/monitoring control systemsTransit systemElectric power system

Owner:TOYOTA TECHN CENT USA +1

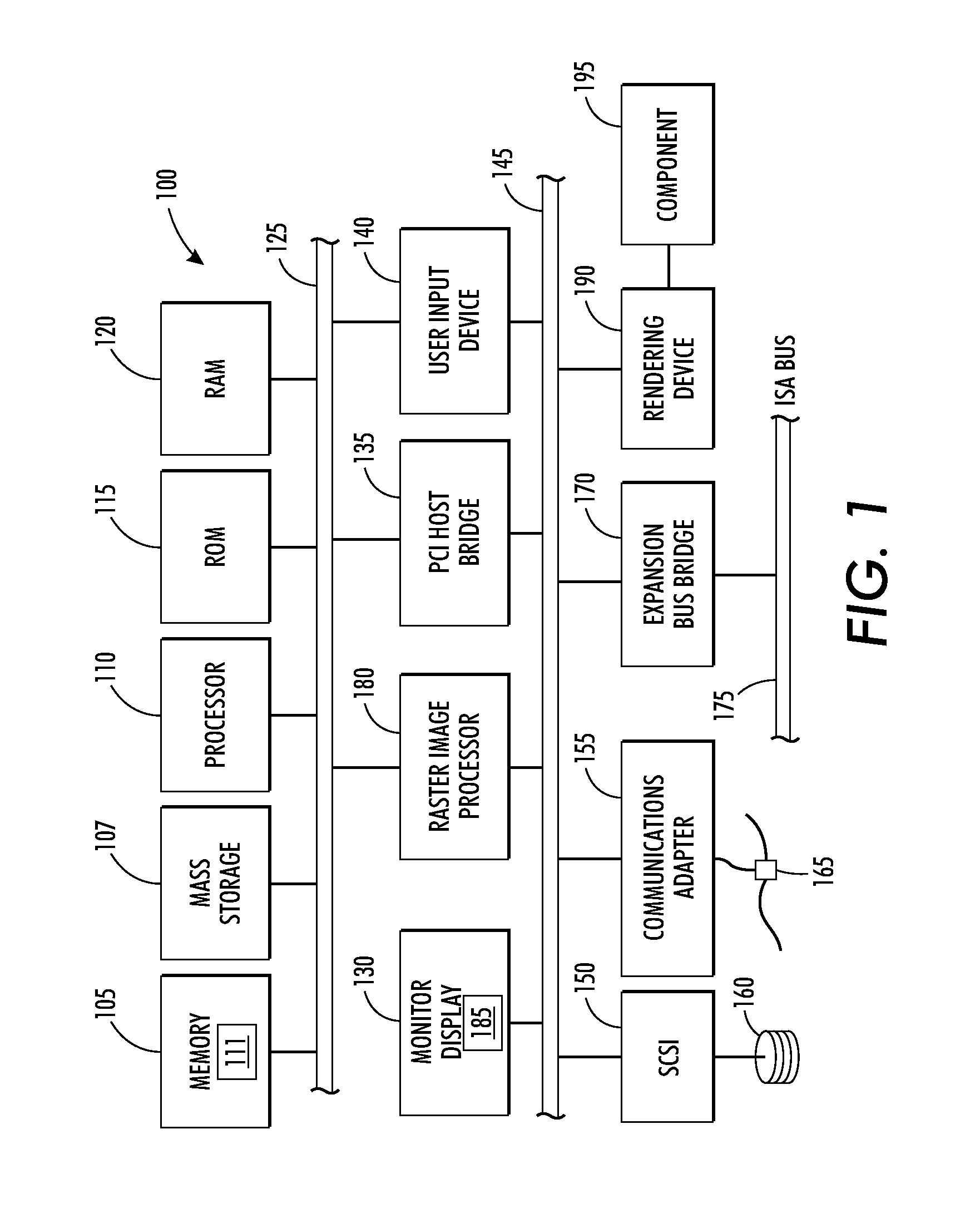

High performance hybrid micro-computer

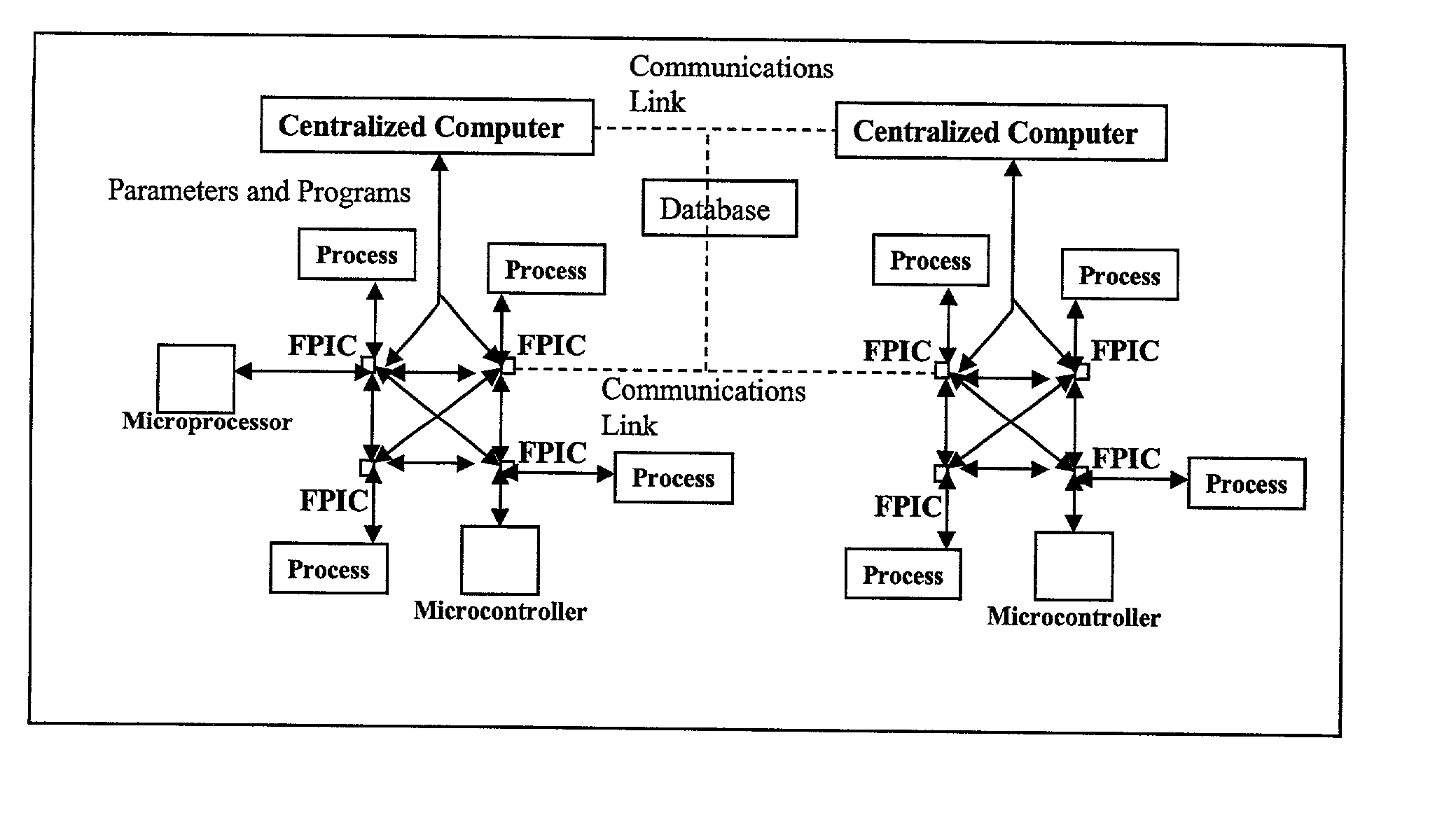

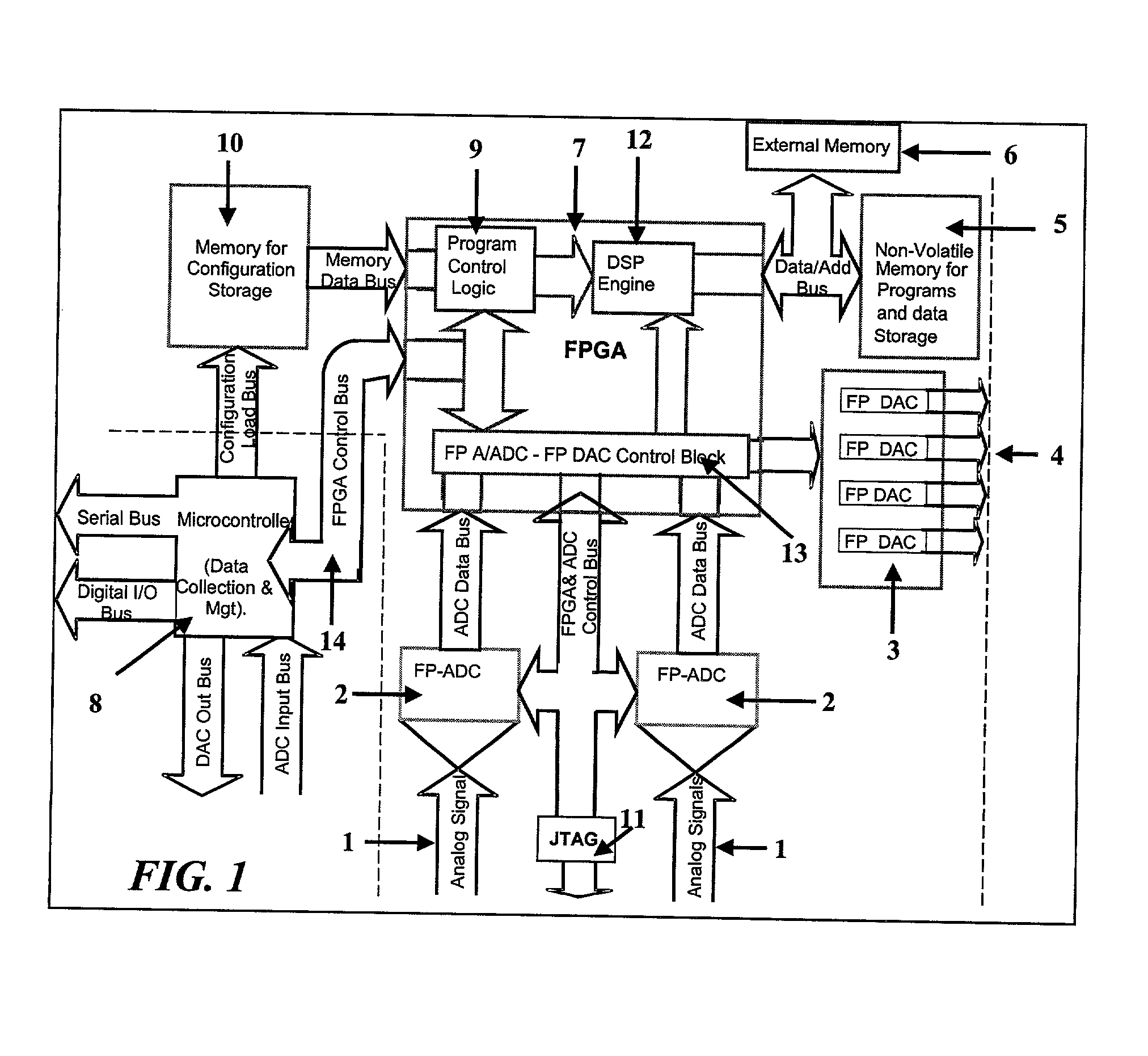

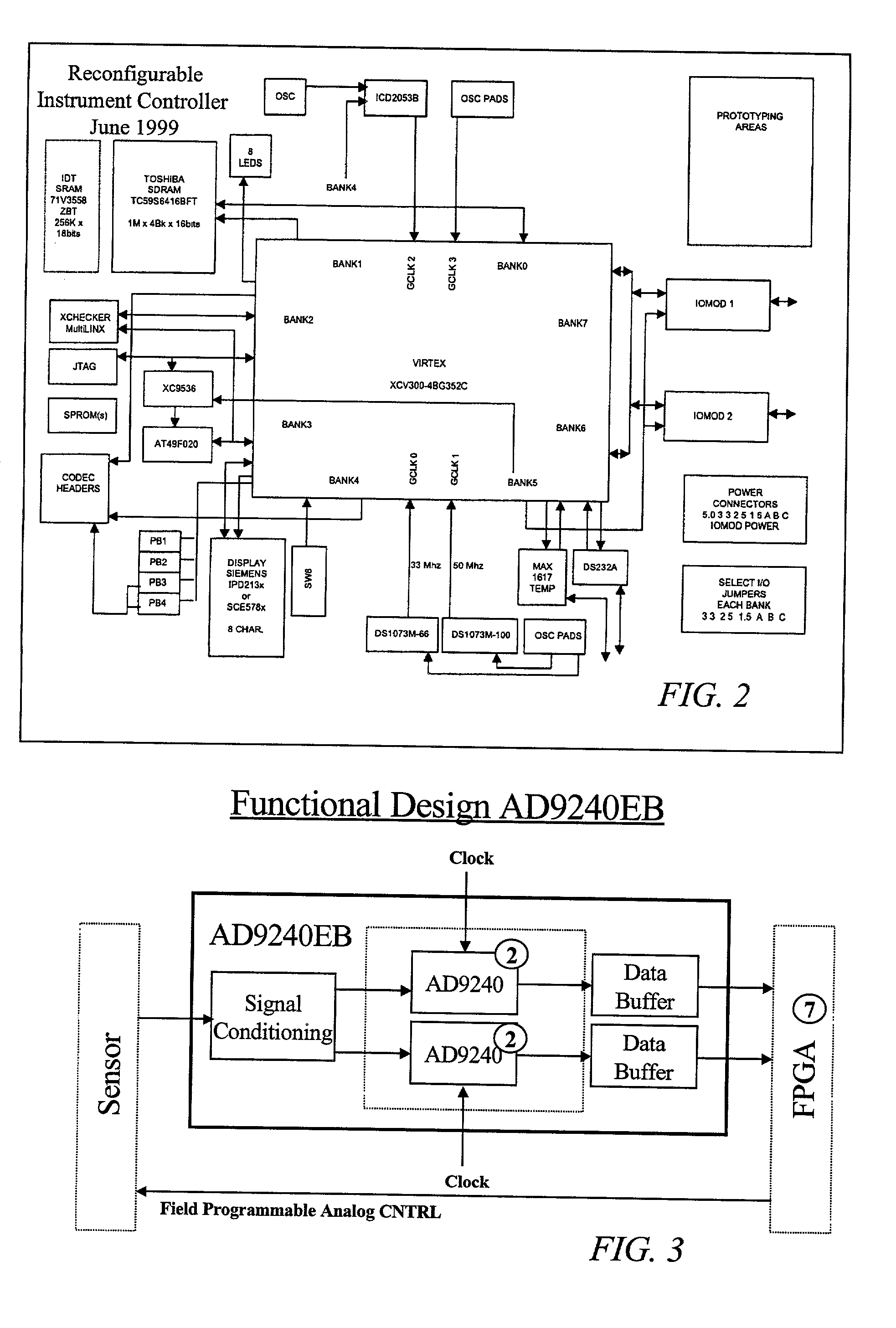

The Field Programmable Instrument Controller (FPIC) is a stand-alone low to high performance, clocked or unclocked multi-processor that operates as a microcontroller with versatile interface and operating options. The FPIC can also be used as a concurrent processor for a microcontroller or other processor. A tightly coupled Multiple Chip Module design incorporates non-volatile memories, a large field programmable gate array (FPGA), field programmable high precision analog to digital converters, field programmable digital to analog signal generators, and multiple ports of external mass data storage and control processors. The FPIC has an inherently open architecture with in-situ reprogrammability and state preservation capability for discontinuous operations. It is designed to operate in multiple roles, including but not limited to, a high speed parallel digital signal processing; co-processor for precision control feedback during analog or hybrid computing; high speed monitoring for condition based maintenance; and distributed real time process control. The FPIC is characterized by low power with small size and weight.

Owner:BLEMEL KENNETH G

Tool and method for fault detection of devices by condition based maintenance

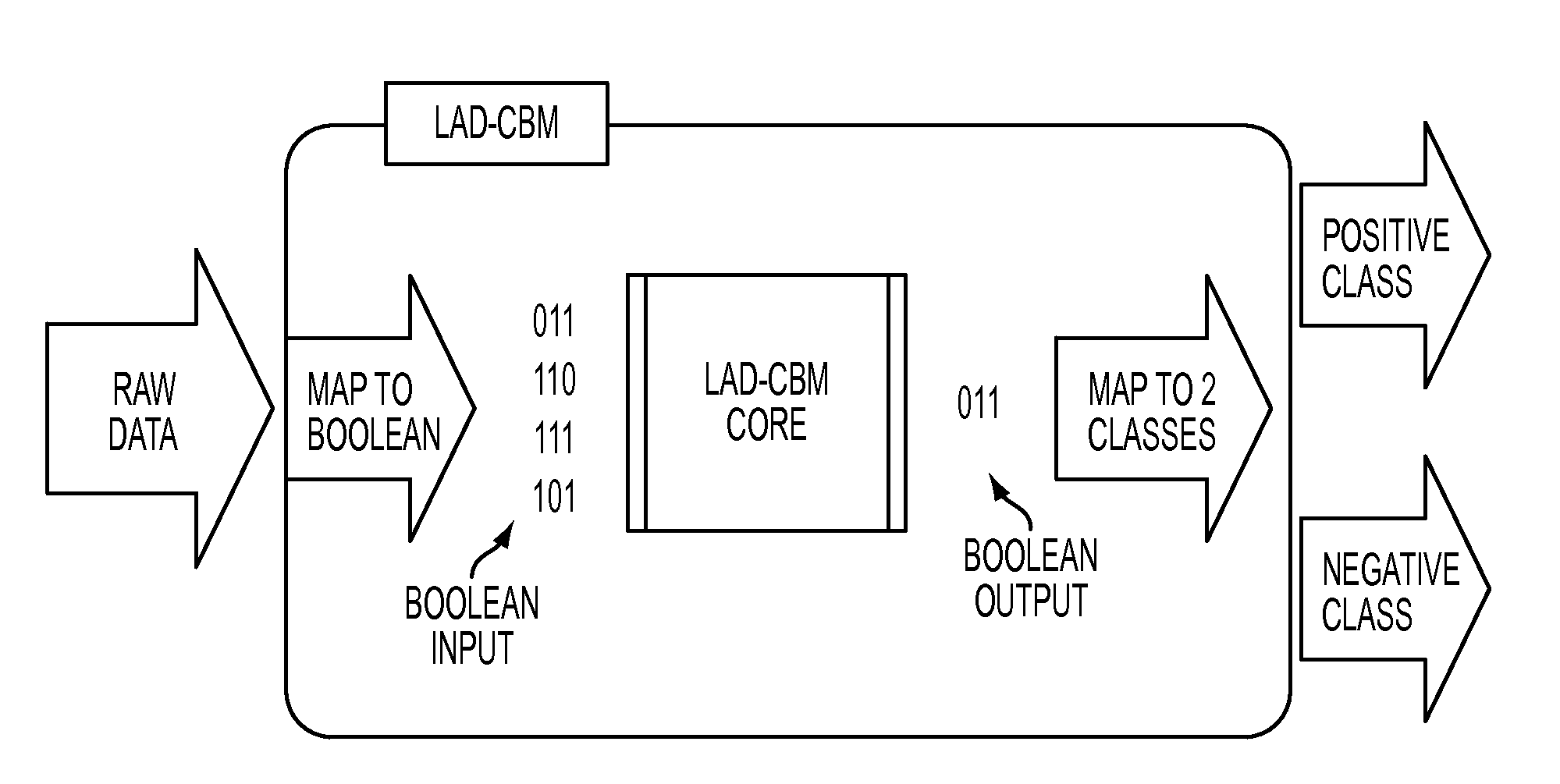

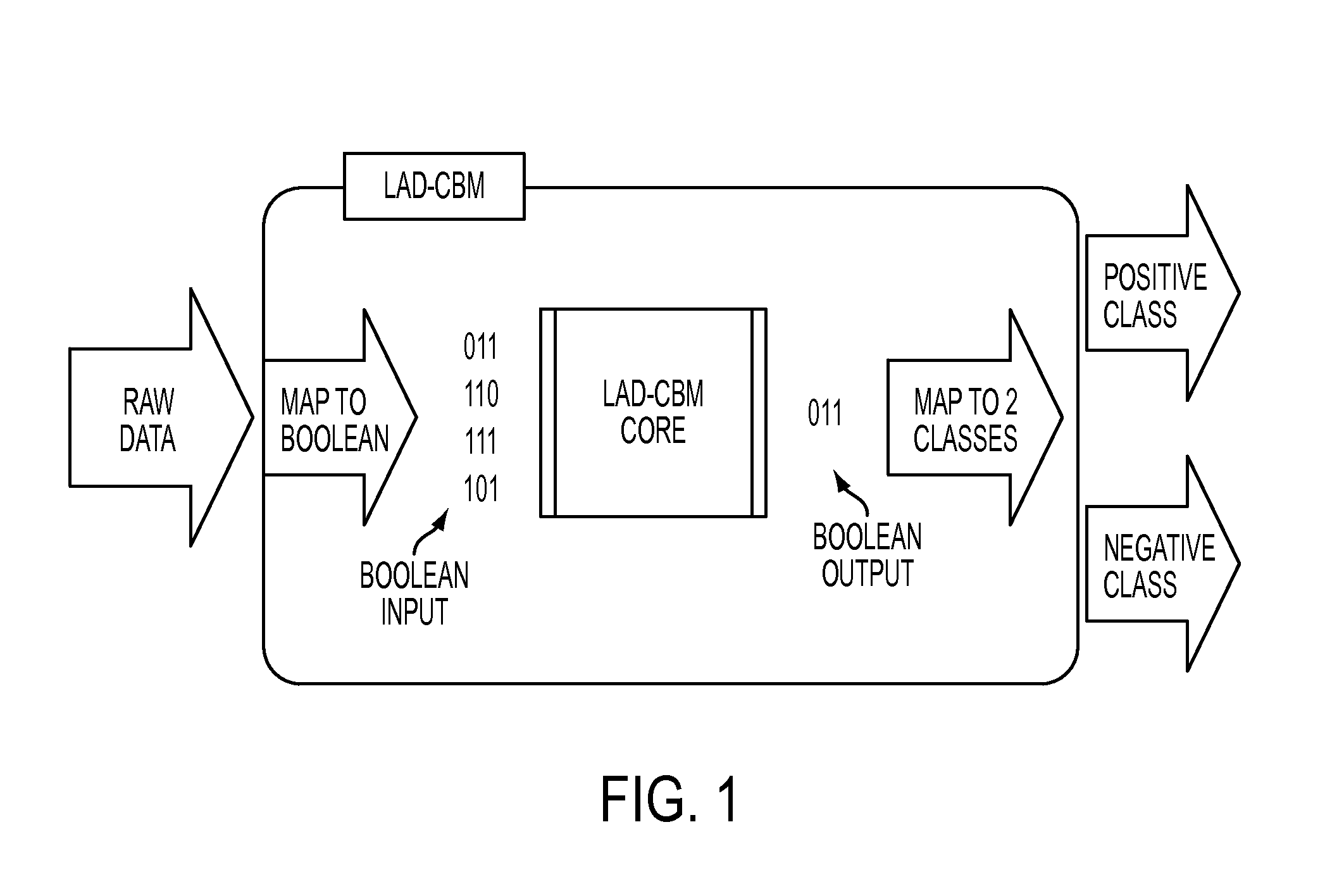

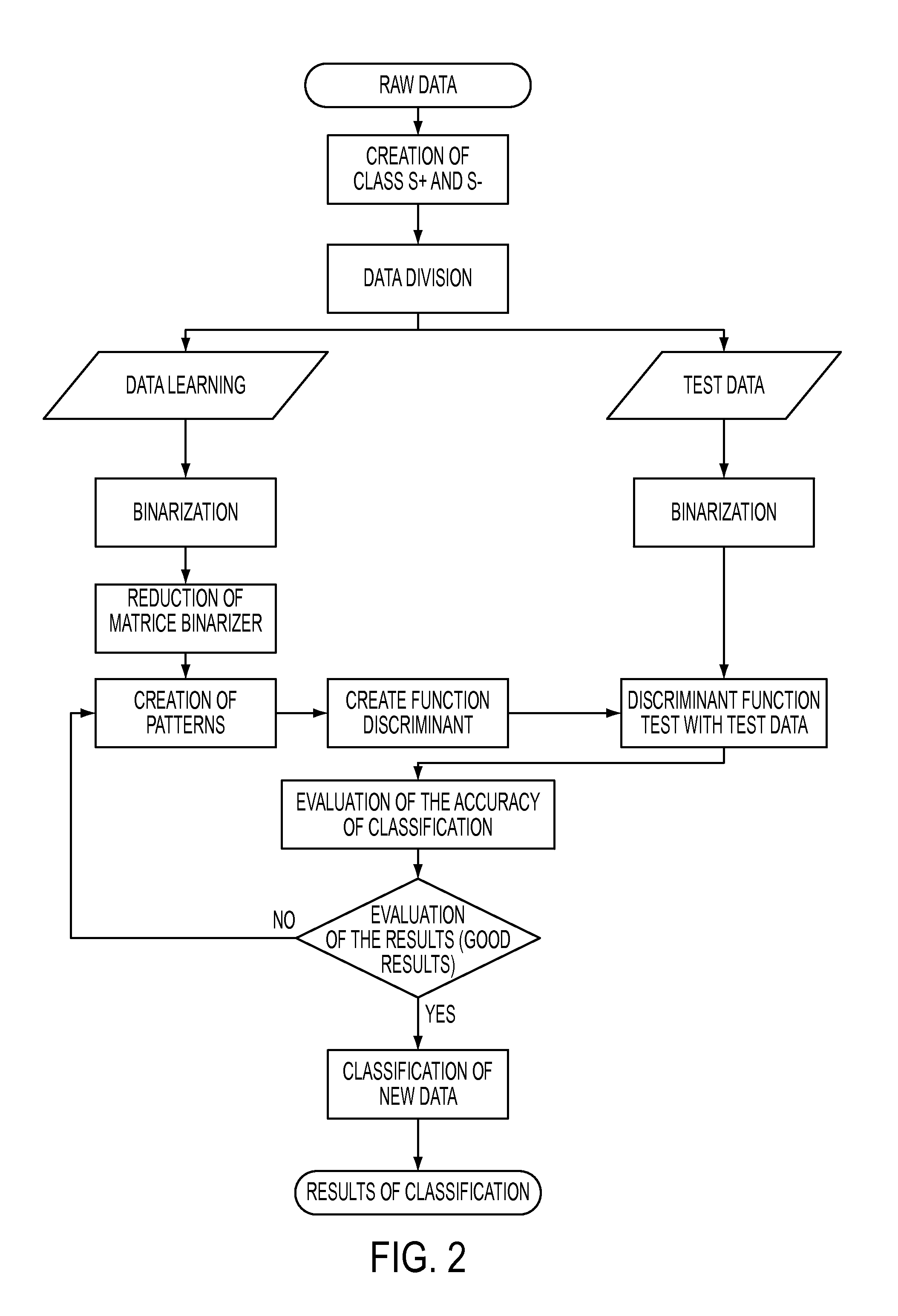

ActiveUS20130132001A1Testing/monitoring control systemsDigital computer detailsLearning dataDevice failure

The present tool and method relate to device fault detection, diagnosis and prognosis. More particularly, the present tool and method store in a database a plurality of measured indicators representative of at least one dynamic condition of the device. The present tool and method further binarize by a processor the plurality of measured indicators, and analyze the plurality of binarized measured indicators using a machine learning data tool for extracting at least one pattern from the binarized measured indicators by adding at least one different constraint to each iteration. The at least one extracted pattern is indicative of whether the device has a fault or not.

