Complete earth pressure balance shield construction soil mass improvement test method

A technology of earth pressure balance shield and test method, which is applied in soil material testing, material inspection products, instruments, etc., can solve the problem of less research on soil pressure distribution and pressure transfer law in soil cabin, and less research on soil performance. , there is no set of test methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

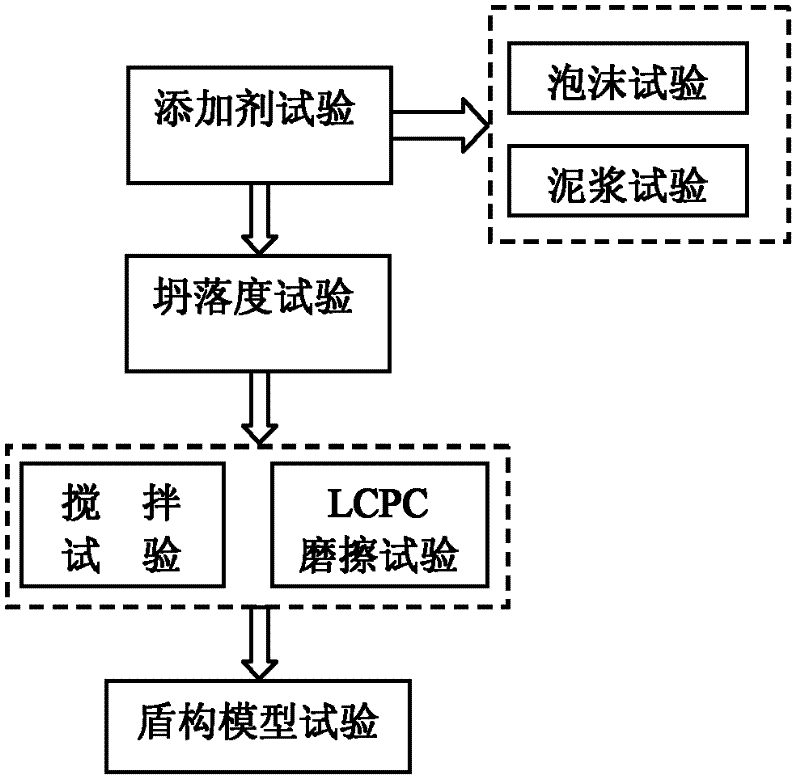

[0036] A set of earth pressure balance shield construction soil improvement test method of the present invention, its implementation steps are as follows:

[0037] Step 1: Additive test. Including foam test and mud test, first use different concentrations of foaming liquid (generally 1%, 2%, 3%, 4%, 5%, 6%) to produce foam, and evaluate the foam performance; secondly, according to the particle size of the soil sample Match curves to prepare mud with different concentrations, so that the fine particles in the soil layer can reach 20% to 30%.

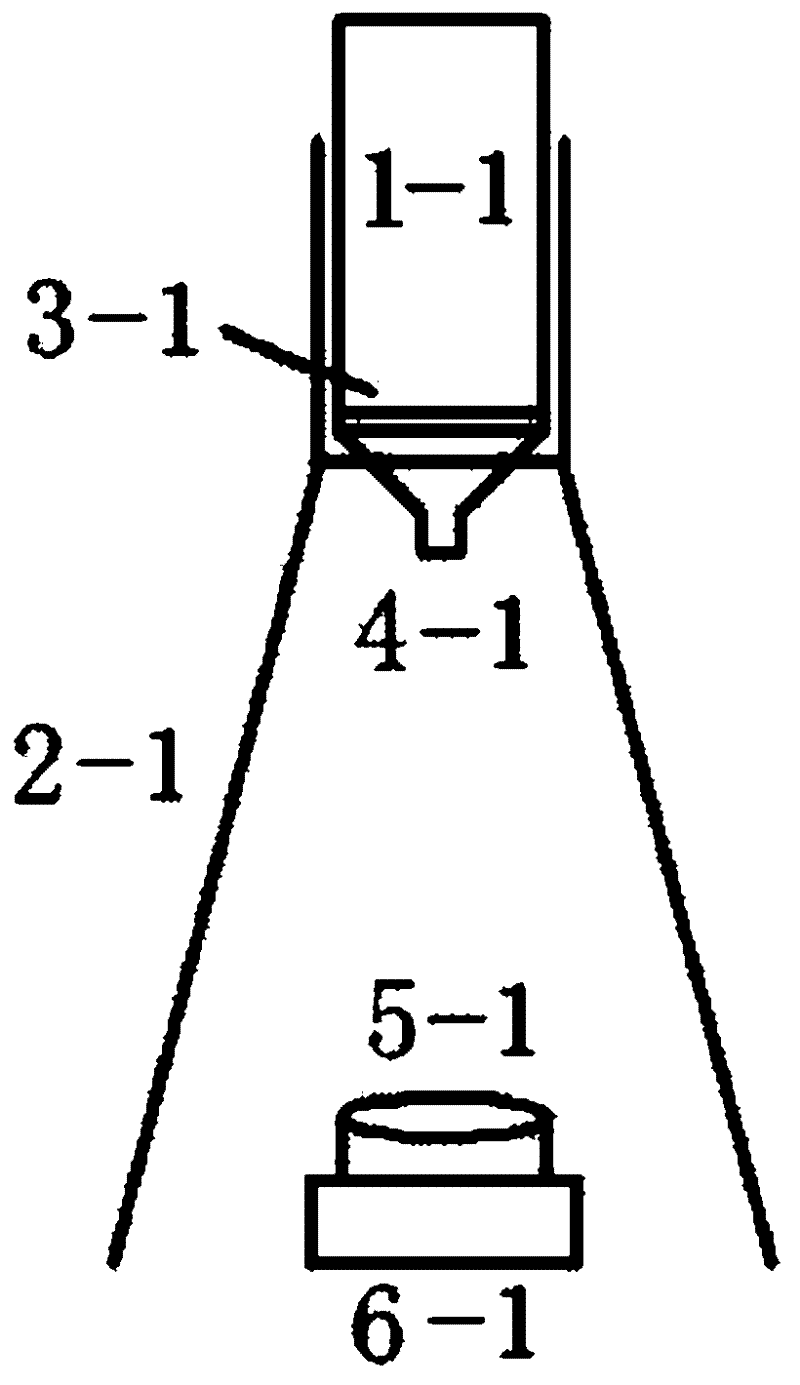

[0038] Use the half-life test rack to measure the expansion ratio and half-life of the foam to evaluate the foam performance, such as figure 2 As shown, the half-life test rack includes a cylinder 1-1, a funnel 4-1, a filter screen 3-1, a tripod 2-1, a container 5-1 and an electronic balance 6-1. The material of the cylinder 1-1 is plexiglass, a container for storing foam, one end of the cylinder 1-1 is connected to the funnel 4-1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com