Motion control and vibration control experimental system for flexible cantilever beam in noninertial system

A flexible cantilever and motion control technology, applied in the field of mechanical engineering, can solve problems such as the inability to realize the active control of vibration, the inability to realize the motion control and precise positioning of the flexible beam, and the inability to apply the experimental research of the rotating flexible beam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

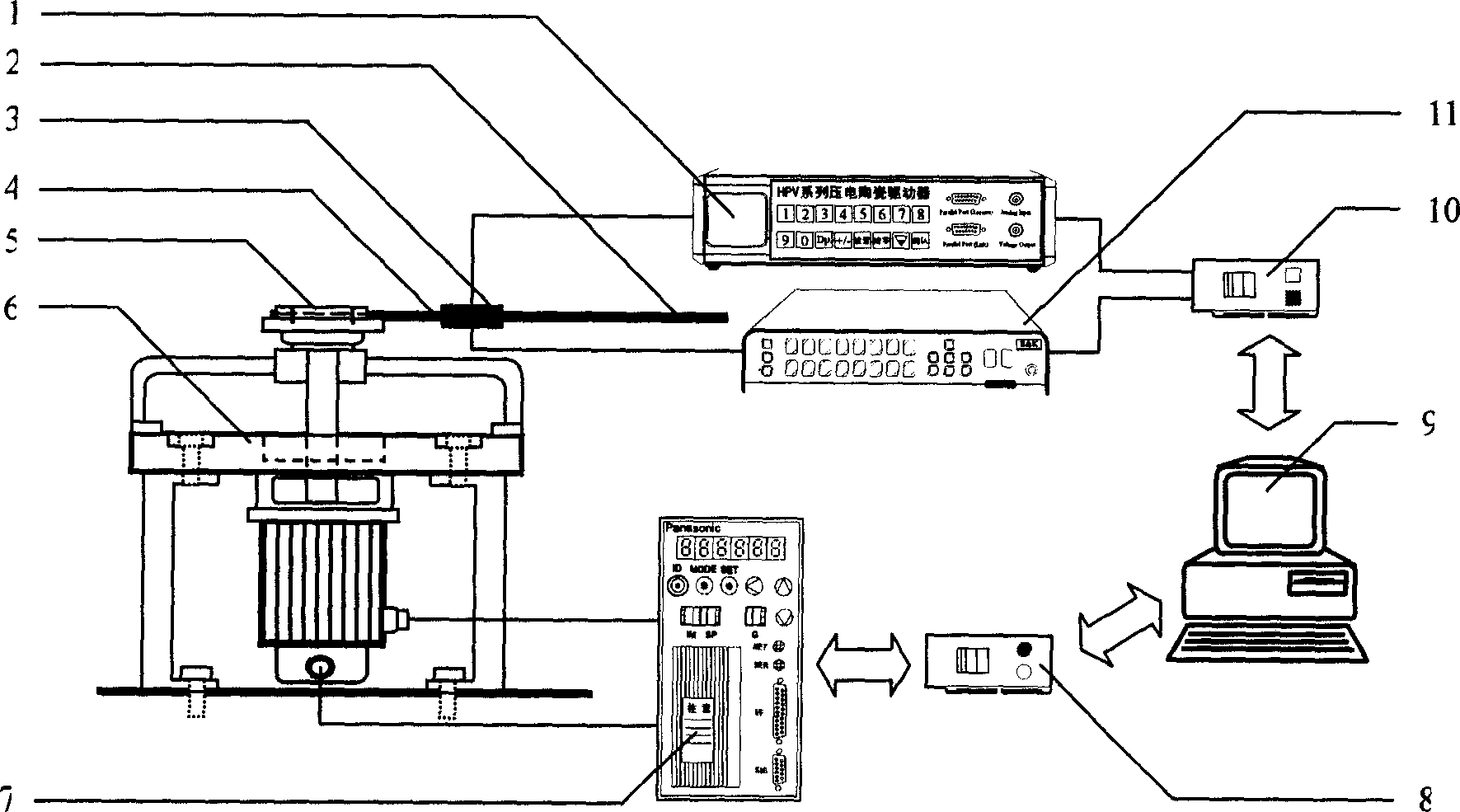

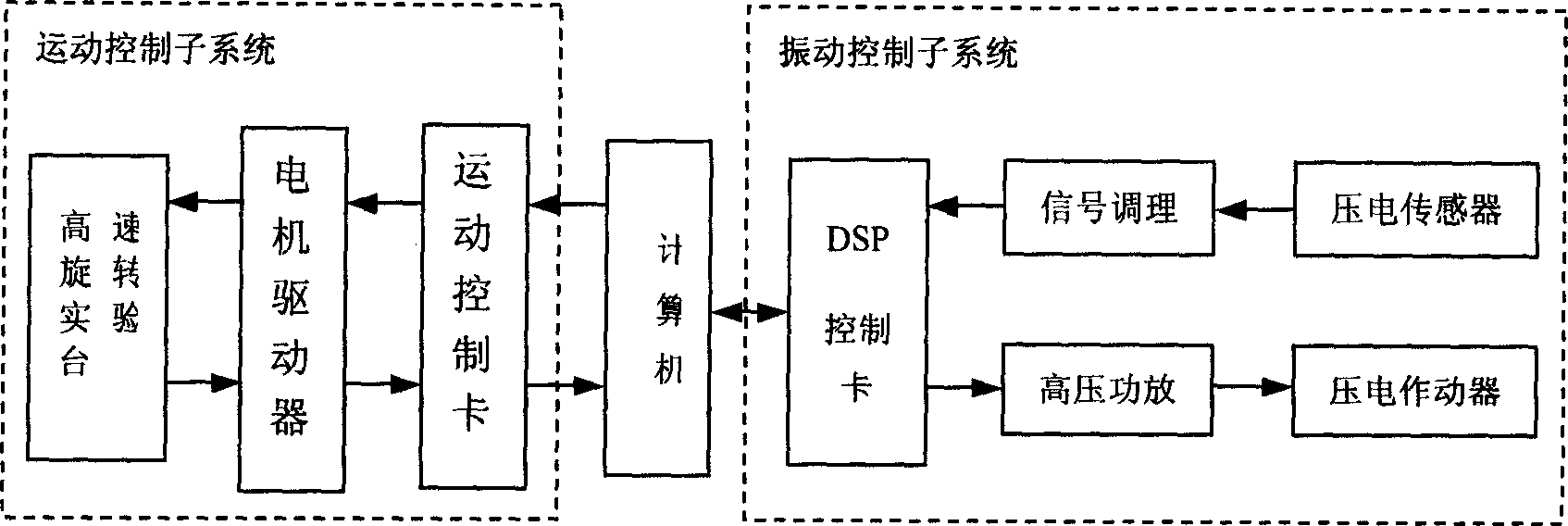

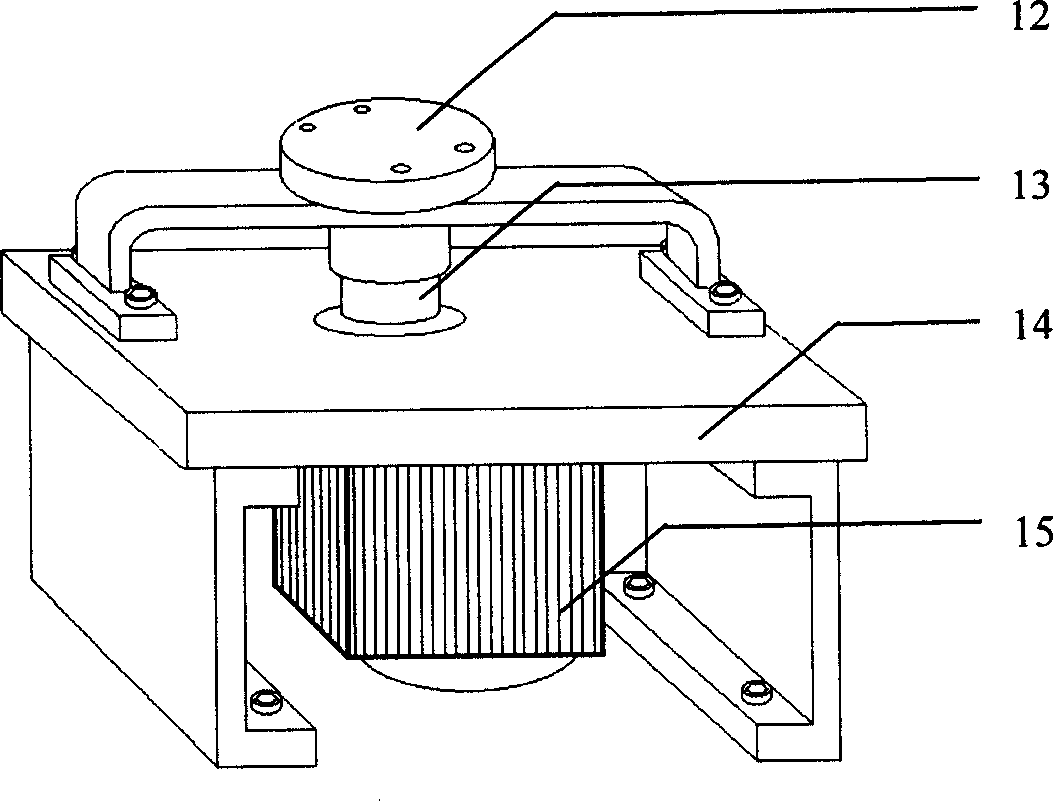

[0013] Such as figure 1 As shown, the present invention includes: a high-voltage power amplifier 1, an aluminum beam 2, a piezoelectric actuator 3, a piezoelectric sensor 4, a fixture 5, a high-speed rotating test bench 6, a motor driver 7, and a motor motion control card 8 based on a PCI bus , computer 9, DSP control card 10 and signal conditioning amplifier 11 based on PCI bus. The piezoelectric sensor 4 and the piezoelectric actuator 3 are pasted on the aluminum beam 2, and are set on the high-speed rotating test bench 6 through the fixture 5. The analog output terminal of the DSP control card 10 is connected to the analog input terminal of the high-voltage power amplifier 1, and the high-voltage power The voltage output terminal of the amplifier 1 is connected to the electrode of the piezoelectric actuator 3, the electrode of the piezoelectric sensor 4 is connected to the analog input terminal of the DSP control card 10 through the signal conditioning amplifier 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com