Method for testing and evaluating antifriction abrasion resistance of lubricating oil by utilizing friction test machine

A friction testing machine, anti-friction and anti-wear technology, which is applied in the direction of mechanical devices, measuring devices, material inspection products, etc., can solve the problem of low accuracy of anti-friction and anti-wear properties of lubricating oil, increased manpower, material and financial resources, and large volume, etc. problems, to achieve the effect of concise and clear test methods, avoiding personnel errors, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

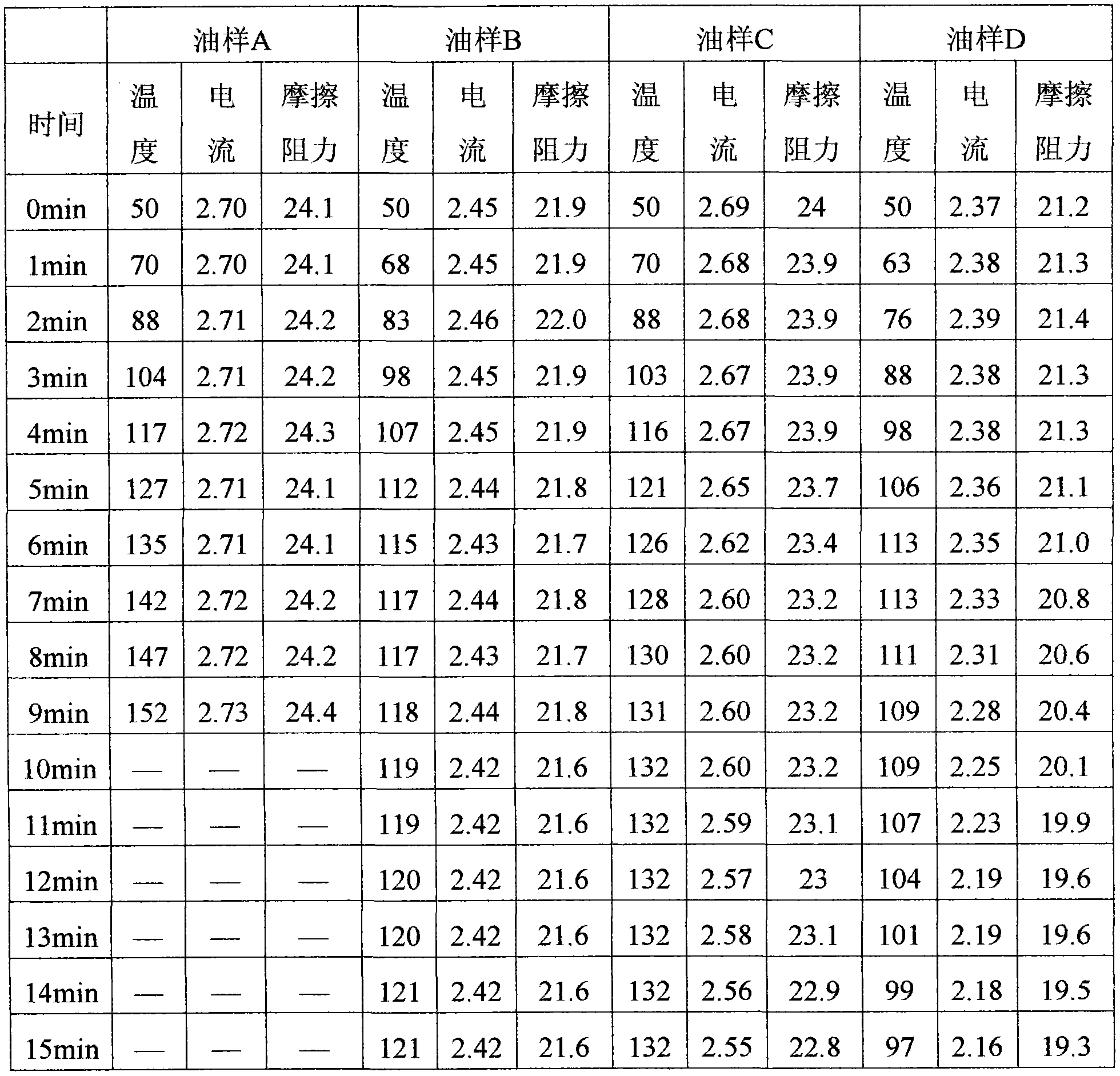

[0084] In this embodiment, the anti-friction and anti-wear performance of the liquid lubricating material is tested.

