Test device and test method for measuring circumferential tensile property of composite material pipe for structural engineering

A composite material and structural engineering technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, analyzing materials, etc., can solve problems such as poor adaptability, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be described in further detail below in conjunction with specific embodiments.

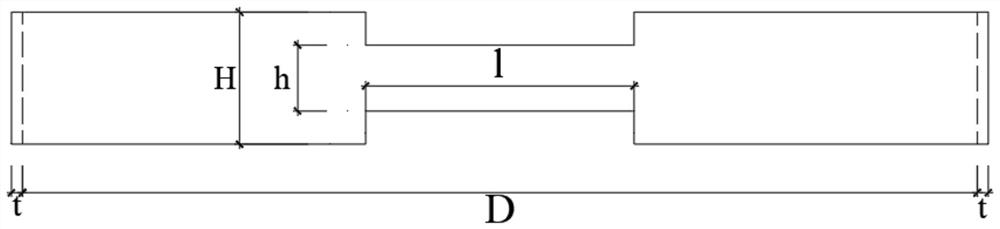

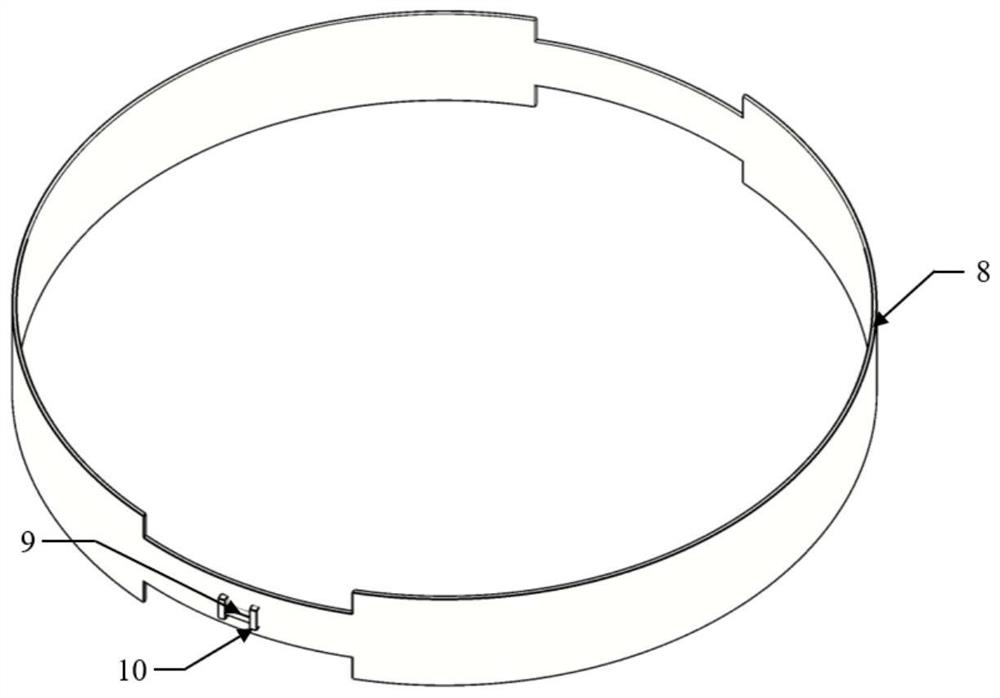

[0089]A test device for measuring the hoop tensile properties of composite material pipes for structural engineering, including two tensile arc-shaped steel blocks, two fixed arc-shaped steel blocks, four screws, connecting nodes, two connectors, and two support rods , traction mechanism, axial strain gauge, and ring strain gauge; the four screws are all fixed to the connection nodes, and the four screws are distributed in a cross shape; one end of the connector is a screw, and the other end of the connector is a nut; two fixed arcs The inner surface of the steel block is provided with threaded holes, the screw end of the connecting piece is threadedly connected with the threaded hole of the fixed arc-shaped steel block, the nut end of the connecting piece is threadedly connected with the screw rod, and the two connecting pieces are arranged in a line; one end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com