Riveting production equipment

A production equipment and riveting technology, applied in the field of manufacturing, can solve the problems of explosion, concentration, and damage to surrounding circuits, and achieve the effect of improving the strength of lightning resistance and solving the problem of failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

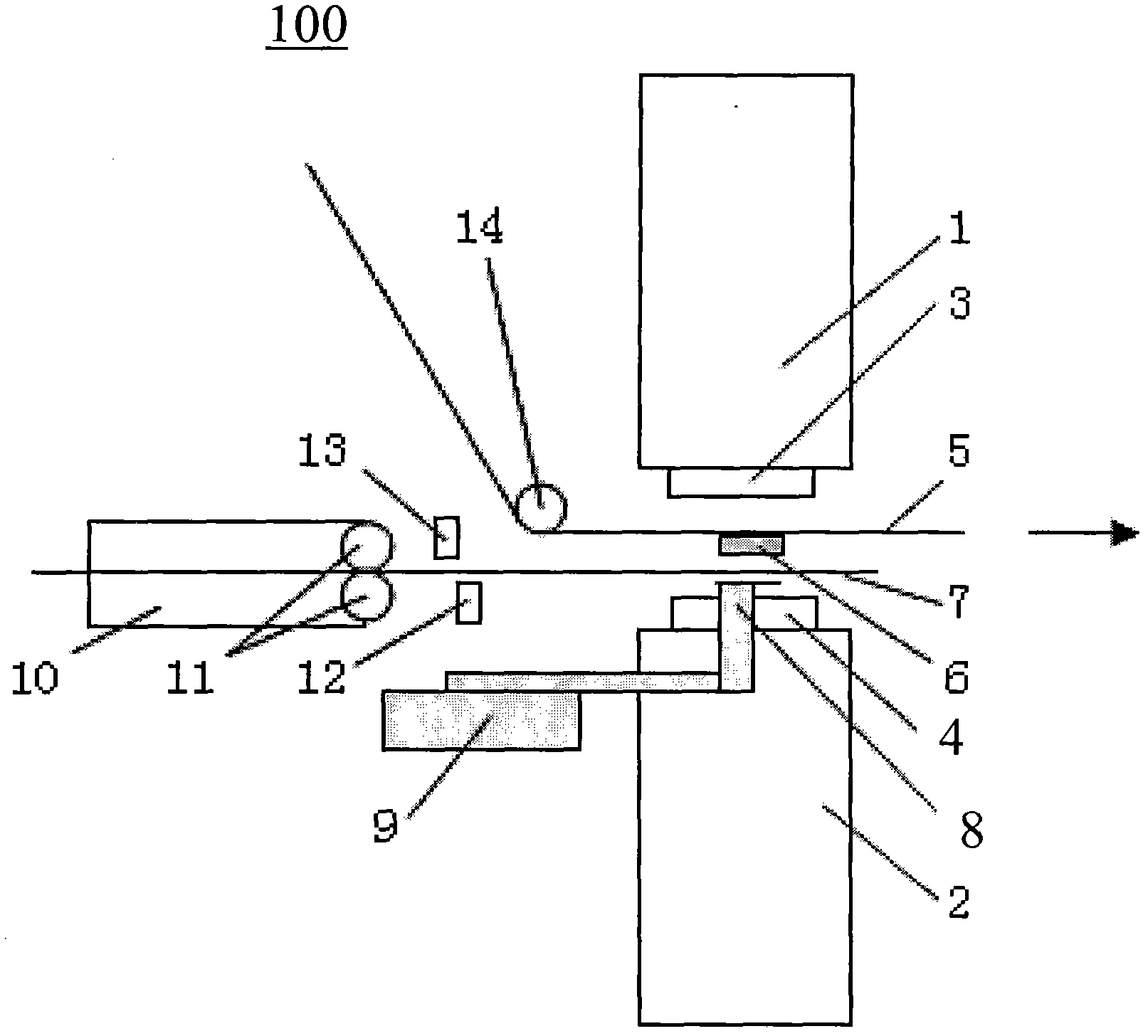

[0013] Please refer to the figure, it is a kind of riveting production equipment 100 provided by the present invention, which includes riveting upper film assembly 1, riveting lower die assembly 2, riveting upper die 3, riveting lower die 4, negative electrode aluminum foil 5, guide foil 6 , pad foil 7, foil guide bracket 8, cylinder assembly 9, feeding assembly 10 provided with feeding master-slave roller 11, pad foil scissors 12, 13 and guide wheel 14 for guiding the negative aluminum foil 5.

[0014] The riveting upper die assembly 1 and the riveting lower die assembly 2 are vertically oppositely arranged, and the riveting upper die 3 and the riveting lower die 4 are arranged opposite to each other with a movable A channel through which the negative electrode aluminum foil passes, and the guide foil 6 is arranged in the channel and under the negative electrode aluminum foil. The riveting lower die assembly 2 is connected with the cylinder assembly 9 , and the foil guide bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com