Method for monitoring sleeve circumferential strain by using optical fibre grating sensor

A fiber grating and circumferential strain technology, applied in the direction of optical devices, measurements, instruments, etc., can solve problems such as corrosion, inaccurate casing circumferential strain signals, and susceptibility to downhole electromagnetic interference, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

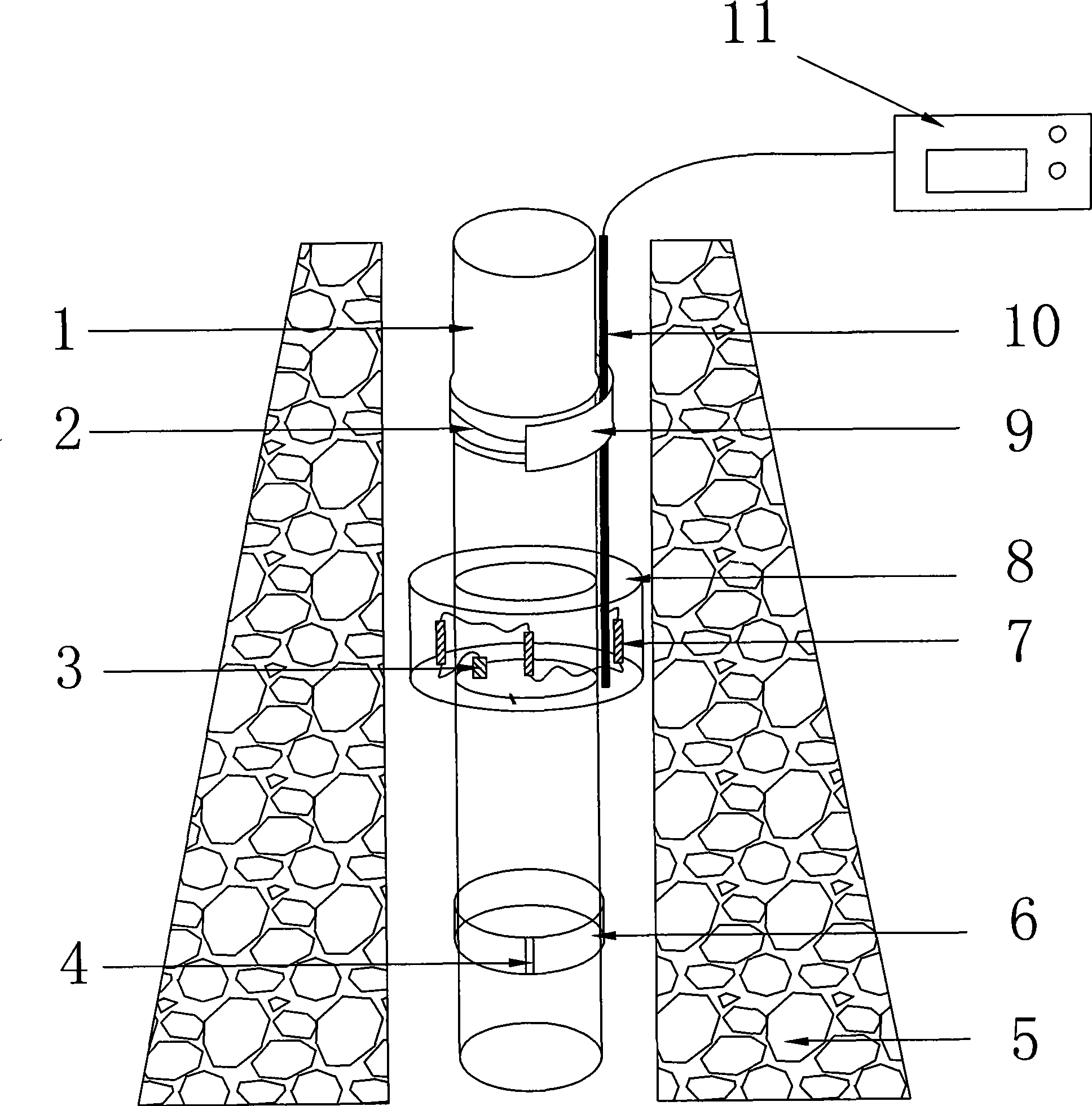

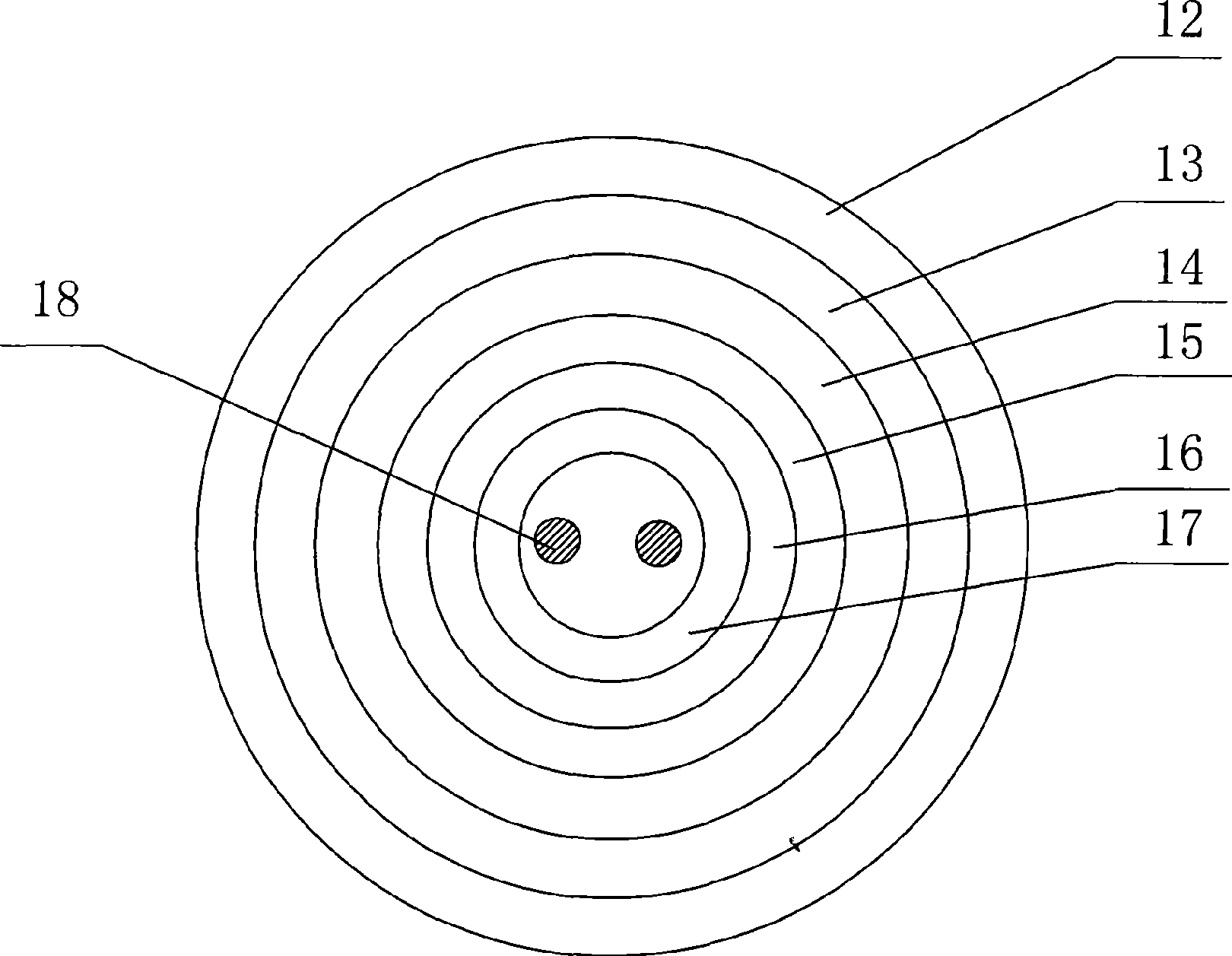

