Process for production of seamless metal pipe by cold rolling

A technology of seamless metal pipes and cold rolling mills, applied in the direction of metal rolling, etc., can solve the problems of unproposed high-quality seamless steel pipes, and achieve the effect of suppressing inner surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

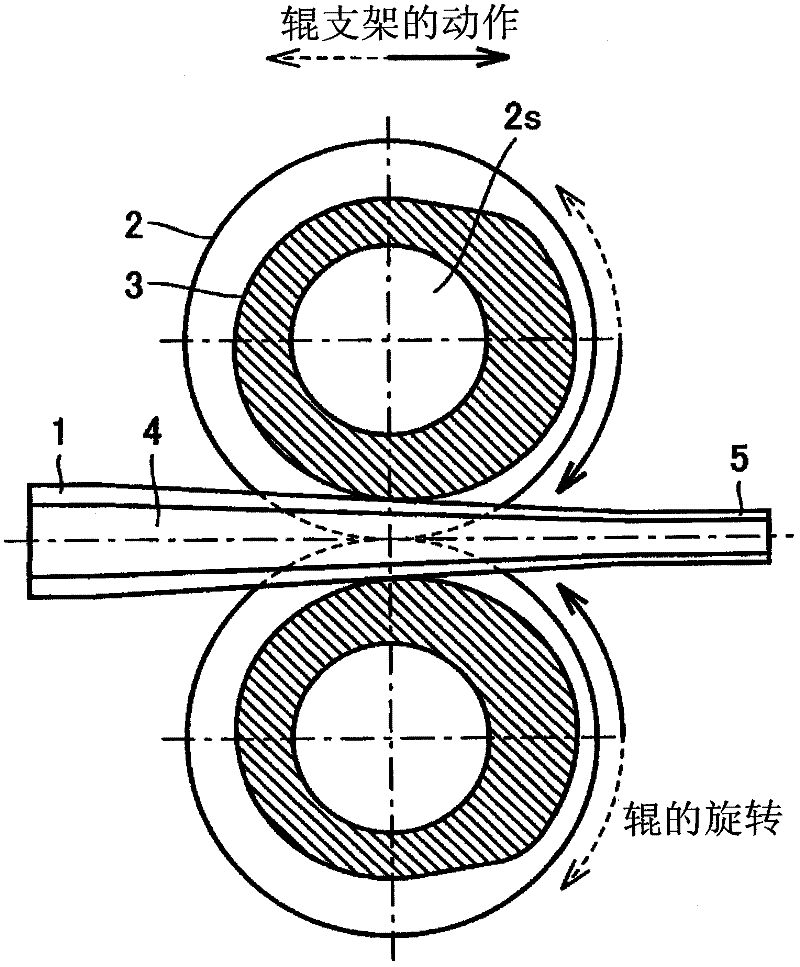

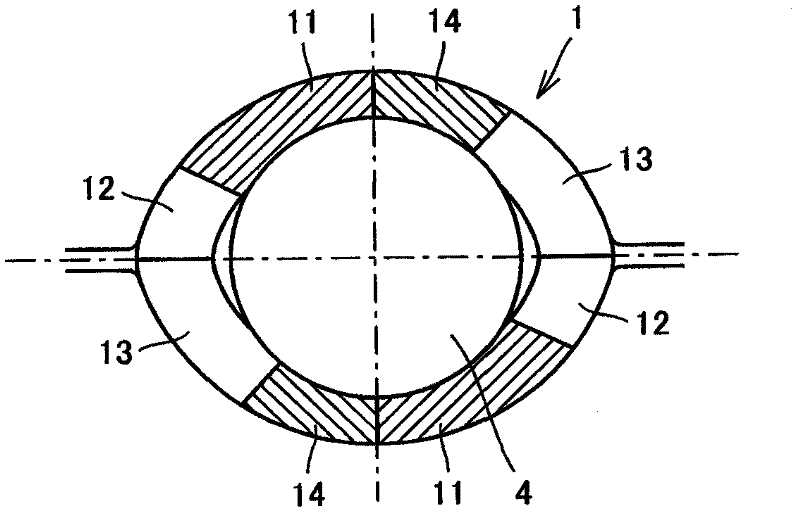

Method used

Image

Examples

Embodiment 1

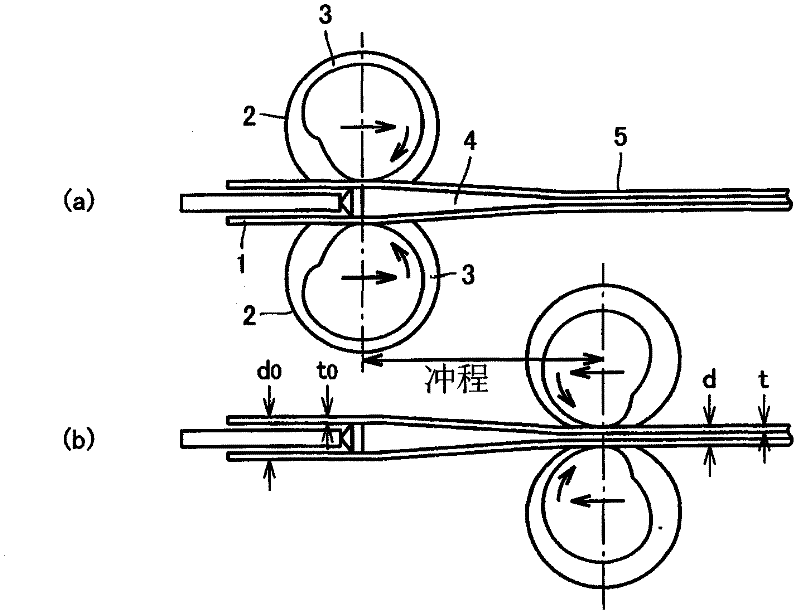

[0045] The 25Cr-30Ni-3Mo high-alloy steel pipe with an outer diameter of 50.8mm and a wall thickness of 5.5mm produced by hot extrusion was used as the test tube billet, and the test tube billet was reduced in diameter and rolled into an outer tube billet by a Pilger cold rolling mill. The diameter is 38.1mm and the wall thickness is 2.4mm. Feed and turn angles are assigned at the start of the stroke. The experimental conditions are summarized as follows.

[0046] Diameter of conical mandrel: dm=39.6~33.1mm (with conical surface)

[0047] Feed to the stroke (feed): f = 8.0mm

[0048] Rotation angle (rotation angle) of the stroke: θ=60°

[0049] Tube blank size: do×to=50.8mm×5.5mm

[0050] Processing size: d×t=38.1mm×2.4mm

[0051] Diameter reduction ratio: d / do=0.75

[0052] Stretch ratio: to(do-to) / t(d-t)=2.91

[0053] Wall thickness / outer diameter ratio: t / d=0.063

[0054] Outer diameter reduction rate / wall thickness reduction rate ratio: Rd / Rt=0.46<1 / 2

[0055] Amo...

Embodiment 2

[0059] 25Cr-30Ni- The 3Mo high-alloy steel pipe was used as the test tube billet, and the test tube billet was reduced and rolled to an outer diameter of 41.0mm and a wall thickness of 2.2mm by using a Pilger cold rolling mill. The outer diameter reduction rate of the stretching and shrinking mill was 77% or less. The experimental conditions are summarized as follows.

