Forming explosive friction testing system and testing method thereof

A technology for testing systems and explosives, which can be used in measuring devices, instruments, and mechanical devices, etc., and can solve problems such as small scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of the present invention is to provide a shaped explosive friction testing system, in order to quantitatively analyze the influence of external friction conditions on the friction coefficient under high pressure and high speed conditions, and improve the application range and numerical simulation accuracy of the friction testing system. Another core of the present invention is to provide a testing method based on the testing system.

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

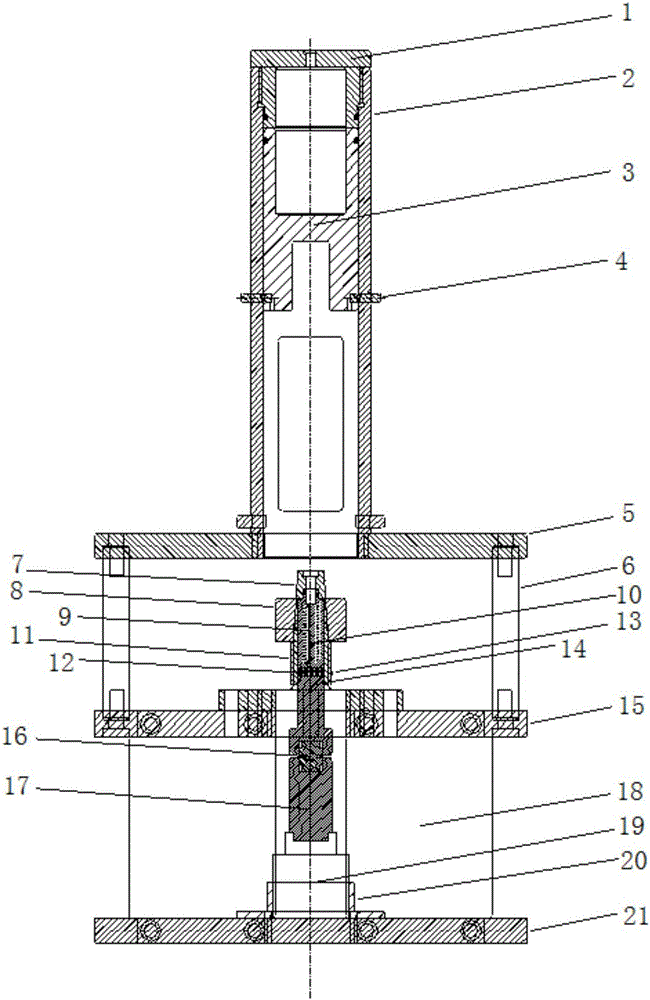

[0027] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the shaped explosive friction testing system provided by the present invention.

[0028]In a specific embodiment, the present invention provides a shaped explosive friction testing system com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com