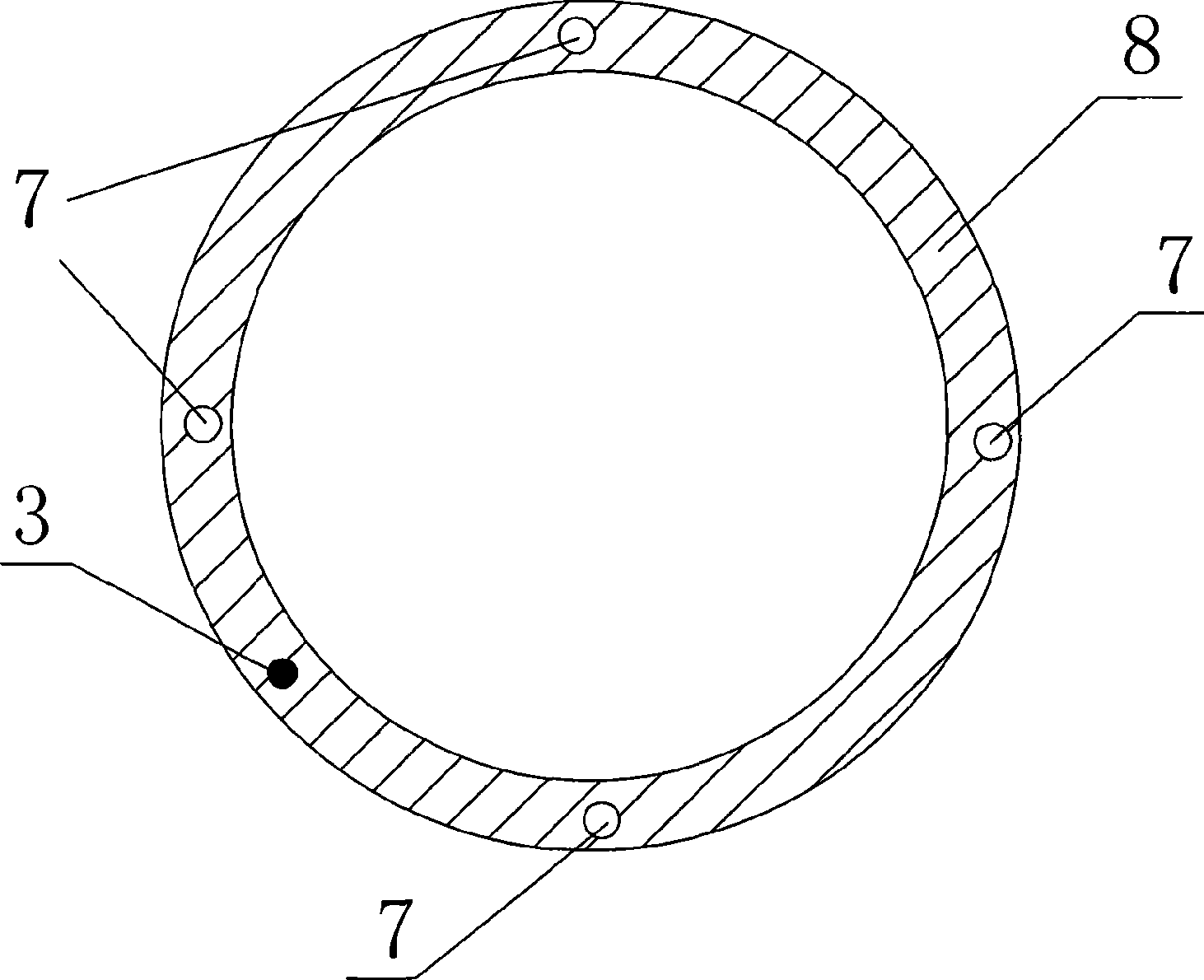

[0030] The present invention will be further described below in conjunction with accompanying drawing:

[0031] The method described in the present invention is to apply the optical fiber grating sensor principle, and arrange the optical fiber grating sensor along the circumferential direction of the casing outside the surface of the preset casing in the section where the casing loss occurs frequently. Wherein a plurality of bare fiber grating sensors are evenly distributed around the casing, and adjacent interval sections form a certain angle. Arrange fiber optic temperature compensation sensors at corresponding distances from this group of sensors. The fiber grating sensor is used to monitor the micro-deformation of the casing and its stress within a certain range from the sensor, and the temperature compensation sensor is used as the temperature compensation of the strain sensor and downhole temperature monitoring. The sensor transmits the underground signal to the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com