Two-dimensional micro-force measuring sensors

A technology for measuring sensors and micro-forces, applied in the field of sensors, can solve the problem of low resolution of force measurement, and achieve the effects of easy implementation, simple structure, and guaranteed measurement accuracy and resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

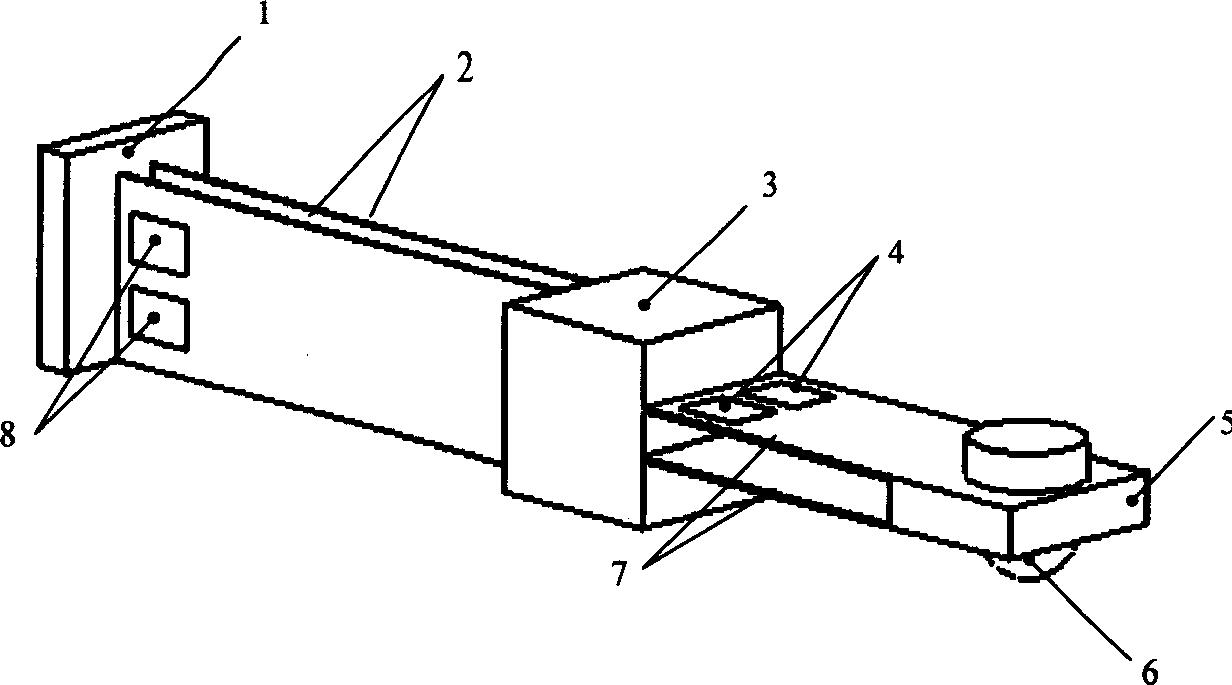

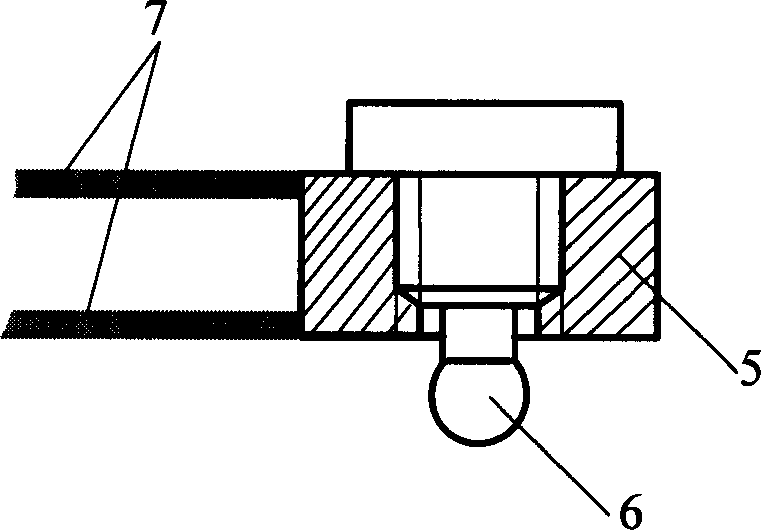

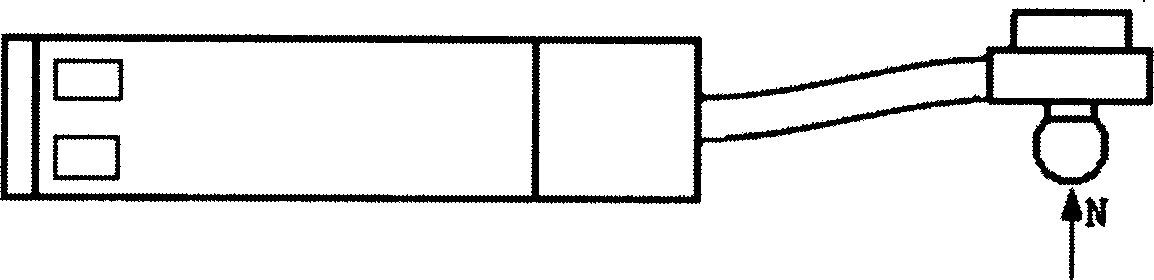

[0015] The two-dimensional micro-force measurement sensor of the present invention adopts an elastic body cantilever structure, such as figure 1 As shown, the vertical curved beam 2 and the horizontal curved beam 7 are respectively composed of two parallel elastic bodies, and the cube connecting block 3 connects the vertical curved beam 2 and the horizontal curved beam 7 perpendicular to each other in the length direction to form the main structure of the cantilever. The other end of the vertical curved beam 2 is connected to the fixed plate 1 to form a fixed constraint, and the other end of the horizontal curved beam 7 forms a cantilever free end. Four strain gauges 4 are symmetrically pasted on the front and back of any one of the horizontal curved beams 7 to form a full bridge circuit, and the position is close to the connecting block 3; another four strain gauges 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com