[0085] Test oil sample A, oil sample B, oil sample C and oil sample D according to the following steps:

[0086] 1) Put the lubricating oil test sample into the oil storage box 11, fix it with clips 18, set the weight load to 5Kg, and set the time to 1-15 minutes. In order to ensure the accuracy of the test, set the initial temperature of the test to 50 ℃;

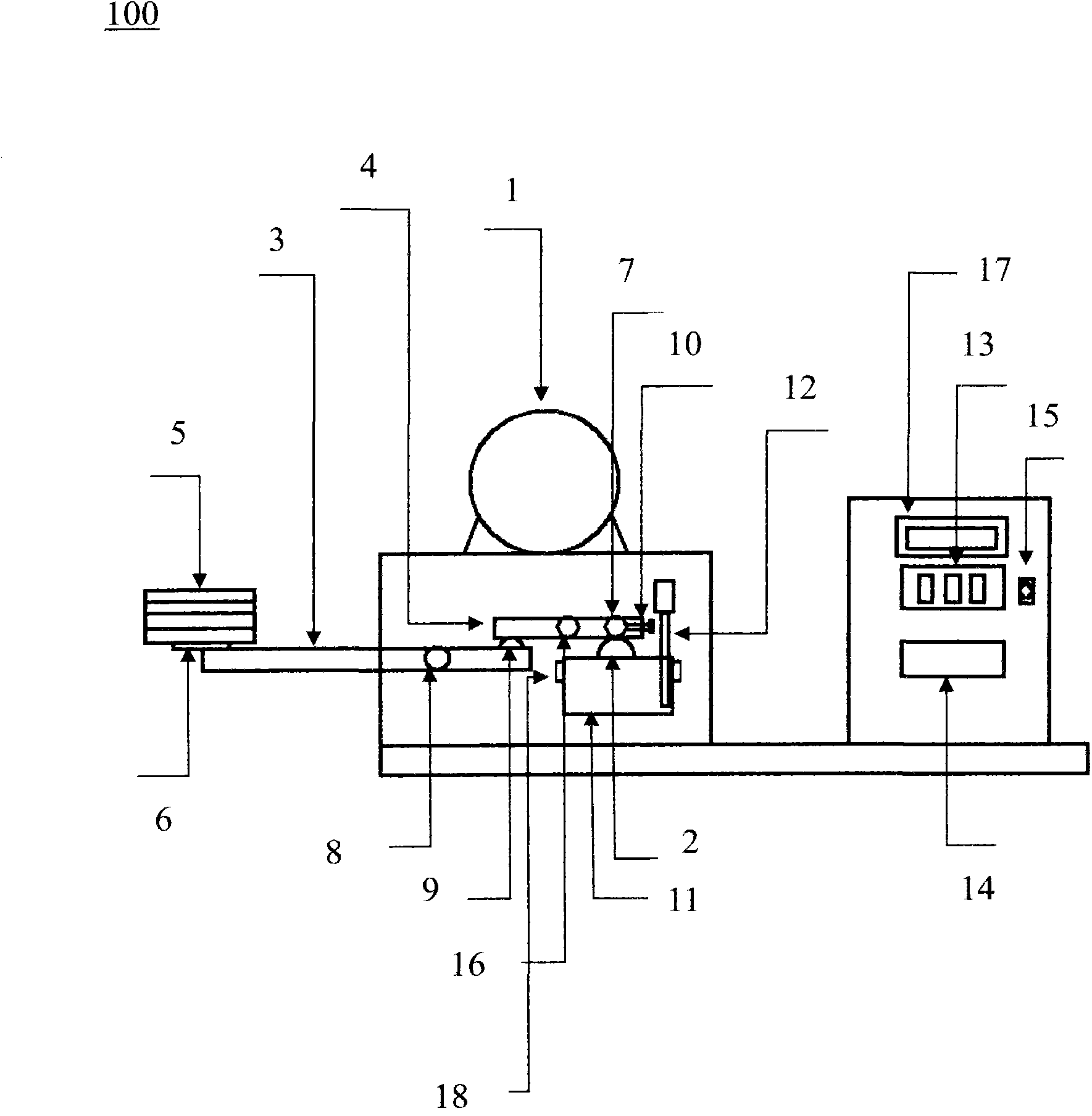

[0087] 2) Press the power switch 15 to start the motor 1, so that the motor 1 drives the rotating friction wheel 2 to rotate, so that the rotating friction wheel 2 and the fixed friction wheel 7 undergo sliding friction, and the heat and resistance generated by the frictional movement pass through the temperature display device 16 And frictional resistance calculation display unit 17 shows;

[0088] 3) Start recording when the temperature reaches 50°C, and record the measurement results of the temperatur...