Owner:POLYVALOR LP

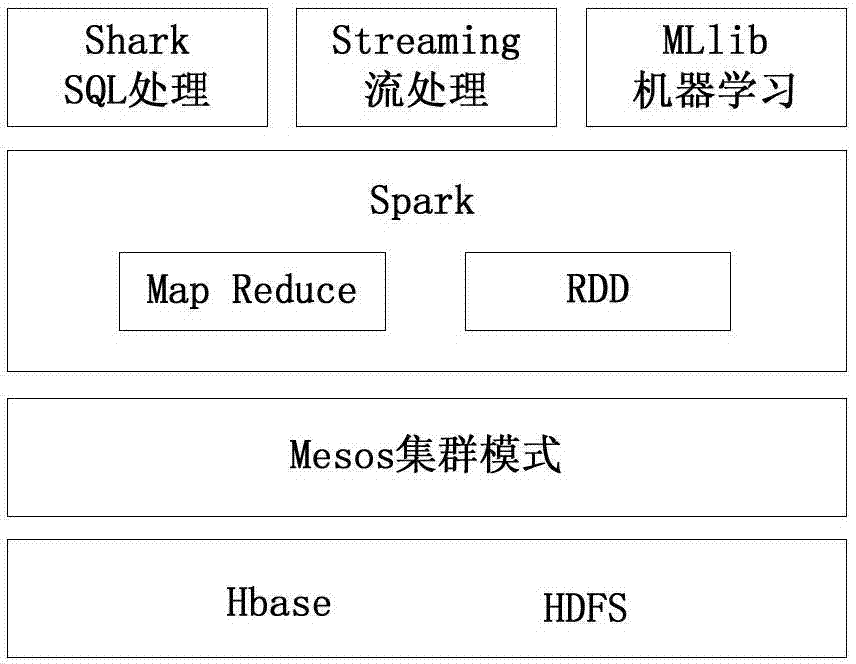

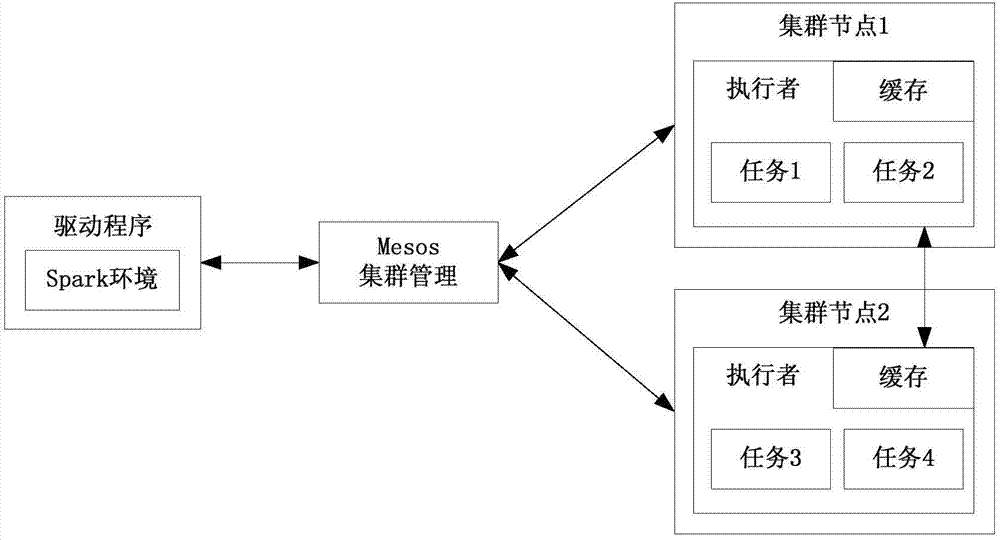

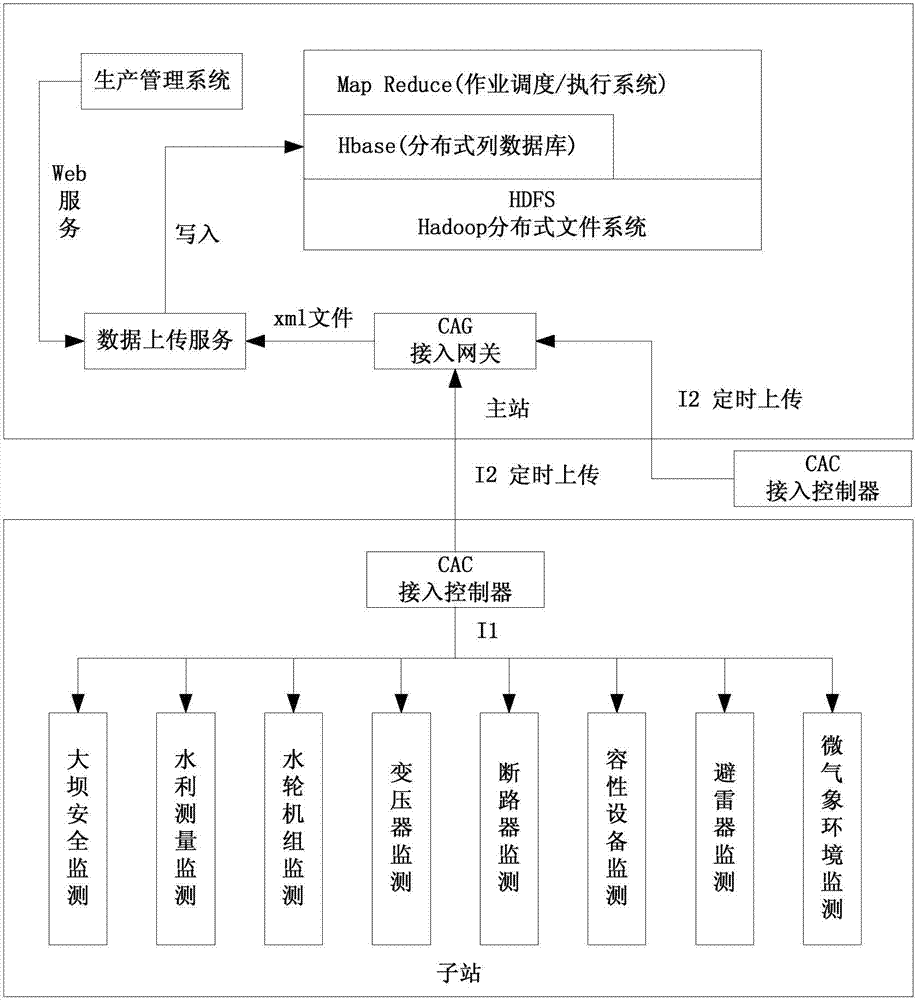

Hydroelectric equipment monitoring and fault diagnosis system based on big data technology

ActiveCN104281130ARealize unified accessRealize the loadTotal factory controlProgramme total factory controlRelevant informationDependability

The invention discloses a hydroelectric equipment monitoring and fault diagnosis system based on the big data technology. The hydroelectric equipment monitoring and fault diagnosis system comprises a visualization display module, an alarm management module, a query and statistics module and a fault diagnosis nodule. The visualization display module collects to-be-monitored information of a substation through a state access controller and uploads the information to a data uploading server through the state access controller, in this way, the data uploading server module can upload the equipment monitoring data to an Hbase database, query and statistics can be conducted on relevant information, and equipment monitoring information and equipment-related statistical information can be displayed. The alarm management module generates an alarm record through configuration of combined alarm conditions of an equipment monitoring point. The query and statistics module is used for achieving the functions for history query of the equipment monitoring data and general information query of equipment-related accounts. The fault diagnosis nodule adopts various fault diagnosis models or prediction models for conducting equipment fault diagnosis and early warning. By the adoption of the hydroelectric equipment monitoring and fault diagnosis system based on the big data technology, equipment diagnosis efficiency can be improved, the equipment diagnosis level can be increased, the basis is provided for equipment condition-based maintenance, the maintenance cost is reduced, and power supply reliability is improved.

Owner:STATE GRID CORP OF CHINA +1

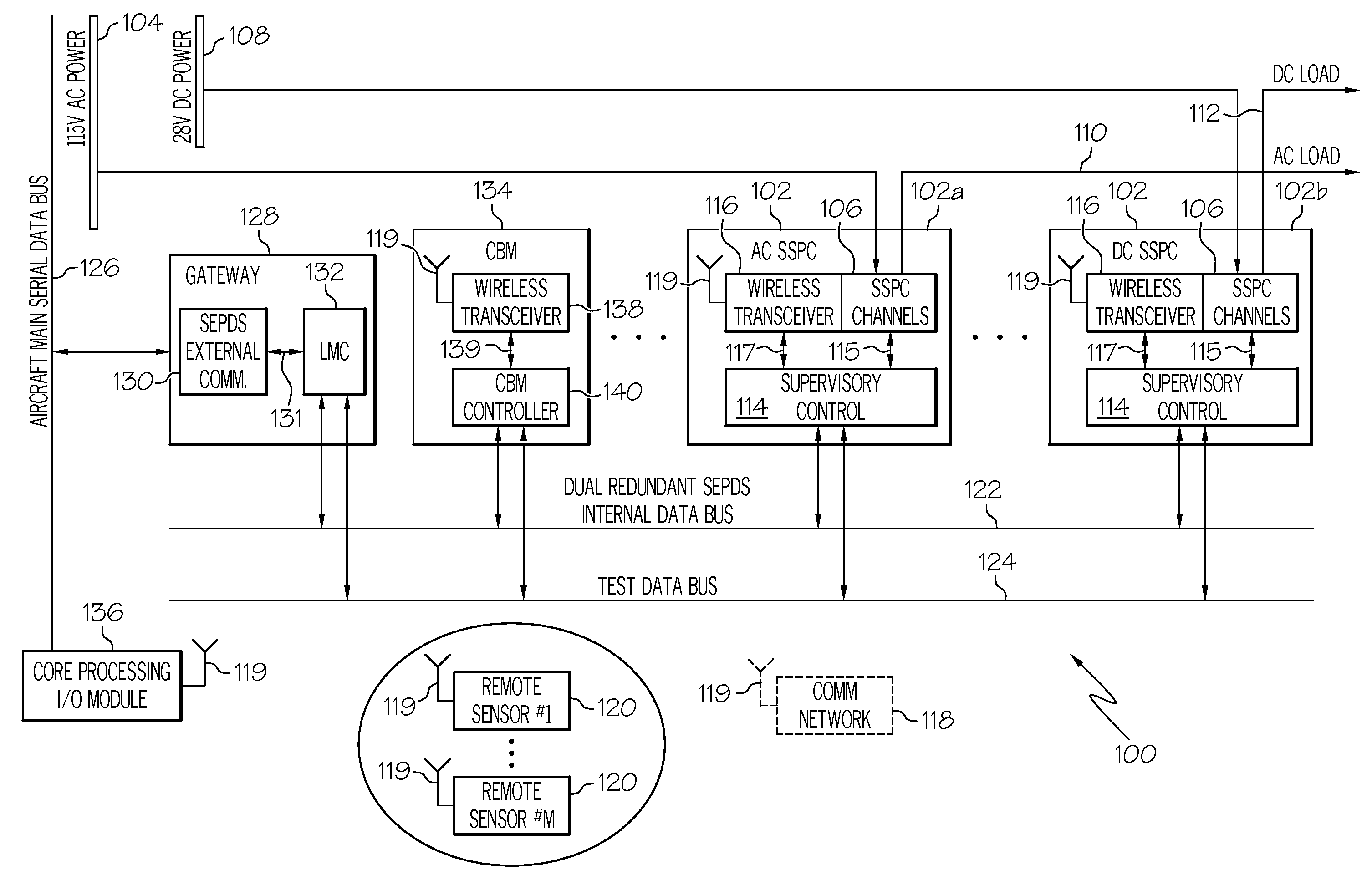

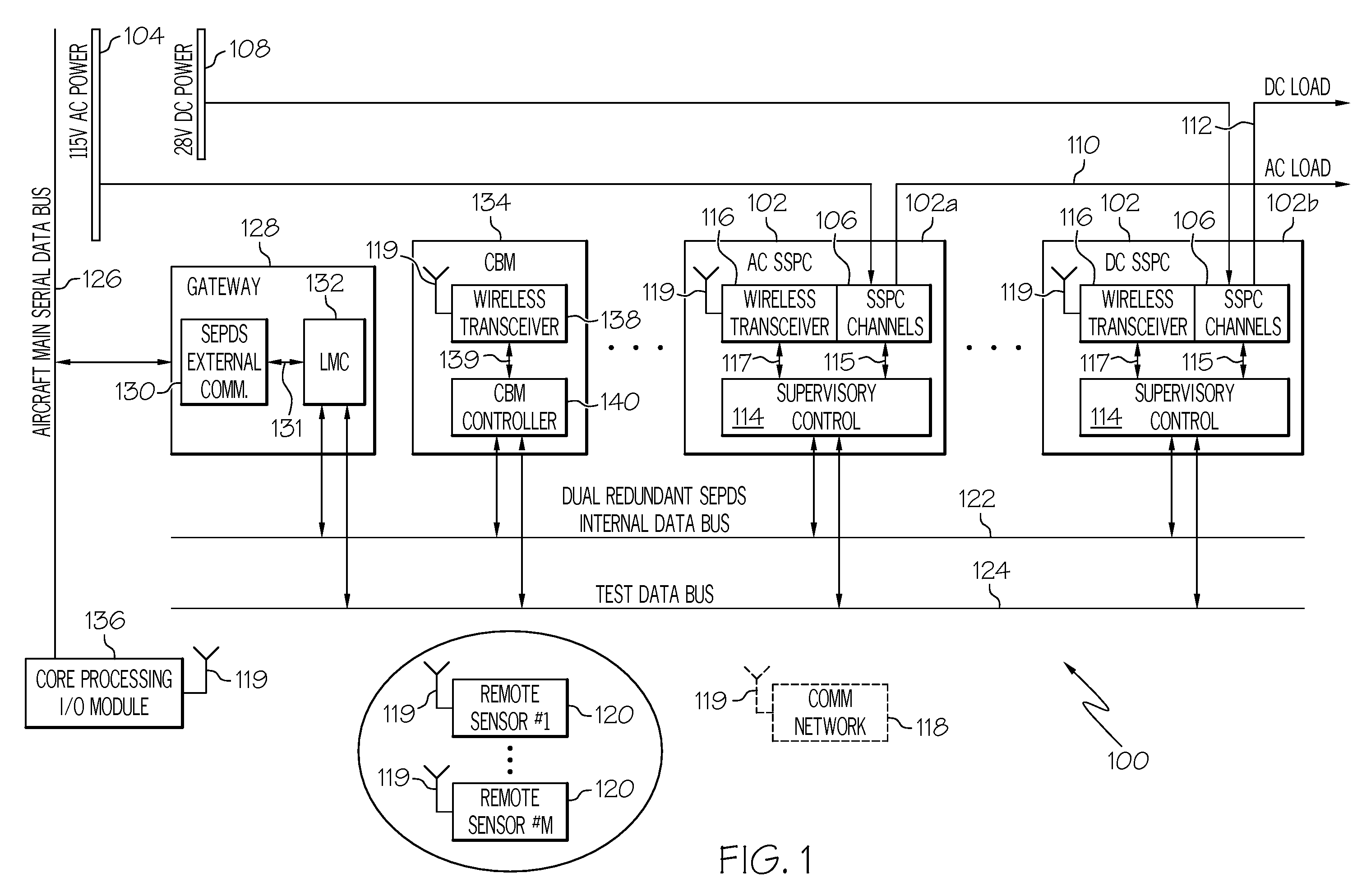

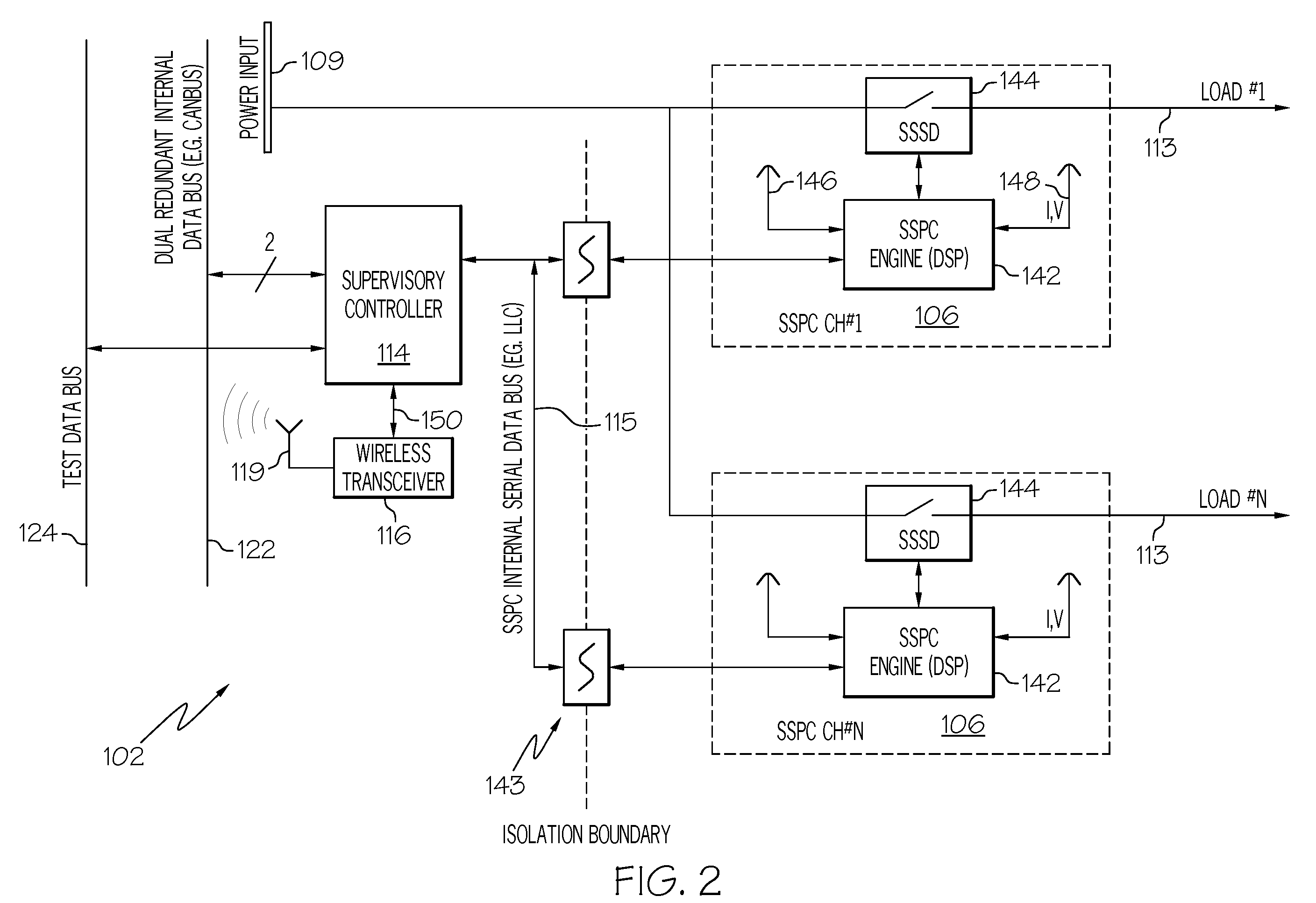

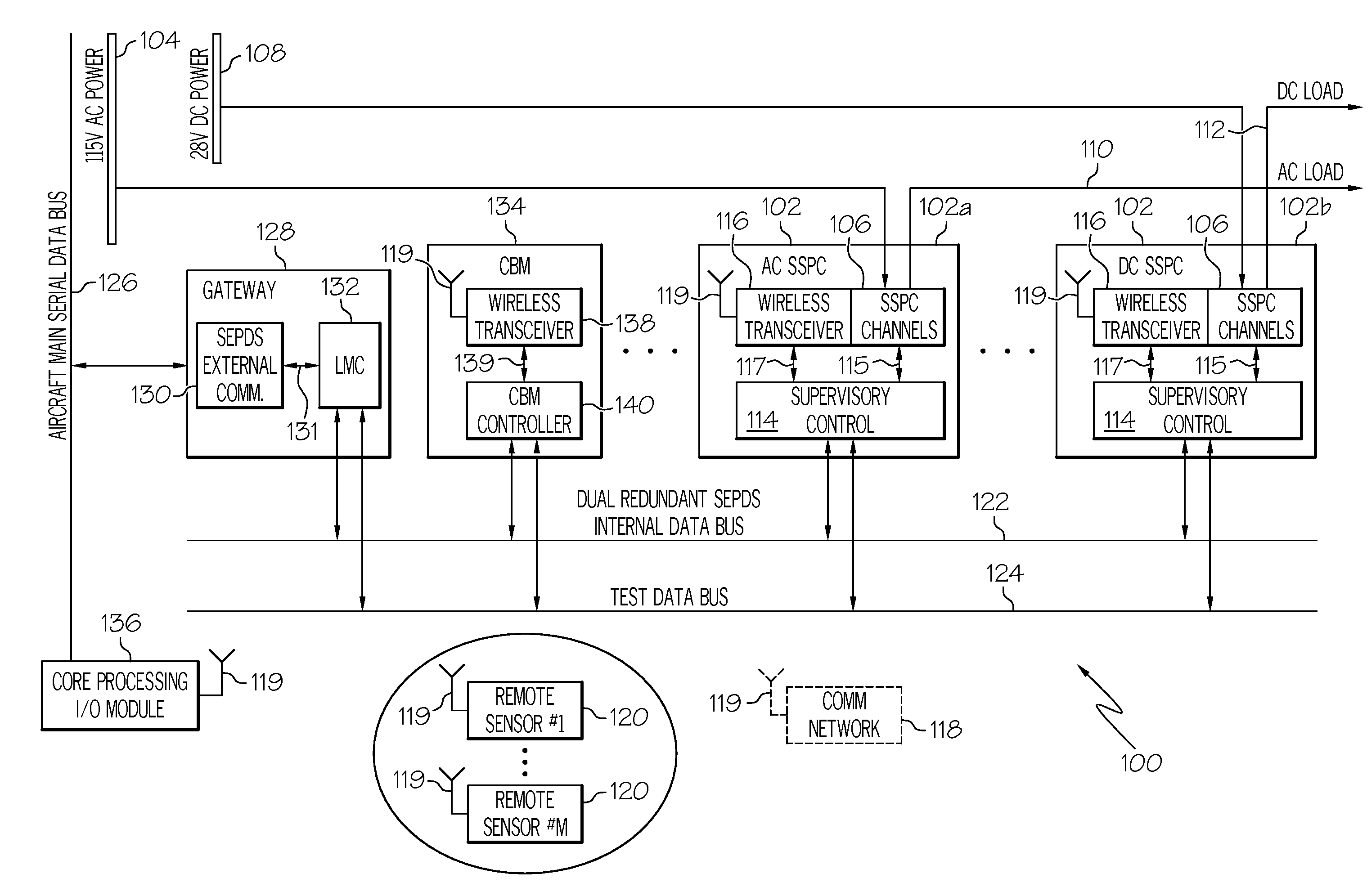

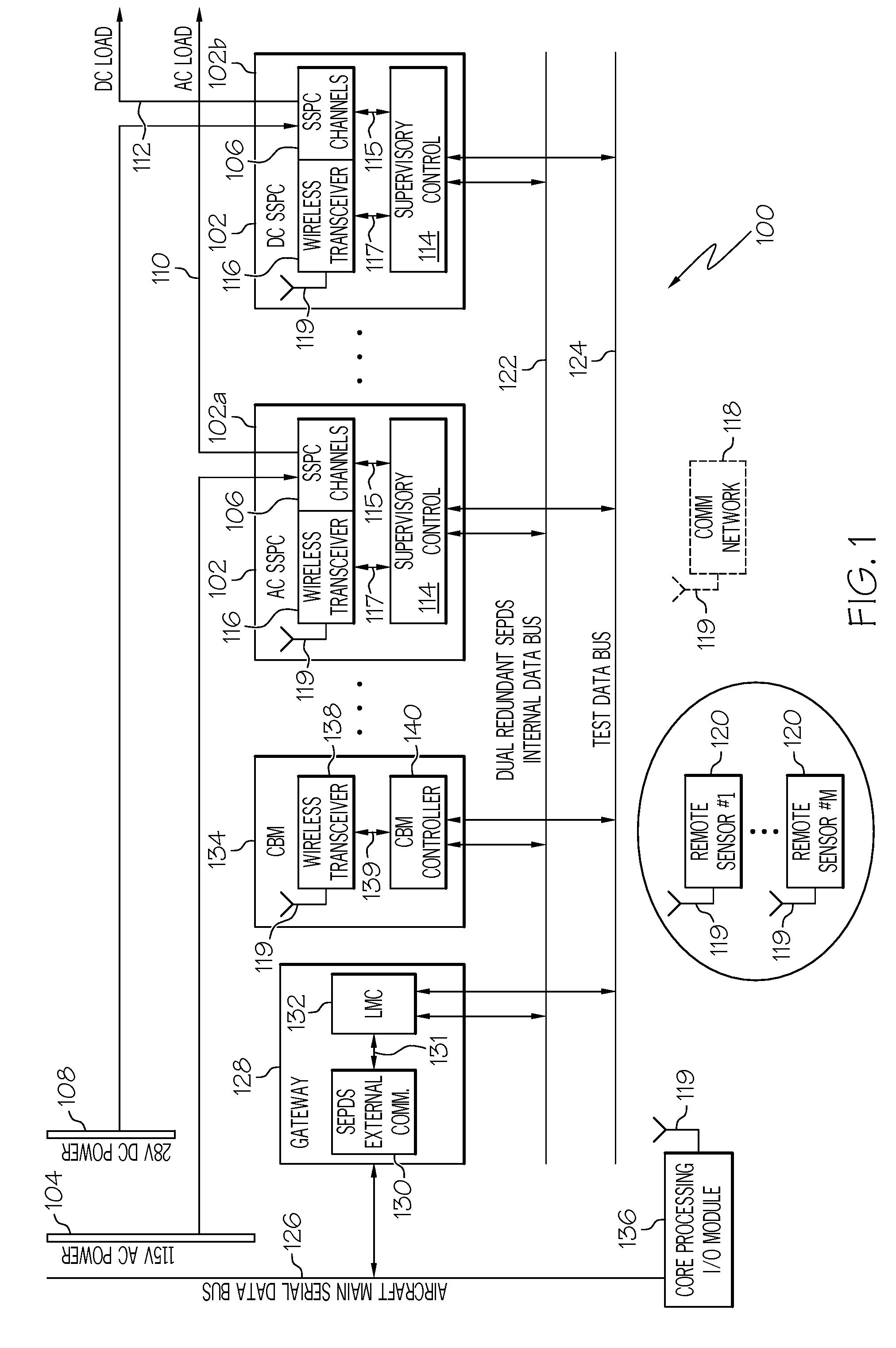

Intelligent aircraft secondary power distribution system that facilitates condition based maintenance

An electrical power distribution system comprises a solid state power controller in communication with an aircraft system main data bus via a gateway module and a condition based maintenance module in communication with the solid state power controller via a communication network distinct from the main data bus. A method of load / feeder health assessment for an electrical power distribution system includes applying a controlled excitation to a load; sampling information from the load / feeder system for the load; characterizing a normal behavior of the load / feeder system for the load; determining if the load characteristics are within the normal behavior profile for the load; and shutting down power to the load if load characteristics are not within the profile when immediate action is indicated or generating a health message for the load when immediate action is not required.

