System for accurately testing friction damping

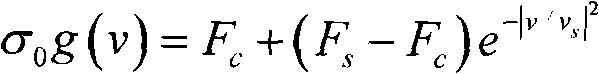

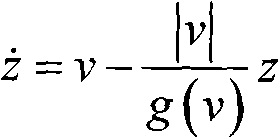

A test system and friction damping technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of low friction test efficiency, inability to perform high-frequency dynamic friction test, poor accuracy, etc., and achieve high reciprocating motion frequency and control accuracy. The effect of high, high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

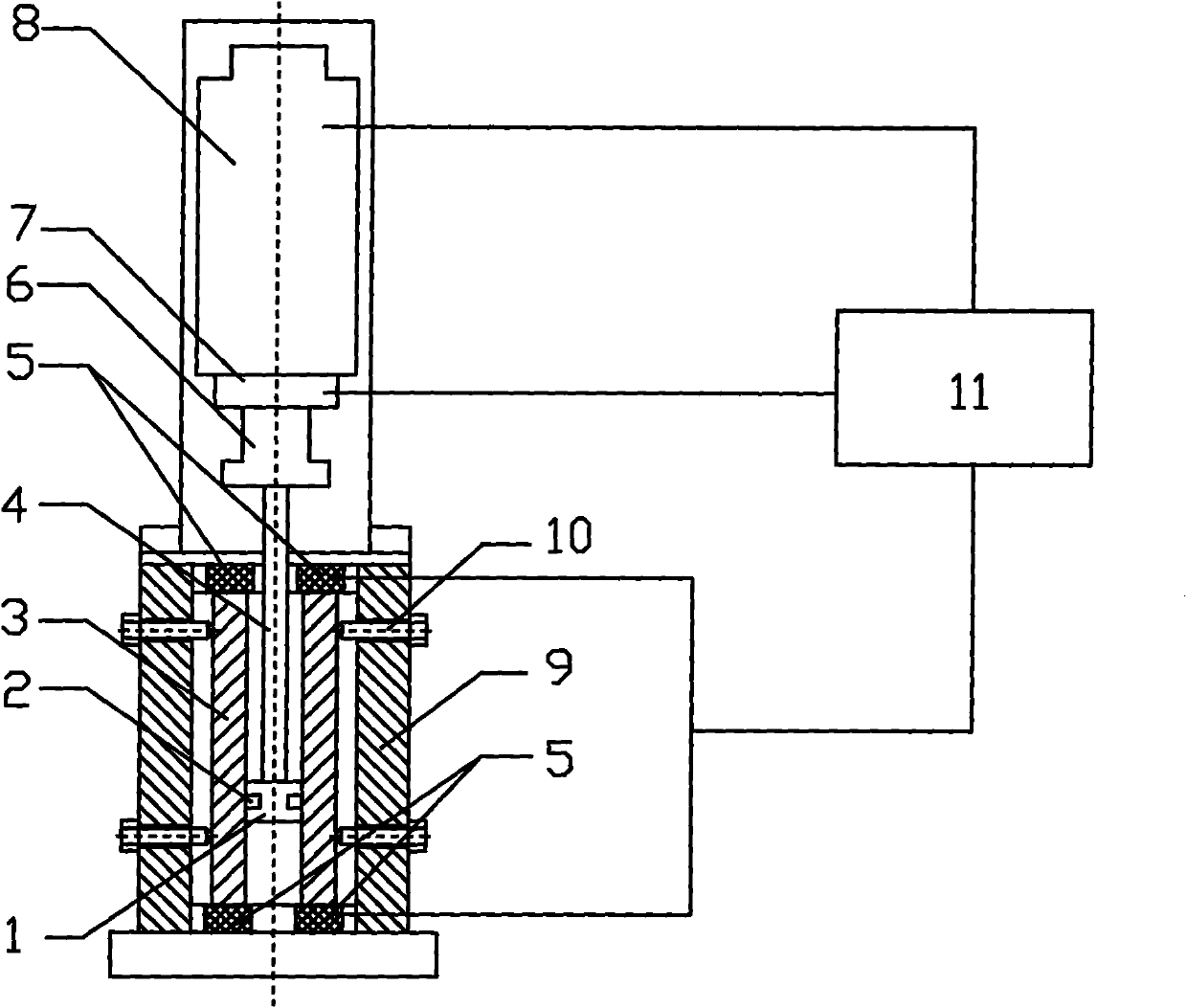

[0008] Such as figure 1 As shown, the present invention includes a piston 1, a damping seal 2, a sleeve 3, a piston rod 4, a force sensor 5, a ferrule coupling 6, a displacement sensor 7, a driving motor 8, and a measurement and control platform 11; 9. Sleeve centering adjustment rod 10. Piston 1, damping seal 2 and sleeve 3 cooperate to simulate the structure of the moving parts of the valve, and then assemble with the test bench body 9 and sleeve centering adjustment rod 10 to form a test bench for the friction test system; piston 1 passes through piston rod 4 And the ferrule coupling 6 is rigidly connected with the drive motor 8, the force sensor 5 at both ends of the sleeve 3 and the displacement sensor 7 of the drive motor 8 are connected with the measurement and control table 11, and the drive motor 8 is connected with the measurement and control table 11 to form the control of the friction test system Test Bench. The measurement and control station 11 mainly completes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com