Embodiment 2

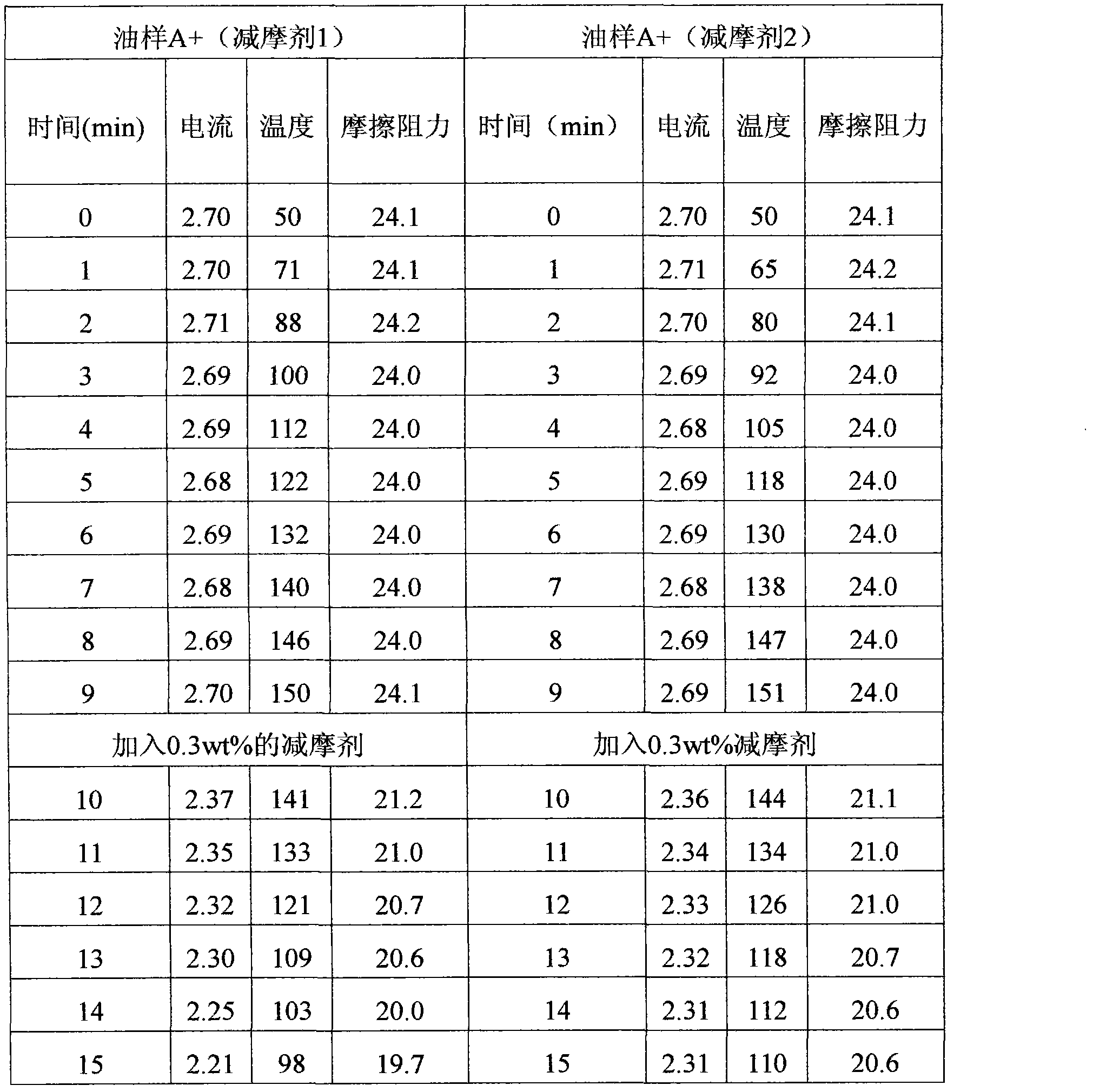

[0102] What this embodiment tests is the anti-friction and anti-wear properties of the anti-friction and anti-wear agent

[0103] Test oil sample A+ (friction reducer 1) and oil sample A+ (friction reducer 2) according to the following steps:

[0104] 1) Put the lubricating oil test sample into the oil storage box 11, fix it with clips 18, set the weight load to 5Kg, and set the time to 1-15 minutes. In order to ensure the accuracy of the test, set the initial temperature of the test to 50 ℃;

[0105] 2) Press the power switch 15 to start the motor 1, so that the motor 1 drives the rotating friction wheel 2 to rotate, so that the rotating friction wheel 2 and the fixed friction wheel 7 undergo sliding friction, and the heat and resistance generated by the frictional movement pass through the temperature display device 13 , the current measuring device 14 and the frictional resistance calculation display unit 17 are displayed;

[0106] 3) start recording when the temperature ...

Embodiment 3

[0119] This embodiment tests the anti-friction and anti-wear properties of the semi-solid lubricating anti-friction material.

[0120] Test semi-solid lubricant sample A and semi-solid lubricant sample B according to the following steps:

[0121] 1) Put the semi-solid lubricant sample into the oil storage box 11, fix it with clips 18, set the weight load to 5Kg, and set the time to 1-15 minutes. In order to ensure the accuracy of the test, set the initial temperature of the test to 50°C;

[0122] 2) Press the power switch 15 to start the motor 1), so that the motor 1 drives the rotating friction wheel 2 to rotate, so that the rotating friction wheel 2 and the fixed friction wheel 7 undergo sliding friction, and the heat and resistance generated by the frictional movement pass through the temperature display device 13. The current measuring device 14 and the frictional resistance calculation display unit 17 are displayed;

[0123] 3) Record the measurement results of the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com