Owner:HONEYWELL INT INC

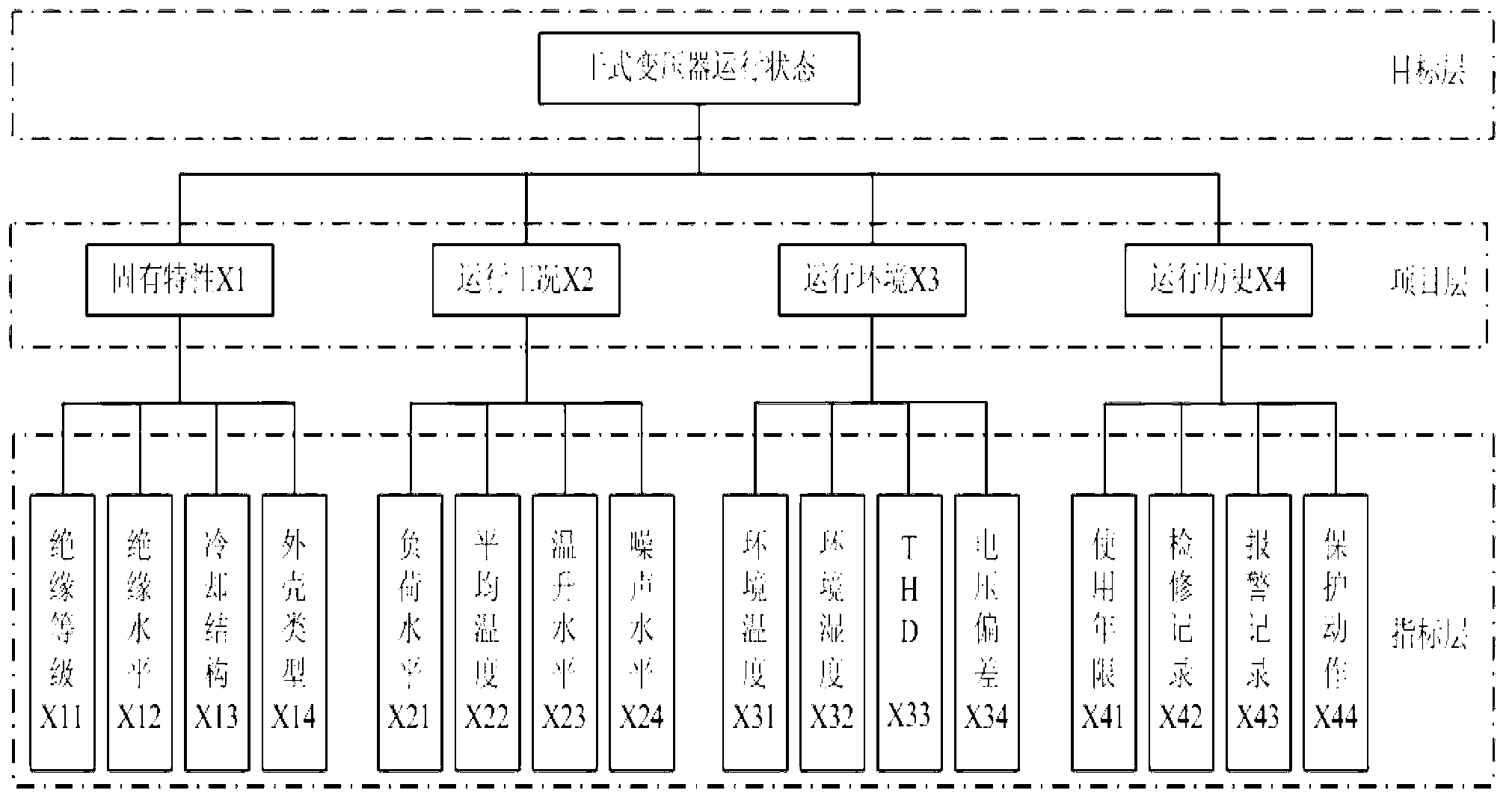

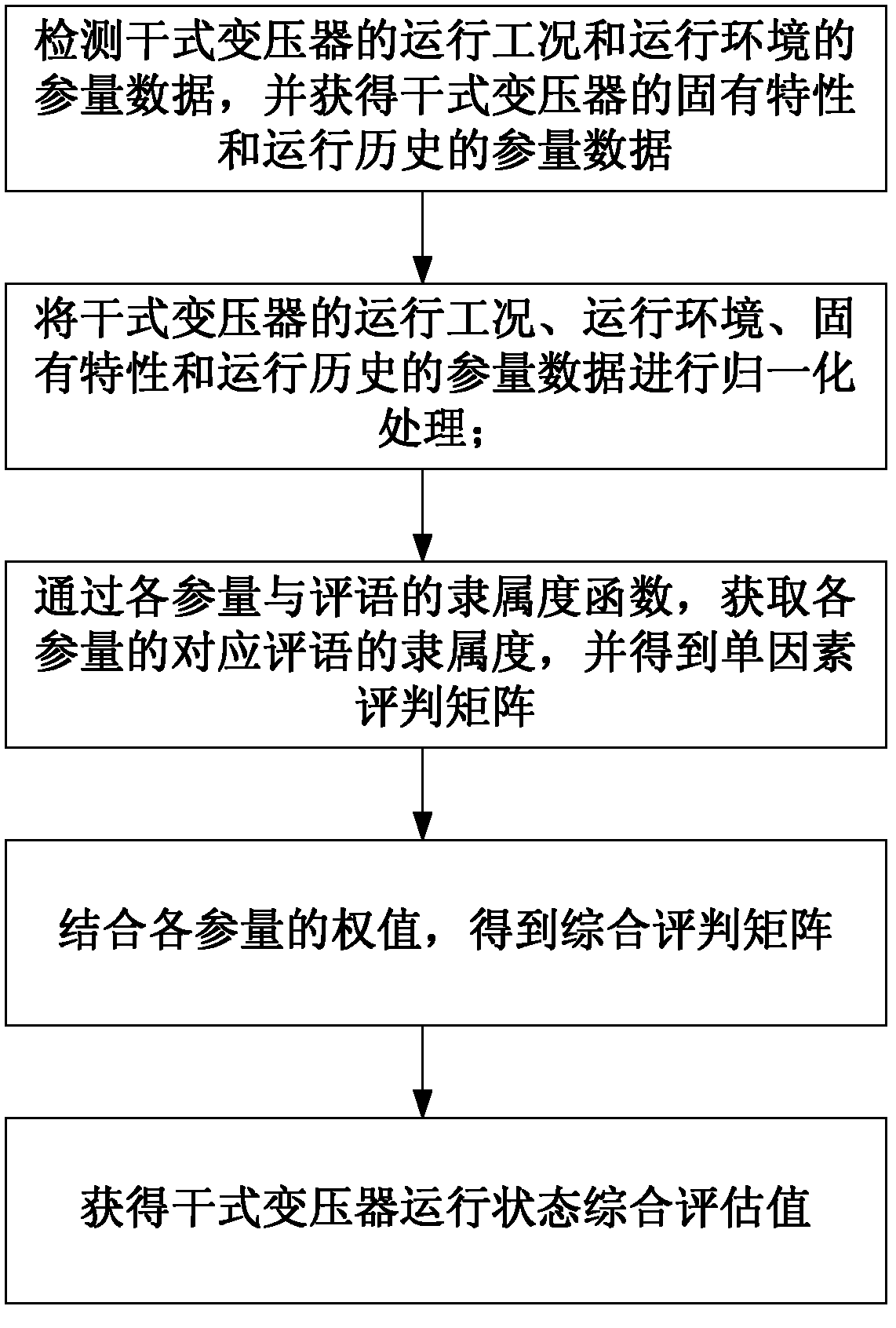

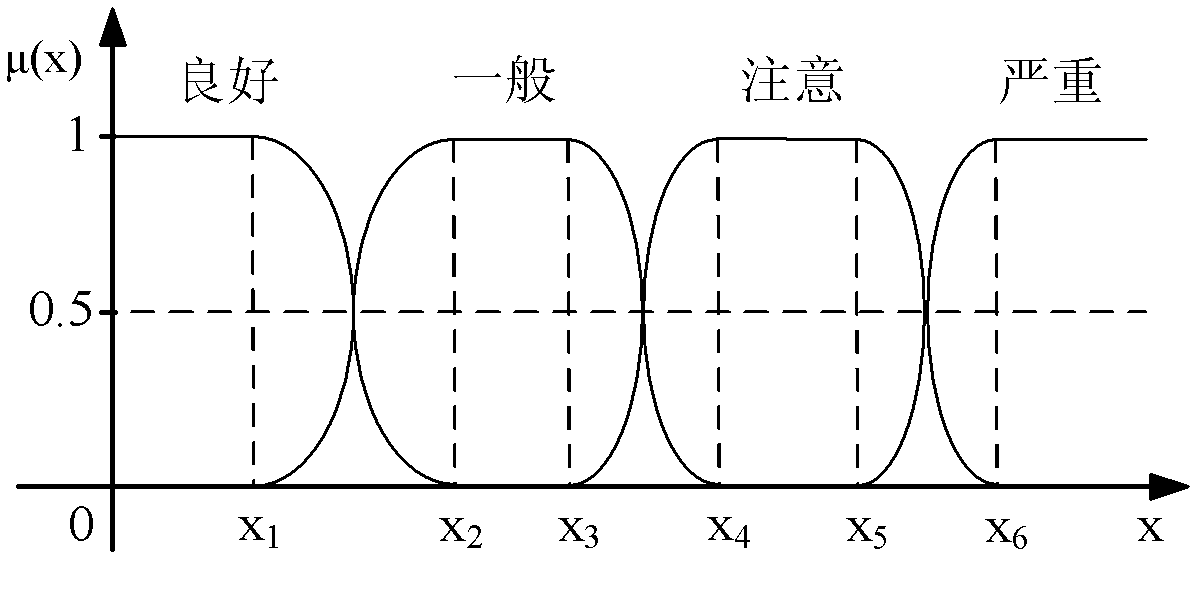

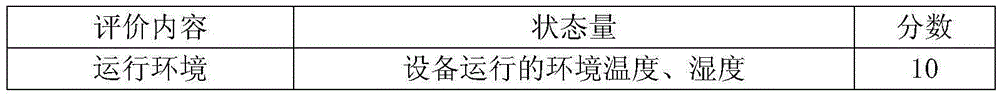

Method for evaluating operation state of dry type transformer

The invention relates to the technical field for evaluating the operation state of a transformer, in particular to a method for evaluating the operation state of a dry type transformer. Influences of parameters to the operation state of the dry type transformer are integrated, reliable level analysis is carried out on the operation state of the dry type transformer, and the convenience is brought for operators to hold the operation condition of the dry type transformer in real time and immediately make condition based maintenance. The method comprises the following steps of: 1) detecting parameter data of the operation state and an operation environment of the dry type transformer, and obtaining inherent characteristics of the dry type transformer and parameter data of the operation history; 2) normalizing parameter data of the operation states, the operation environment, the inherent characteristics and the operation history of the dry type transformer; 3) obtaining each parameter membership corresponding to a comment through a membership function of each parameter and the comment, and obtaining a single factor judge matrix; 4) obtaining a comprehensive judge matrix by combining weights of the parameters; and 5) obtaining a comprehensive evaluation value the operation state of the dry type transformer. The operation state of the dry type transformer can be reflected through the evaluation value.

Owner:CHONGQING UNIV

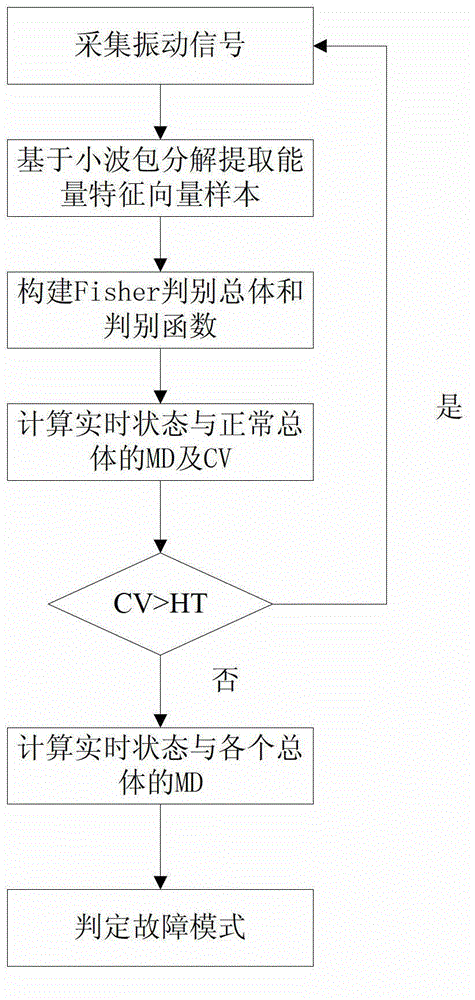

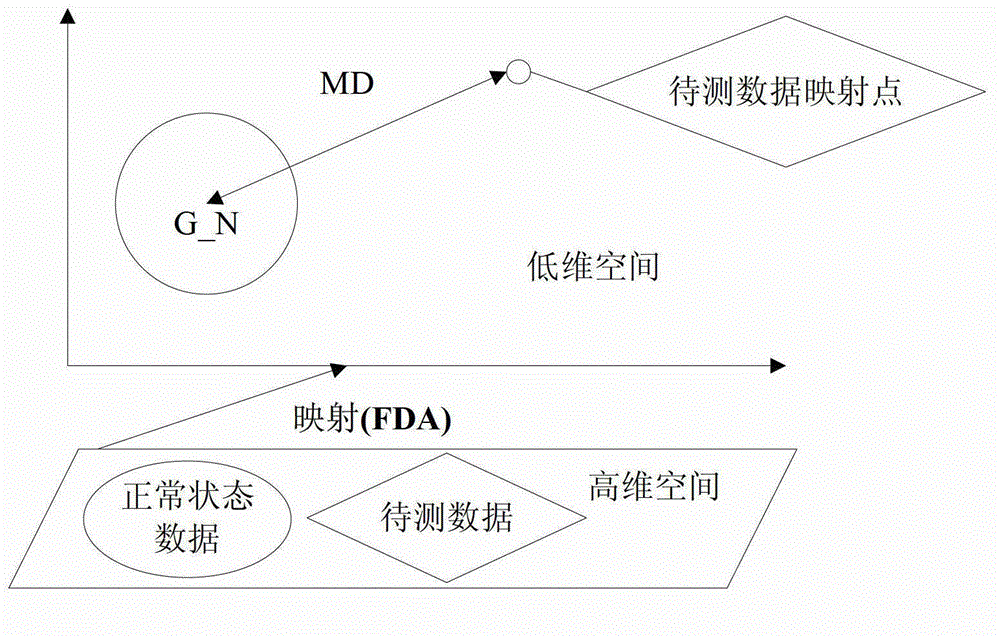

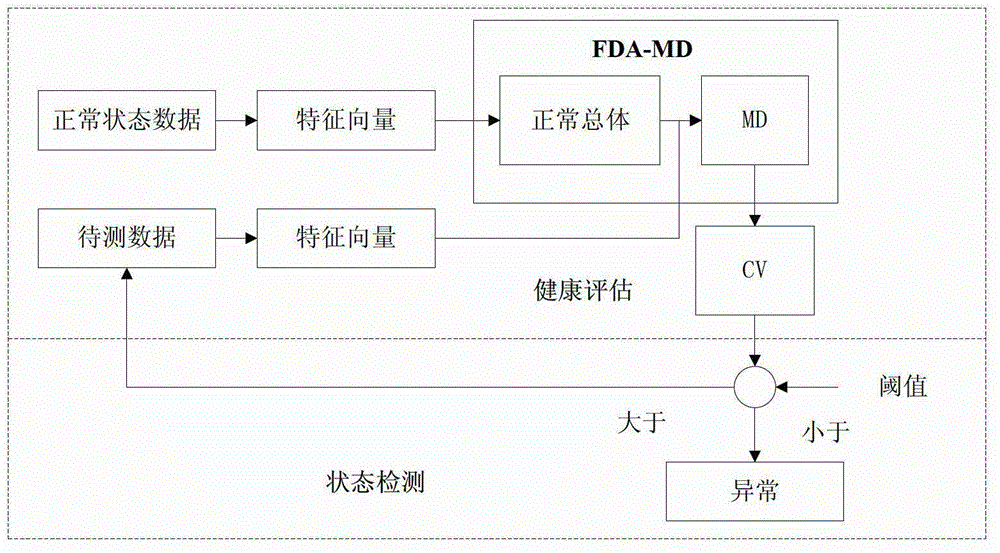

Health assessment and fault diagnosis method for rotating machinery based on fisher discriminant analysis and mahalanobis distance

ActiveCN102944435ASolve the hot issues of comprehensive health managementRealize intelligent maintenanceStructural/machines measurementSpecial data processing applicationsDiagnosis methodsMahalanobis distance

The invention discloses a health assessment and fault diagnosis method for rotating machinery based on fisher discriminant analysis and a mahalanobis distance, which belongs to the technical field of condition-based maintenance of the rotating machinery. The method comprises the steps of extracting an energy eigenvector based on wavelet packet decomposition, constructing a discriminant analysis function, conducting health status assessment, conducting fault detection on the rotating machinery, and finally conducting fault diagnosis on the rotating machinery. The method constructs a comprehensive frame integrating the status assessment, the fault detection and the fault diagnosis, solves the hotspot problem in comprehensive health management of the rotating machinery at present, achieves intelligent maintenance of the rotating machinery, can establish an assessment and diagnosis model without full life status monitoring data of the rotating machinery, reduces the dependence on historical data, and is very high in engineering applicability.

Owner:北京恒兴易康科技有限公司

Intelligent aircraft secondary power distribution system that facilitates condition based maintenance

An electrical power distribution system comprises a solid state power controller in communication with an aircraft system main data bus via a gateway module and a condition based maintenance module in communication with the solid state power controller via a communication network distinct from the main data bus. A method of load / feeder health assessment for an electrical power distribution system includes applying a controlled excitation to a load; sampling information from the load / feeder system for the load; characterizing a normal behavior of the load / feeder system for the load; determining if the load characteristics are within the normal behavior profile for the load; and shutting down power to the load if load characteristics are not within the profile when immediate action is indicated or generating a health message for the load when immediate action is not required.

Owner:HONEYWELL INT INC

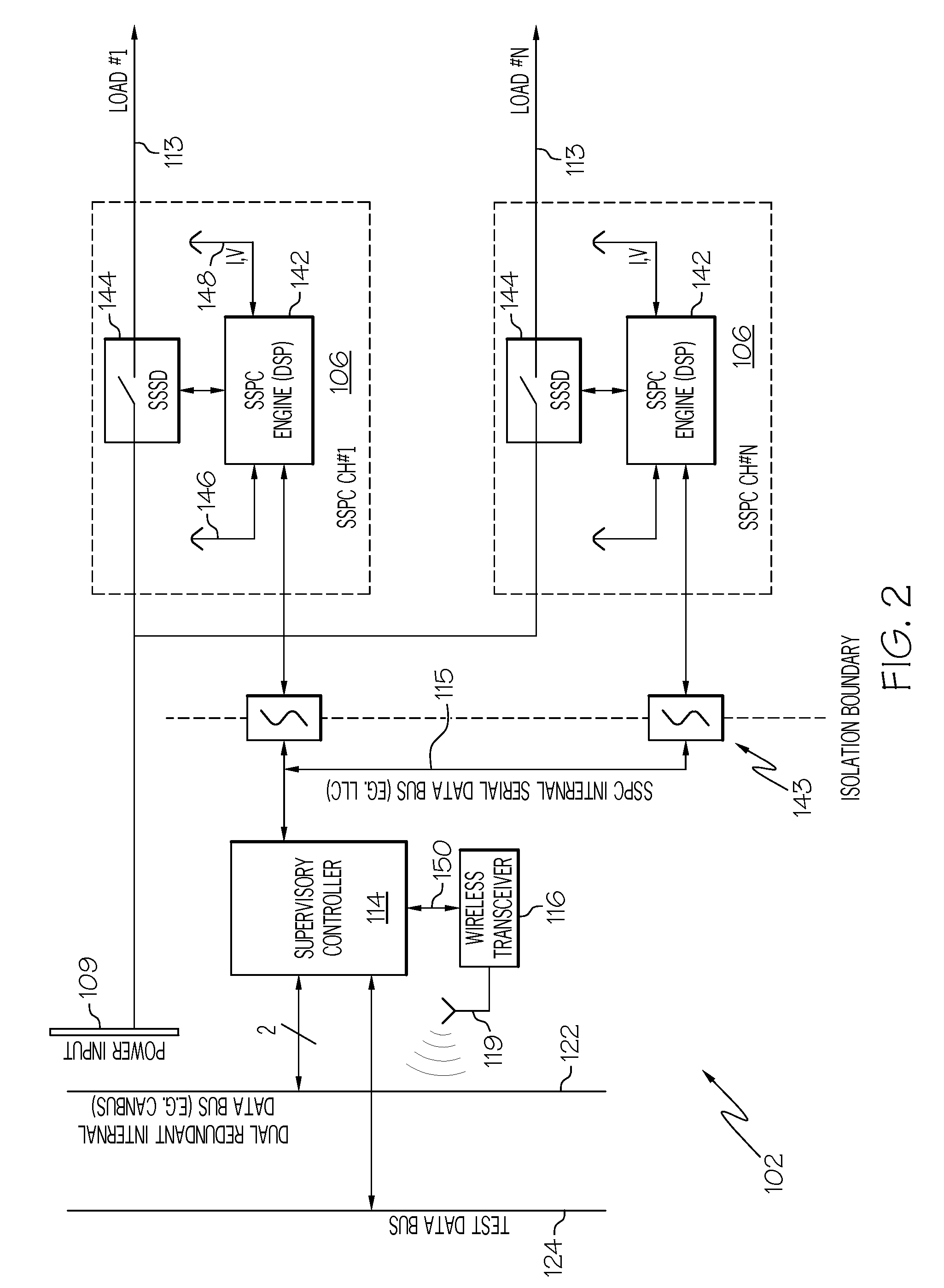

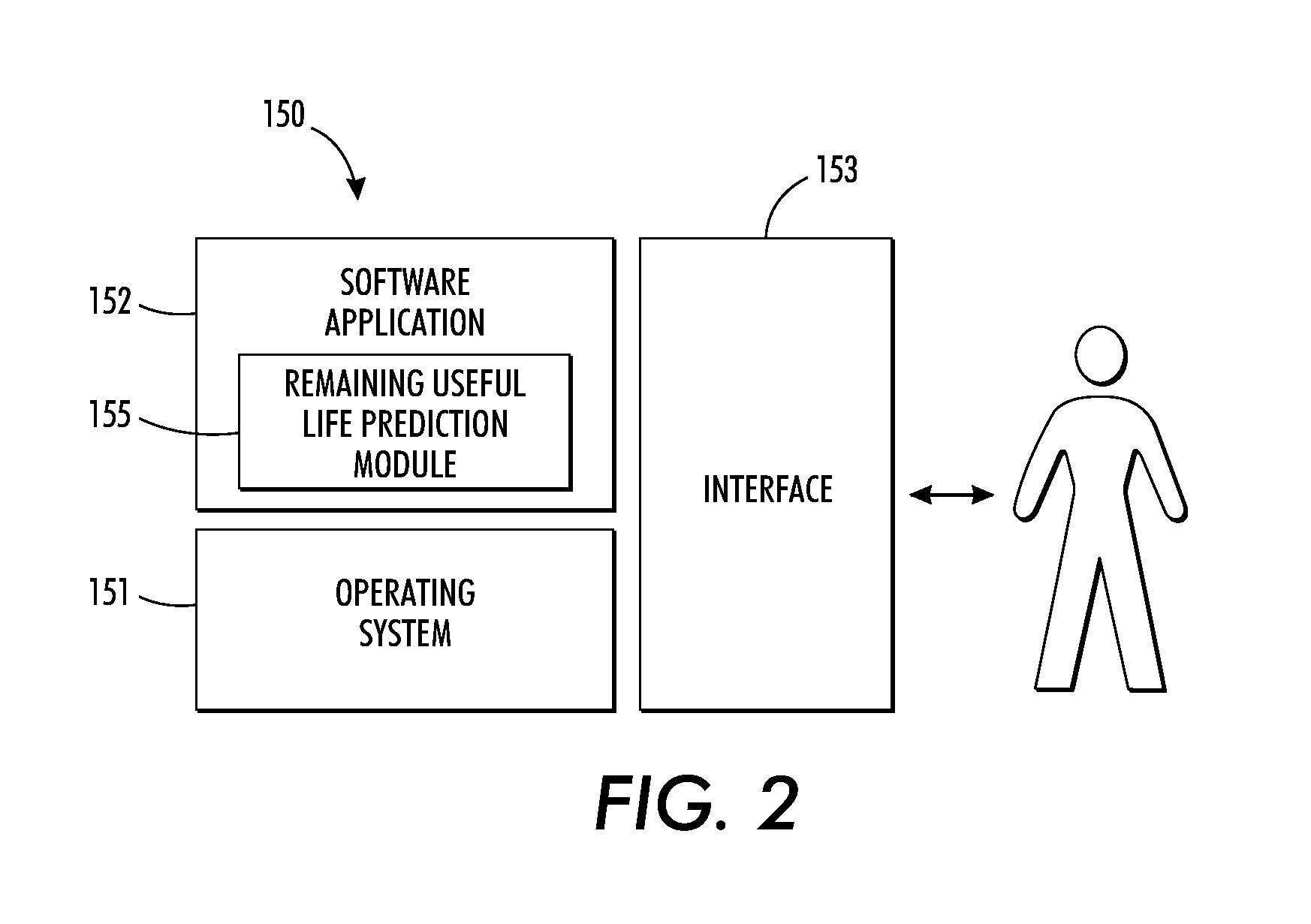

System and method for predicting remaining useful life of device components

InactiveUS20120143564A1Lower service costsAccurate predictionTesting/monitoring control systemsDigital computer detailsAnalysis dataStatistical analysis

A method and system for accurately predicting the remaining useful life of devices and device components based on rigorous statistical analysis data to reduce service costs by implementing condition-based maintenance is disclosed. One such rigorous statistical model is the general degradation path model. The General Path Model is used to generate simulated data that shares similar data characteristics of historical field failure data. This generated data can be used in a reliability study based on Monte Carlo techniques for RUL prediction. The study can be used to investigate the effects of influential factors such as suspension percentage and heavy-tailed behavior. The remaining useful life prediction is based on both the fixed-time predictors (such as the market segment) and the time-dependent covariates (e.g., dark decay, printing rate, etc.). The Random Forest Model can also be used for accurately predicting remaining useful life based on both fixed-time predictors and time-dependent covariates, which are both contained in the field data of a component. A relationship between component failure and amount of degradation makes it possible to use degradation models for accurate predictions of failure time.

