High-durability floor wax

A technology of floor wax and durability, applied in the direction of water-based dispersant, etc., can solve the problem of poor durability of floor wax, and achieve the effect of preventing damage, improving gloss and good brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

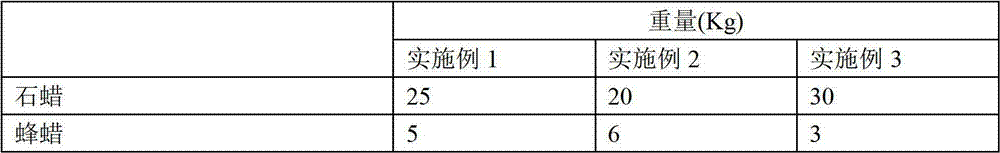

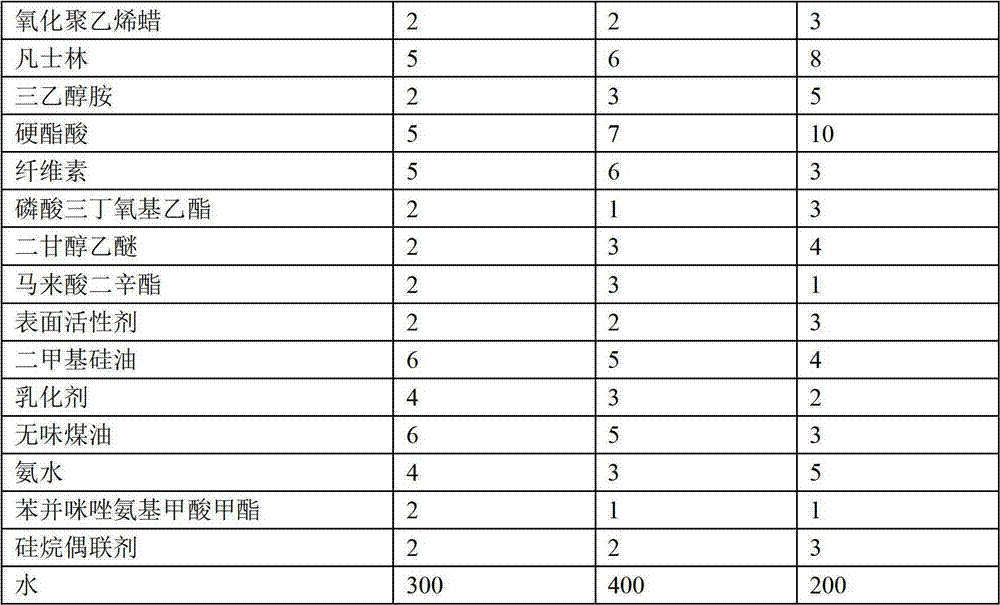

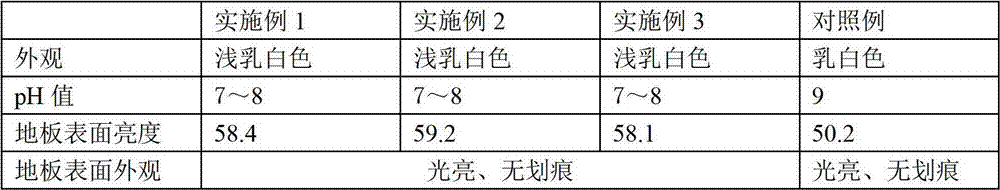

[0018] The components were prepared in the weight ratios shown in Table 1.

[0019] The weight proportion of table 1 embodiment 1~embodiment 3

[0020]

[0021]

[0022] In the above examples, the surfactant is sodium α-olefin sulfonate.

[0023] The concentration of ammonia water is 20%.

[0024] Cellulose adopts hydroxyethyl cellulose.

[0025] The above-mentioned emulsifier adopts Span-80.

[0026] The above-mentioned silane coupling agent uses KH-570.

[0027] The preparation method is:

[0028] S1: Add water, paraffin wax, beeswax, and oxidized polyethylene wax into the reaction kettle, heat up to 80-90°C while stirring, and stir evenly;

[0029] S2: Then add surfactant, stearic acid, and triethanolamine, keep the temperature of the reactor at 80-90°C, and react for 1-2 hours;

[0030] S3: add vaseline, cellulose, tributoxyethyl phosphate, diethylene glycol ethyl ether, dioctyl maleate, simethicone, emulsifier, odorless kerosene, ammonia water, benzimidazole c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com