SiCN/TiCN multi-layer film tool coating layer and preparation method thereof

A multi-layer film and cutting tool technology, applied in coating, cutting tools for lathes, metal material coating technology, etc., can solve the problems of high brittleness of coatings, and achieve stable coating performance, strong flexibility, and easy adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

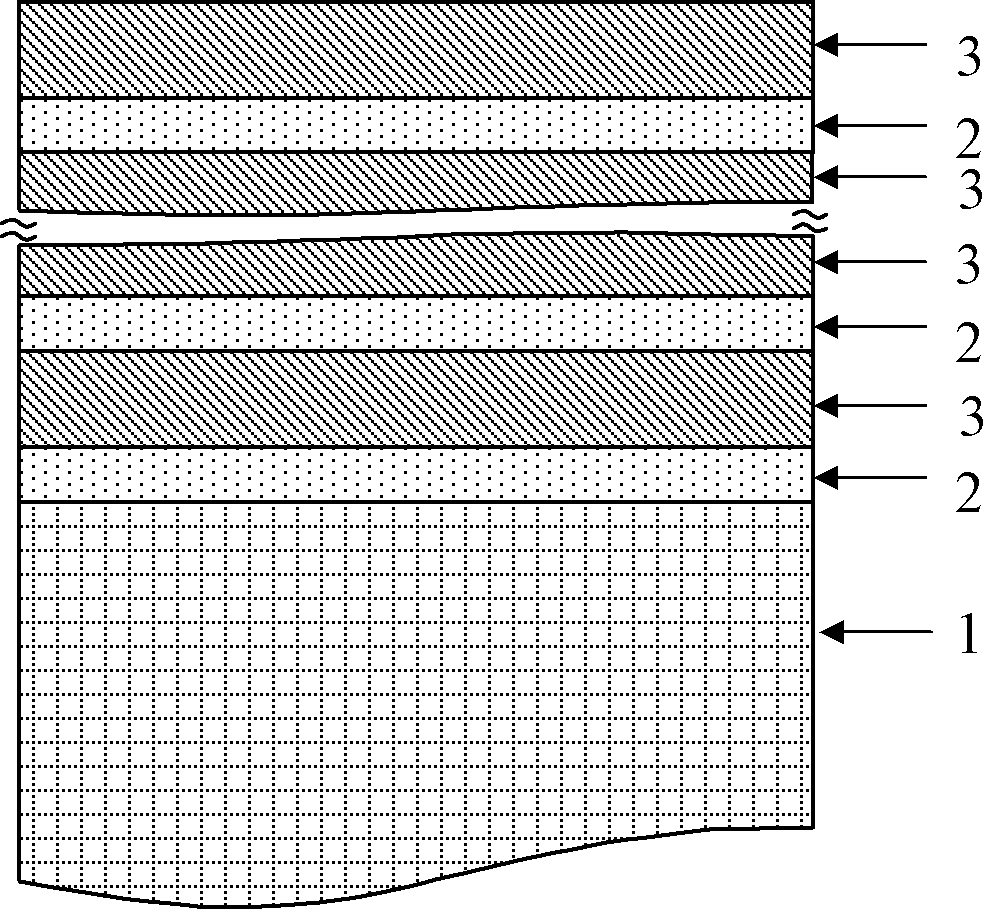

[0022] Refer to attached figure 1 , the SiCN / TiCN multilayer film tool coating of the present invention selects the cemented carbide tool as the substrate, and on the basis of the tool substrate 1, first deposits a layer of TiCN layer 2, and then deposits a layer of SiCN layer 3, followed by alternate deposition The TiCN layer 2 and the SiCN layer 3 form a multilayer structure, and the outermost layer is the SiCN layer 3 .

[0023] Define the sum of the thicknesses of each adjacent single layer of TiCN and single layer of SiCN as the modulation period of the multilayer coating; define the ratio of the thickness of each single layer of TiCN and single layer of SiCN as the modulation ratio of the multilayer coating. Both the modulation period and the modulation ratio are variable, and the modulation period can be single period or multiple periods, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com