Owner:XEROX CORP

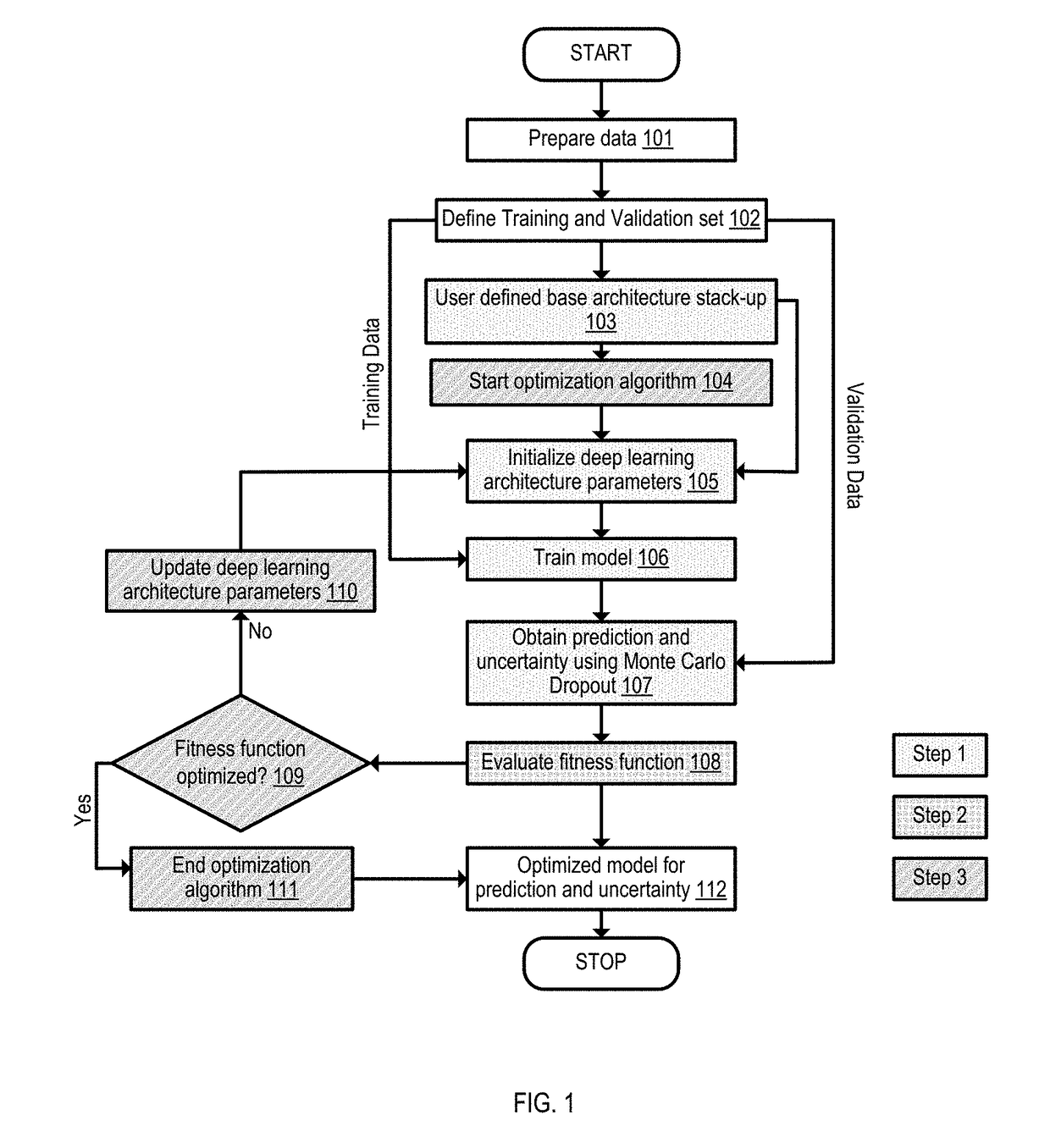

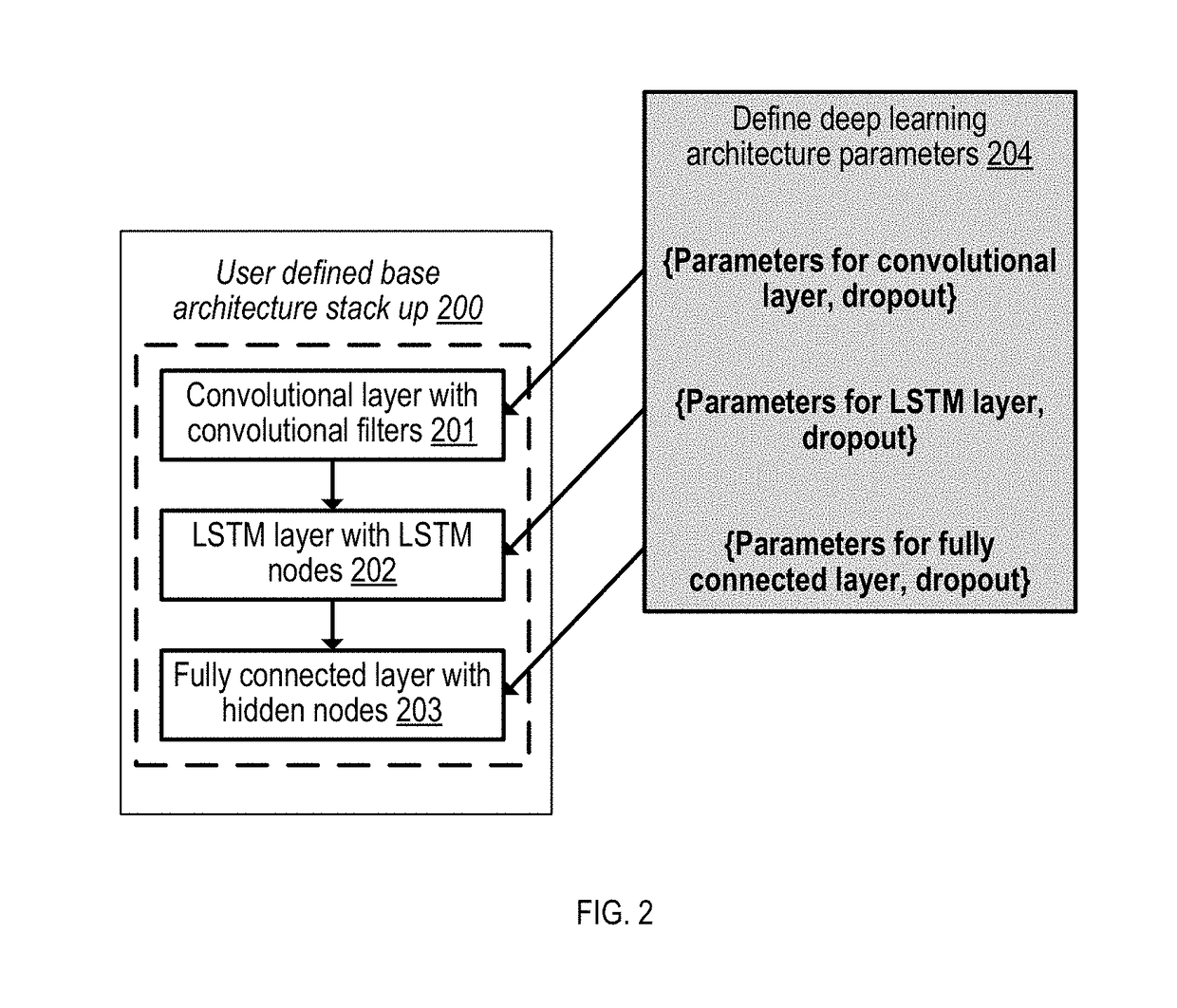

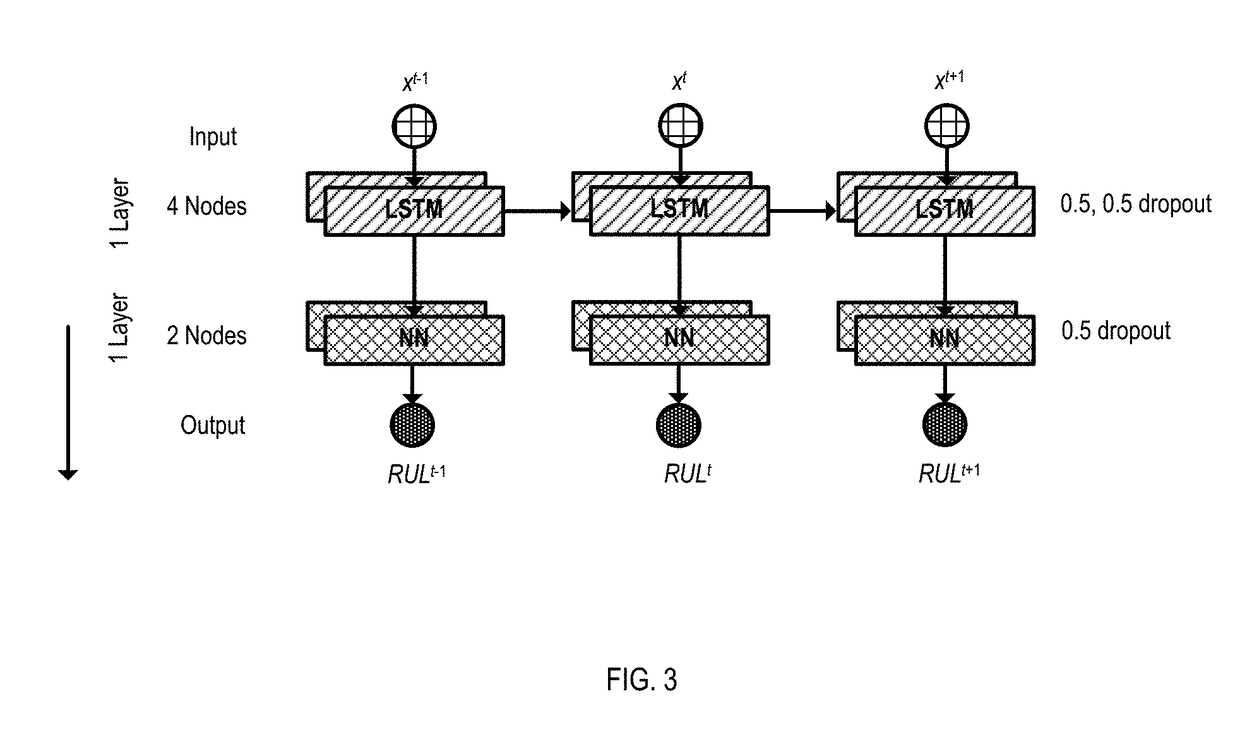

Deep learning network architecture optimization for uncertainty estimation in regression

InactiveUS20180341876A1Function increaseTesting/monitoring control systemsMachine learningMaintenance planningNetwork architecture

Equipment uptime is getting increasingly important across different industries which seek for new ways of increasing equipment availability. Detecting faults in the system by condition based maintenance (CBM) is not enough, because at the time of fault occurrence, the spare parts might not available or the needed resources (maintainers) are busy. Therefore, prediction failures and estimation of remaining useful life can be necessary. Moreover, not only predictions but also uncertainty in the predictions is critical for decision making. Example implementations described herein are directed to tuning parameters of deep learning network architecture by developing a mechanism to optimize for accuracy and uncertainty simultaneously, thereby achieving better asset availability, maintenance planning and decision making.

Owner:HITACHI LTD

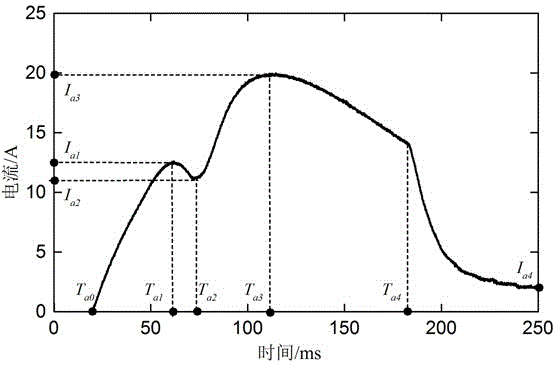

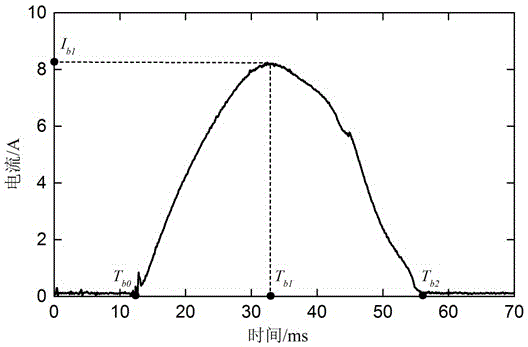

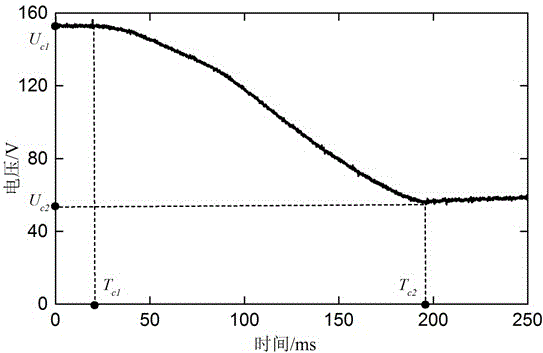

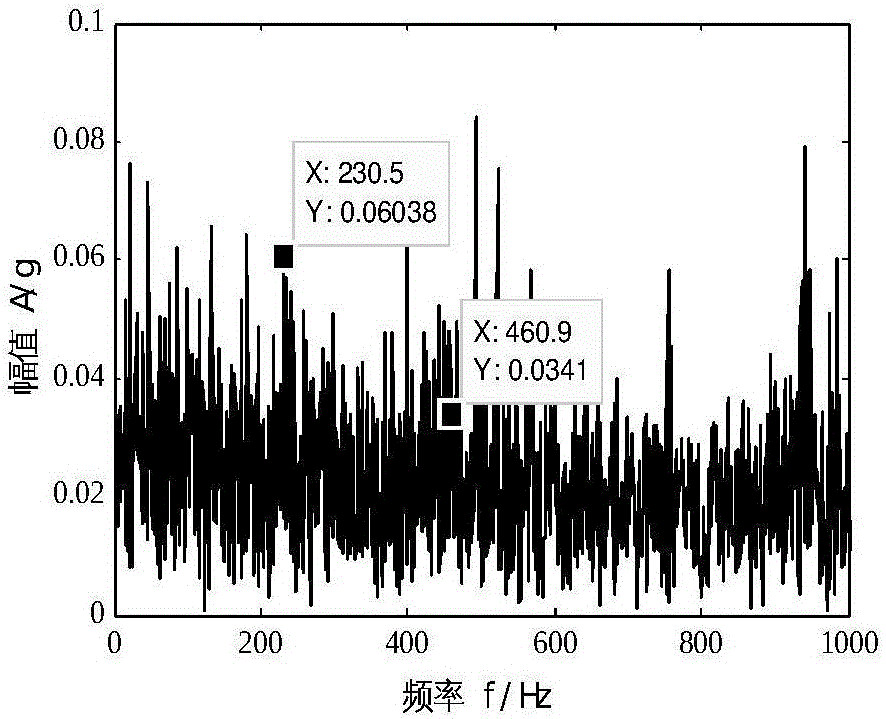

Permanent magnetic mechanism high voltage vacuum circuit breaker fault mode identification method

ActiveCN106199412AIncomplete solutionSolve the contradiction of information redundancy in multi-parameter monitoringCircuit interrupters testingClassification methodsHigh pressure

A permanent magnetic mechanism high voltage vacuum circuit breaker fault mode identification method comprises a fault condition information classification method, a condition information feature extraction method and a fault classification identification method. The fault information classification method is to classify permanent magnetic mechanism high voltage vacuum circuit breaker fault information into loop condition information, mechanical condition information and a vacuum extinction chamber condition information. The condition information feature extraction method is to carry out extraction in the time domain and the frequency domain for different kinds of condition information. The fault classification identification method is based on a method of support vector machine increment learning, draws on a fault sample training classification model, and continuously accumulates new samples to improve the classification identification accuracy. The invention solves problems that fault monitoring information acquisition is not comprehensive and the fault identification accuracy is low, effectively identifies common faults of a permanent magnetic mechanism high voltage vacuum circuit breaker, and has a guiding effect for breaker condition based maintenance and fault diagnosis.

Owner:TAIYUAN UNIV OF TECH

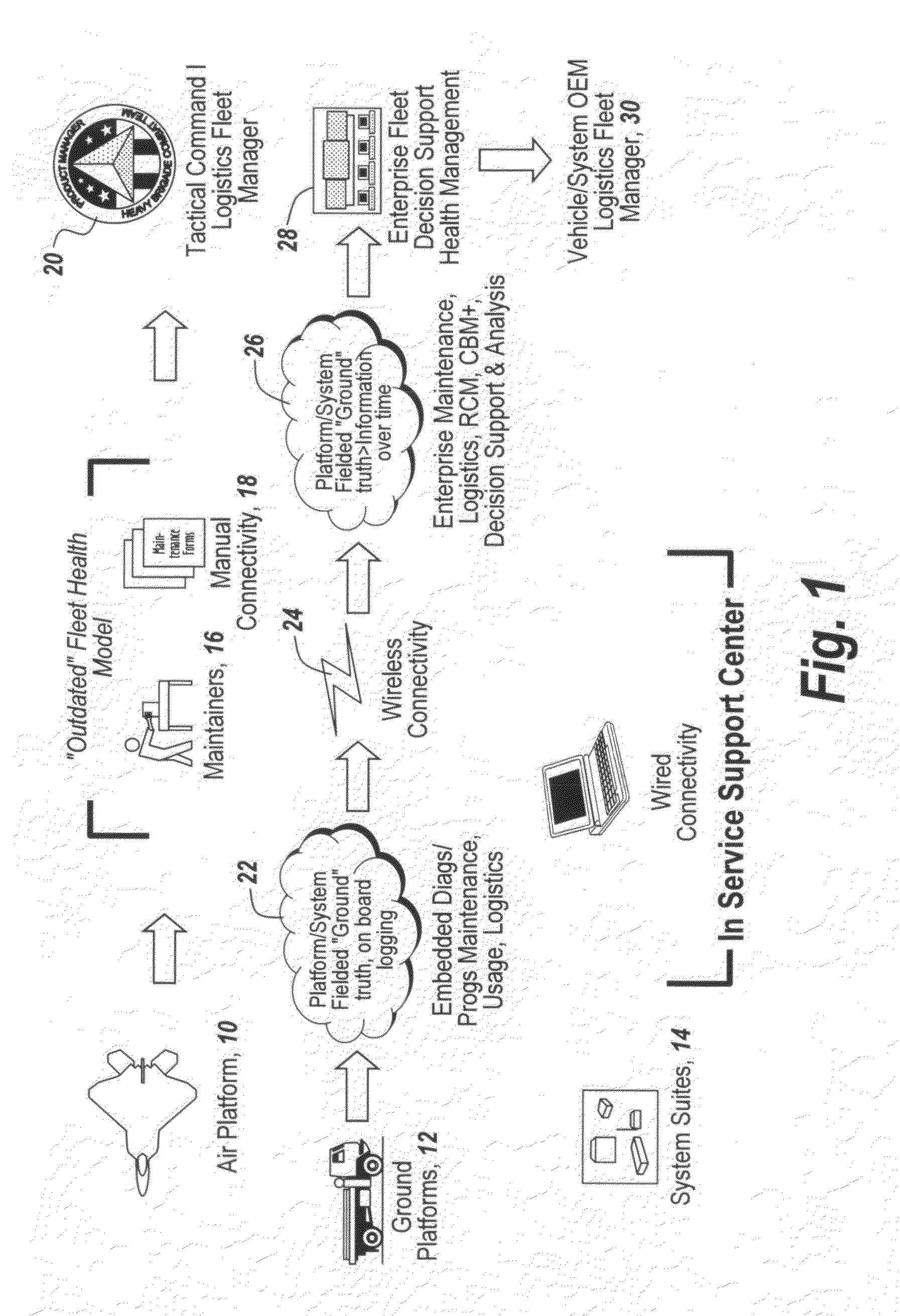

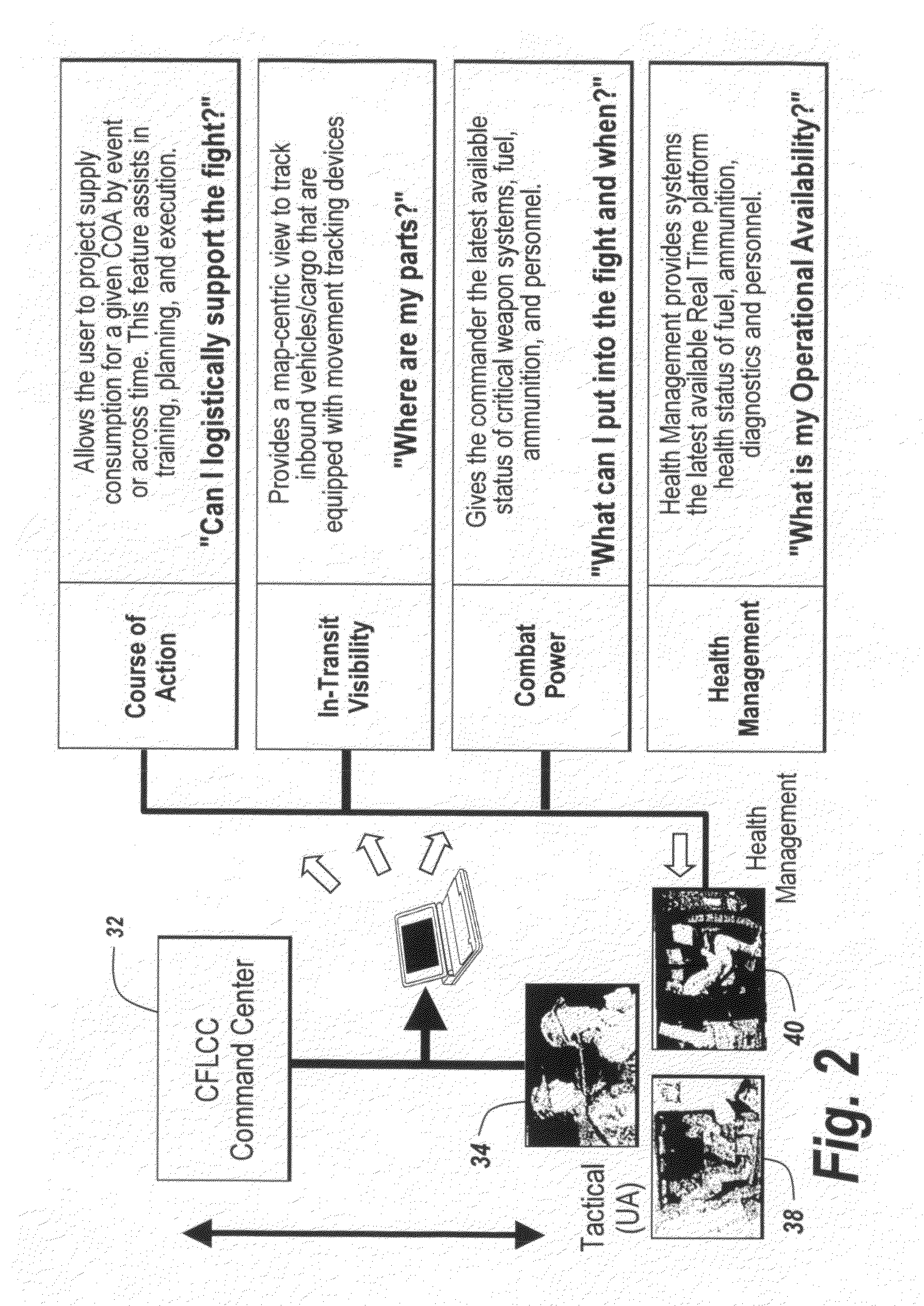

In service support center and method of operation

InactiveUS20100217638A1Increase awarenessLower life cycle costsVehicle testingRegistering/indicating working of vehiclesFleet managementMaintenance management

In a method for in service support for a vehicle fleet wherein the improvement comprises providing Reliability Centered Maintenance (RCM), Conditioned Based Maintenance (CBM), Fleet Management (FM), Vehicle / Component Asset Tracking, Stores / Consumable Inventory, and maintenance management.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

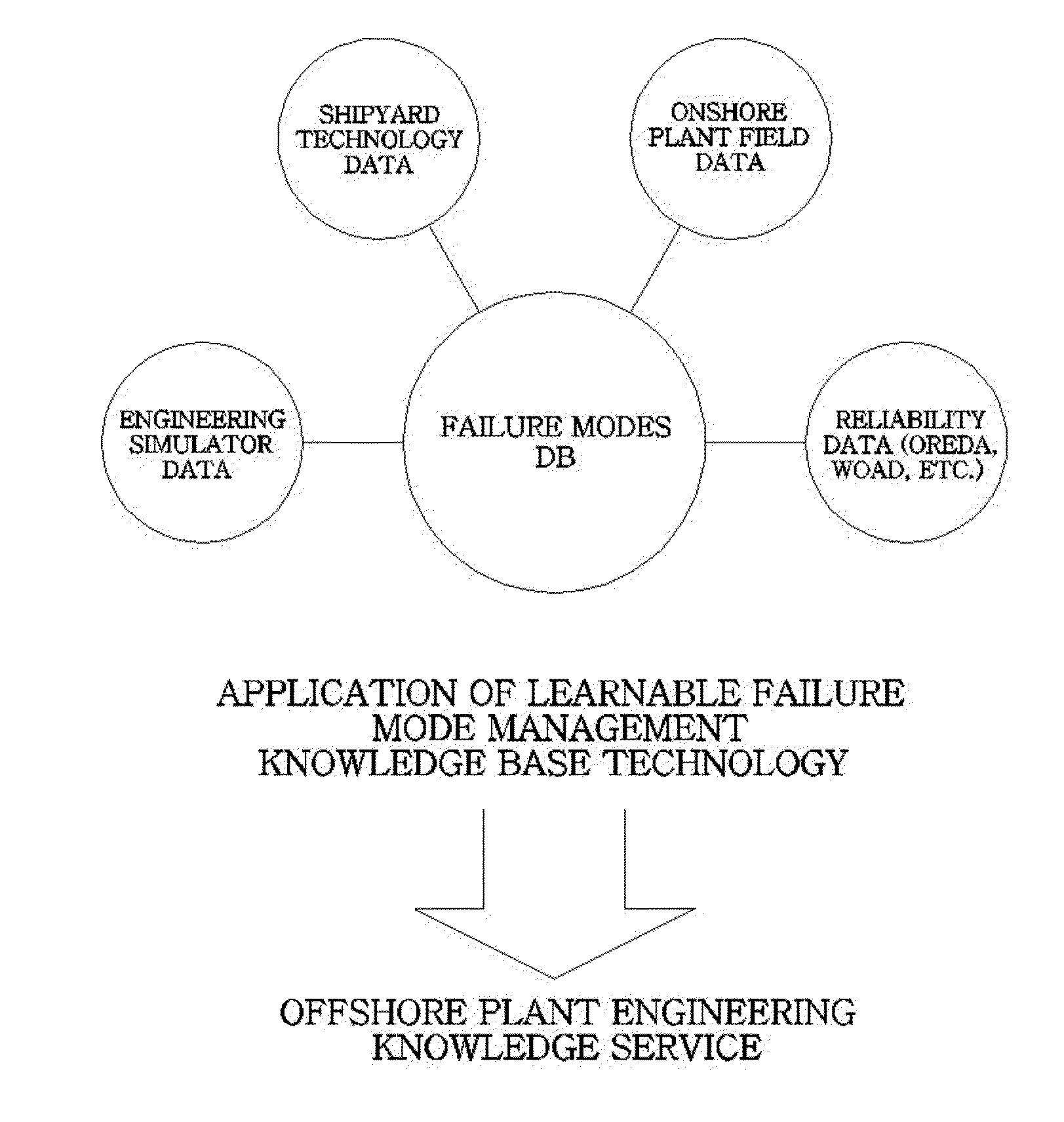

Method and apparatus for managing failure modes for condition based maintenance in marine resource production equipment

ActiveUS20160239743A1Improve reliabilityArtificial islandsWaterborne vesselsData acquisitionVirtualization

Provided is a method and apparatus for managing failure modes for condition based maintenance in marine resource production equipment. The apparatus includes a distributed control system (DCS), monitoring, and performance evaluation module that constructs a distributed control system for the systematic collection and management of maintenance data, develops a real-time data management and monitoring system, and develops an offshore plant performance monitoring level performance evaluation system, a condition based maintenance platform that maps data from a real-time sensor database of the distributed control system (DCS), monitoring, and performance evaluation module, stores the mapped data, and manages learnable failure modes based on normal mode and failure mode data, a diagnosis, prediction, maintenance, and shape management module that develops technology for automatically improving the reliability of condition based maintenance based on the learnable failure mode management according to data transmitted from the distributed control system (DCS), monitoring, and performance evaluation module to the condition based maintenance platform, develops an offshore plant diagnosis, prediction, and maintenance system, and develops a diagnosis and condition based maintenance operating platform and a shape management system, and a virtual offshore plant simulator that constructs a virtual offshore plant simulator, constructs a scenario based operation training system, and develops a condition based maintenance solution and an input and output virtualization system for interoperation with a supervisory control and data acquisition (SCADA) system for an offshore plant.

Owner:PARTDB

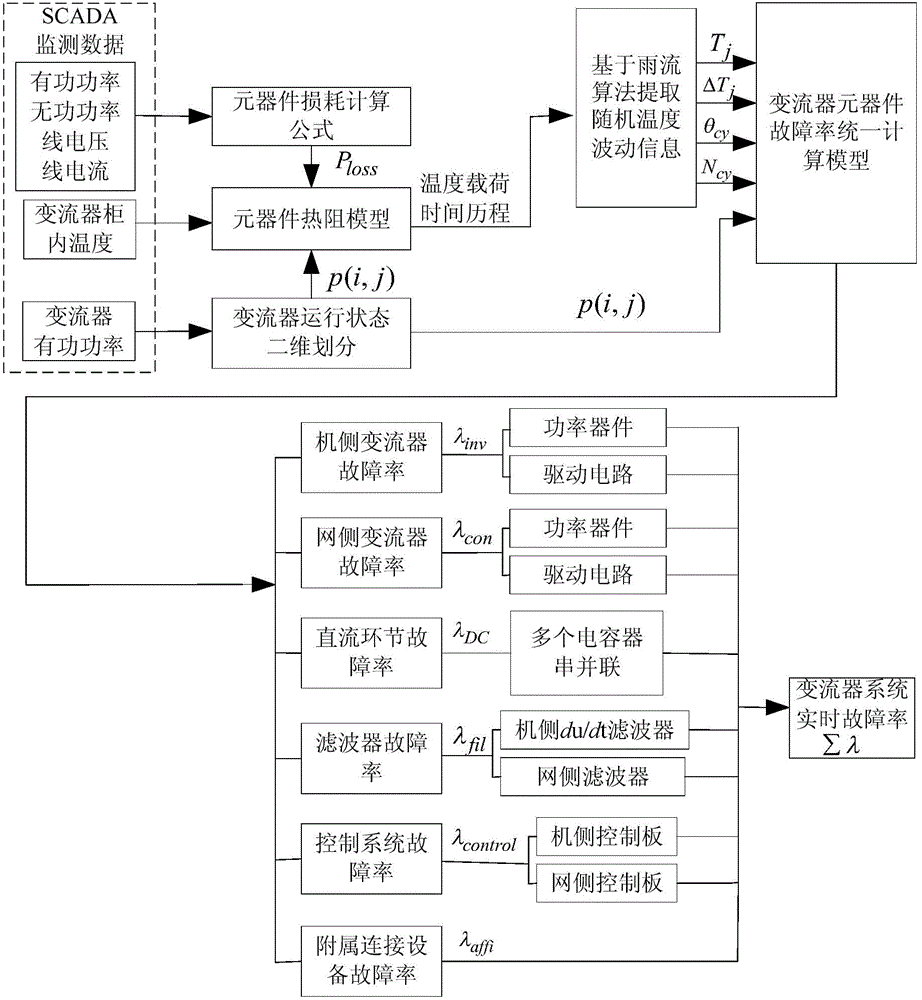

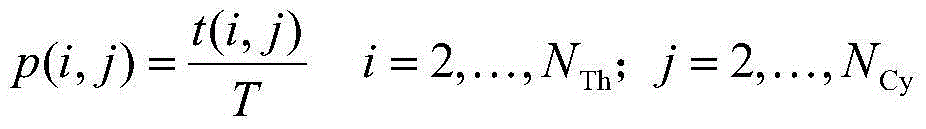

Real-time reliability evaluation method for converter for wind power generation

The invention discloses a real-time reliability evaluation method for a converter for wind power generation, and belongs to the technical field of wind power converter reliability assessment. The method is based on wind generating set state monitoring data, random temperature fluctuation information of components is extracted through a rain flow algorithm, and then the real-time failure rate of a wind power converter is calculated. According to the real-time reliability evaluation method, consideration can be given to the influence on the real-time reliability of the wind power converter by the magnitude of operating power and the power fluctuation intensity of a wind generating set at the same time, a scientific basis is provided for condition based maintenance of the wind power converter, besides, technical support is provided for selection of the appropriate converter according to different wind farm wind conditions, and the efficient, reliable and safe operation of the wind generating set can be ensured.

