Health assessment and fault diagnosis method for rotating machinery based on fisher discriminant analysis and mahalanobis distance

A technology of Mahalanobis distance and discriminant analysis, applied in the testing of machine/structural components, special data processing applications, measuring devices, etc., can solve problems such as poor evaluation effect and poor robustness, and achieve reduced dependence and high engineering application performance, improved versatility and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

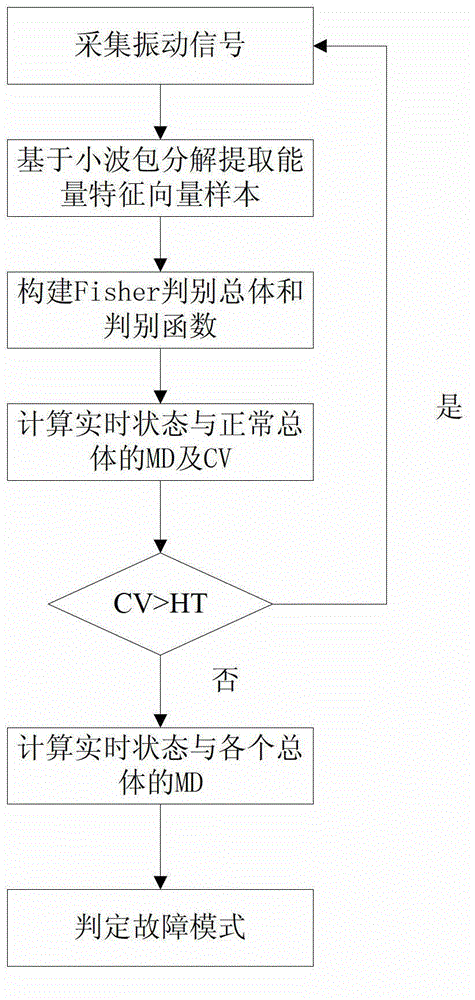

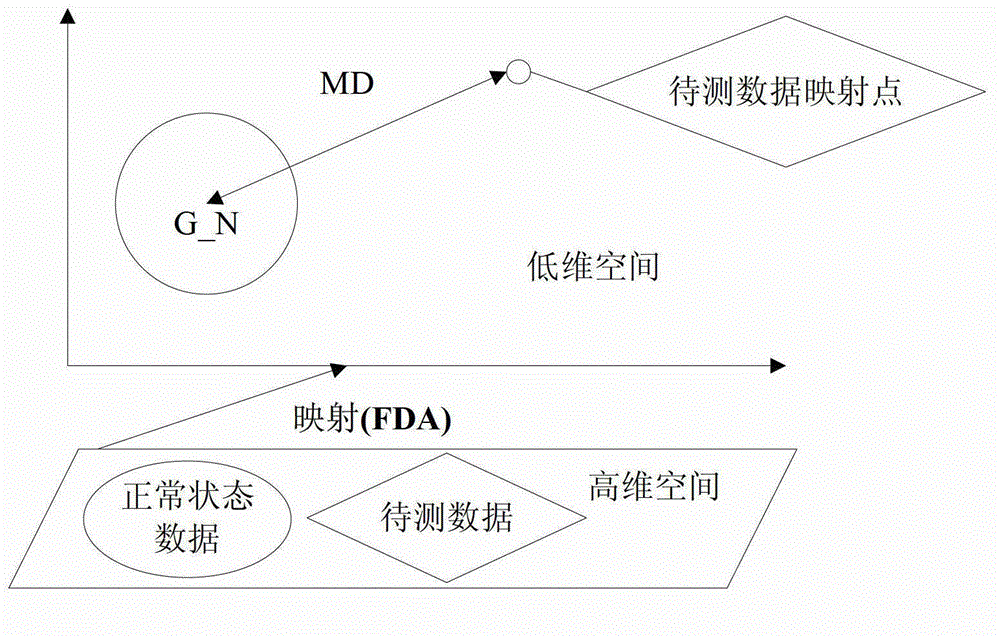

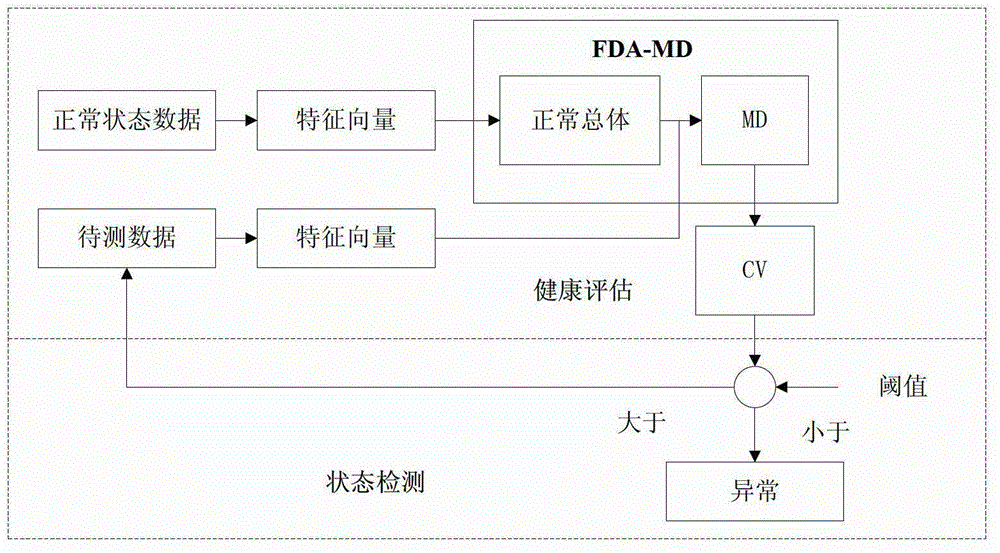

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Hydraulic pump health assessment and fault diagnosis.

[0061] The hydraulic pump is the core of the entire hydraulic system, and its working state directly affects the operating state of the entire hydraulic system. Therefore, the health status assessment and fault diagnosis of hydraulic pumps are of great significance. In this example, a hydraulic pump (SCY type axial piston pump) is used for verification. Inject two typical faults (ball head looseness, valve plate wear) respectively, collect vibration signals through acceleration sensors under normal and two fault states, set the shaft speed to 528r / min, and the sampling frequency to 1000HZ. Adopt the method provided by the present invention to carry out hydraulic pump health status assessment and fault diagnosis below:

[0062] Step 1. Energy features are extracted based on wavelet packet decomposition.

[0063] When the hydraulic pump is in the normal state and the ball head is loose and the valve p...

Embodiment 2

[0076] Example 2: Bearing Health Assessment and Fault Diagnosis

[0077] Bearings are typical important parts of rotating machinery equipment, and the failure of bearings will cause a series of damage to machinery equipment, resulting in safety, mission, and economic impacts. Therefore, the health status assessment and fault diagnosis of bearings are very important. In this example, the bearing (model 6205-2RS JEM SKF) test bench is used for verification. The test bearing supports the entire shaft, and injects a single point fault of 7 mils into the inner ring, outer ring, and rolling body through electrical separation. Under four states (normal, inner ring fault, outer ring fault, rolling element fault), the vibration signal is collected through the acceleration sensor, the shaft speed is set to 1750R / MIN, and the sampling frequency is 12000HZ.

[0078] Step 1. Energy features are extracted based on wavelet packet decomposition.

[0079] When the bearing is normal and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com