Modified graphene material, lubricating oil containing modified graphene material and preparation method thereof

A graphene and modification technology, applied in the petroleum industry, lubricating compositions, base materials, etc., can solve problems such as affecting the overall performance of lubricating oil, easy failure of active agents, etc., to reduce wear capacity, improve overall performance, and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

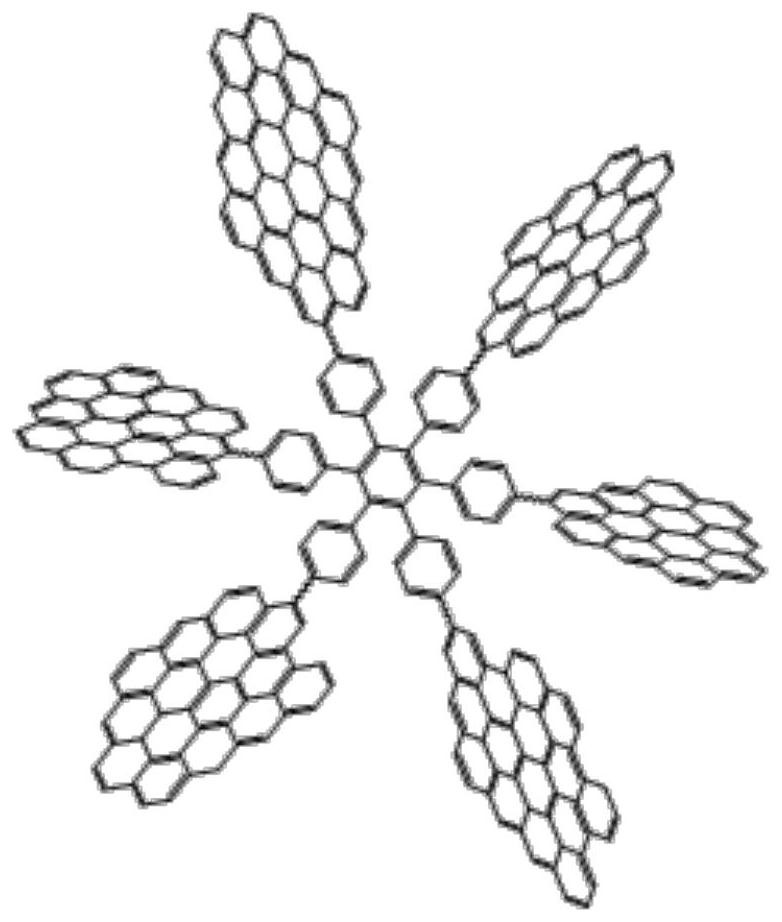

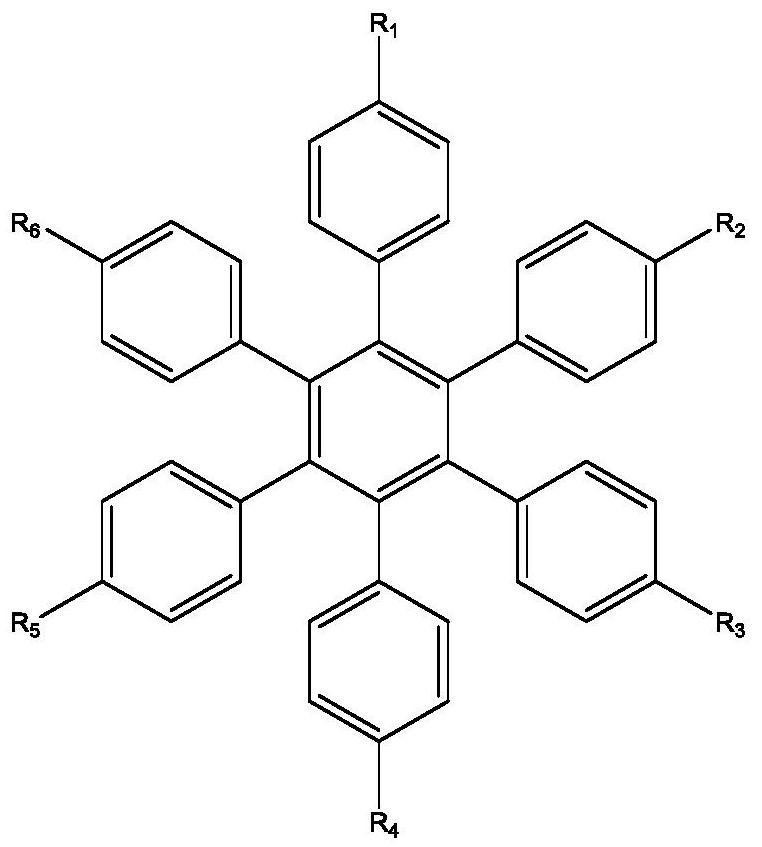

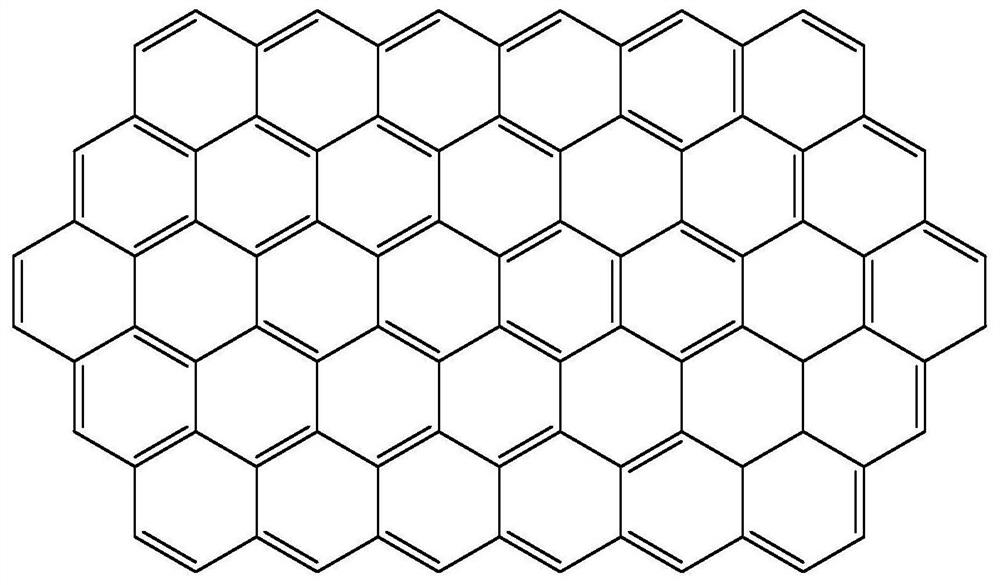

[0034] see Figure 4 and Figure 5 , the embodiment of the present invention also provides a preparation method of a modified graphene material, including: step 101, after mixing small molecules containing benzene rings and graphene, grinding to obtain a uniformly mixed mixture, and pressing the mixture into a mixture ; Step 102, the mixture is electrochemically reacted in the acid solution to obtain an electrolyte containing benzene ring small molecule chain graphene; Step 103, the electrolyte containing benzene ring small molecule chain graphene is ultrasonicated by an ultrasonic machine, Then the acid solution is removed by centrifugation to obtain the modified graphene material.

[0035] In the preparation process of the modified graphene material provided by the embodiment of the present invention, firstly, graphene and small molecules containing benzene rings are mixed, and the mixing can be performed in any container. In order to uniformly disperse graphene and small ...

Embodiment 1

[0053] Step 201, mellitic acid and small-sheet graphene are mixed uniformly in an agate mortar in a ratio of mellitic acid: small-sheet graphene=1:50 according to the mass ratio, and then ground in an agate mortar for 10 minutes by a grinding rod , the mellitic acid is dispersed in the small sheet graphene to obtain a mixture.