Owner:CHONGQING UNIV

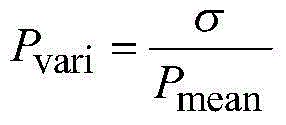

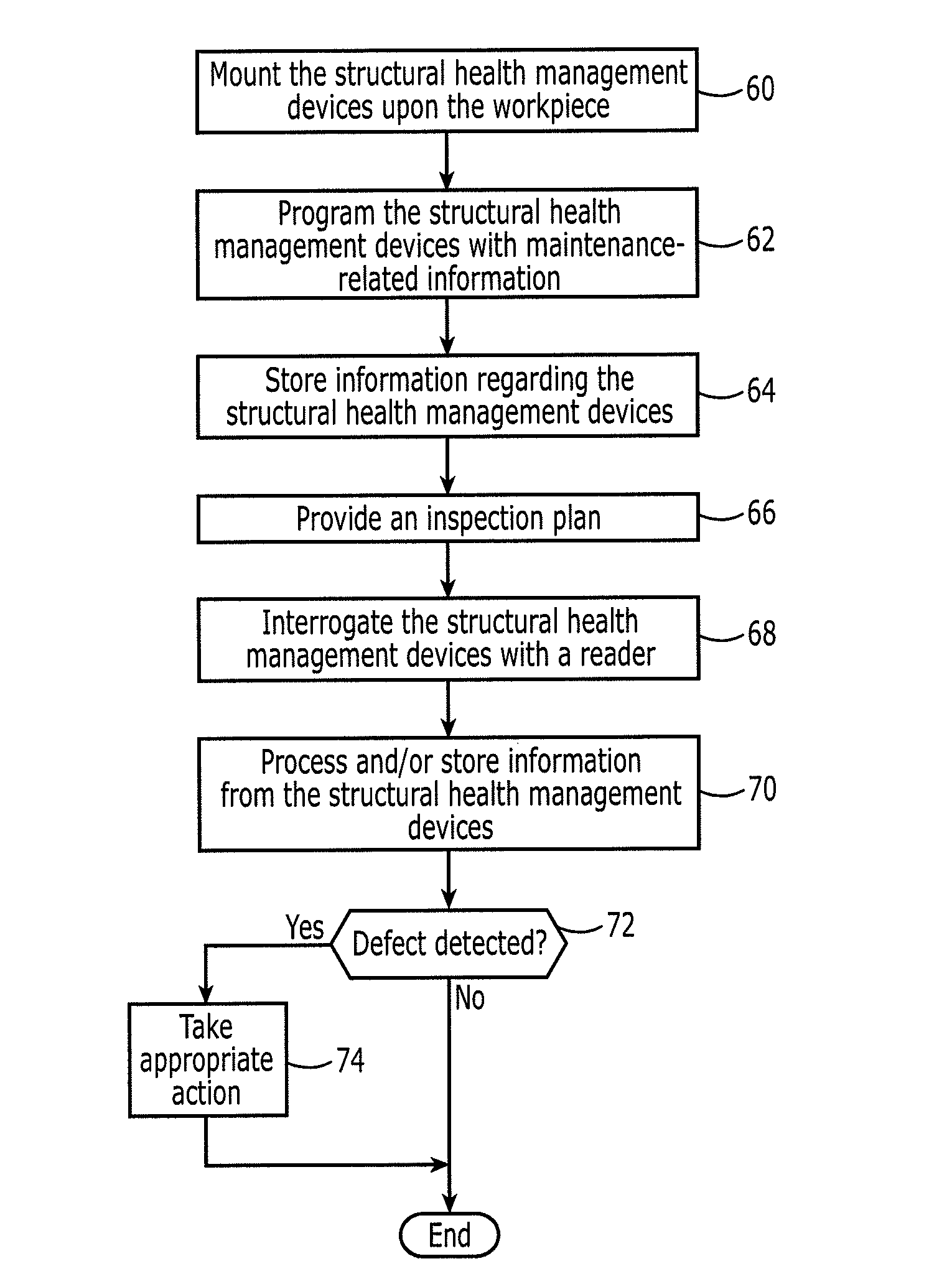

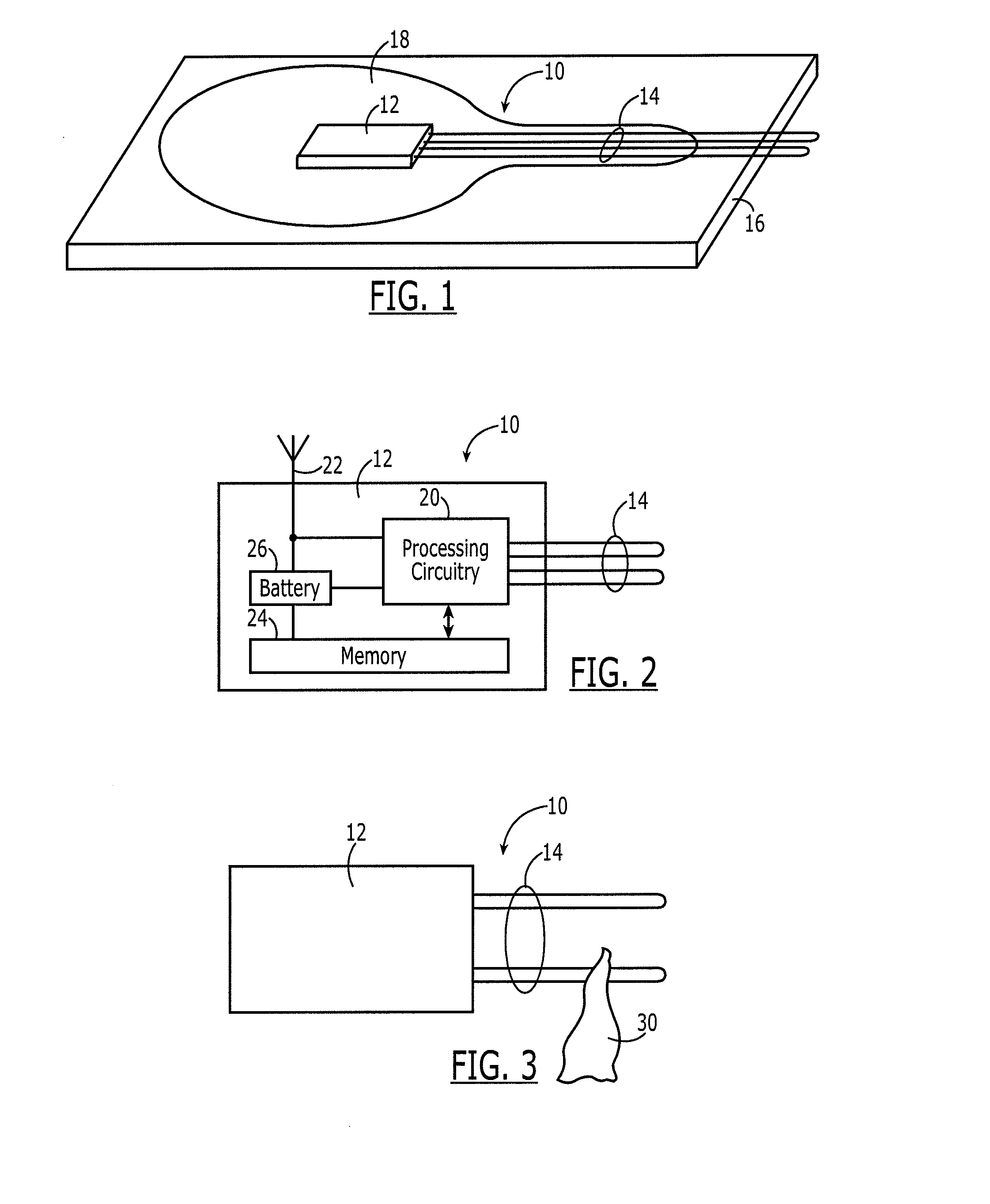

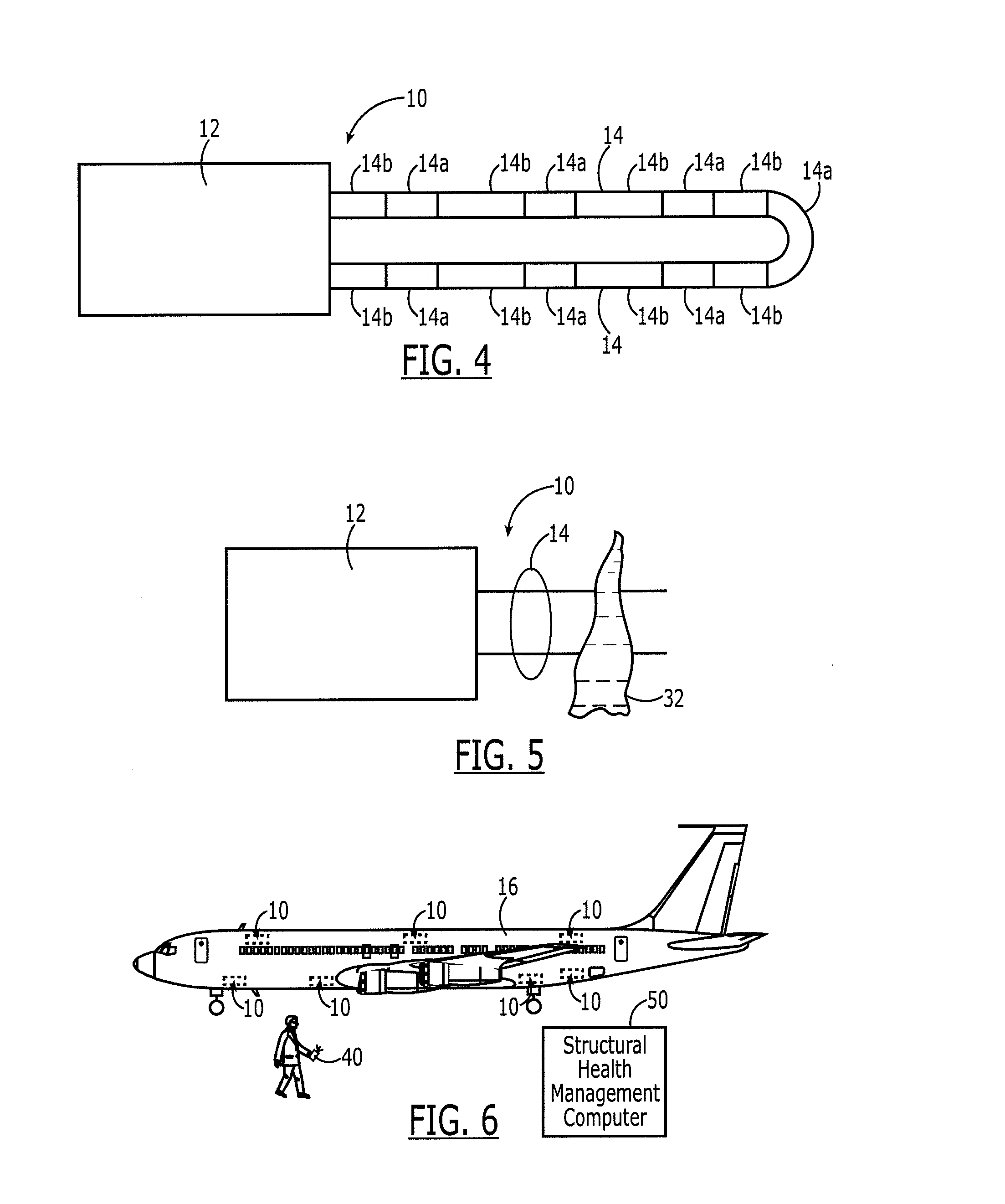

Structural health management device and associated system and method

ActiveUS20110291802A1Shorten the timeEfficient and cost-effectiveResistance/reactance/impedenceSubscribers indirect connectionEngineeringCondition-based maintenance

A structural health management device, system and method are provided for facilitating the inspection of a structure, such as in accordance with a condition-based maintenance strategy. A structural health management device may include a radio frequency identification (RFID) tag and at least one sense line communicably coupled to the RFID tag and configured to extend at least partially along a workpiece. The sense line may be formed of different materials depending upon the objective of the inspection. The RFID tag may include processing circuitry and an antenna configured to facilitate offboard communication. The processing circuitry may be configured to interrogate the at least one sense line to determine a change in continuity which is indicative of a change in the structural health of the workpiece. The structural health management device may therefore detect the onset of structural issues in a timely manner.

Owner:THE BOEING CO

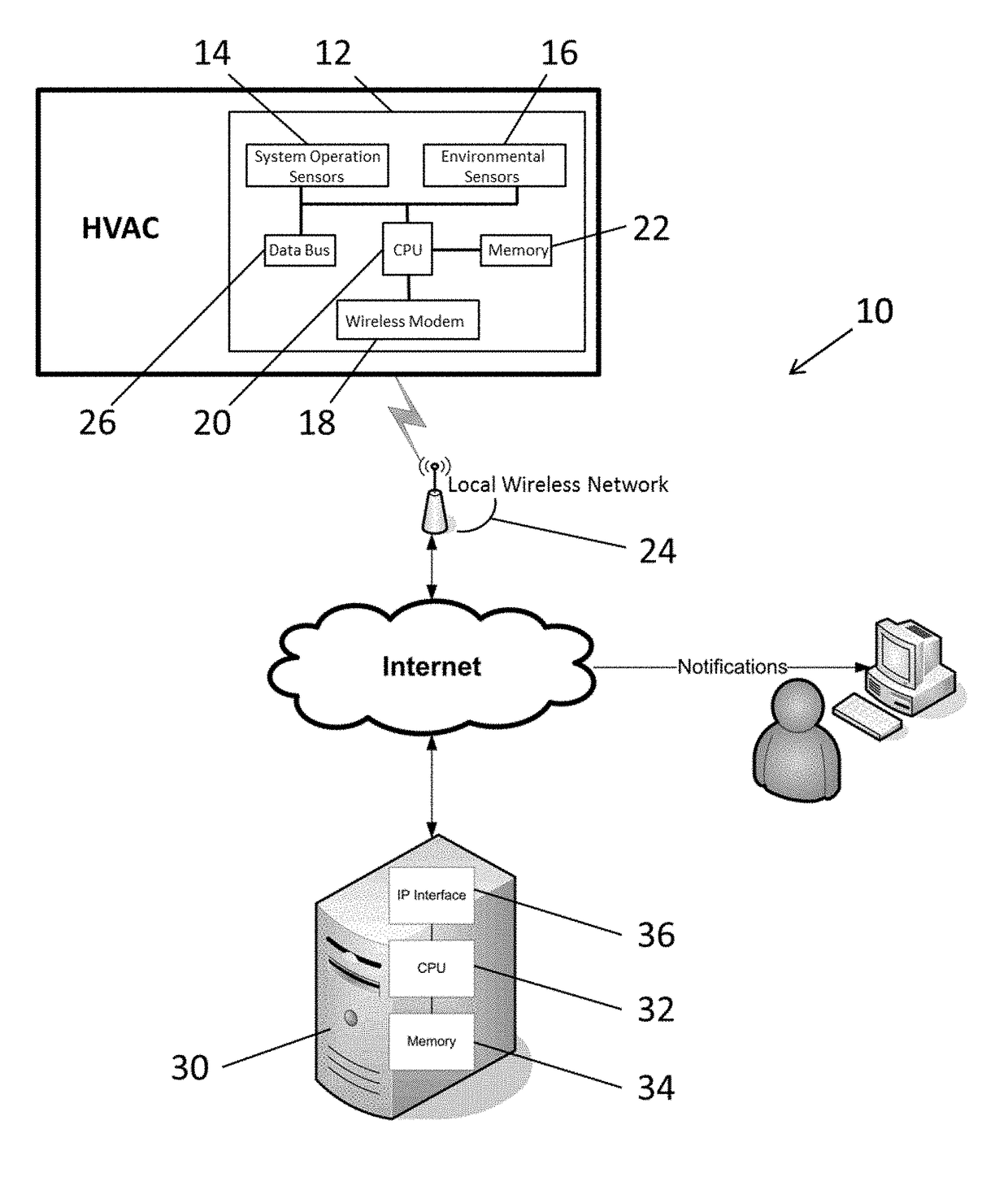

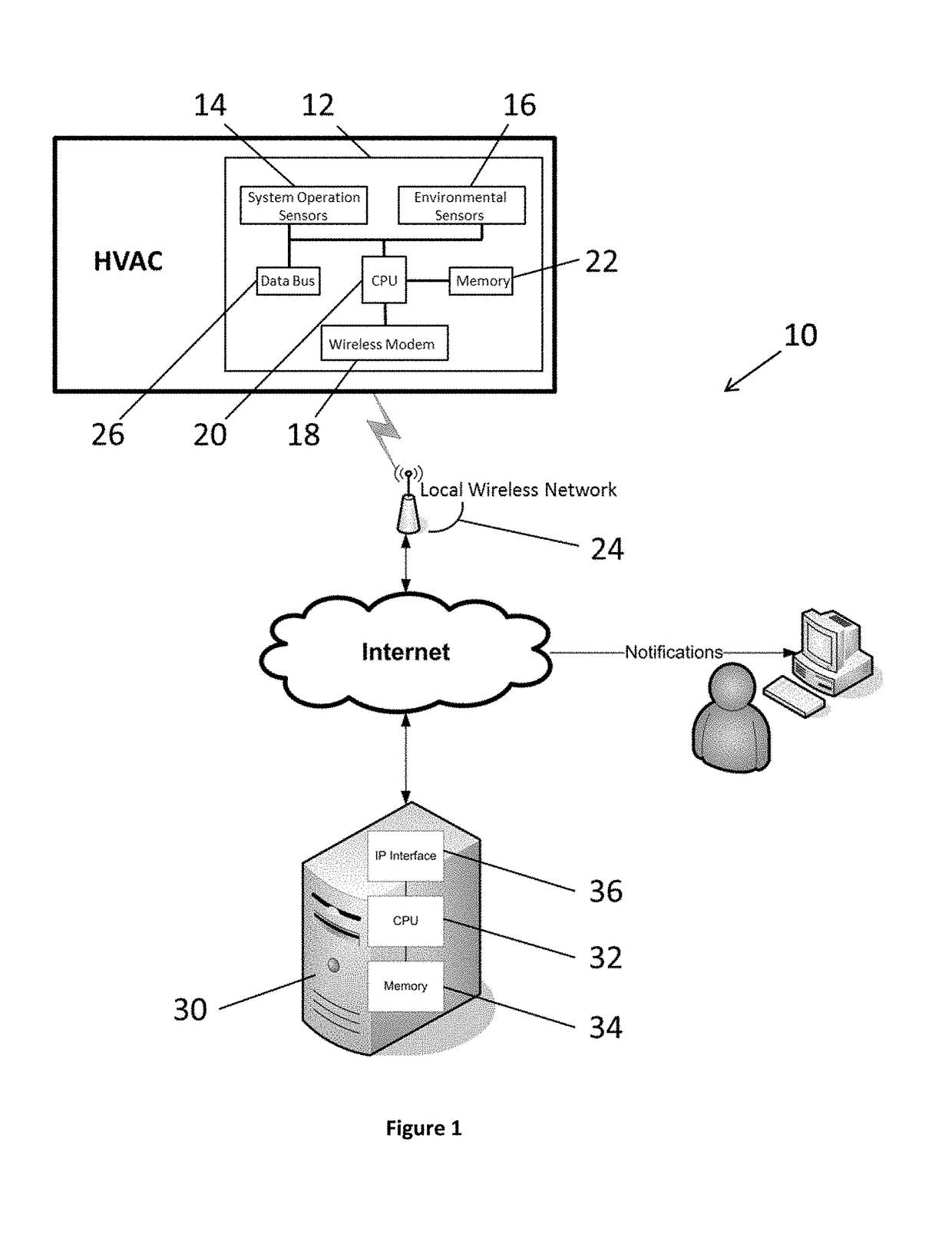

HVAC condition based maintenance system and method

InactiveUS9696056B1Easy and efficient to manufactureDurable and reliable constructionProgramme controlMechanical apparatusMulti unitData transmission

The HVAC condition based maintenance system and method provides for a system to reduce operating costs by replacing existing time based scheduled maintenance with an on-condition based maintenance system and method for continuous monitoring and acquiring condition based data from an operating HVAC system, transmitting data to a remote server for storage, analysis and trending, recognizing operational performance reductions based on the comparison of current trending to historical data, and for triggering notification of failures and corrective action based on routine, impending and immediate problem recognition. Additionally, the acquired data is used to derive actual heat load characteristic of the building, identify HVAC system deficiencies, building deficiencies and installation issues and load imbalance of multi-unit systems providing direction for system improvements.

Owner:SYST PROWORKS INC

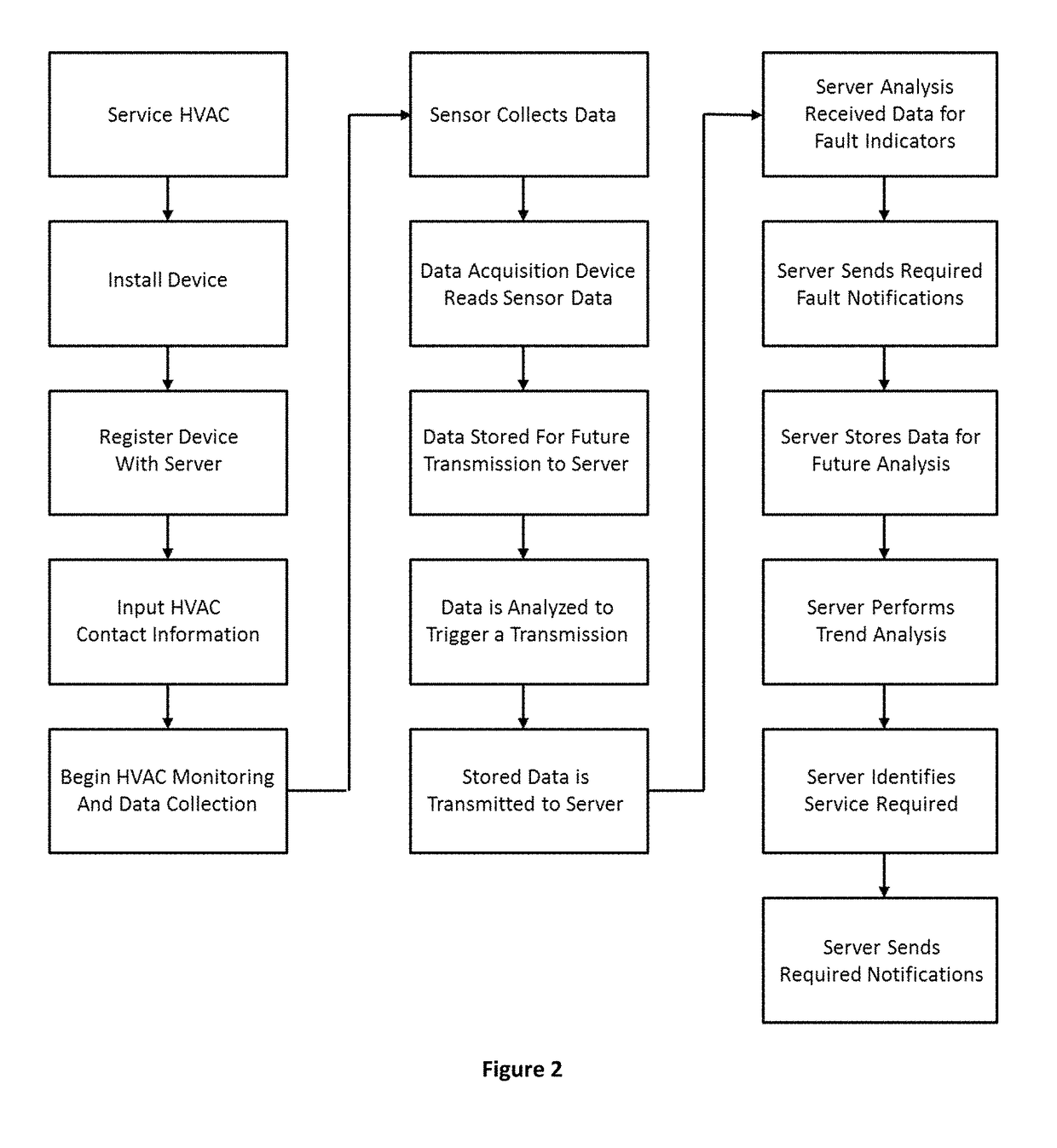

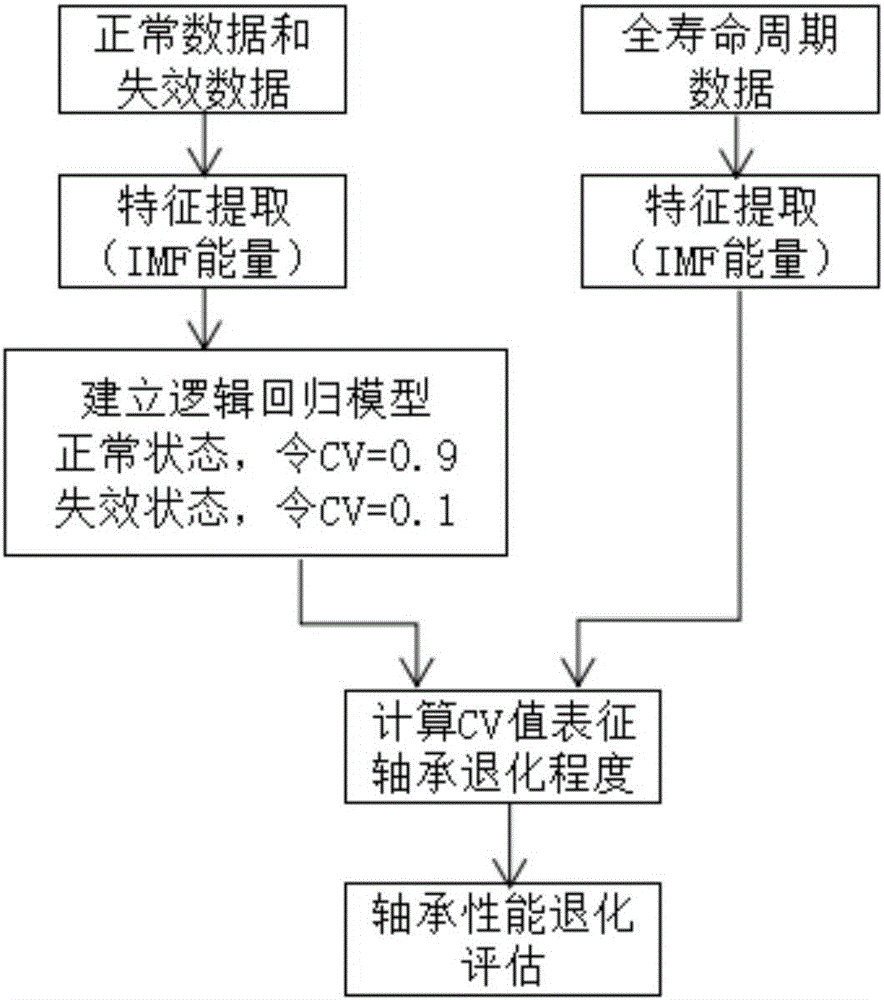

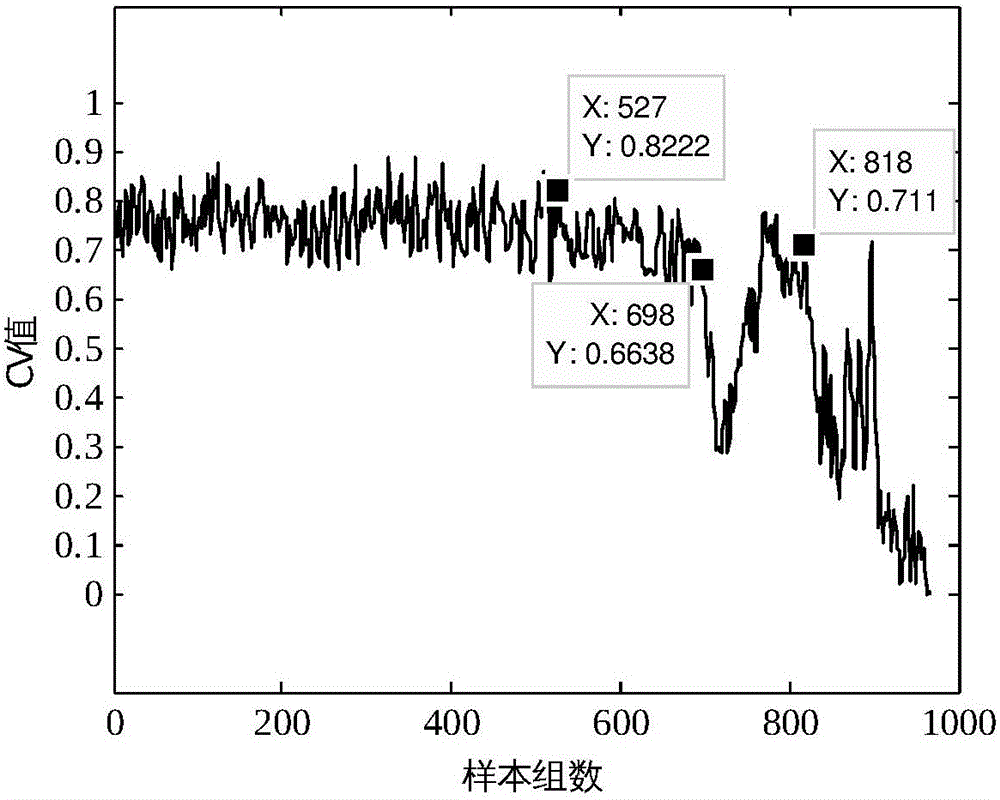

Antifriction bearing performance degradation assessment method based on empirical mode decomposition and logistic regression

InactiveCN106053066AAccurate expressionAccurately reflectMachine bearings testingDecompositionEngineering

The invention discloses an antifriction bearing performance degradation assessment method based on empirical mode decomposition and logistic regression, comprising the step of: first, extracting the intrinsic mode function energy of bearing vibration signals as a characteristic vector; second, building a logistic regression model by utilizing the characteristic vectors of a bearing normal state and a failure state to obtain regression parameters; and finally, calculating the assessment index of a bearing signal life cycle, and thereby assessing antifriction bearing performance degradation conditions. According to assessment results, the method can timely discover early faults, well describe each phase of bearing performance degradation, and facilitate early detection of bearing initial faults and failure critical points so as to perform condition-based maintenance.