[0060] The diameter of the tapered mandrel: dm=36.4mm (no tapered surface)

[0061] Feed to stroke: f=8.0mm

[0062] Rotation angle of forward stroke: θ=60°

[0063] Tube size: do×to=48.6mm×6.0mm

[0064] Processing size: d×t=41.0mm×2.2mm

[0065] Diameter reduction ratio: d / do=0.84

[0066] Stretch ratio: to(do-to) / t(d-t)=3.0

[0067] Wall thickness / outer diameter ratio: t / d=0.054

[0068] Outer diameter reduction rate / wall thickness reduction rate ratio: Rd / Rt=0.25<1 / 2

[0069] Among them, the outer diameter reduction rate: Rd={1-(do / d)}×100(%)

[0070] Wall thickness reduction rate: Rt={1-(to / t)}×1...

Embodiment 3

[0073] The 25Cr-30Ni-3Mo with an outer diameter of 101.6mm and a wall thickness of 7.0mm will be produced by a cross piercer, a mandrel mill and a sizing machine using the Mannesmann mandrel rolling process. The high-alloy steel pipe is used as the test tube billet, and the test tube billet is reduced and rolled to an outer diameter of 88.9mm and a wall thickness of 2.8mm by using a Pilger cold rolling mill. The outer diameter reduction rate of the sizing machine is 33% or less. The experimental conditions are summarized as follows.

[0074] The diameter of the tapered mandrel: dm=83.8mm (no tapered surface)

[0075] Feed to stroke: f=10.0mm

[0076] Rotation angle of forward stroke: θ=60°

[0077] Tube blank size: do×to=101.6mm×7.0mm

[0078] Processing size: d×t=88.9mm×2.8mm

[0079] Diameter reduction ratio: d / do=0.88

[0080] Stretch ratio: to(do-to) / t(d-t)=2.8

[0081] Wall thickness / outer diameter ratio: t / d=0.032

[0082] Outer diameter reduction rate / wall thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com