[0054] Step 202, weighing 0.5 g of the mixture, using an infrared tablet press to press it into a mixture under a pressure of 10 MPa, and the mixture is a thin sheet.

[0055] Step 203, connect the sheet to the positive pole of the power supply through a wire, connect the platinum sheet to the negative pole of the power supply through a wire, add 80mL of concentrated sulfuric acid into a 100mL flask, and heat the concentrated sulfuric acid water bath to 35-40°C. Then insert the slice and the platinum slice into the concentrated sulfuric acid in parallel, keep the distance between the two electrodes 3cm, and the power supply is a DC voltage of 10V, star...

Embodiment 2

[0063] Step 301, mix phenol and small-sheet graphene uniformly in an agate mortar at a mass ratio of phenol:small-sheet graphene=1:50, grind and disperse in the agate mortar for 10 minutes to obtain a mixture.

[0064] Step 302, weighing 0.5 g of the mixture, using an infrared tablet press to press it into a mixture under a pressure of 10 MPa, and the mixture is flakes.

[0065] Step 303, connect the sheet to the positive pole of the power supply through a wire, connect the platinum sheet to the negative pole of the power supply through a wire, add 80mL of concentrated sulfuric acid into a 100mL flask, and heat the concentrated sulfuric acid water bath to 55-60°C. Then insert the thin slice and the platinum slice into the concentrated sulfuric acid in parallel, keep the distance between the two electrodes 3cm, and the power supply is a DC voltage of 10V, start the power supply, and keep the concentrated sulfuric acid temperature at 55-66°C, continue the reaction for 30min, take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com