Owner:EAST CHINA JIAOTONG UNIVERSITY

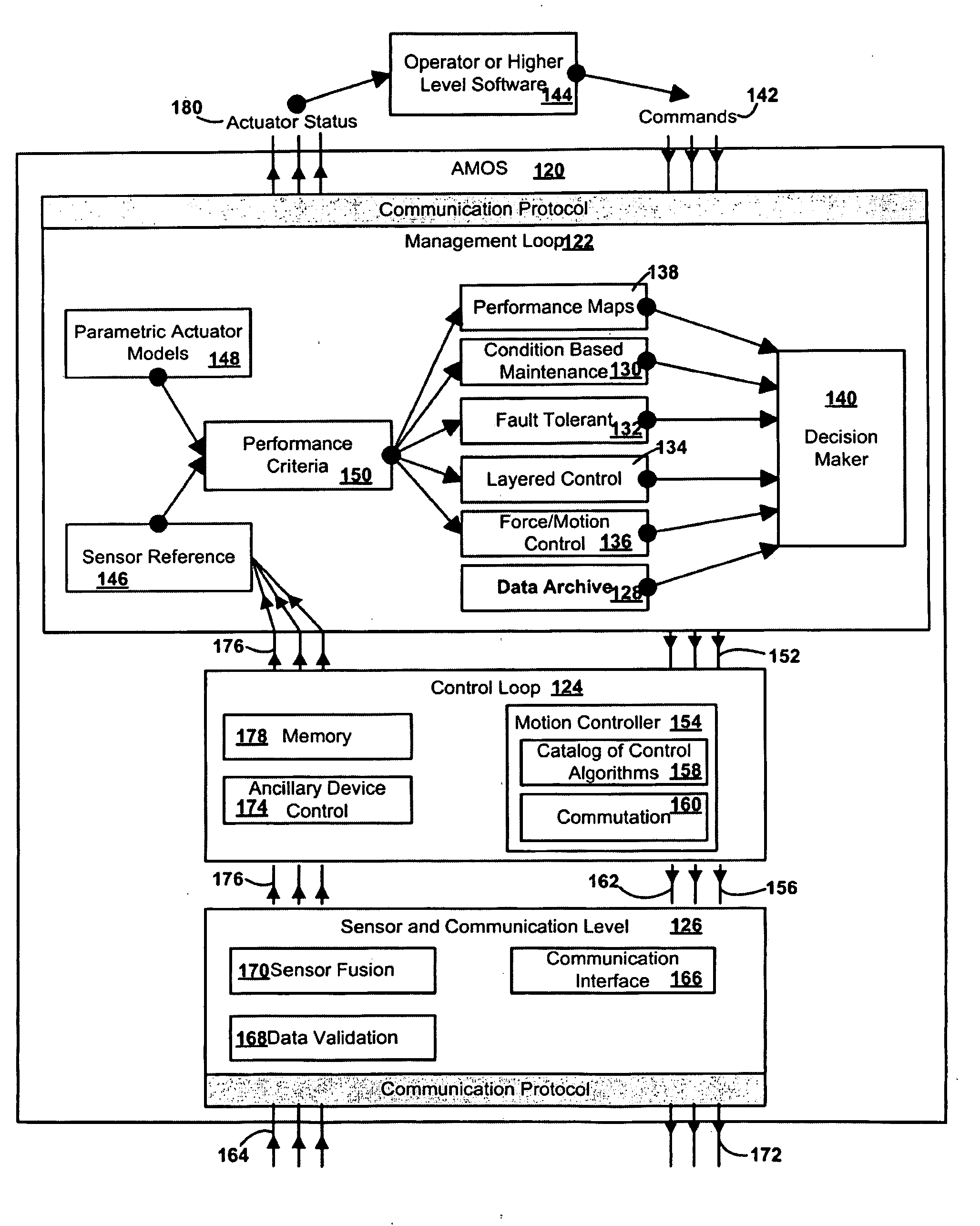

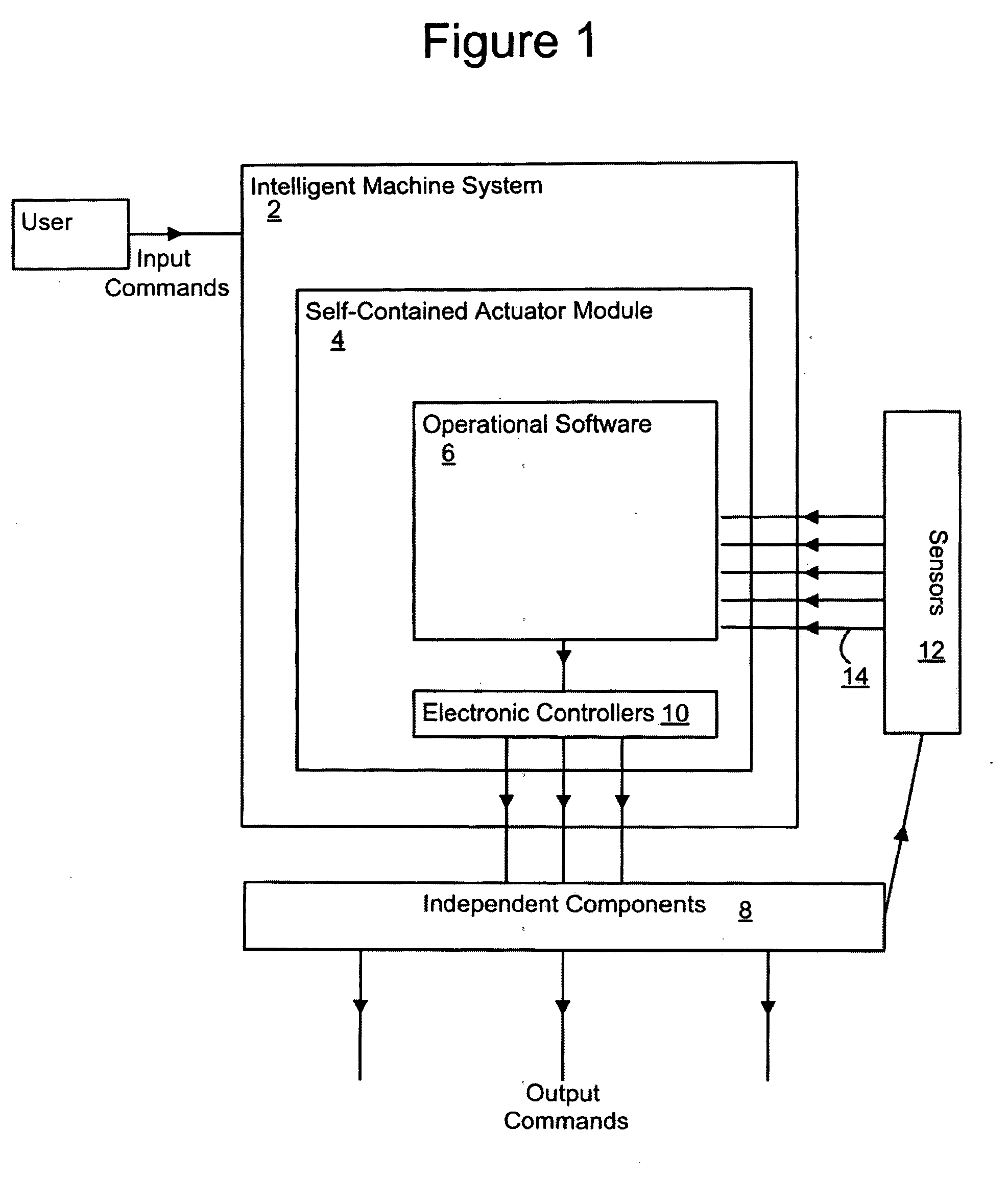

Performance maps for actuator intelligence

InactiveUS20080269922A1High fault toleranceHigh maintenanceProgramme controlAdaptive controlThree levelFault tolerant architecture

A four level fault tolerant architecture for the intelligent machine system is based on the basic component of a self contained actuator module with standardized interfaces. This system architecture organizes all of the operational software to make it universal, high performing, fault tolerant, and use condition-based maintenance. The independent structural layers are structured and prioritized by the advanced electronic controllers. The sensor module creates an accurate parametric representation of the electro-mechanical actuator, and manages all resources in the electro-mechanical actuator. The system will also comprise of operational criteria, maximum performance envelopes, condition-based maintenance, fault tolerance, layered control, and force / motion control. The system allows independent development of different components of the framework, categorized into three levels: the management level, the servo control level, and the senor and communication level. The present disclosure establishes a fully responsive actuator whose intelligence manages a sufficiently broad set of choices.

Owner:TESAR DELBERT

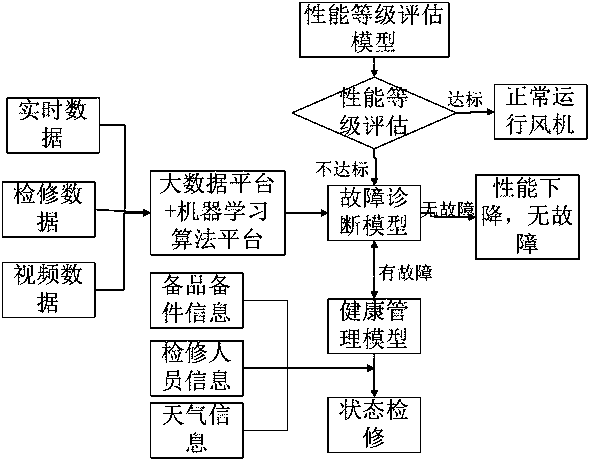

Wind turbine generator health management method based on machine learning algorithm platform

PendingCN109492777AAccurate Health Assessment ReportAccurate device health analysisCharacter and pattern recognitionResourcesEngineeringPerformance grade

The invention provides a wind turbine generator health management method based on machine learning algorithm platform. The health management method includes: theoretical power generation balance analysis, performance grade evaluation, fault diagnosis model and health management model design, health evaluation and health analysis, health management is the realization of condition-based maintenance.According to the deep application of the theoretical electric quantity balance analysis method, Combining Big Data Technology, through the combination of machine learning and artificial intelligence,to realize the prediction and evaluation of the health status of the fan and its accessories and main equipment, finally, the maintenance mode of wind turbine generator system is transited from planned maintenance and fixed maintenance to condition-based maintenance, so as to reduce the power loss of planned maintenance, unplanned maintenance and performance loss of wind turbine generator system,so as to achieve the goal of increasing the power generation of wind farm station and improving the economic benefit of wind farm station.

Owner:国电电力宁夏新能源开发有限公司

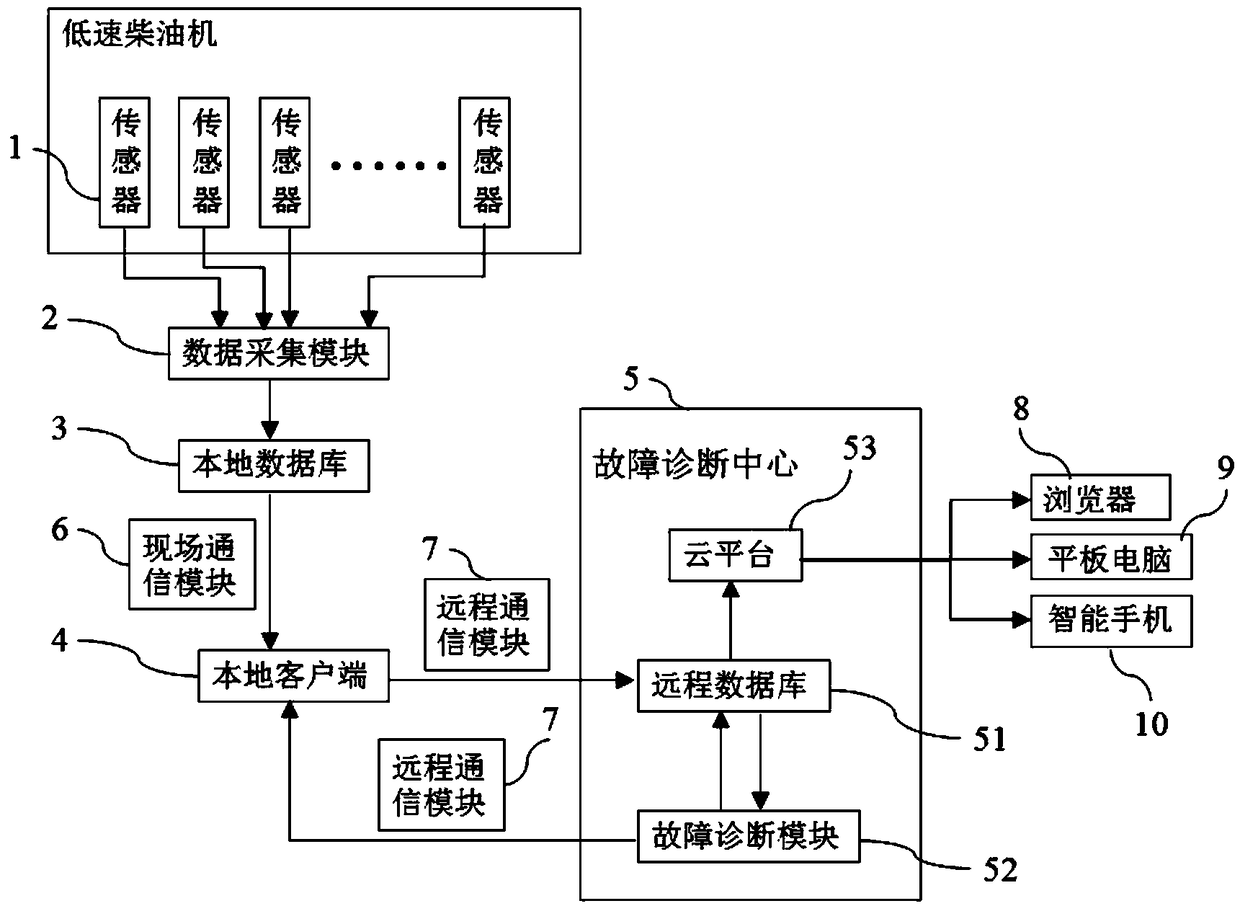

Remote state monitoring and fault diagnosis system for low-speed diesel engine

InactiveCN109100150AImplementation statusImplement fault diagnosisInternal-combustion engine testingQuality of serviceLow speed

The invention discloses a remote state monitoring and fault diagnosis system for a low-speed diesel engine. The remote state monitoring and fault diagnosis system comprises a data acquisition module,a local database, a field communication module, a local client, a remote communication module, a fault diagnosis center and a cloud platform. Through adoption of the remote state monitoring and faultdiagnosis system for the low-speed diesel engine, remote state monitoring and fault diagnosis of the low-speed diesel engine are realized on the basis of remote communication, fault diagnosis and a cloud platform technology, thereby greatly improving the service quality and the service efficiency, improving the running safety of the diesel engine, and reducing direct or indirect losses caused by the shutdown of the diesel engine. Meanwhile, the remote state monitoring and fault diagnosis system can change an original regular maintenance system into a condition-based maintenance system, therebygreatly lowering the maintenance cost.

Owner:中国船舶重工集团柴油机有限公司

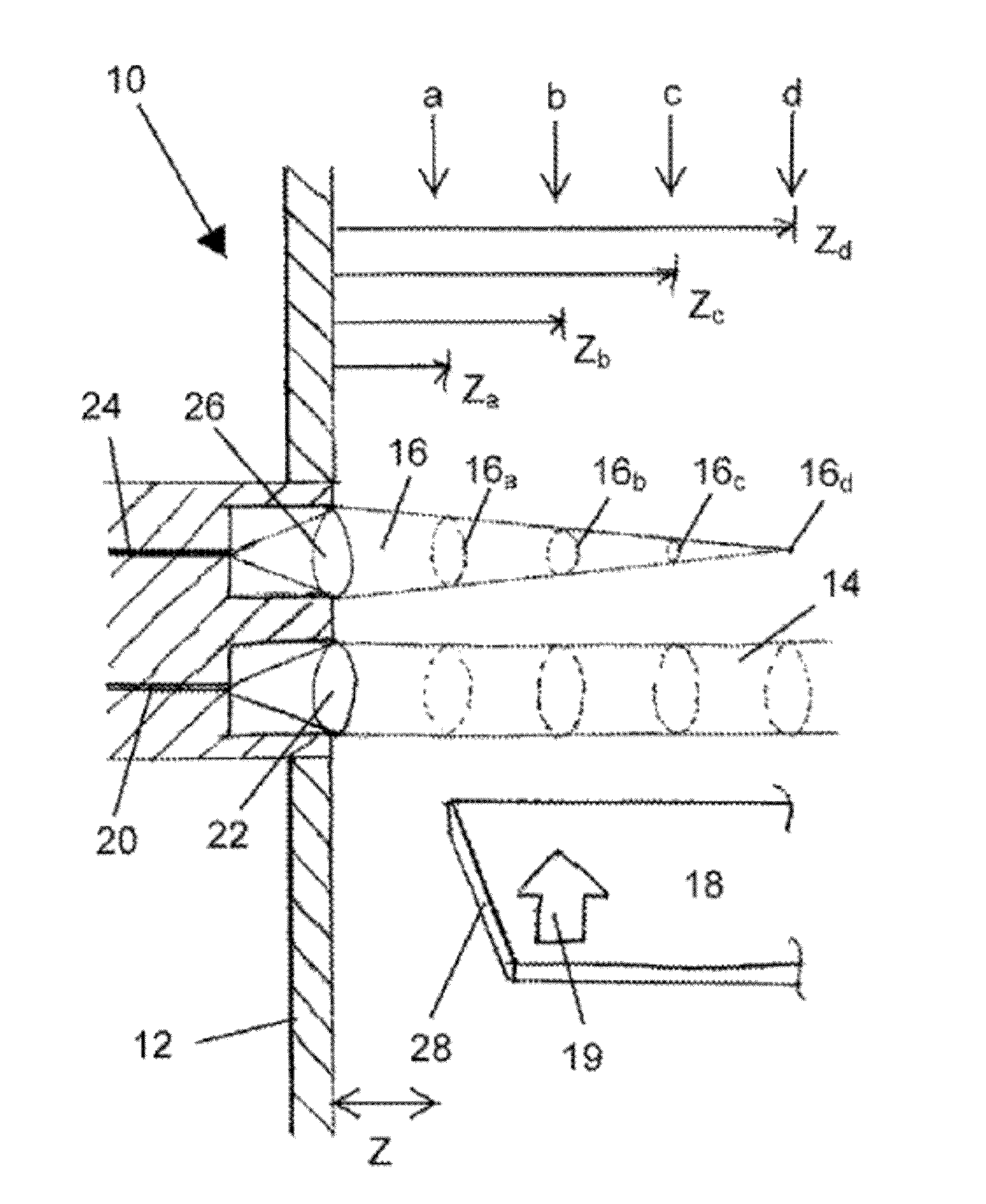

Method for Detecting Foreign Object Damage in Turbomachinery

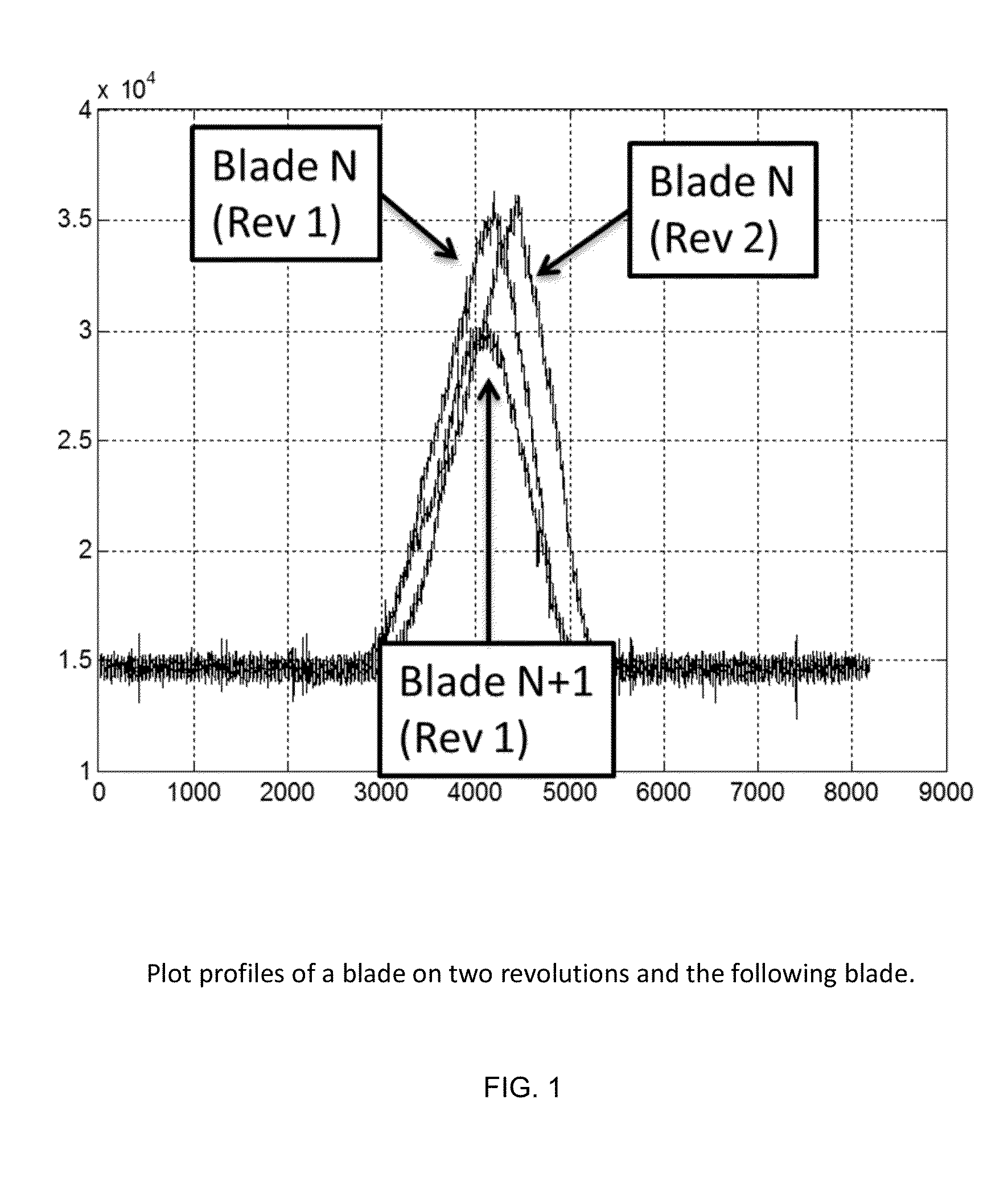

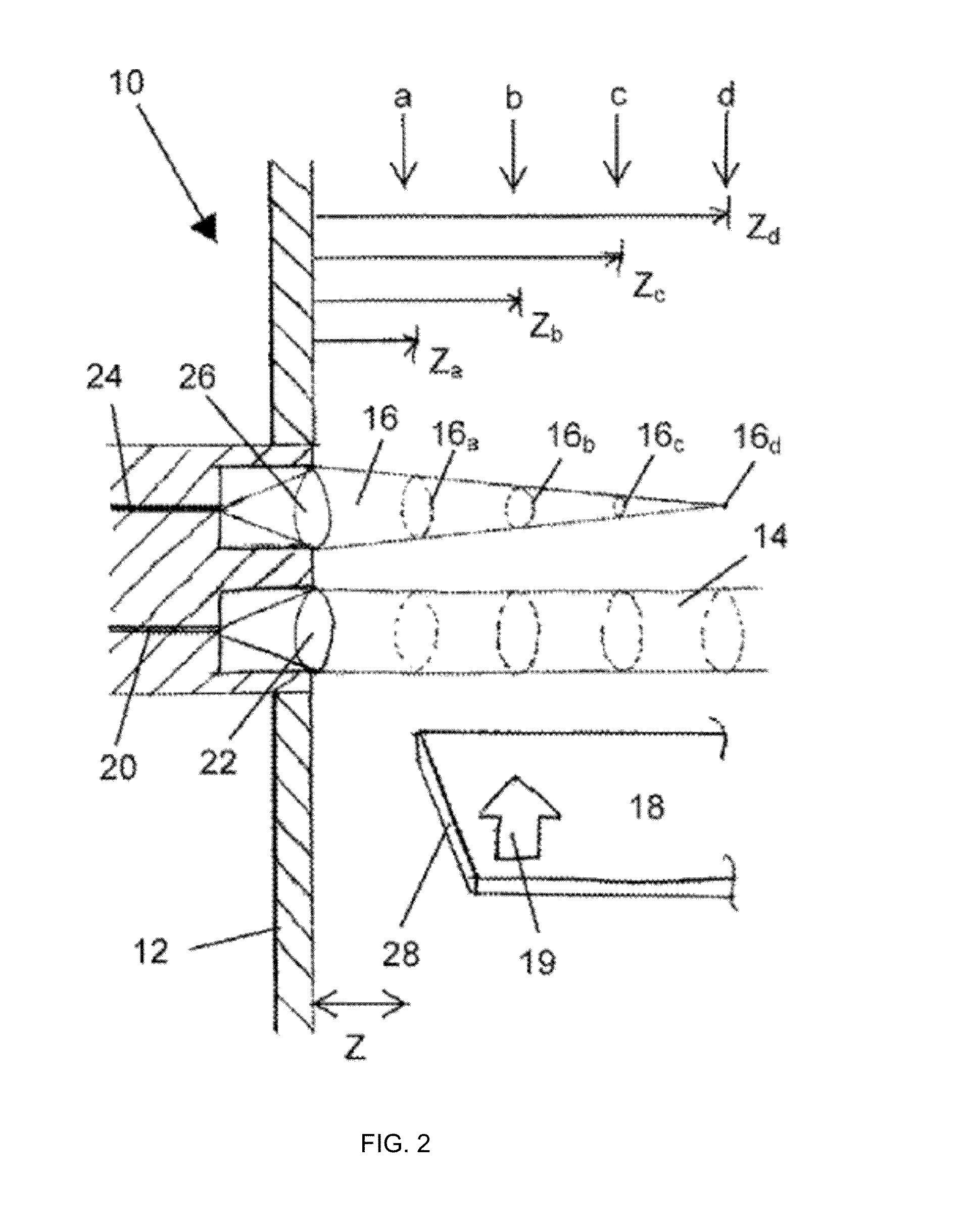

ActiveUS20130006541A1Low costRemoval costPlug gaugesEngine fuctionsForeign object damageOperational costs

The present invention relates to systems and methods for real-time health monitoring of engines to monitor turbomachinery blades during engine operation and report anomalous behavior and shape of the blades if it occurs, such as damage by FOD. The system comprises sensor(s) for obtaining a blade reflection profile from a blade passing by the sensor(s) during a revolution of the rotor in combination with a processor for performing timing calculations and / or fingerprint comparisons with reference data to identify a change in blade fingerprint relative to the reference data, which may indicate blade damage. Such systems can reduce operational costs, enhance safety and improve operational readiness by facilitating condition-based maintenance of engine rotors as opposed to schedule-based solutions. The invention can prevent the needless loss of life and assets caused by undetected minor levels of blade damage that may lead to unexpected catastrophic failure of an engine.

