Method and device for measuring levels of cast-iron and slag in a blast furnace

A blast furnace, horizontal technology, applied in the level and slag level, strain gauge sensor field, can solve the problem of inaccurate measurement, not allowing measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

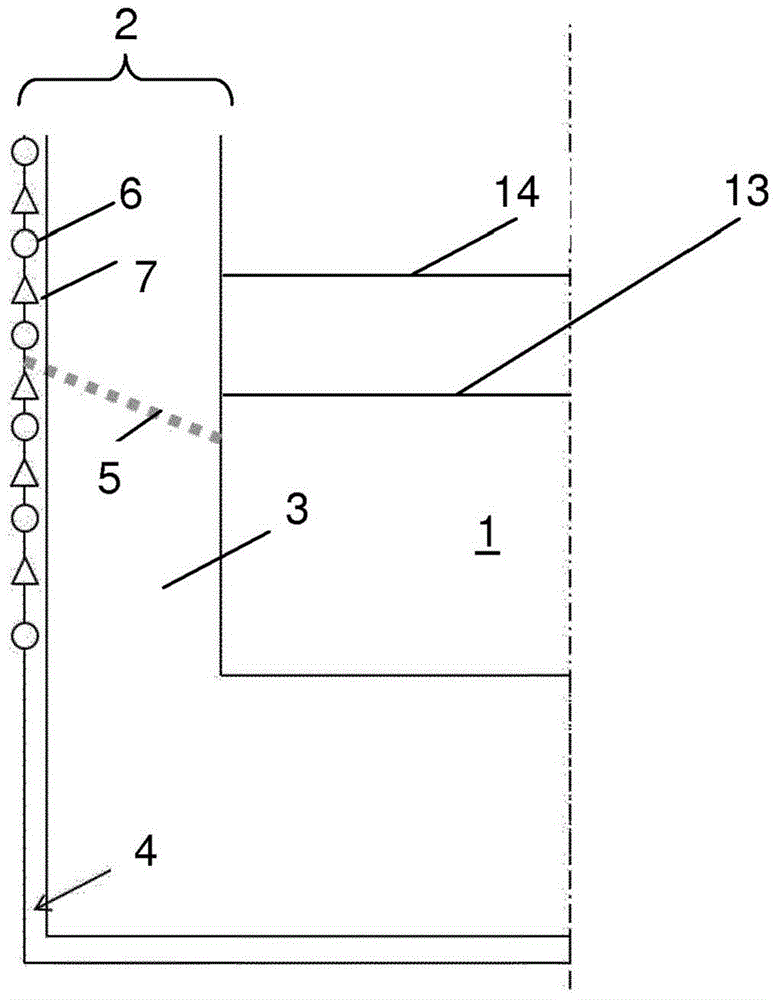

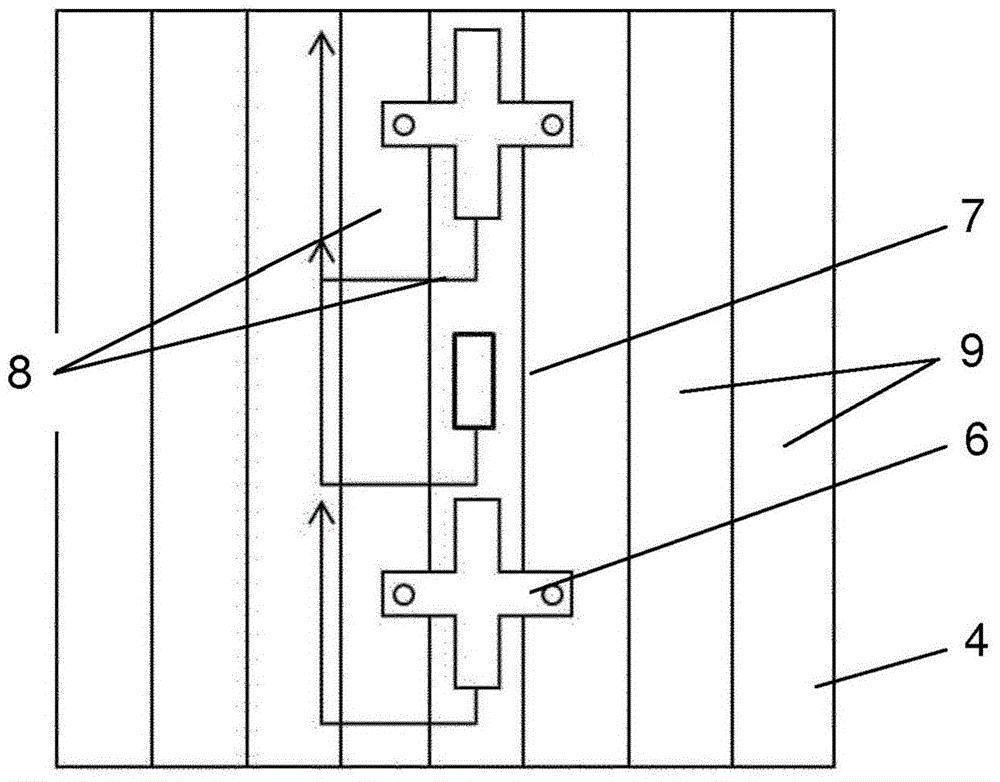

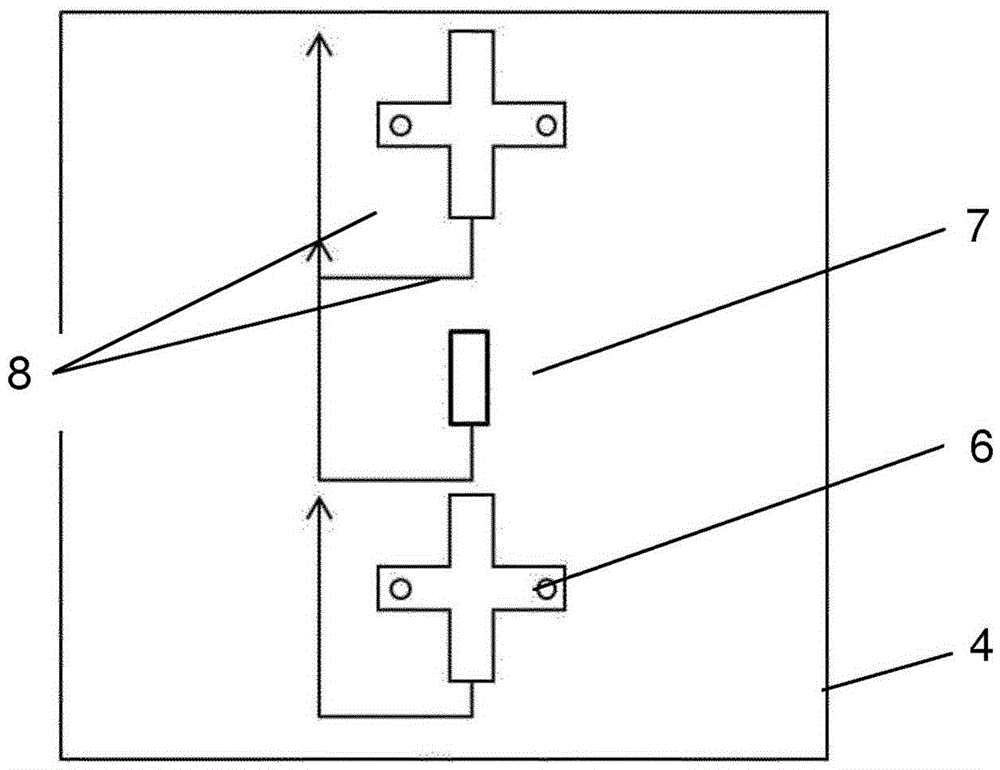

[0056] figure 1 is a schematic view in vertical section of the wall 2 of the hearth 1 of a blast furnace. The wall consists of refractory material 3 and steel shields 4 . According to a preferred embodiment of the device according to the invention, the steel shield of the outer wall is equipped with strain gauge sensors 6 , indicated by circles, arranged alternately with thermal sensors 7 , indicated by triangles. figure 1 A non-limiting example with six strain gauge sensors 6 and five thermal sensors 7 attached to the outer surface of the steel shield 4 is shown. The position of the outflow hole 5 is also shown.

[0057] At high temperatures in the hearth 1, the refractory material 3 may soften and / or be subject to erosion and corrosion. Without a cooling system, they have a limited lifespan. Cooling is achieved by circulating water through plates and pipes enclosed in the walls of the blast furnace. The hearth 1 of the blast furnace can be cooled by flowing water throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com