Intelligent anchorage device and method for testing axial force of anchor rod by using intelligent anchorage device

An anchorage, intelligent technology, applied in the direction of measuring force, installing anchor rods, measuring devices, etc., can solve problems such as increasing the amount of earthwork excavation, hidden dangers in engineering safety, expensive dynamometers, etc., to achieve good response and ensure The effect of project safety and project cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

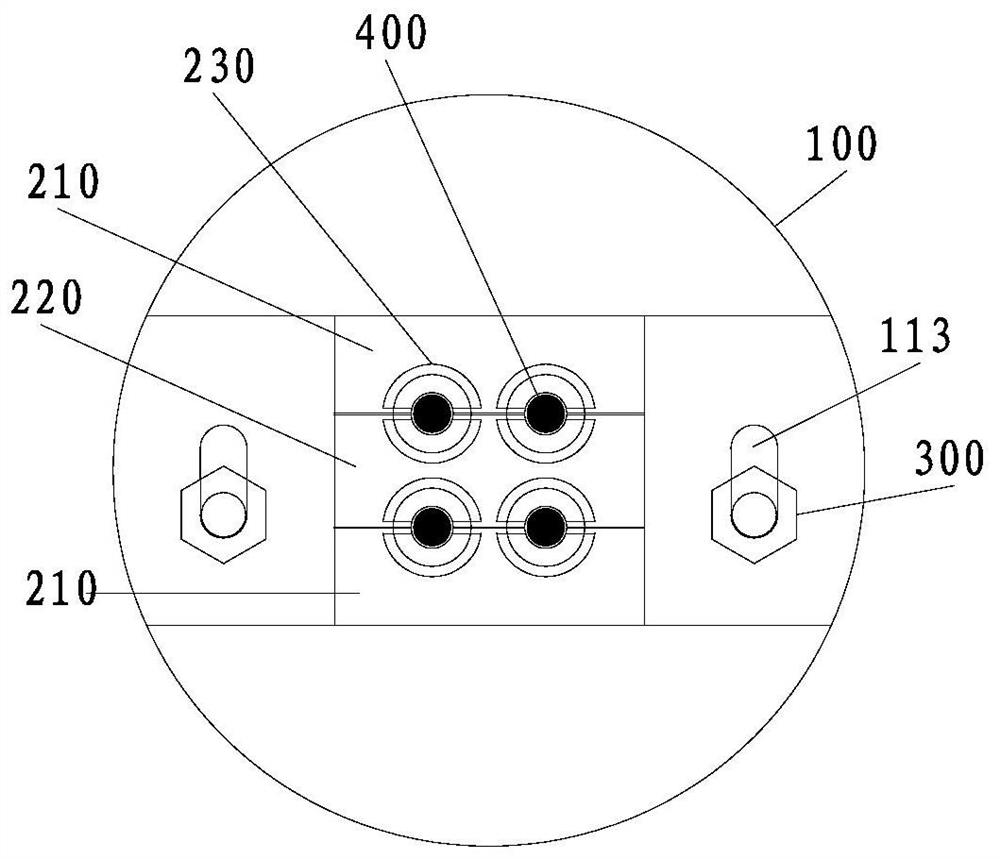

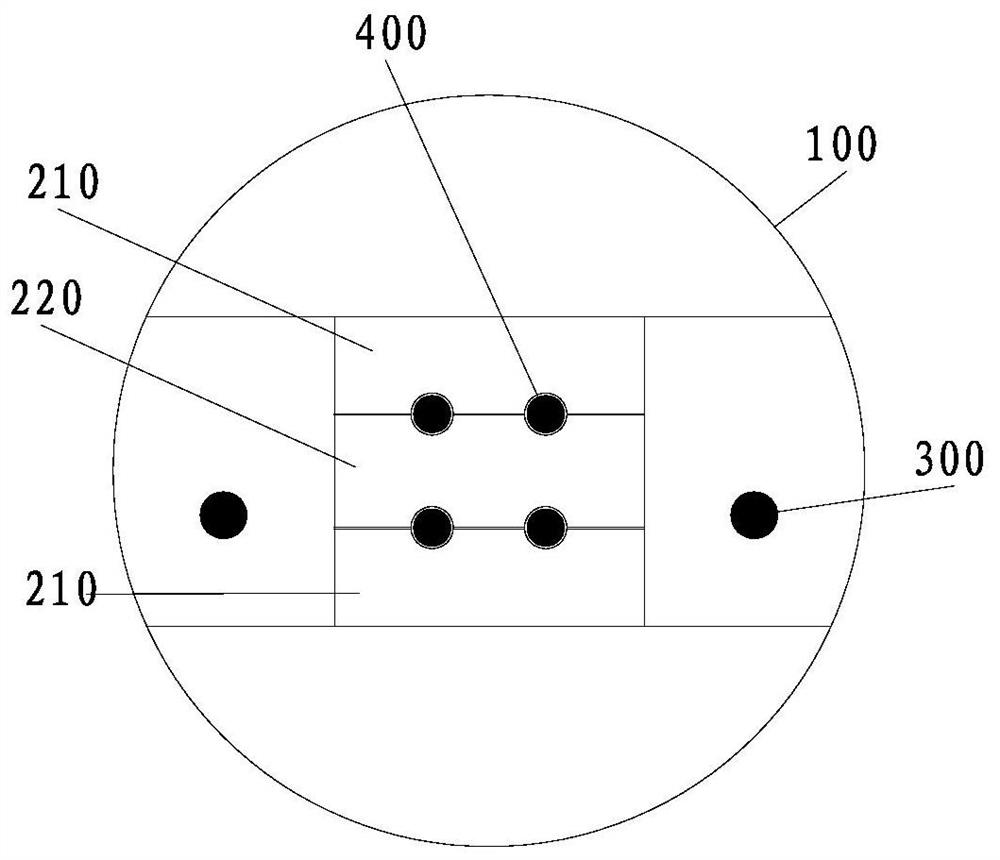

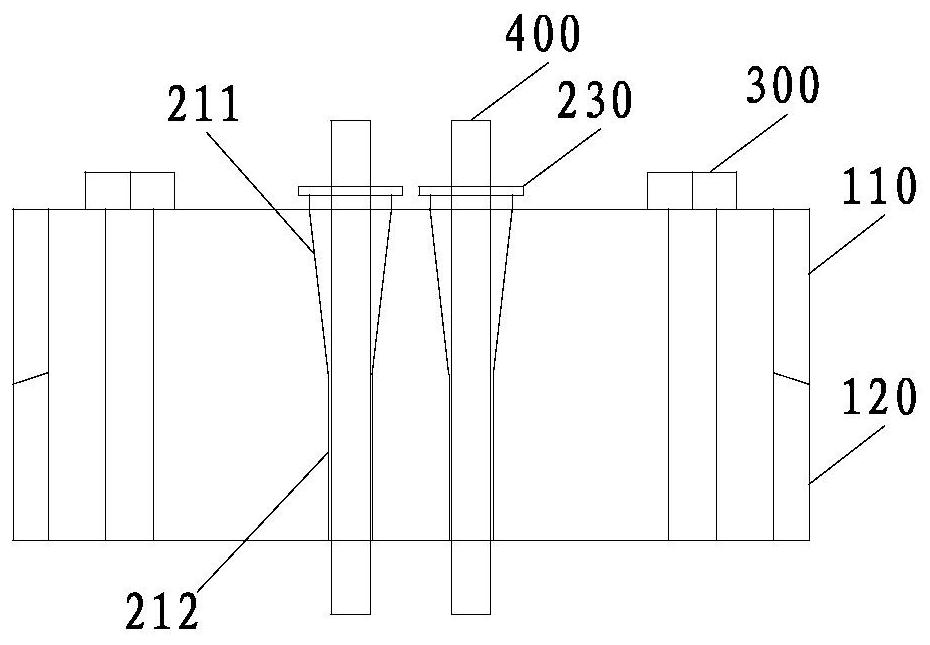

[0091] refer to Figure 1 to Figure 39 , the present invention firstly proposes a self-unlocking anchor for recoverable anchor rods, specifically referring to Figure 1 to Figure 22 , comprising an anchor ring 100, a split anchor 200 for clamping an anchor steel strand, a clip 230 and a T-shaped screw 300. In an embodiment, the anchor steel strand is a steel strand 400, and the anchor ring 100 Set outside the split anchor 200. The anchor ring 100 includes a first anchor ring 110 and a second anchor ring 120, the first anchor ring 110 includes an upper end ring 114 and two upper wedge platforms 111 separately arranged on the upper side of the upper end ring 114, the two Each upper wedge platform 111 is provided with a continuous elongated unlocking groove 113 , the unlocking groove 113 penetrates from the upper end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com