Owner:PRIME PHOTONICS LC

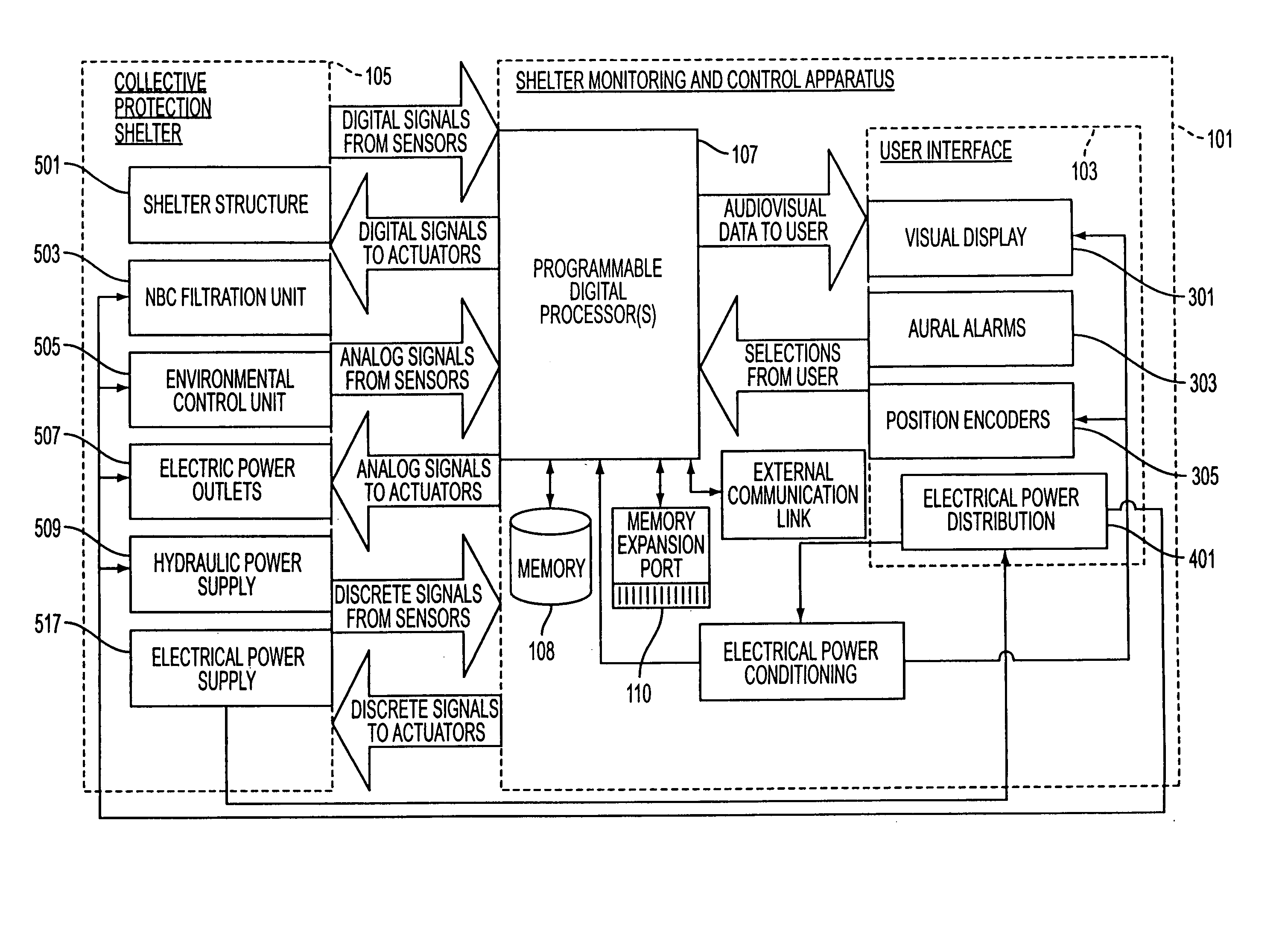

Apparatus for monitoring and controlling an isolation shelter and providing diagnostic and prognostic information

ActiveUS20050049753A1Reduces volume and weight and costSimplifies availabilitySampled-variable control systemsSafety arrangmentsCollective protectionCondition-based maintenance

Monitoring and controlling apparatus and related methods for use with collective protection shelters or other isolation environments utilizing one or more digital processors to monitor and control the operation of the shelter. The apparatus affords shelter design and functional growth flexibility, along with diagnostic and prognostic capability, including condition based maintenance, interactive electronic manuals, and access to systems for replacement parts requisition. Further, the physical and functional expandability of the apparatus affords easy incorporation of shelter design changes, user interface design changes, and sensor design changes as well as improved functional and operational flexibility. The system also decreases volume and weight over prior designs.

Owner:DRS SUSTAINMENT SYST

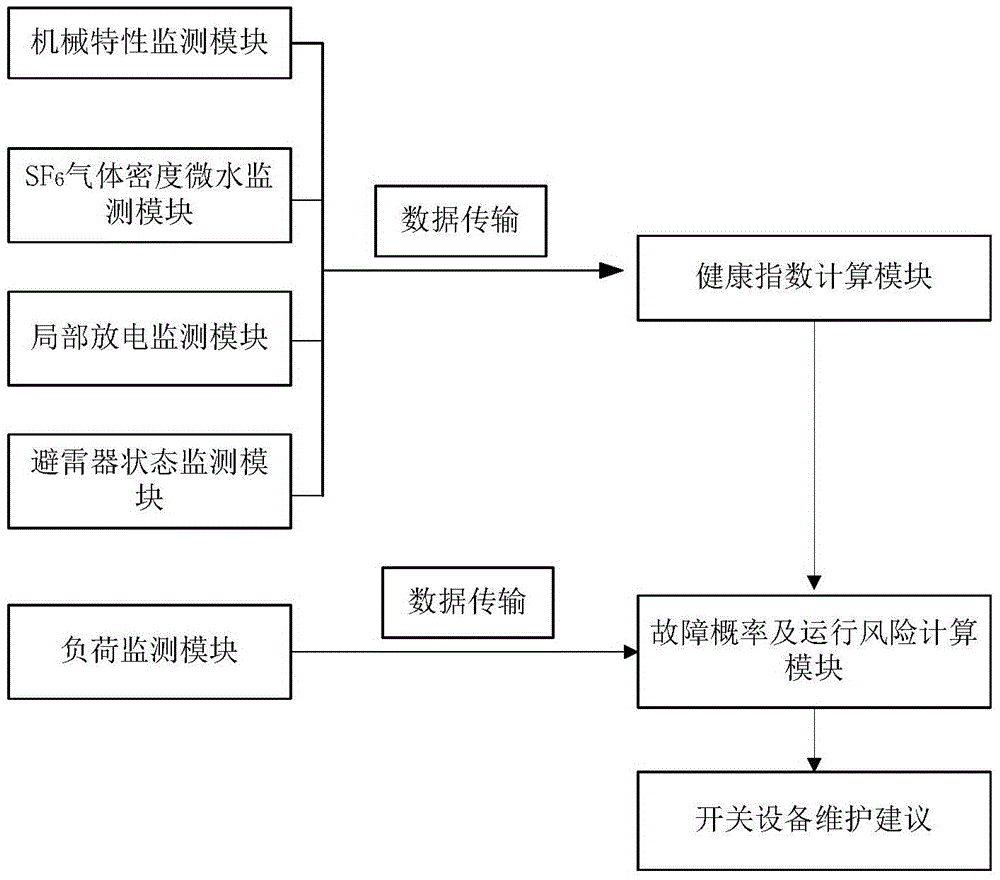

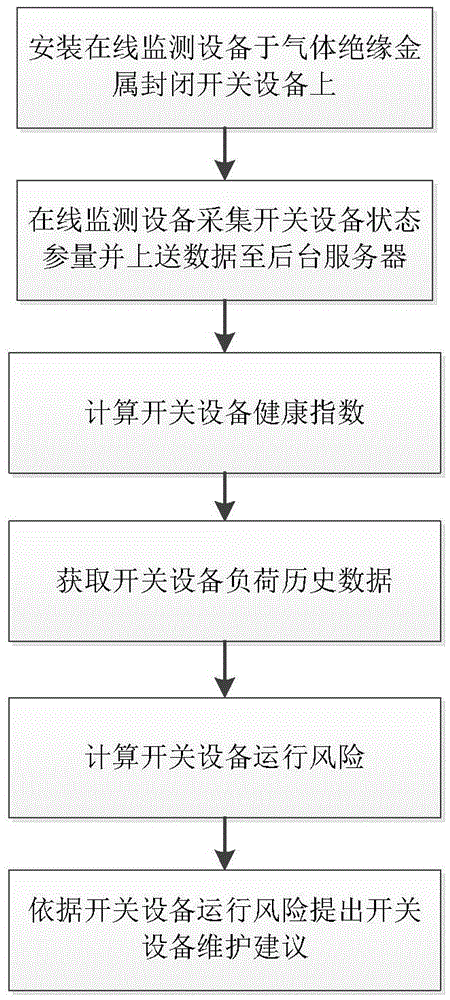

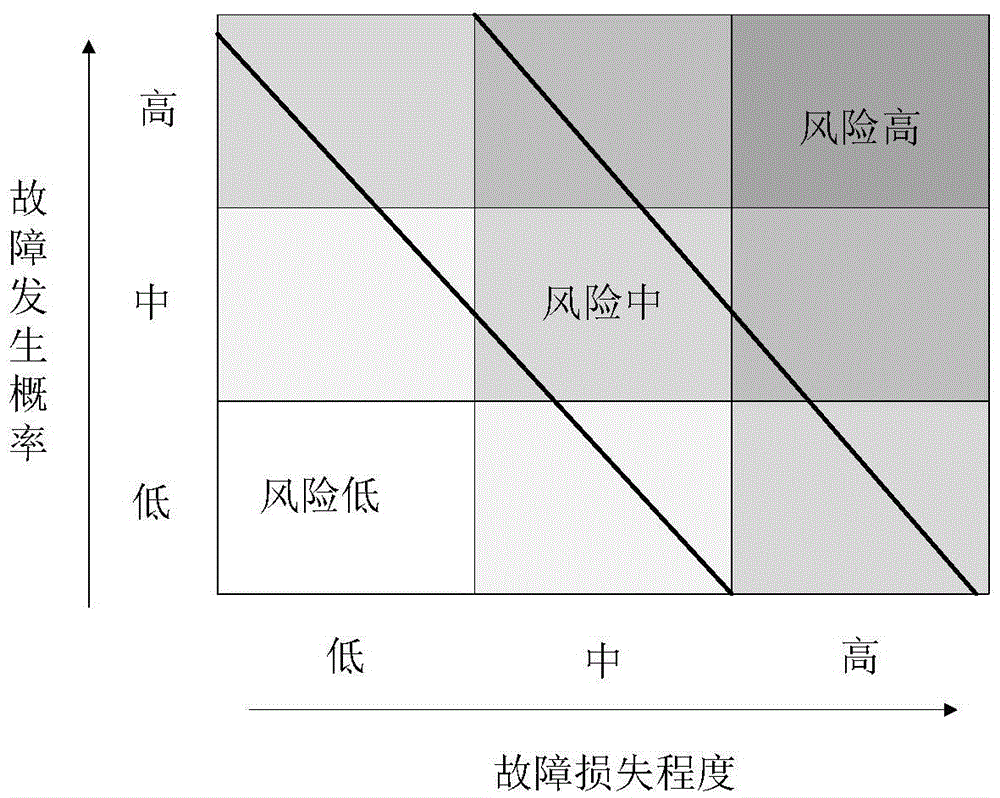

Method for assessing operation risk of gas insulated metal enclosed switchgear

The invention relates to a method for assessing operation risks of a gas insulated metal enclosed switchgear. The health index of the switchgear is calculated based on parameters including switch mechanical characteriztic parameters, SF6 gas density and humidity, partial discharge parameters, lightning arrester state parameters and the like. The operation fault probability of the switchgear is calculated according to the health index, the load history, the operating maintenance history and the basic data of the gas insulated metal enclosed switchgear, the operation risks are further calculated according to the importance and fault loss degree of the equipment, so that the corresponding assets management and condition-based maintenance suggests are provided for users.

Owner:BEIJING SIFANG JIBAO AUTOMATION

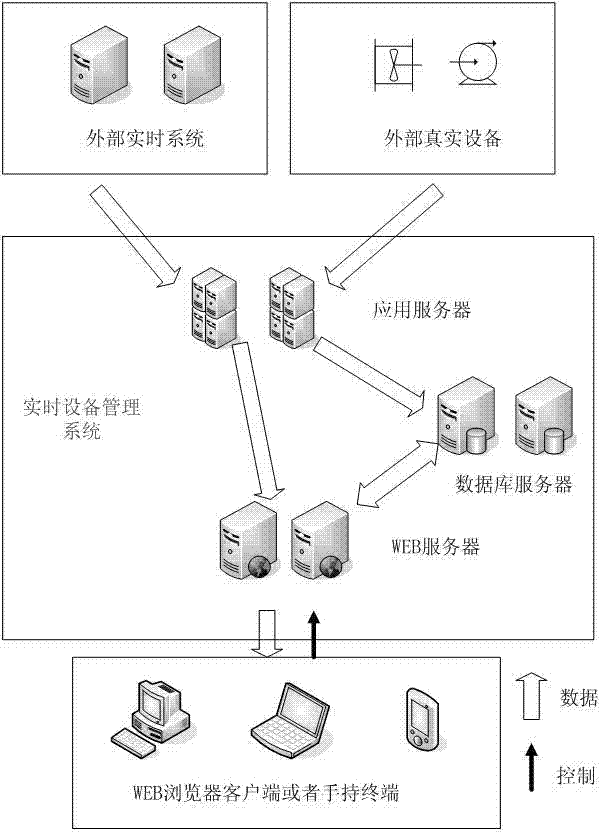

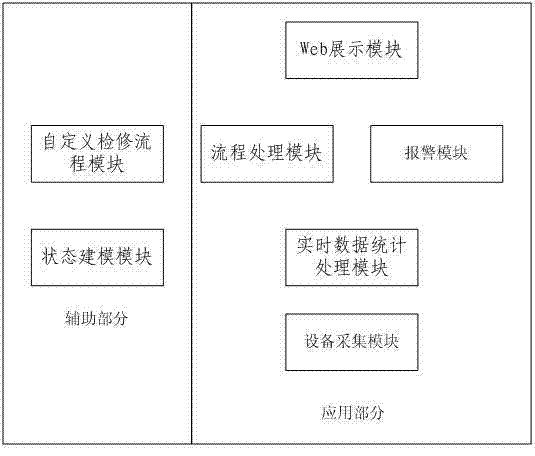

Real-time DMS (device management system) of B/S (browser/server) framework and method thereof

The invention discloses a real-time DMS of a B / S framework and a method thereof. The method comprises steps of real-time device status acquisition and statistics, device condition based maintenance and modeling, real-time overhaul process triggering by a device status fault, and on-line monitoring of real-time status, real-time index and overhaul process of the device. The system has real-time device status acquisition and real-time index statistic functions, has a flexible device status modeling method, can trigger the overhaul process dynamically according to current status change of the device, and can display the real-time status, the real-time index, the overhaul process and device management in a B / S manner. The invention designs and realizes the real-time DMS of the B / S framework. By means of the real-time DMS, device data and statuses from different manufacturers can be obtained through various modes and routes, the overhaul process can be triggered dynamically according to defined status modeling method, system information can be browsed conveniently through various mainstream desktop terminals and mobile terminals, discovery time of device failure and hidden failure danger is shortened greatly, the equipment failure rate can be reduced to a large extent, and influence on production caused by device problems is reduced.

Owner:NARI TECH CO LTD

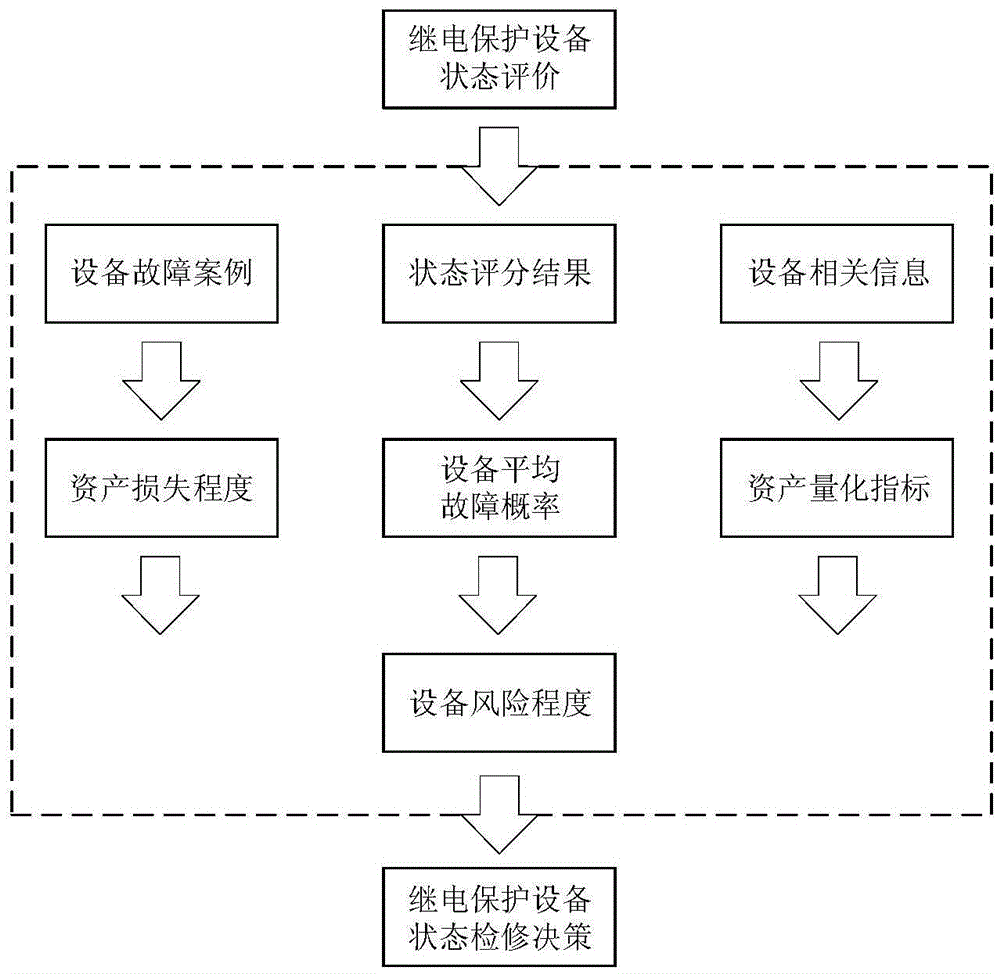

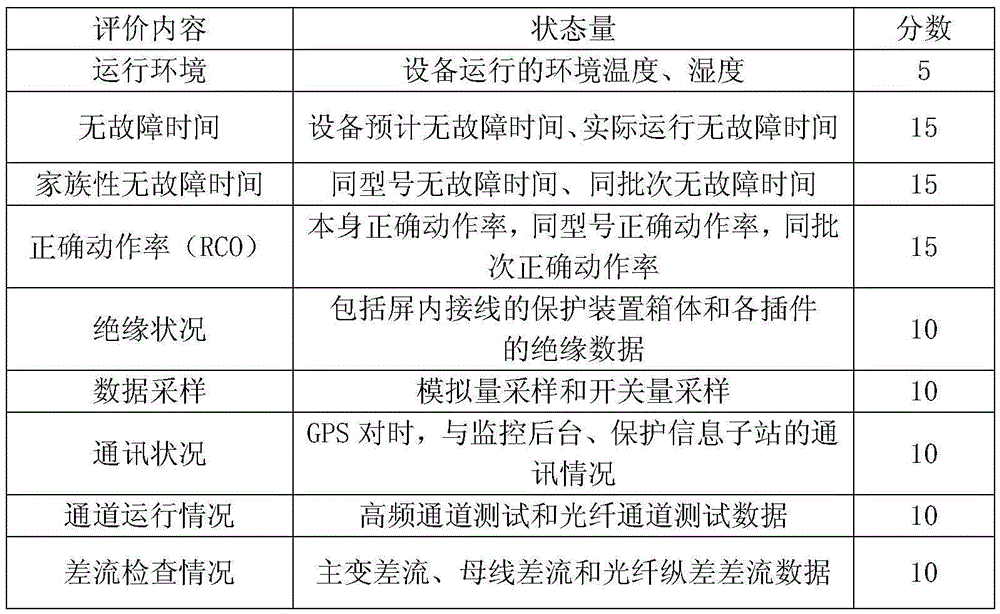

Risk assessment method for relay protection equipment in intelligent substation

InactiveCN105678469ASplit inner connectionResourcesInformation technology support systemSmart substationDecision taking

Provided is a risk assessment method for relay protection equipment in an intelligent substation. The risk assessment method comprises the following steps: 1) obtaining status information of the relay protection equipment through conventional technological means of operation patrol, regular service-stop maintenance or live detection and on-line monitoring and the like, evaluating the operation performance of the equipment, and obtaining quantized states of the relevant equipment in the corresponding assessment time sections through state scores; 2) according to equipment historical fault cases, assessing the re-occurrence possibility of the relevant faults under the existing equipment state, and relevant loss degree after the fault occurs; 3) judging the equipment asset condition and status importance degree thereof according to relevant equipment information comprising equipment account, grid structure, power supply user information and importance degree; and 4) based on the information of the relay protection equipment above, carrying out integration on the state quantity of the equipment and then, carrying out risk assessment, and making a condition-based maintenance decision for relay protection according to the risk degree of the equipment.

Owner:NANJING INST OF PROD QUALITY INSPECTION

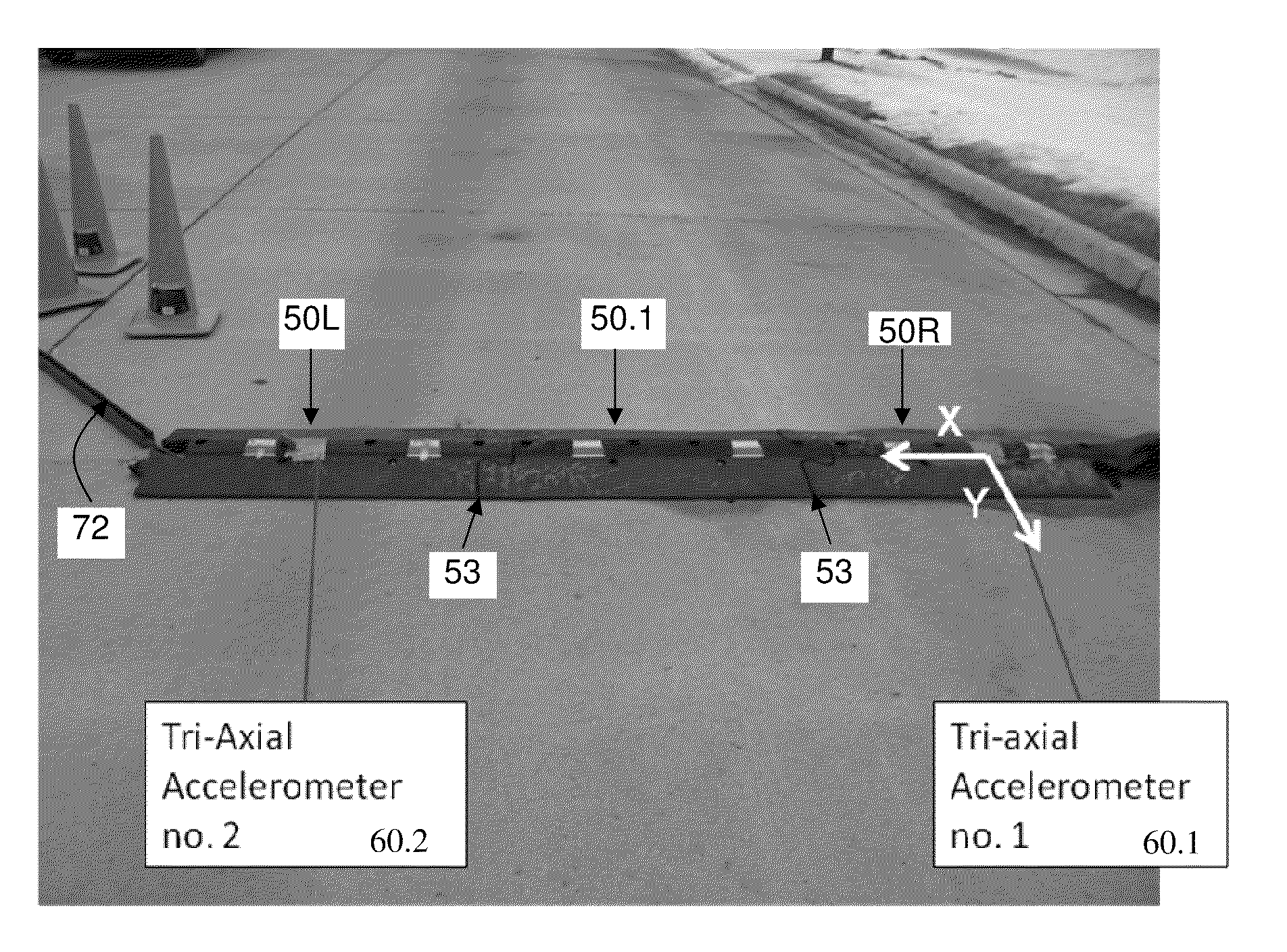

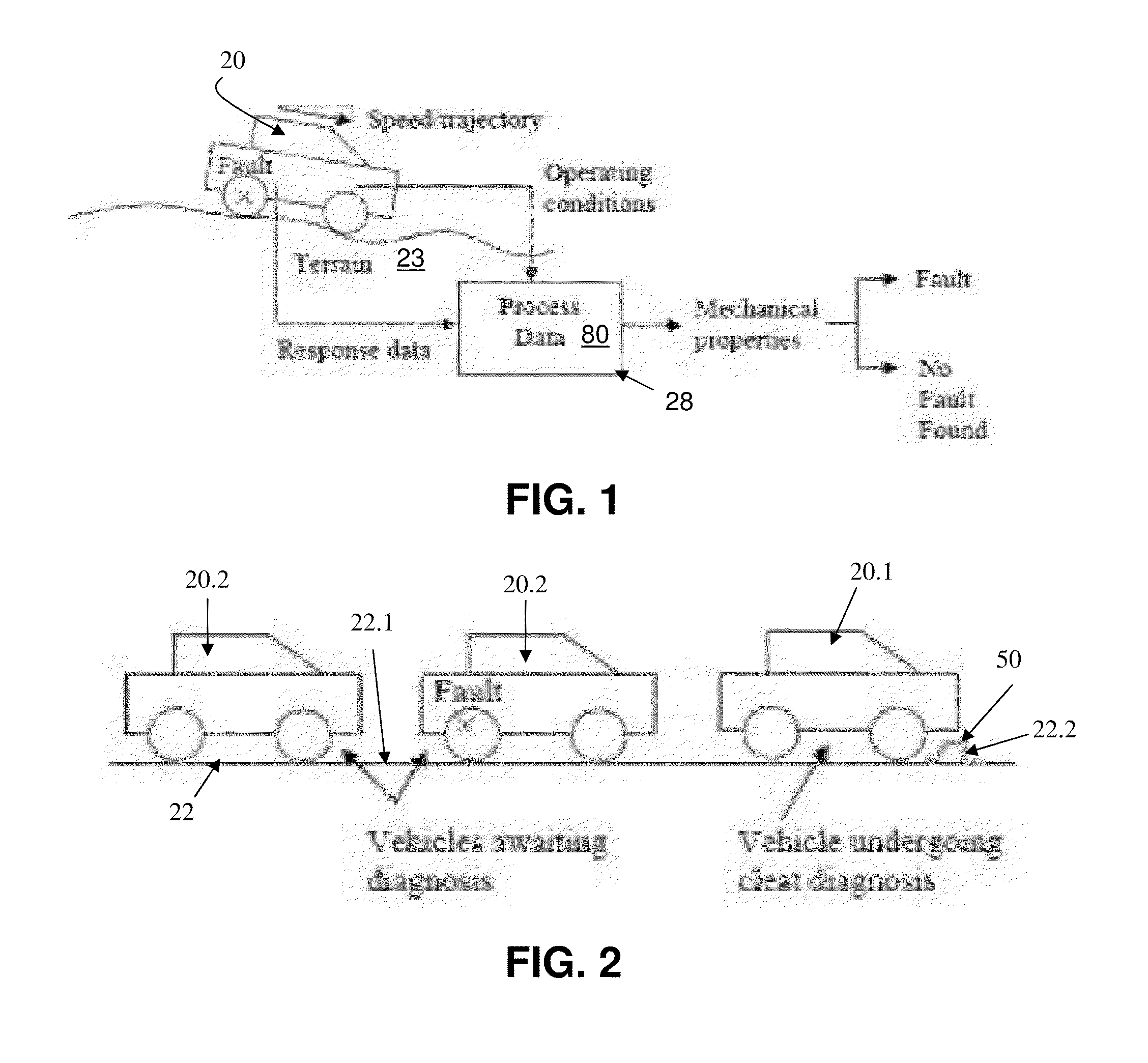

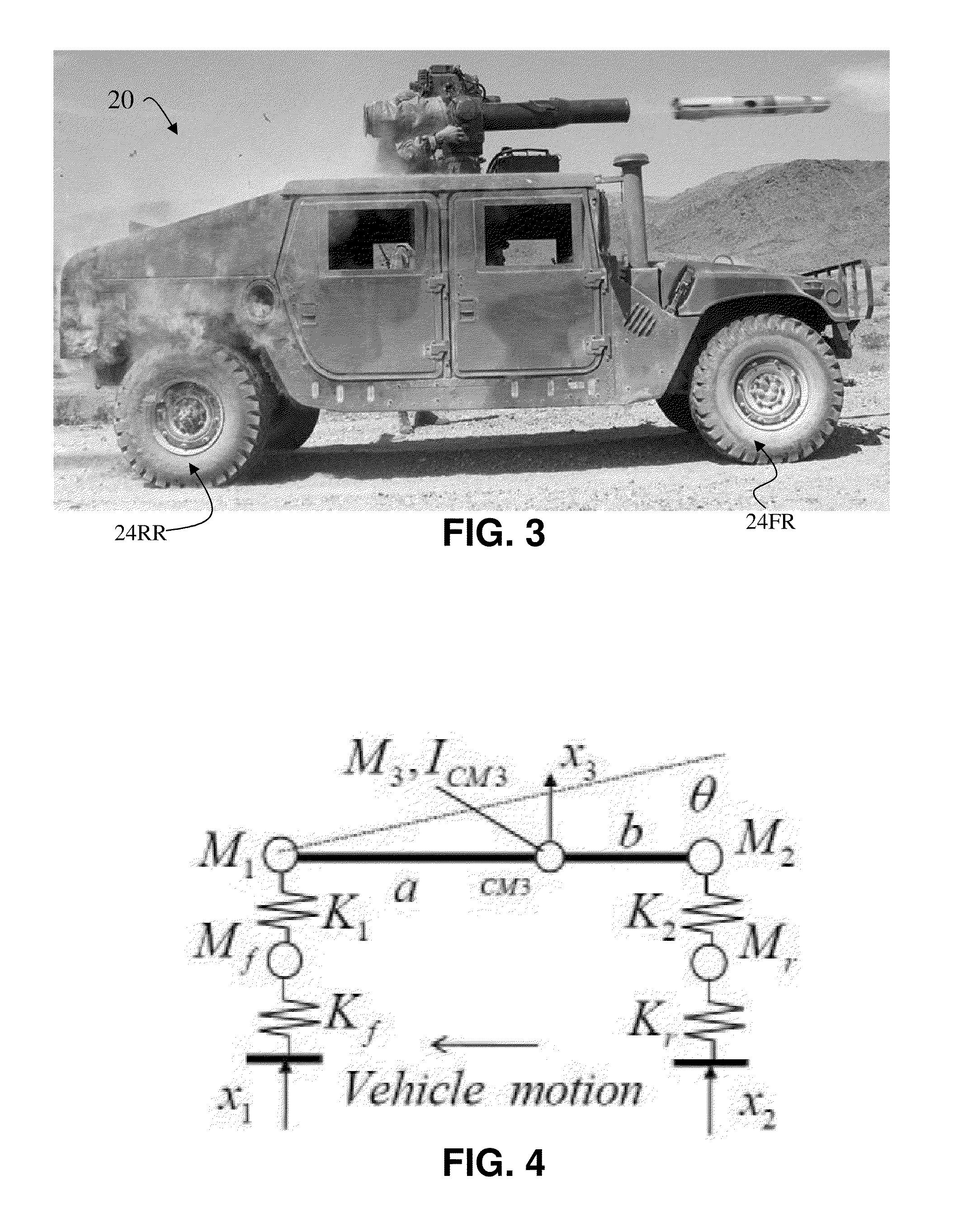

Methods and apparatus for diagnosing faults of a vehicle

InactiveUS20110257900A1Engine testingVehicle suspension/damping testingTriaxial accelerometerGround vehicles

A rubber cleat is instrumented with two triaxial accelerometers to measure the multi-directional response of the cleat due to the forces within the tire footprint of a ground vehicle. The cleat data is used to detect faults in the front and rear suspension in addition to the wheel tire despite variability in the data. This offboard diagnostic technique is proposed to enable condition-based maintenance.

Owner:HONEYWELL INT INC +1

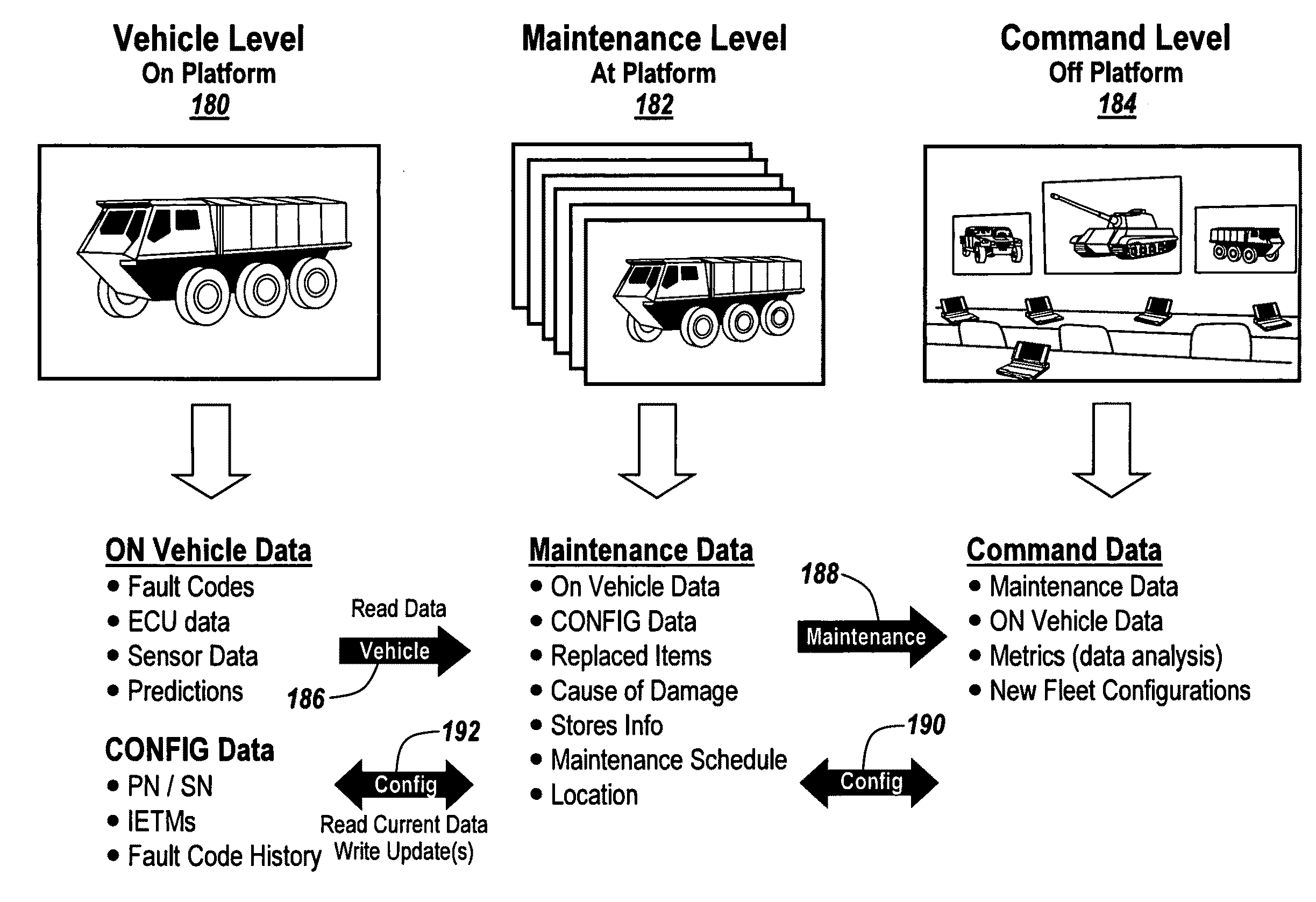

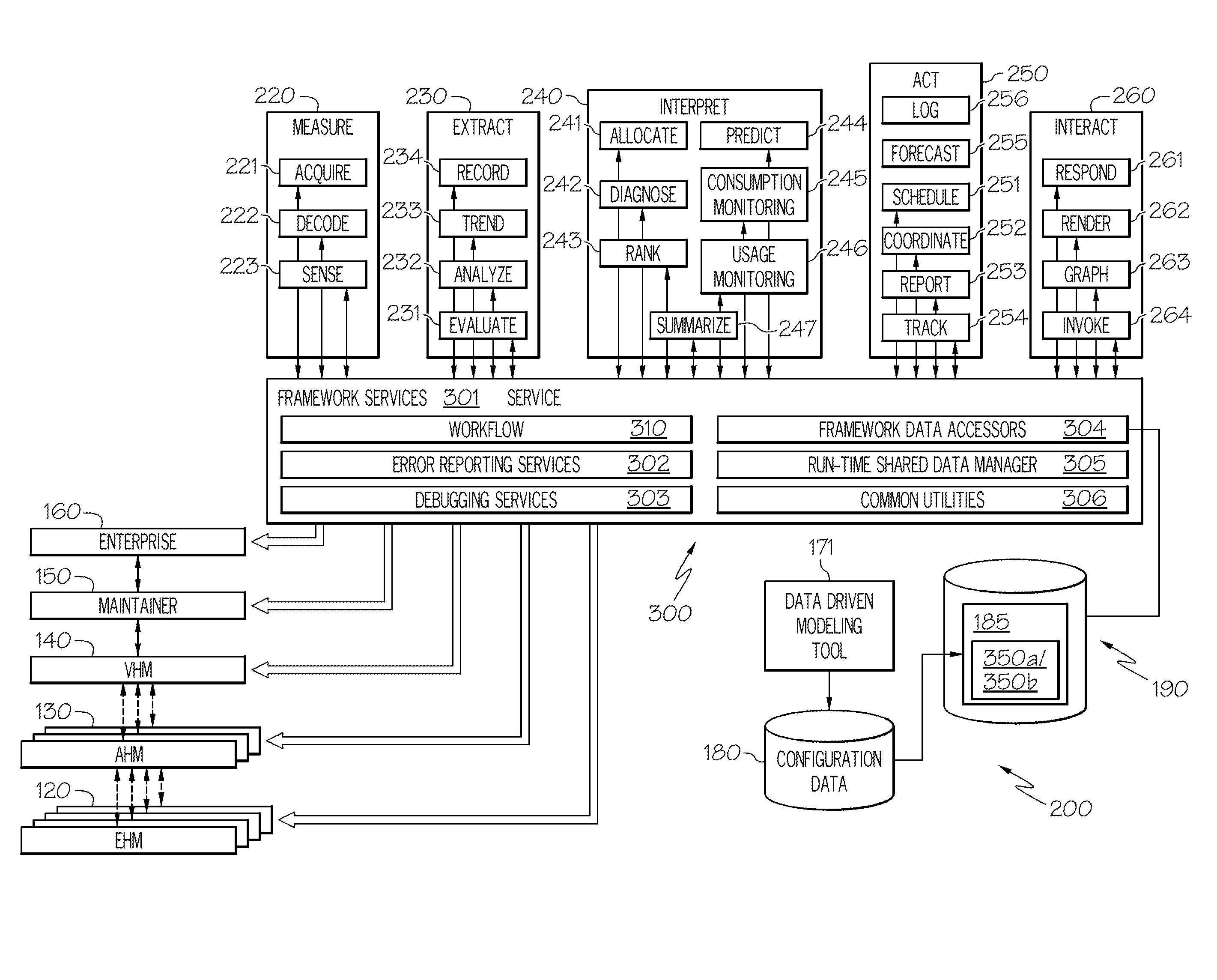

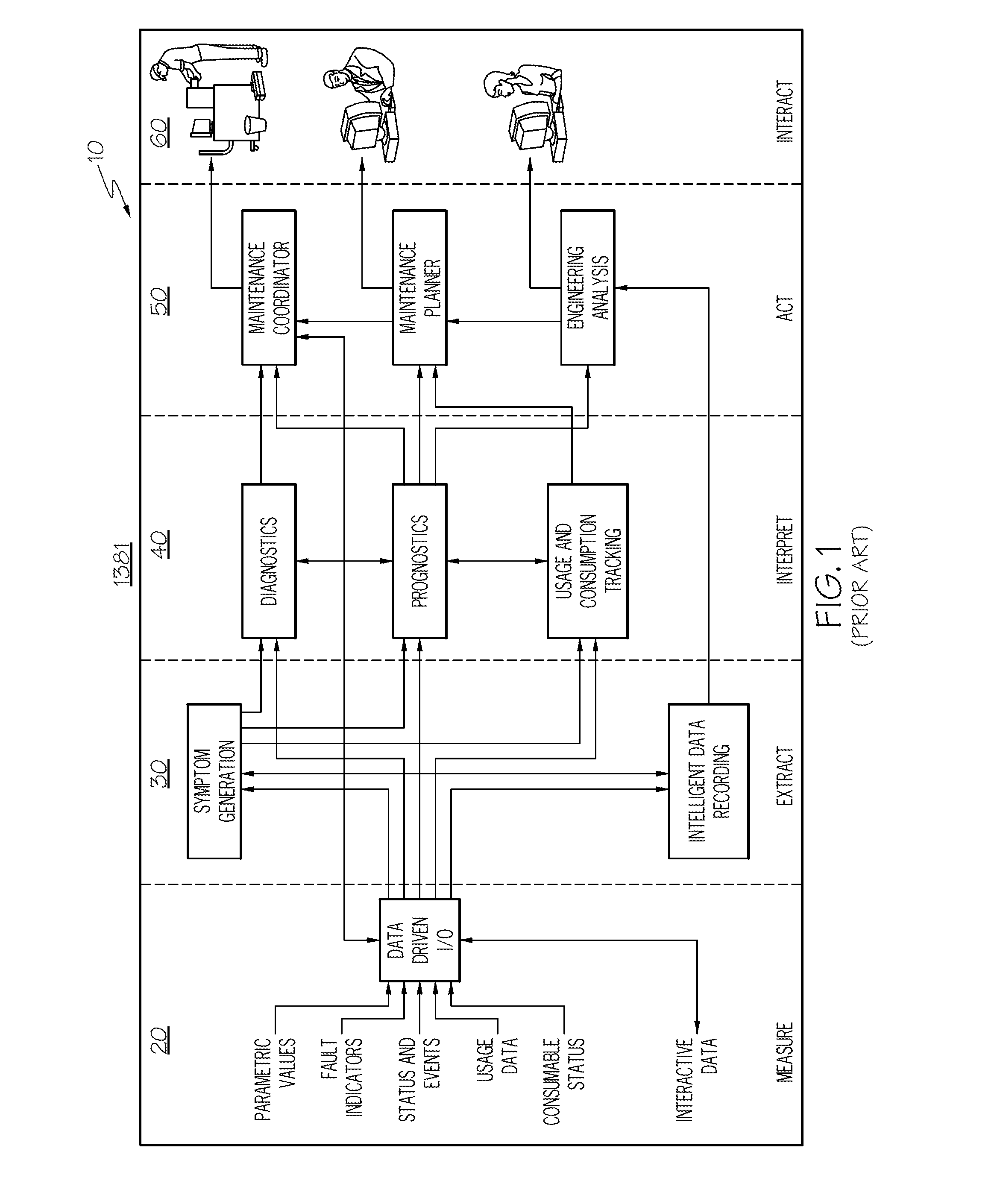

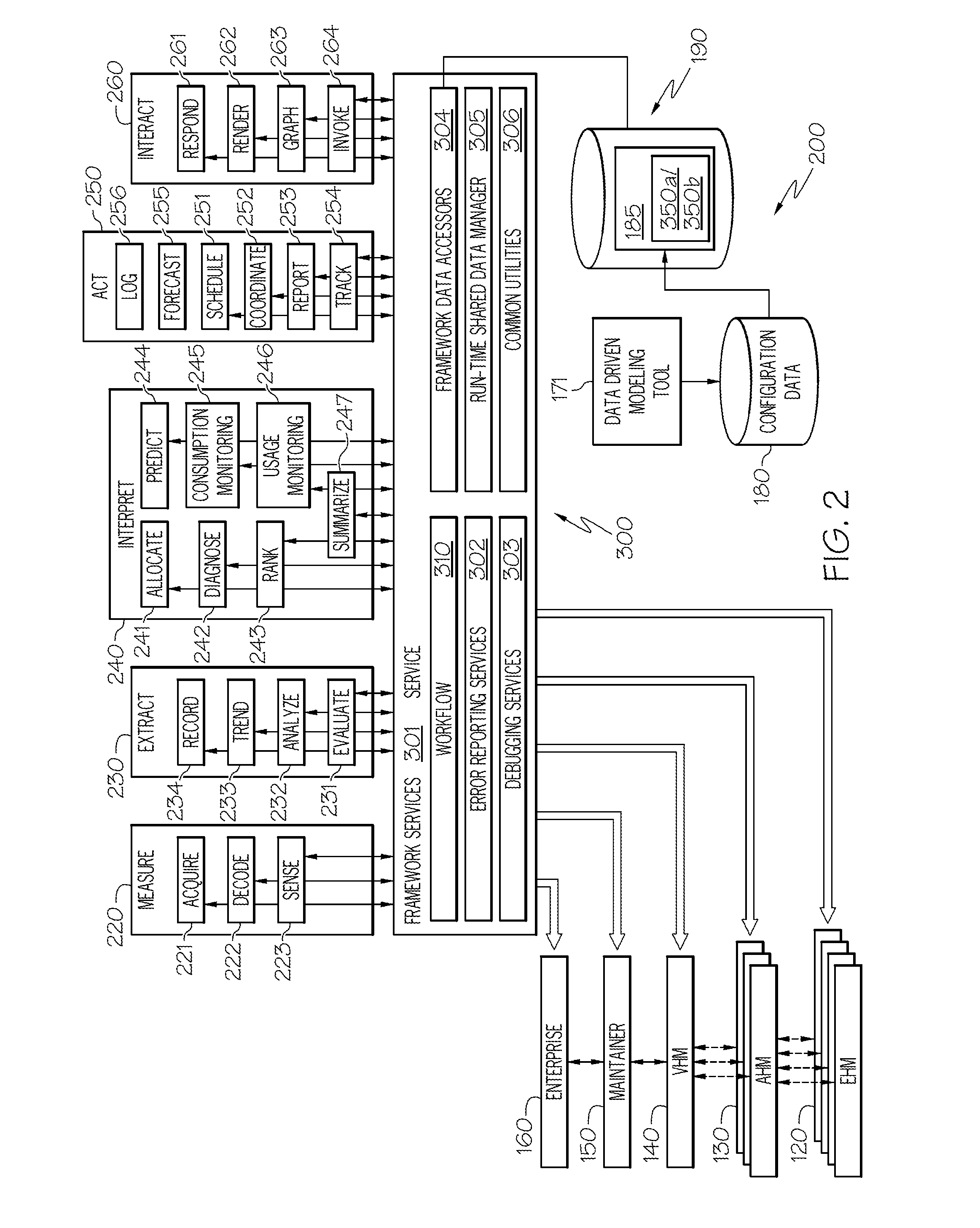

Method for performing condition based data acquisition in a hierarchically distributed condition based maintenance system

A method for accumulating fault condition data from a hierarchical system is presented comprising monitoring an operation of a component with a computing node that includes a processor and a memory. The memory contains a configuration file comprising failure modes (FM), symptoms, tests that identify the symptoms and a corrective action for the symptom. The method further comprises populating at least one of the processor and the memory of the computing node with one or more standardized executable application modules (SEAM) and a workflow service. The one or more SEAMS is configured to create a fault condition record by collecting all FMs that manifest the symptom. For all FMs collected, a list of unique symptoms is produced. Further all tests that can identify the listed unique symptoms and all of the corrective actions associated with the FMs that manifest the symptom are determined from the memory device.

Owner:HONEYWELL INT INC

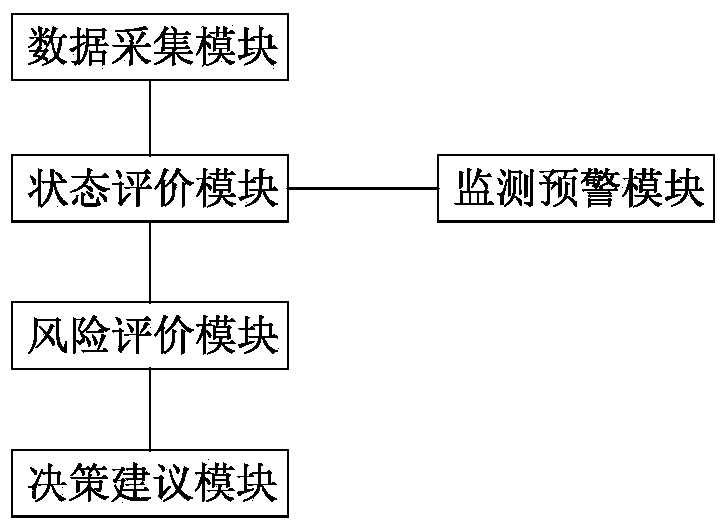

Condition-based maintenance and evaluation decision making system for grid information communication equipment

InactiveCN104346701AEnsure safe and economical operationStrengthen management and standardize managementResourcesDecision systemMaintenance strategy

The invention discloses a condition-based maintenance and evaluation decision making system for grid information communication equipment. The condition-based maintenance and evaluation decision making system comprises a data acquisition module, a condition evaluation module, a monitoring and early warning module, a risk evaluation module and a decision making suggestion module, wherein the data acquisition module is used for acquiring the characteristic condition quantities of the information communication equipment, and storing the characteristic condition quantities in a database; the condition evaluation module is used for performing condition evaluation on the information communication equipment according to the characteristic condition quantities, the preset basic data and the evaluation criterion of the information communication equipment; the monitoring and early warning module is used for judging whether early warning is performed or not according to a condition evaluation result, and sharing corresponding monitoring and early warning module information for an external information distributing platform to call; the risk evaluation module is used for performing risk evaluation on the equipment according to the condition evaluation result and preset risk evaluation parameters; the decision making suggestion module is used for generating a maintenance strategy by taking the condition evaluation as the basis through combining the risk evaluation conclusion, and generating a protection equipment maintenance schedule upon the maintenance strategy and the maintenance schedule of primary equipment.

Owner:STATE GRID CORP OF CHINA +2

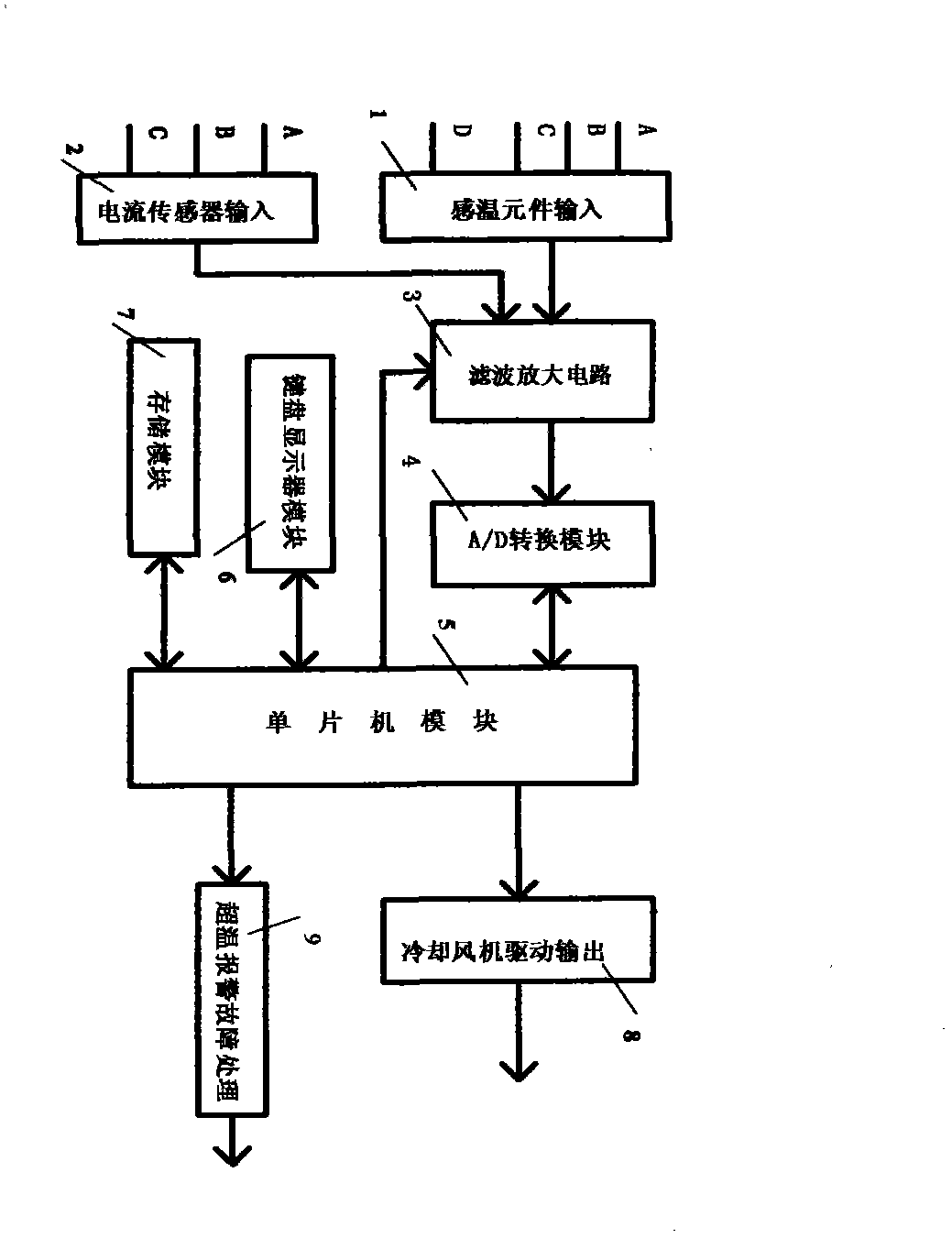

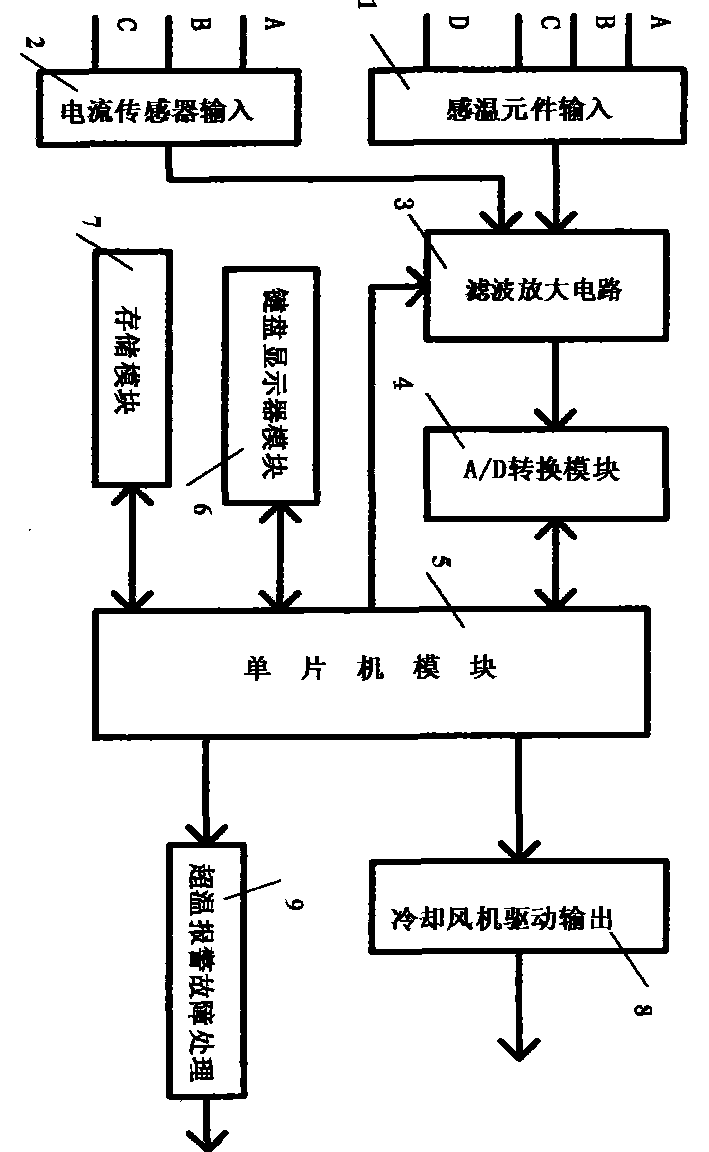

Temperature display controlling device for dry-type transformer

The invention relates to a temperature display controlling device for a dry-type transformer, which is used for temperature display, opening and closing of a cooling fan, as well as overheating and over-temperature alarm and troubleshooting during the site operation, and particularly relates to the device used for detecting temperature time constant variation as well as storing and displaying data of a dry-type transformer switched in a power network. The temperature display controlling device is used for judging the operation condition of the dry-type transformer, capturing failure forewarning information and realizing condition-based maintenance.

Owner:QINGDAO SHENGPING ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com